Method for producing simple planetary gear device and simple planetary gear device

A technology for planetary gears and manufacturing methods, which is applied in the manufacture of simple planetary gears and the field of simple planetary gears, can solve problems such as design difficulties, and achieve the effects of fewer parts, stable fixed functions, and small backlash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

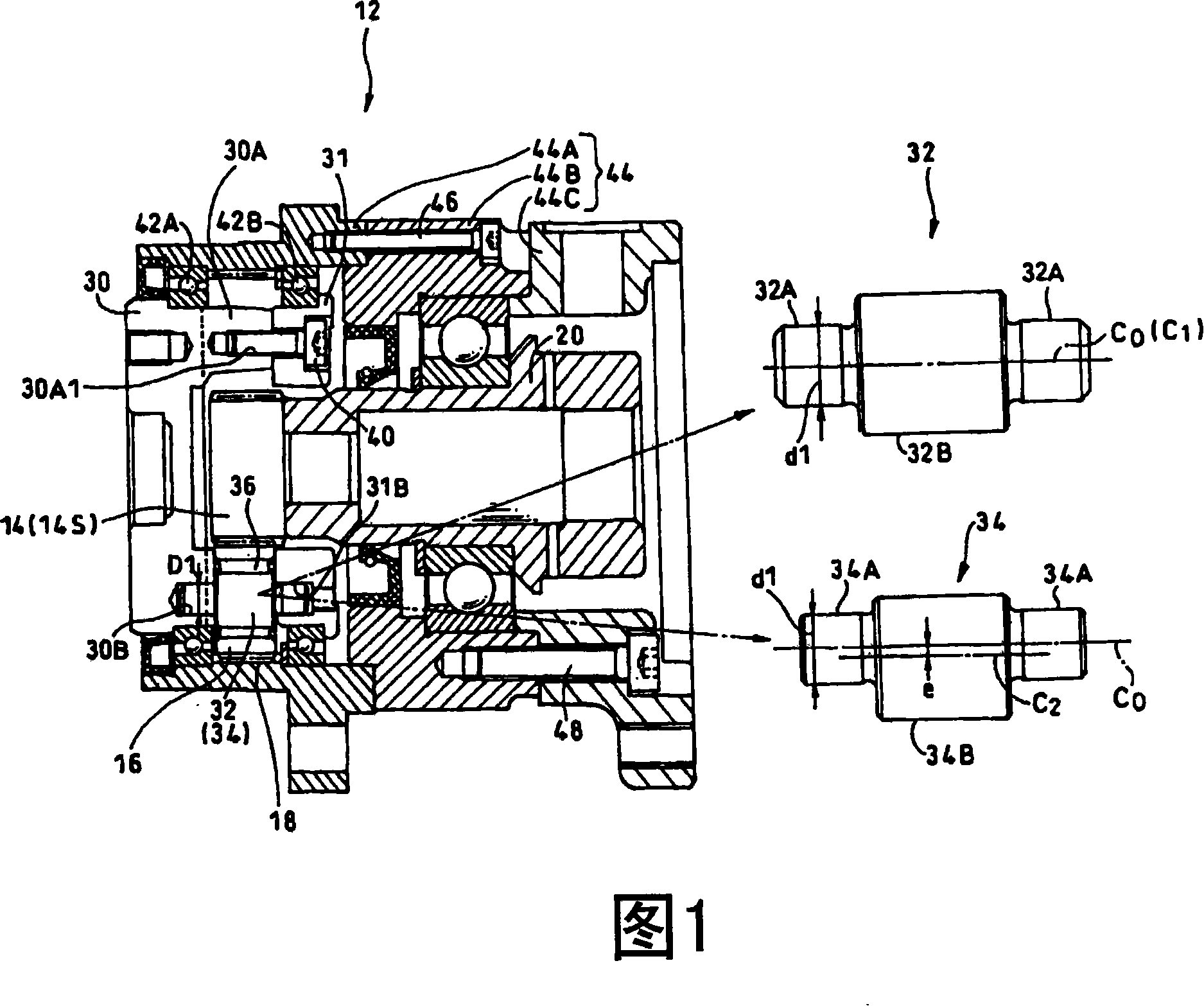

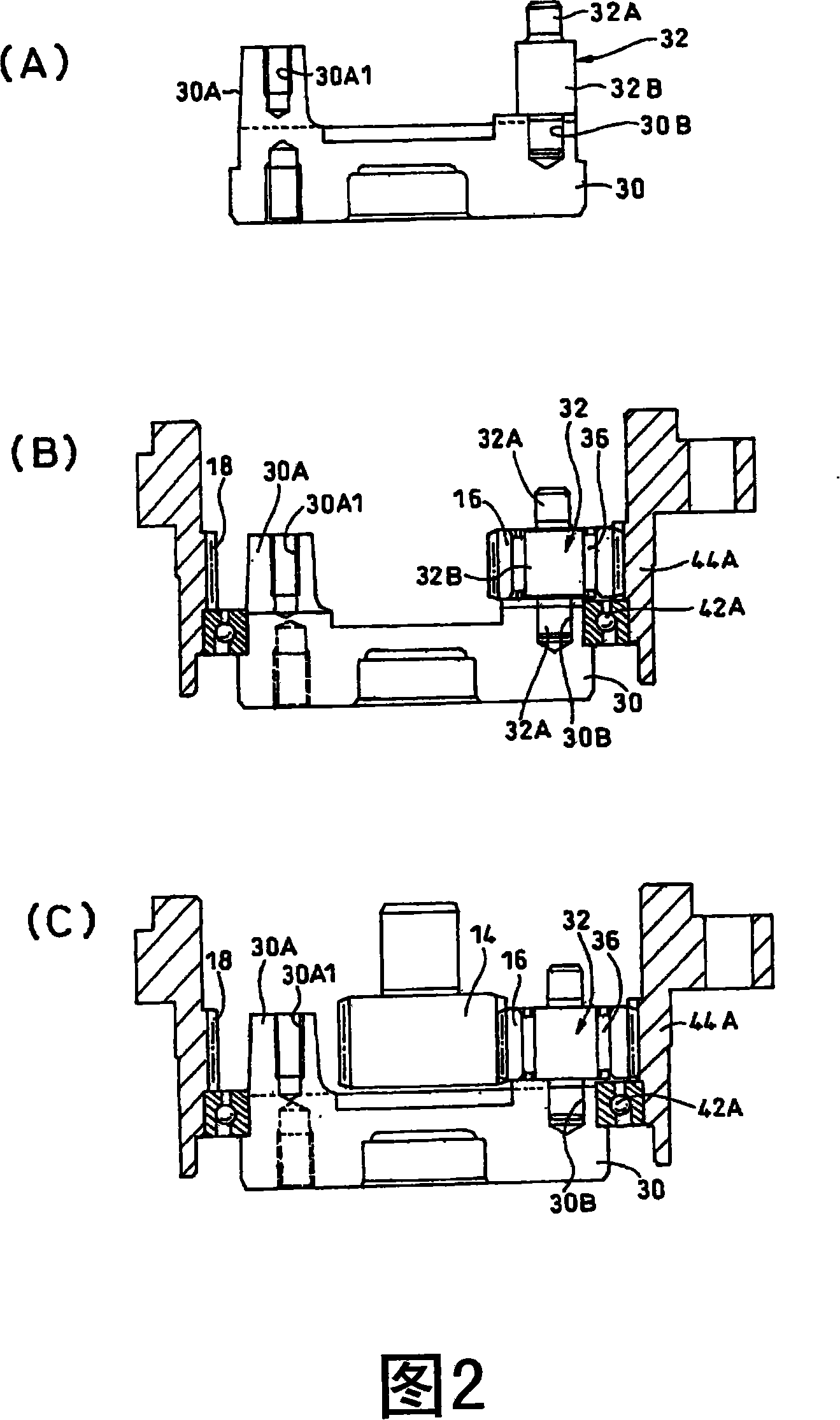

