Two-stage-parallel cycloidal steel ball speed reducer

A technology of cycloidal steel balls and reducers, which is applied to transmission parts, friction transmission devices, belts/chains/gears, etc., can solve the problems of large load on the arm bearing, small transmission ratio, and large inertial force, etc. Transmission accuracy, high transmission accuracy, and the effect of reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

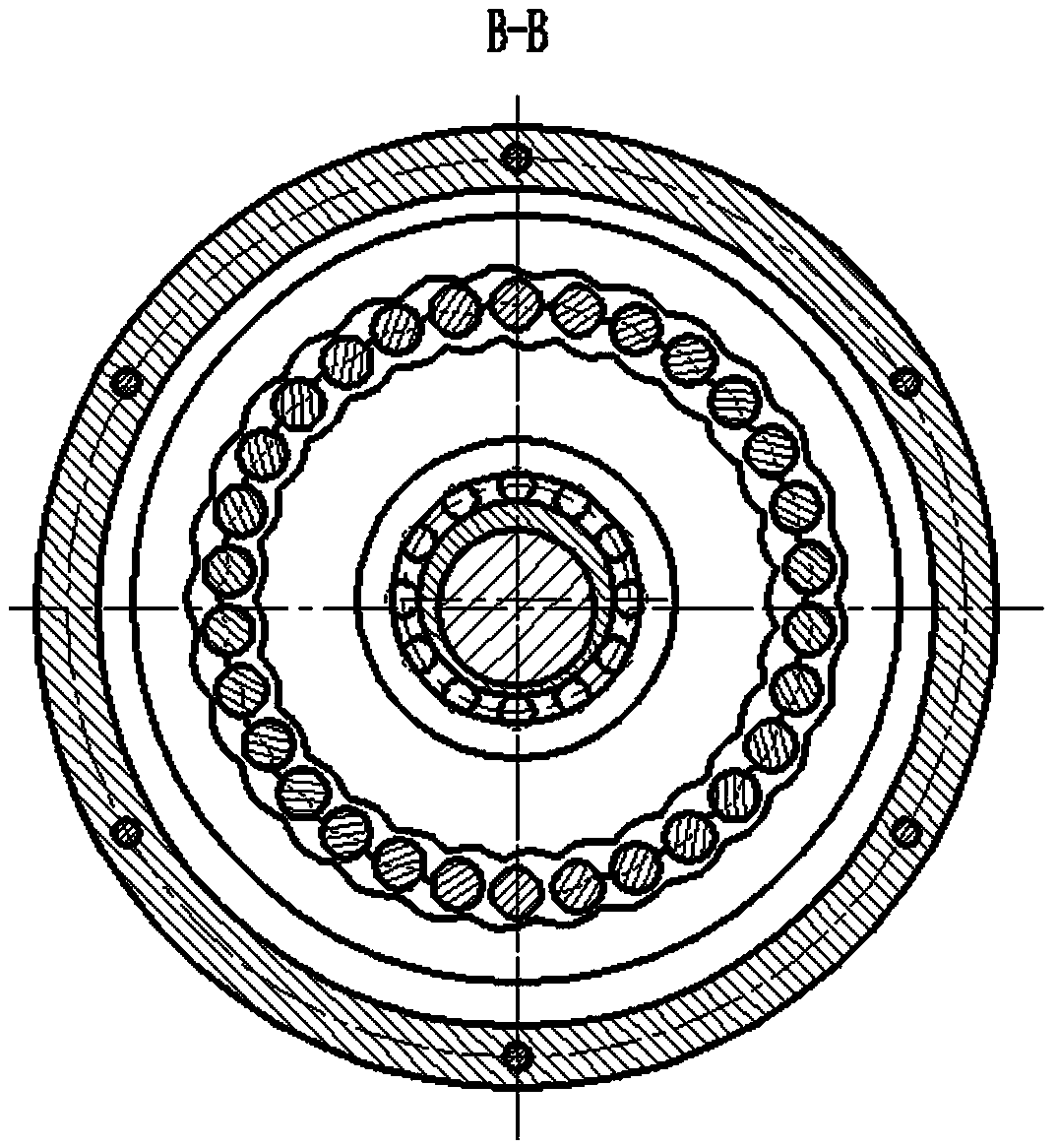

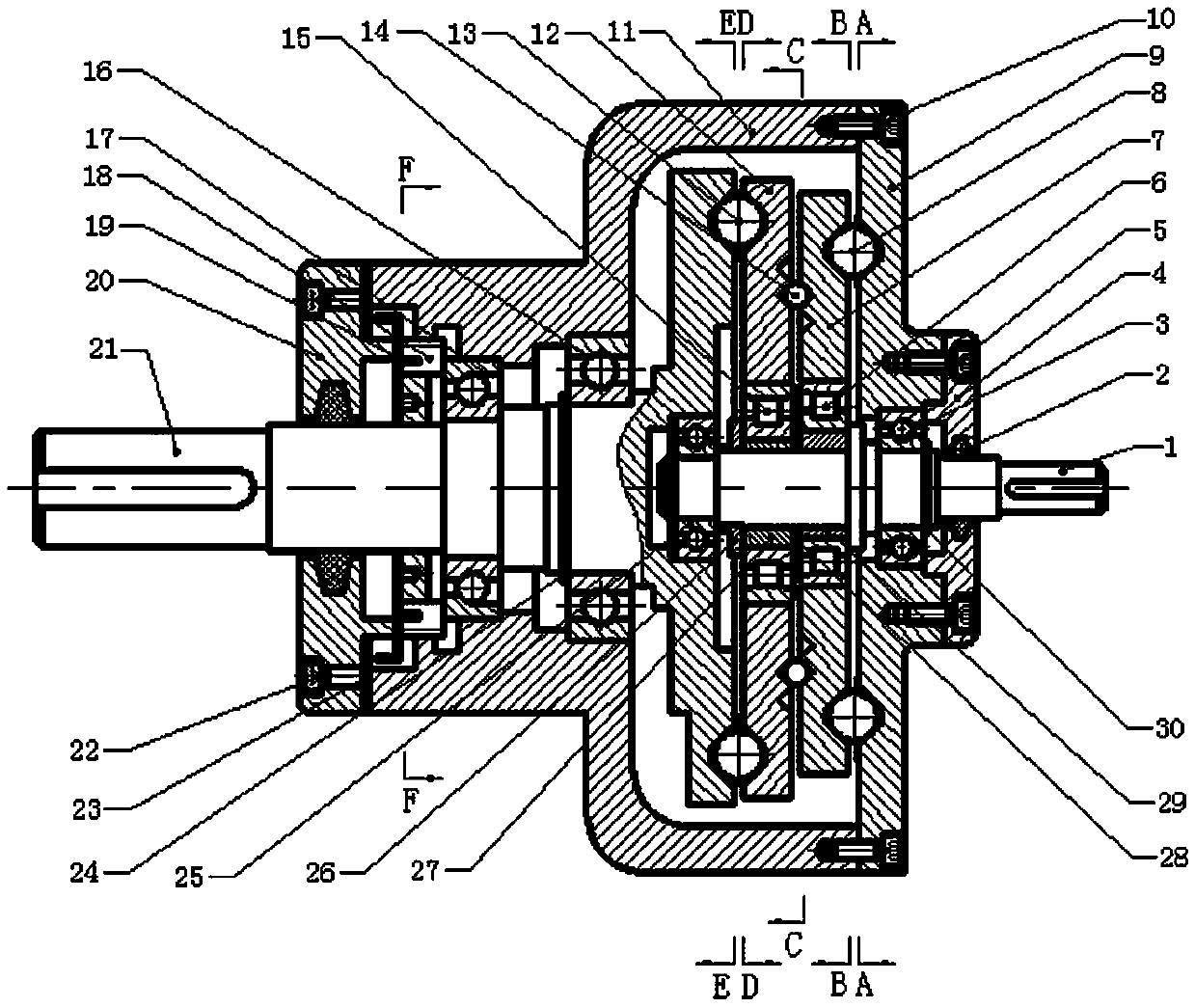

