Electric power steering apparatus

一种电动助力转向、辅助转向的技术,应用在动力转向机构、电动转向机构、传动装置等方向,能够解决制造成本增加、高加工精度等问题,达到增加制造成本、防止金属撞击声的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

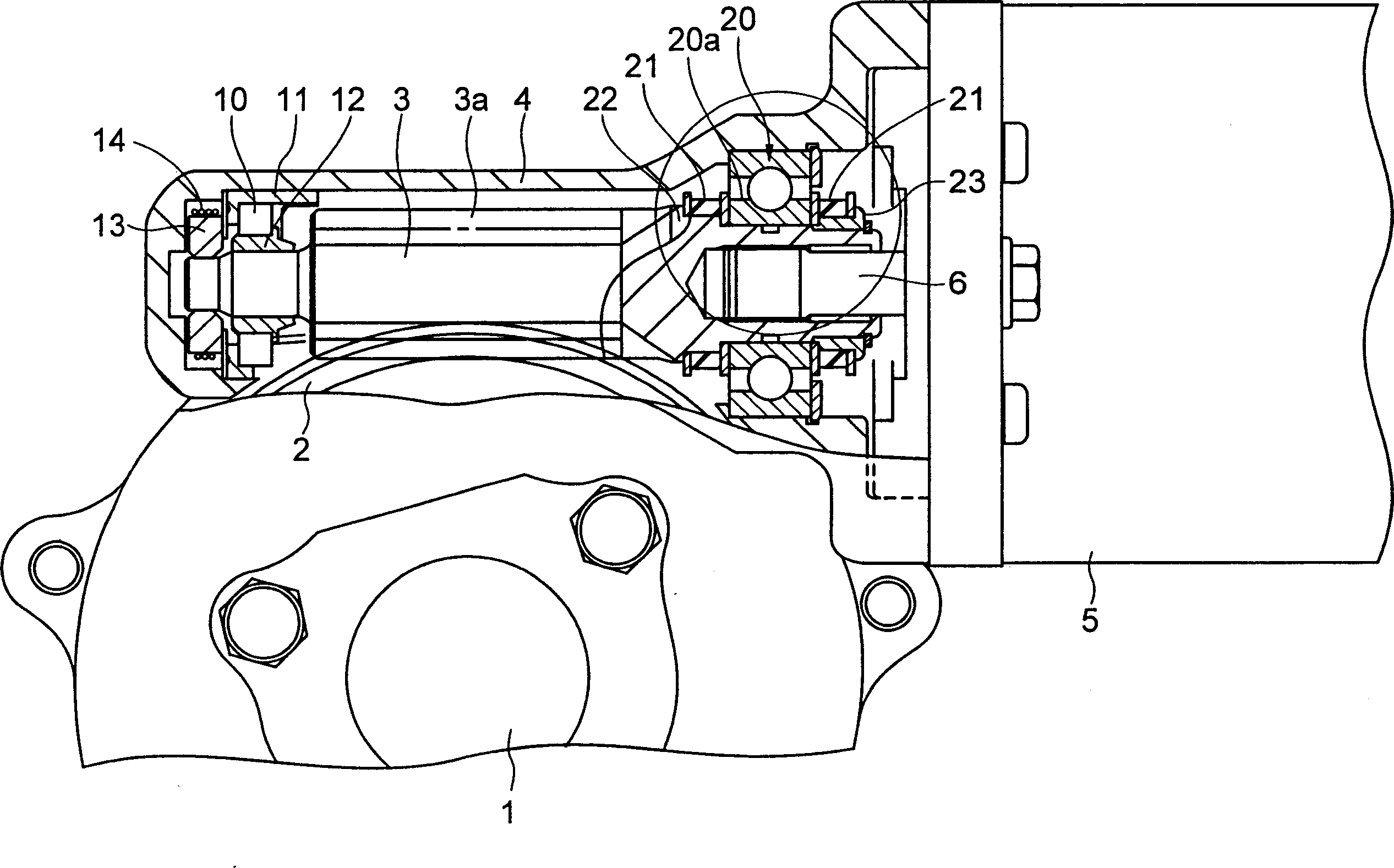

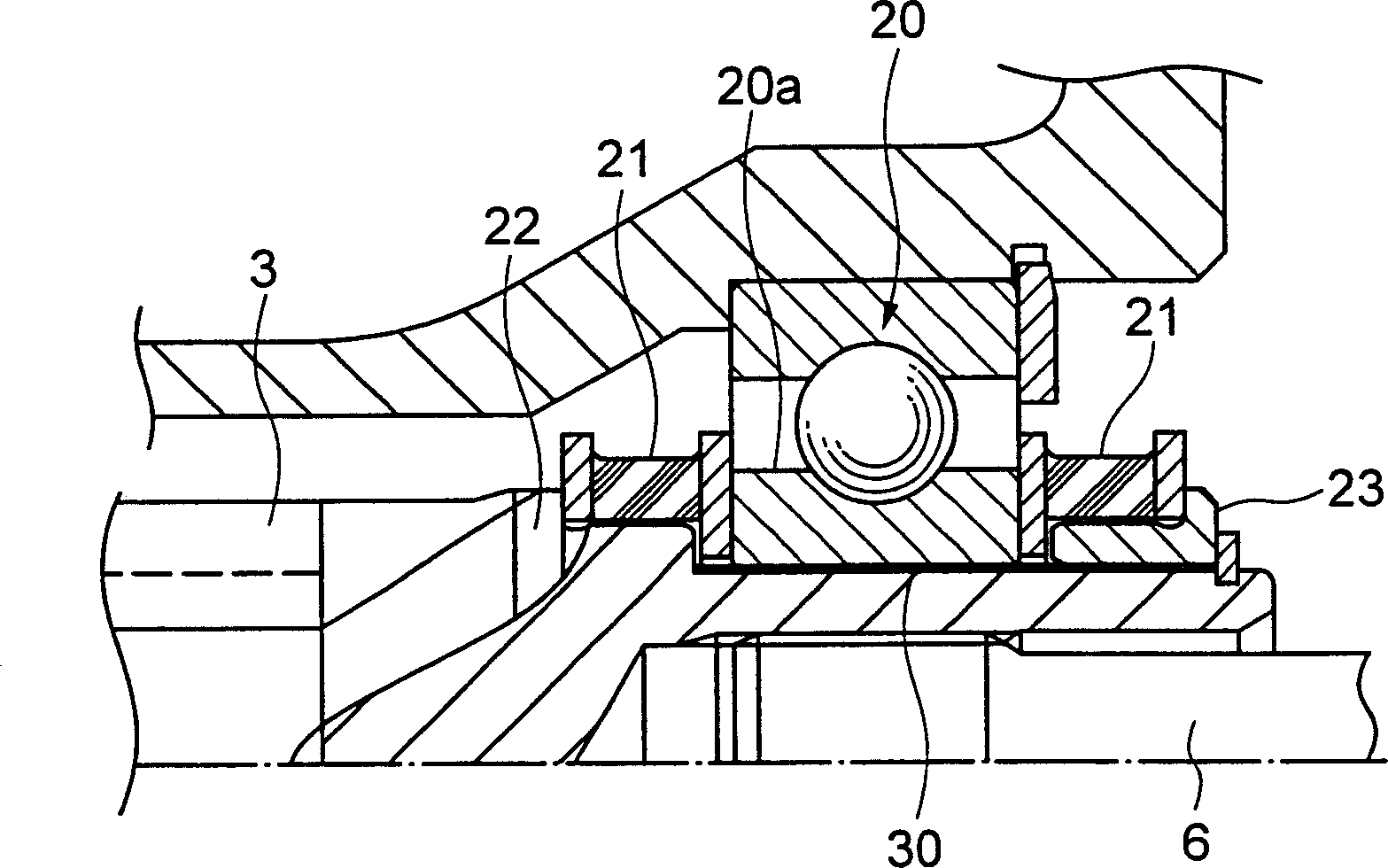

[0047] figure 2 are main parts (corresponding to figure 1 Sectional view of the part surrounded by the middle circle).

[0048] A slight gap is formed between the worm shaft 3 and the inner peripheral surface of the inner ring 20 a of the second bearing 20 so that the worm shaft 3 can be inclined relative to the inner ring 20 a of the second bearing 20 . Due to this feature, the worm shaft 3 can be reliably tilted (rocked) with respect to the inner ring 20 a of the second bearing 20 when the preload is applied by the torsion spring 14 .

[0049] When the worm shaft 3 is tilted or moved radially, shear stress is generated in the rubber buffer 21 , thereby generating a reaction force that makes the worm shaft coaxial with the second bearing 20 .

[0050] A buffer member 30 is provided in at least a part of the minute gap for avoiding a sound generated when the worm shaft 3 comes into contact with the inner ring 20 a of the second bearing 20 under a radial load. Therefore, ev...

