Magnetic element

一种磁性元件、磁性体的技术,应用在磁性材料、磁性物体、电气元件等方向,能够解决非晶箔带制造成本变高、磁性材料实用化迟缓、磁性材料成型性差等问题,达到实现制造设备费、形状自由度提高、制造成本降低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

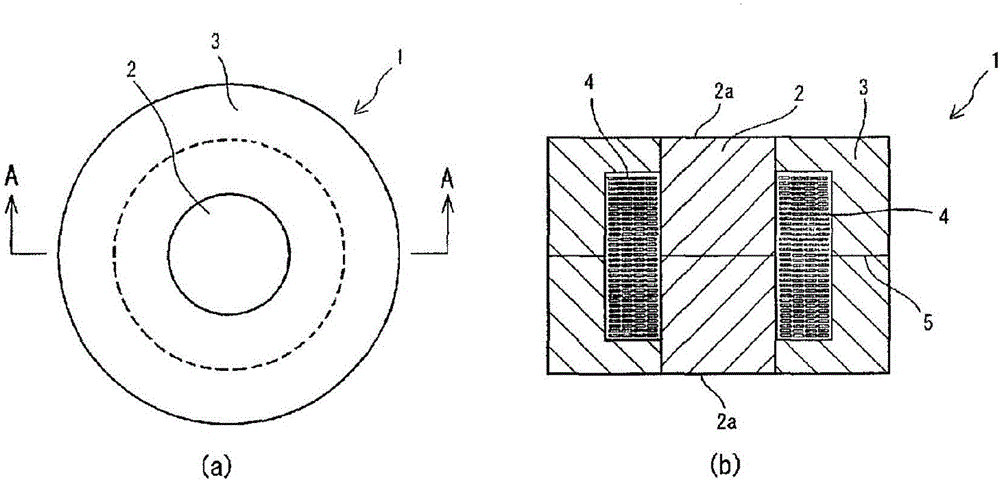

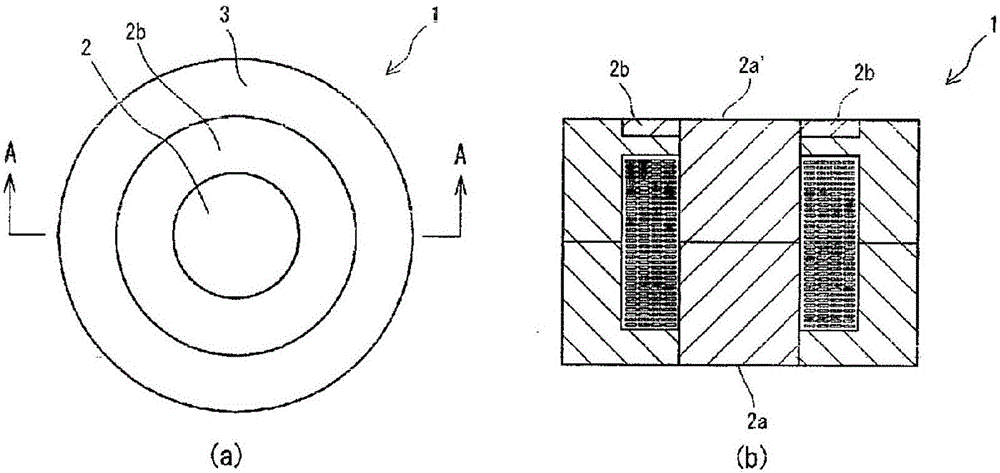

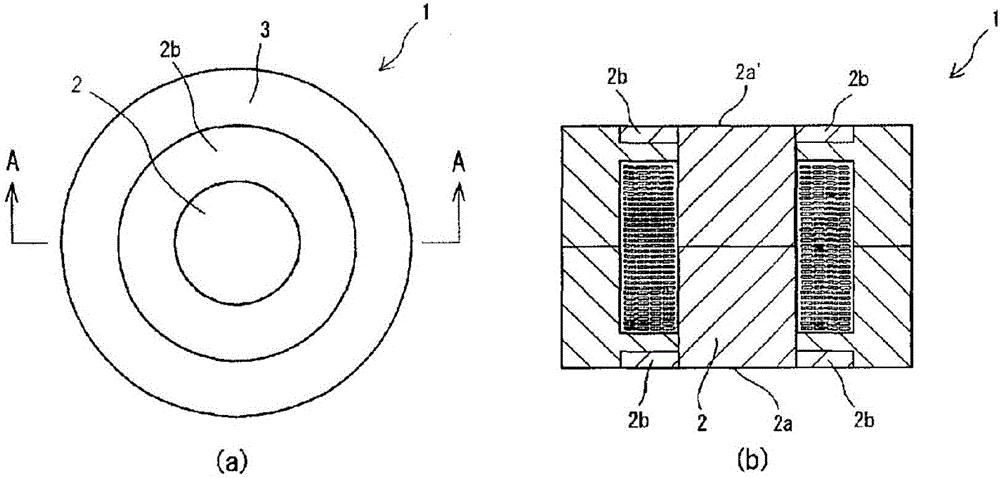

[0028] In the high frequency and high current of electric and electronic equipment, the magnetic element using the ferrite material obtained by the current mainstream compression molding method has excellent magnetic permeability and easy to obtain inductance value, but the frequency characteristic and superimposed current characteristic are poor . On the other hand, a magnetic element using an injection-molded magnetic material containing an amorphous material has excellent frequency characteristics and superimposed current characteristics, but has low magnetic permeability. In addition, in magnetic elements for large currents, in addition to heat generation due to copper loss, heat generation due to iron loss cannot be ignored. Therefore, by using a compression-molded magnetic body with excellent thermal conductivity for the part that is prone to heat generation or the part that is difficult to dissipate heat, and molding and bonding other large or complex-shaped magnetic bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com