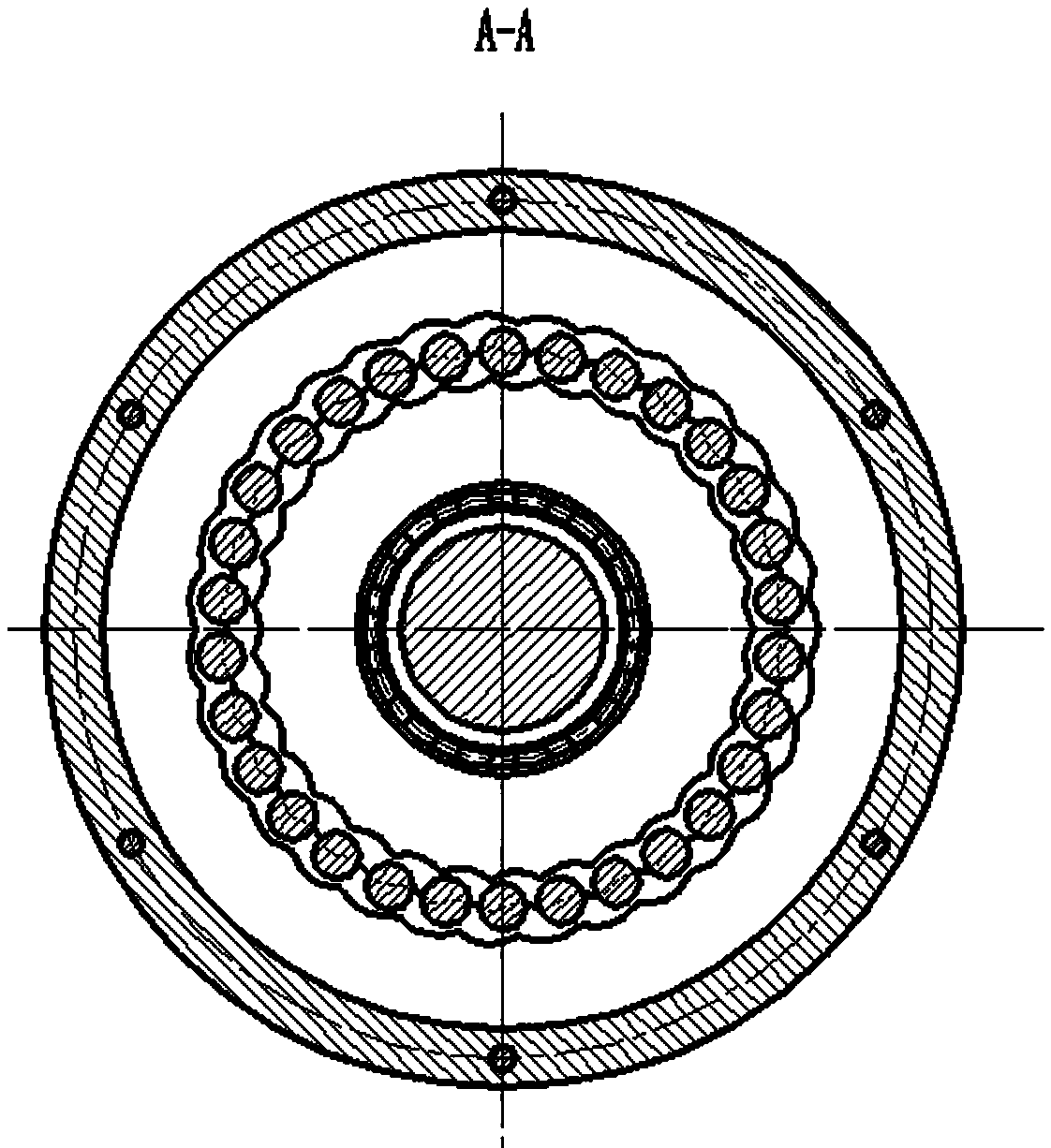

[0031] The accompanying drawing discloses the specific structure of an embodiment of the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings.

[0032] Figure 1 to Figure 6 A two-stage parallel cycloidal ball reducer is shown. The power is input by the input shaft (1). Since the input shaft (1) is fixedly connected with the eccentric sleeve I (29) through interference fit, the input shaft (1) drives the eccentric sleeve I (29) to rotate together, and passes through the eccentric sleeve I (29). The rotating arm bearing I (6) on the top drives the planetary disc I (7) to move. At the same time, the epicycloid closed groove on the right end surface of the planetary disk I (7) pushes the steel ball group (8) to move, and the steel ball group (8) is constrained by the hypocycloid closed groove on the left end surface of the end cover (9) , push back the planetary disk I (7) to rotate at a lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com