Planetary gear transmission device and assembly method thereof

A technology of planetary gear transmission and assembly method, applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of low no-load friction torque stiffness, small transmission backlash, etc., and achieve the effect of low no-load torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

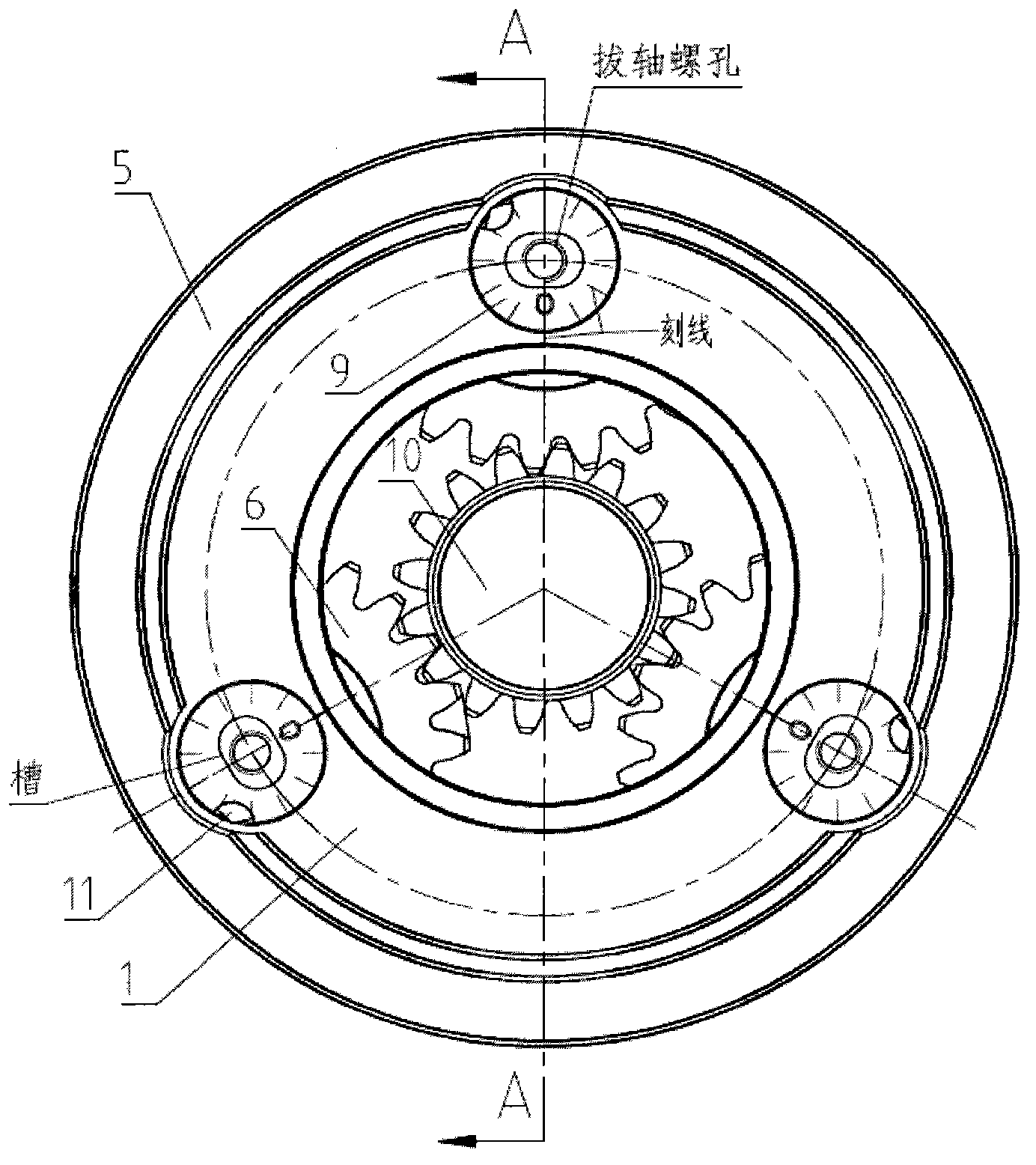

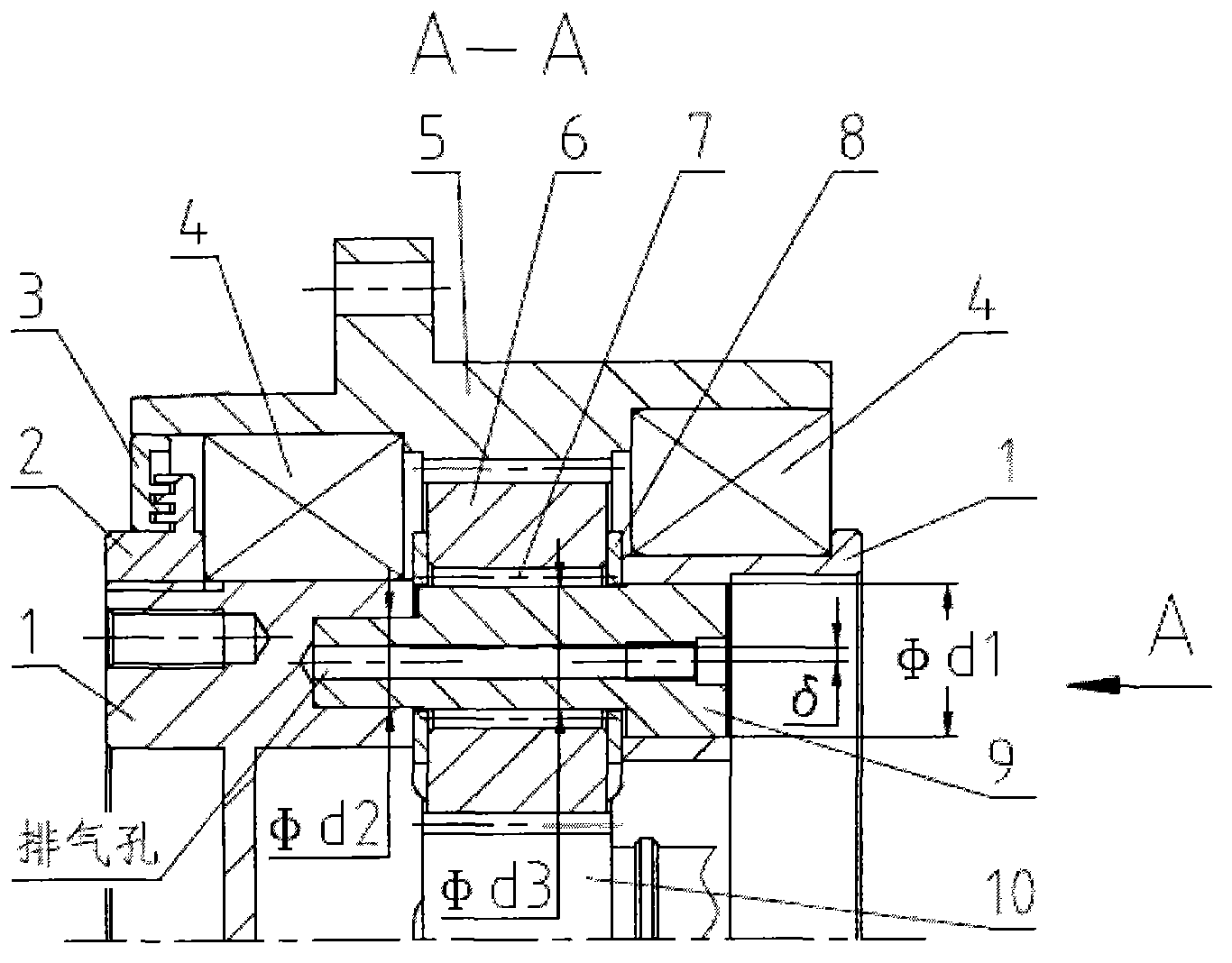

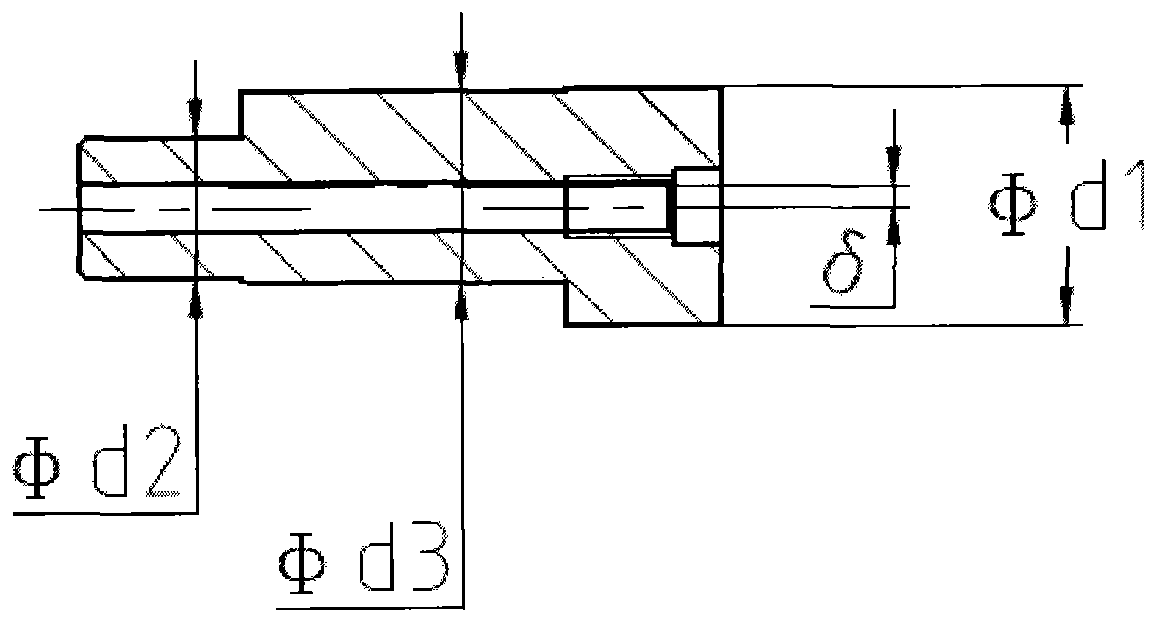

[0015] combined with the present invention figure 1 , 2 , 3. Describe the technical solution of the present invention in detail.

[0016] A planetary gear transmission device of the present invention includes: a planetary carrier 1, a lock nut 2, an oil seal 3, a tapered roller bearing 4, an inner ring gear and a housing 5, a planetary wheel 6, a needle bearing 7, and a wear-reducing pad 8, Planetary shaft 9, sun gear 10, sector key 11; planetary carrier 1 is supported in the ring gear and housing 5 through tapered roller bearing 4, planetary shaft 9 is installed in the hole of planetary carrier 1, and the center hole of planetary wheel 6 The needle bearing 7 is set on the planetary wheel shaft 9; the sun gear 10 is located in the center and meshes with several planetary wheels 6, and the planetary wheel 6 meshes with the inner ring gear and the housing 5; the lock nut 2 is installed on the left end of the planetary carrier 1, and the shaft To the fixed tapered roller bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com