no. 2 example

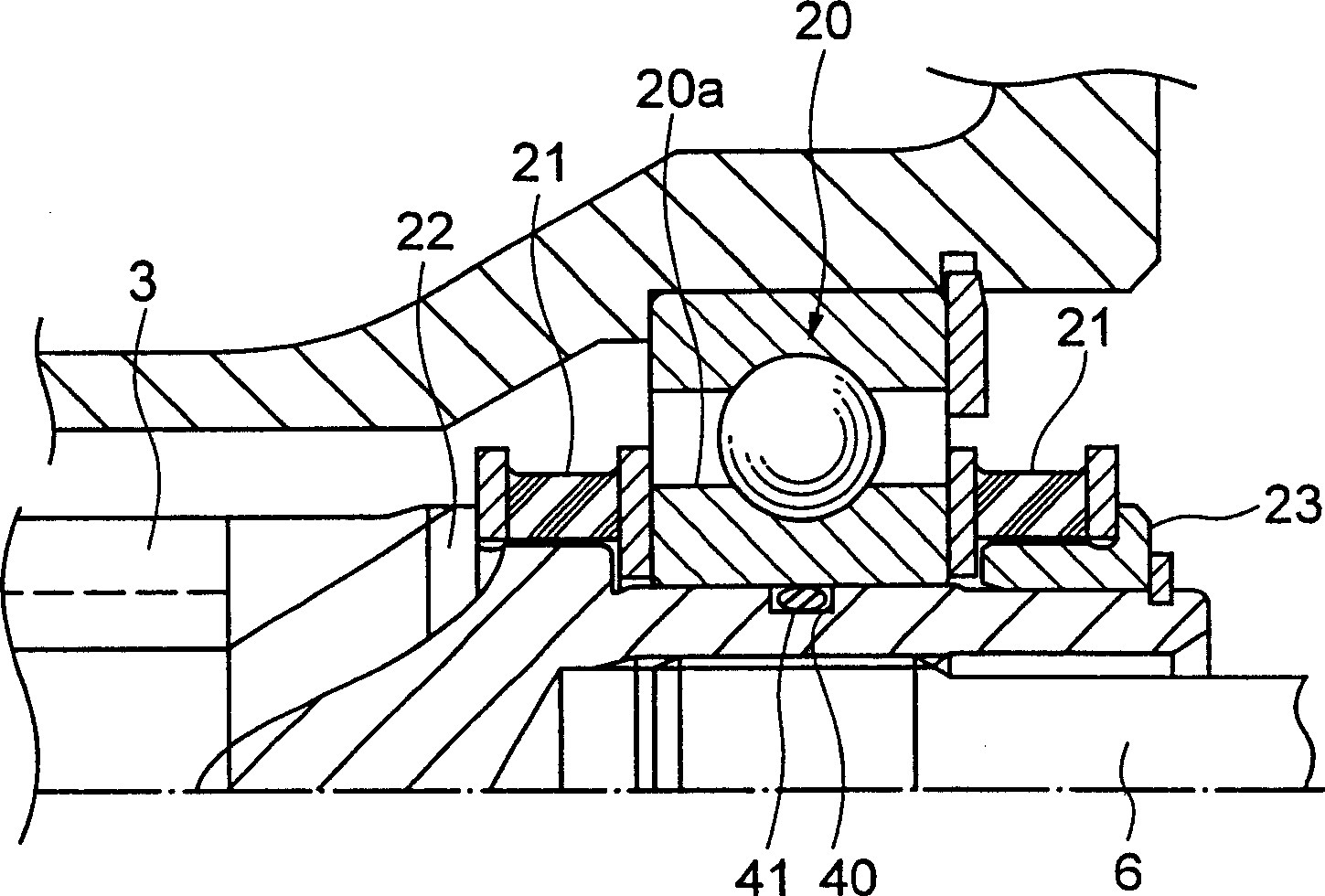

[0053] image 3 is a main part showing the electric power steering apparatus according to the second embodiment of the present invention (corresponding to figure 1 Sectional view of the part surrounded by the middle circle).

[0054] A circumferential groove 40 is formed on the outer peripheral surface of the worm shaft 3 on the inner side in the radial direction of the inner ring 20 a of the second bearing 20 as compared with the first embodiment.

[0055] An O-ring 41 serving as an elastic member is fitted into the circumferential groove 40 . The O-ring 41 is compressed between the inner ring 20a of the second bearing 20 and the worm shaft 3 to generate a (push) repulsion corresponding to the radial movement of the worm shaft 3, which is uniform along the entire circumference. Therefore, the worm shaft 3 can be kept in a floating state (floating type) with respect to the inner ring 20 a of the second bearing 20 so that the worm shaft 3 and the inner ring 20 a of the second...

no. 3 Embodiment

[0060] Figure 4A is to show the main parts of the electric power steering apparatus according to the third embodiment of the present invention (corresponding to figure 1 The cross-sectional view of the part surrounded by the middle circle), Figure 4B is a partial sectional view showing a circumferential groove, an elastic member, and a solid lubricant.

[0061] Compared with the second embodiment, an elastic member 51 integrally formed with a solid lubricant 52 represented by Teflon (polytetrafluoroethylene, registered trademark) is formed in the circumferential groove 50, which is in the second embodiment. The radial inner side of the inner ring 20 a of the second bearing 20 is formed on the outer peripheral surface of the worm shaft 3 .

[0062] Since the friction between the worm shaft 3 and the inner ring 20a of the second bearing 20 is reduced by the solid lubricant 52, the worm shaft 3 can move or tilt more smoothly. Therefore, wear resistance is improved, thereby e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com