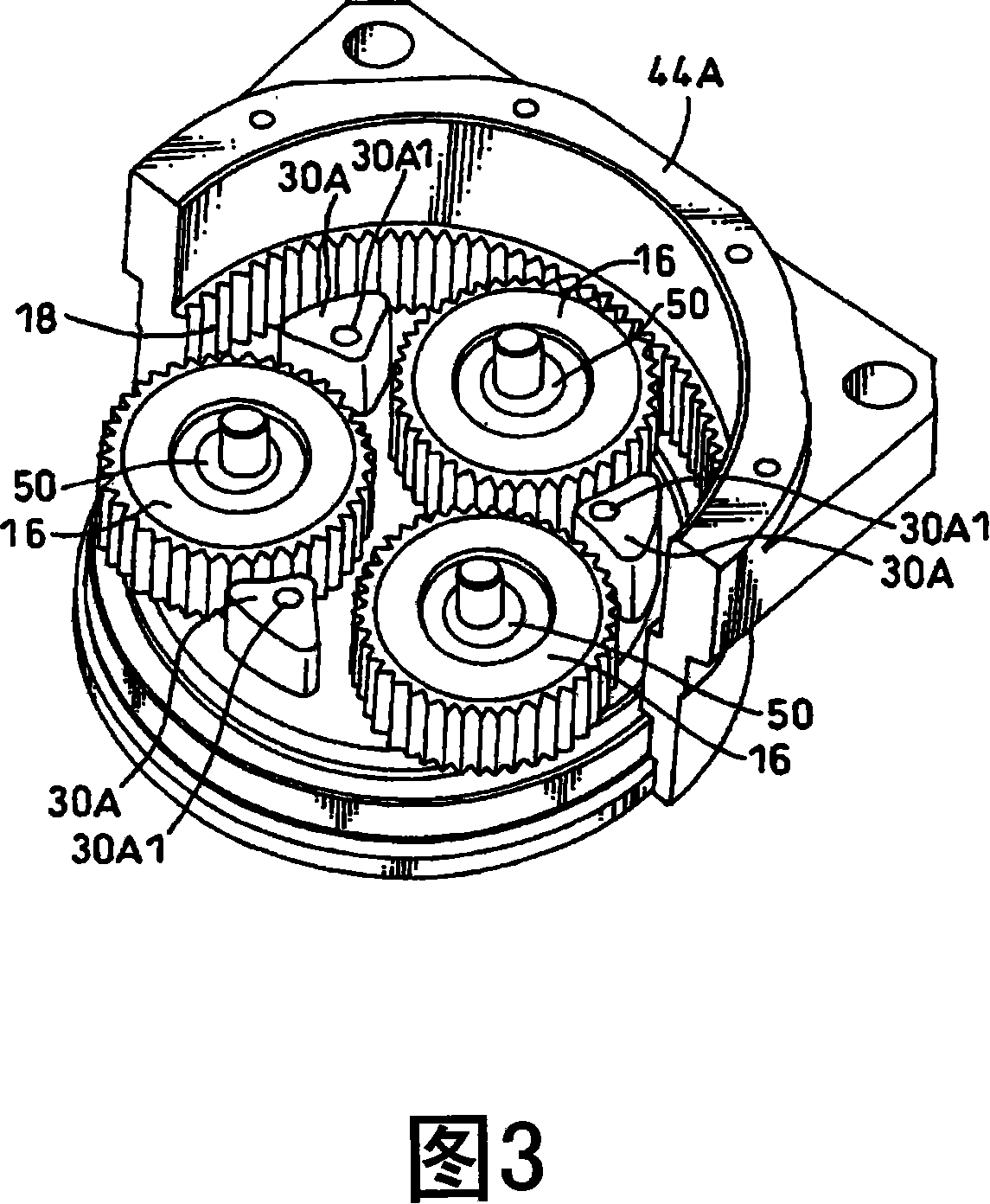

[0034] An example of an embodiment of the present invention will be described in detail below with reference to the drawings.

[0035] FIG. 1 shows the main configuration of a simple planetary gear unit series including a simple planetary gear unit according to an embodiment of the present invention. This series has the same configuration in the reduction ratio, transmission capacity, etc., and the user can select a product group with a large backlash (allowing a large backlash) and a product with a small backlash (only a small backlash is allowed). group to select. Concentric carrier pins without eccentricity are used in product groups with large backlash, and eccentric carrier pins that can realize the present invention are used in product groups with small backlash. For the sake of convenience, we first start with the overall structure of a simple planetary gear device.

[0036] The simple planetary gear unit 12 has a sun gear 14 ( 14 s : described later), three planetary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com