Method of laser joining of aluminum alloy member and resin member

A technology of aluminum alloy parts and joining methods, which is applied in the direction of surface pretreatment bonding methods, laser welding equipment, welding equipment, etc., can solve problems such as inadequacy, and achieve high adhesion strength, air tightness, and excellent adhesion strength Effective effect with airtightness and anchoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

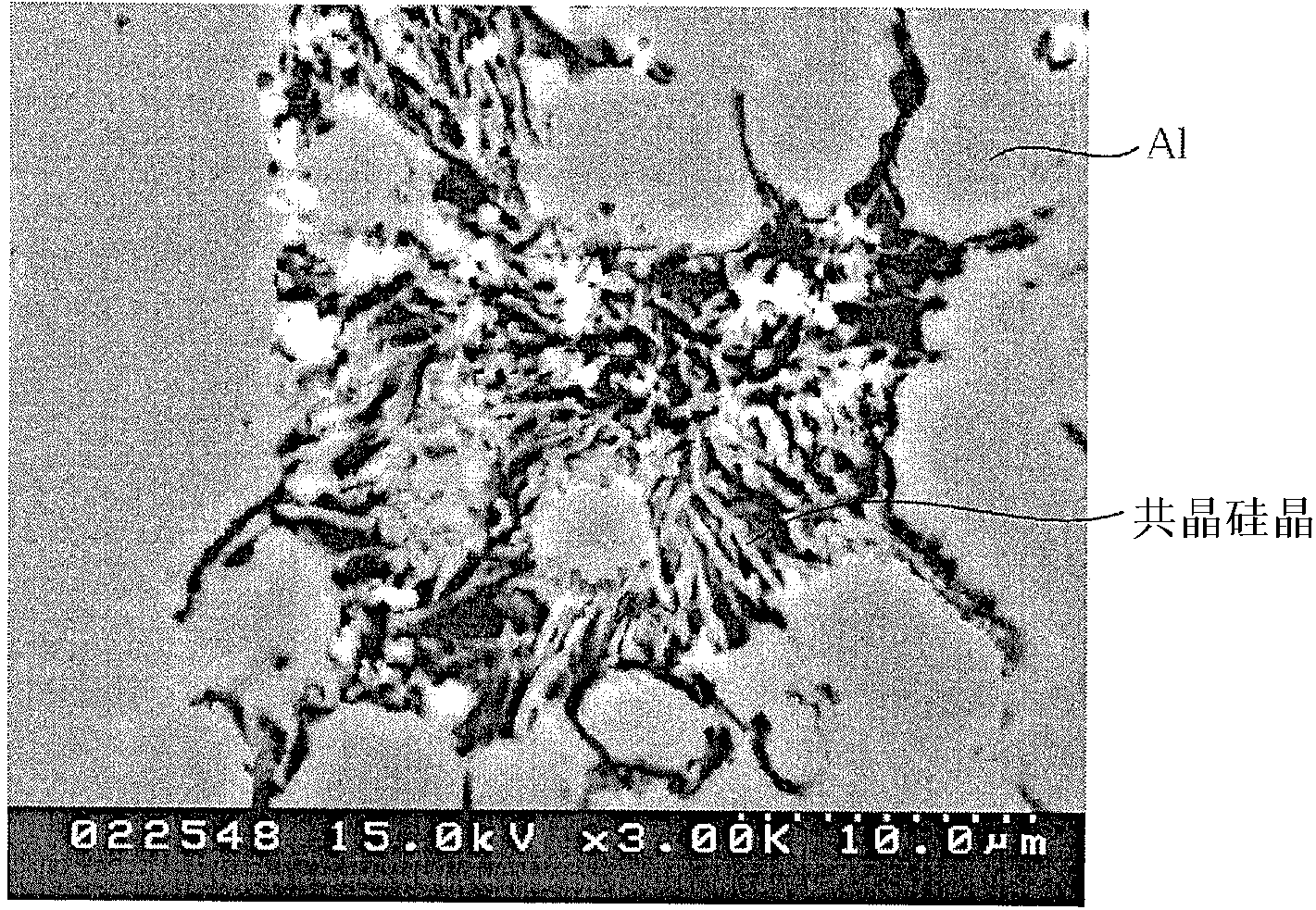

[0037] The inventors conducted intensive studies on the reasons and countermeasures for the failure of the aluminum-resin composite manufacturing method using the laser bonding methods proposed in the above-mentioned Patent Documents 1 and 3 to obtain sufficient bonding strength.

