Power transmission device and method of producing the same

A technology of power transmission device and external gear, which is applied in the direction of transmission device, gear transmission device, wind turbine control, etc., to achieve the effect of strong prevention of reverse drive, small backlash and high operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

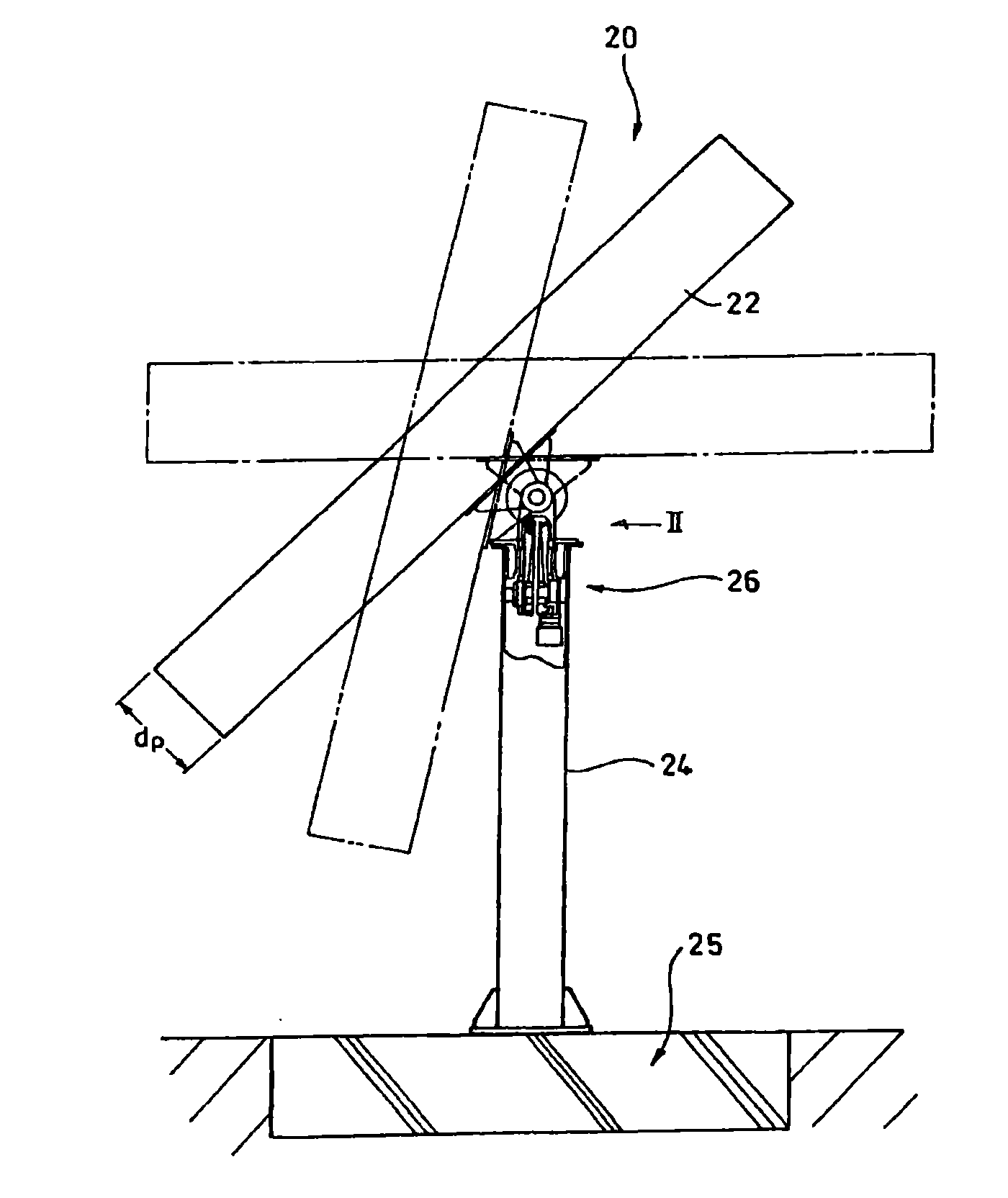

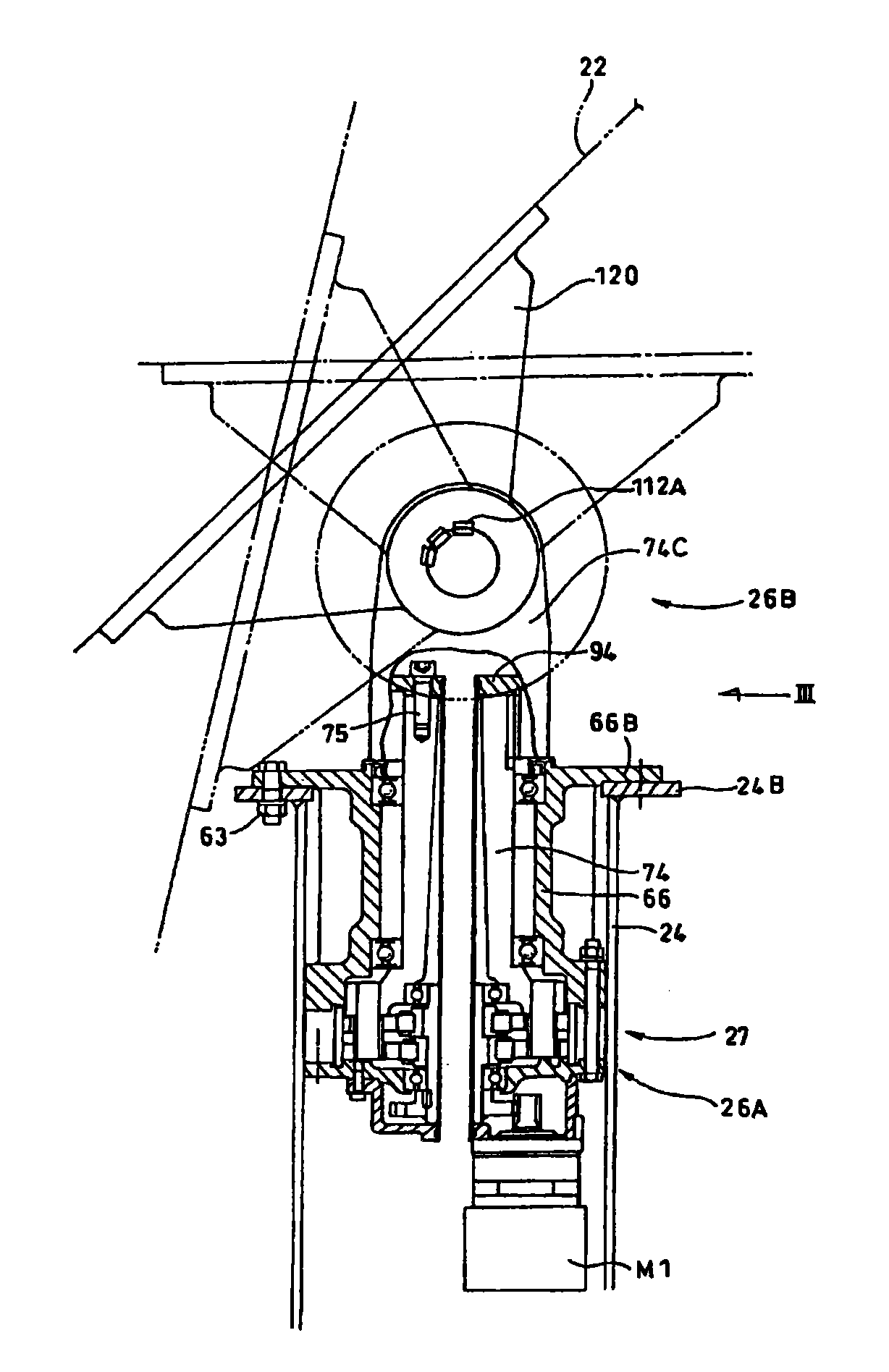

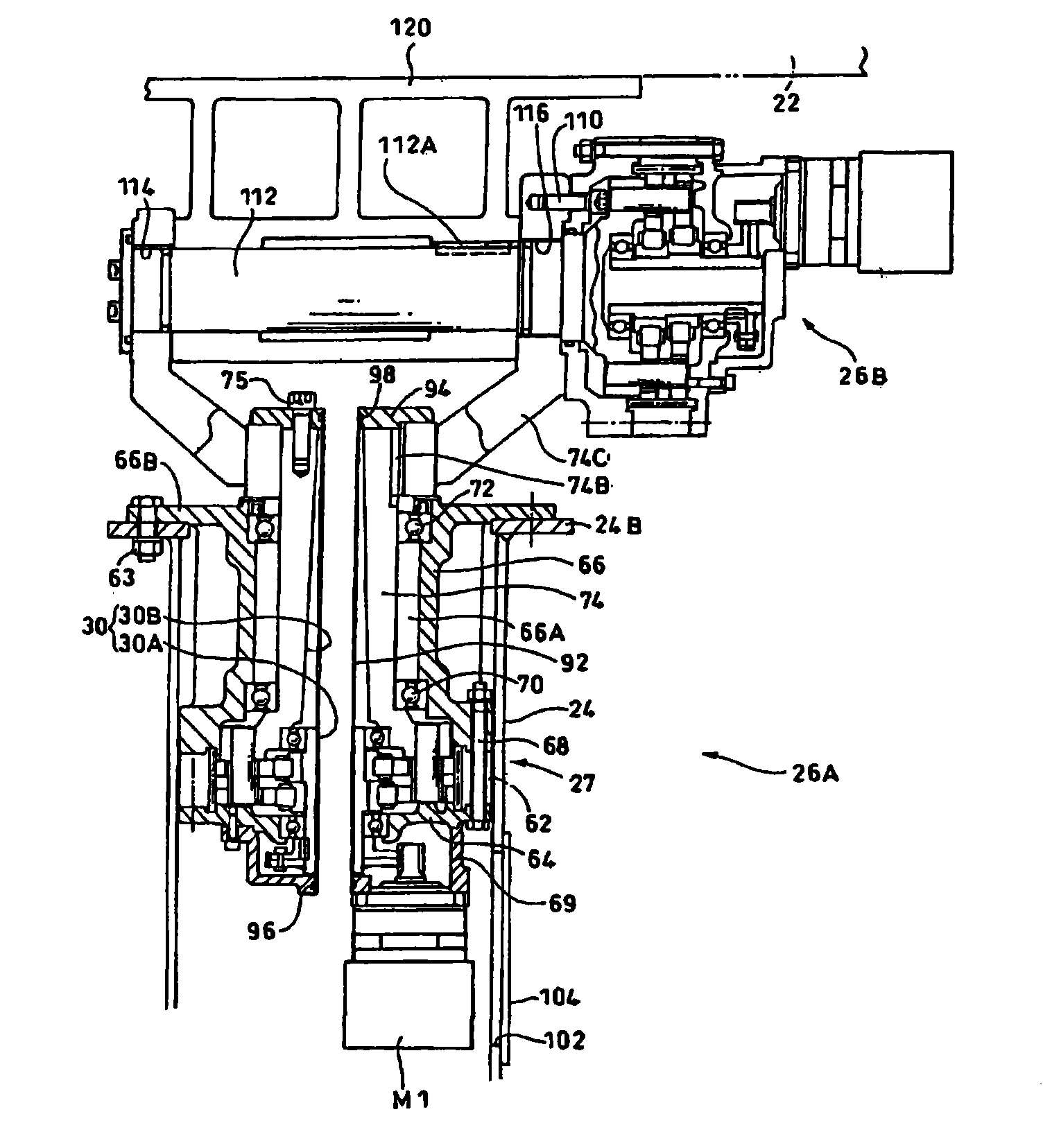

[0033] An example of a driving device of a solar power generation system incorporating a speed reducer which is an example of the power transmission device of the present invention will be described in detail below. figure 1 The outline of the overall structure of this photovoltaic power generation system 20 is shown.

[0034] This solar power generation system 20 has a power generation panel 22 for obtaining electric power from sunlight, and a cylindrical support (support body) 24 for supporting the power generation panel 22 . The cylindrical pillar 24 is erected on an earth platform (base) 25 buried in the ground. The driving device 26 for driving the power generation panel 22 is arranged and housed in the uppermost part of the cylindrical support 24 .

[0035] In order to maximize the power generation efficiency, this embodiment adopts a structure in which sunlight is condensed by a lens not shown in the figure while following the position of the sun, and the light intensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com