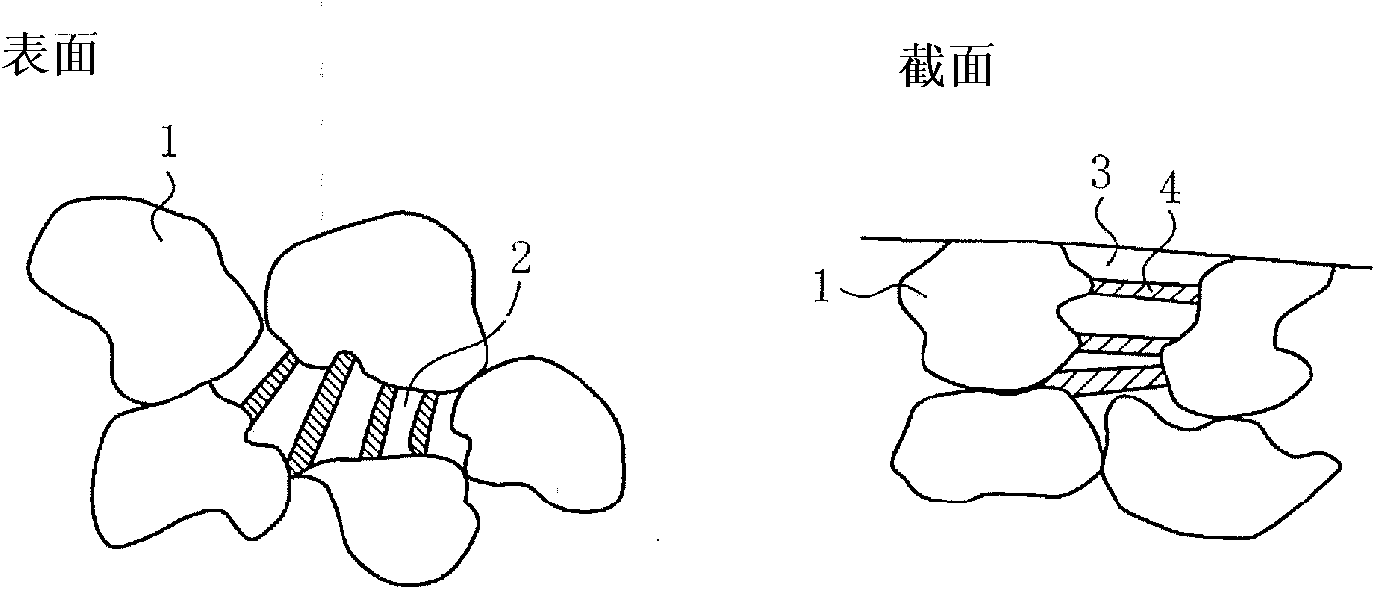

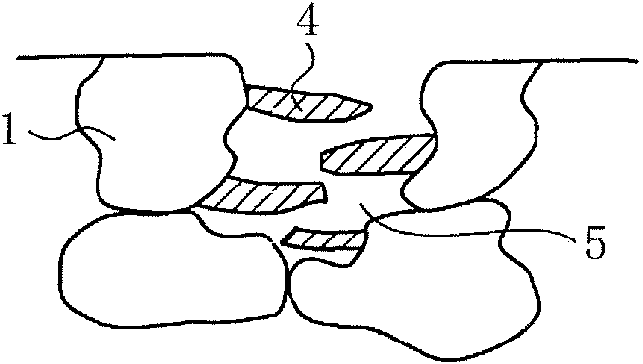

[0038] Assuming that the softened resin part does not mesh well with the unevenness of the aluminum surface during this process, in order to improve the bondability with the composite resin part in the manufacture of aluminum-resin composites, the improvement of the surface shape of the aluminum alloy part is studied Strategy.

[0039] In order to improve the bondability with the resin part, it is effective to form a concavo-convex portion having a high anchoring effect on the surface of the aluminum alloy part. However, it is difficult to exhibit the anchoring effect by general etching treatment for Al alloys for casting, which have a wide range of metal compositions and complex metal structures. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com