Drawtube, lens module with the same, and lens module assembling method

A lens module and assembly method technology, applied in the field of optical systems, can solve the problems of assembly process waste, lens module failure, discarding, etc., and achieve the effects of improving assembly yield, avoiding relative movement, and ensuring imaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

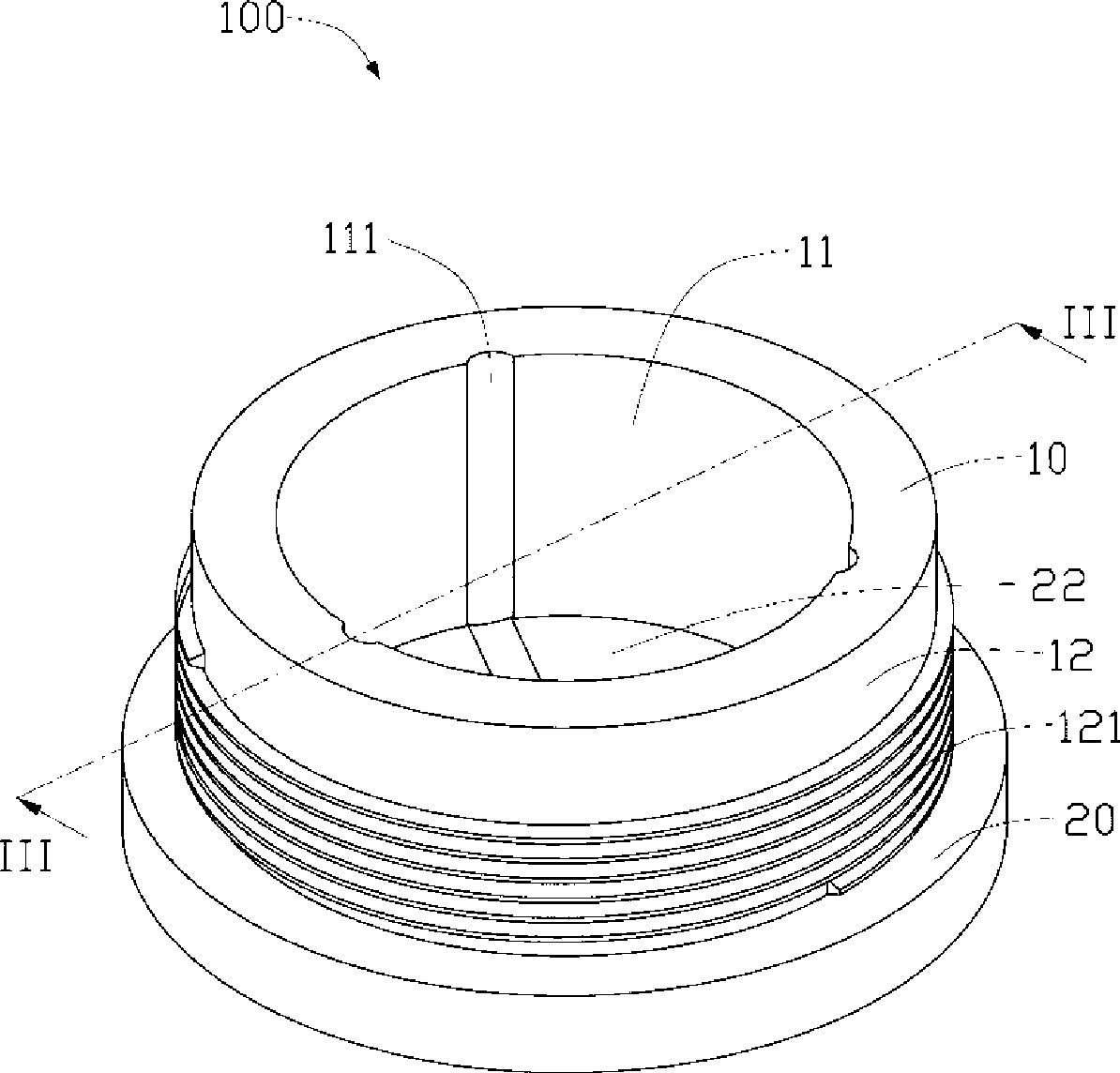

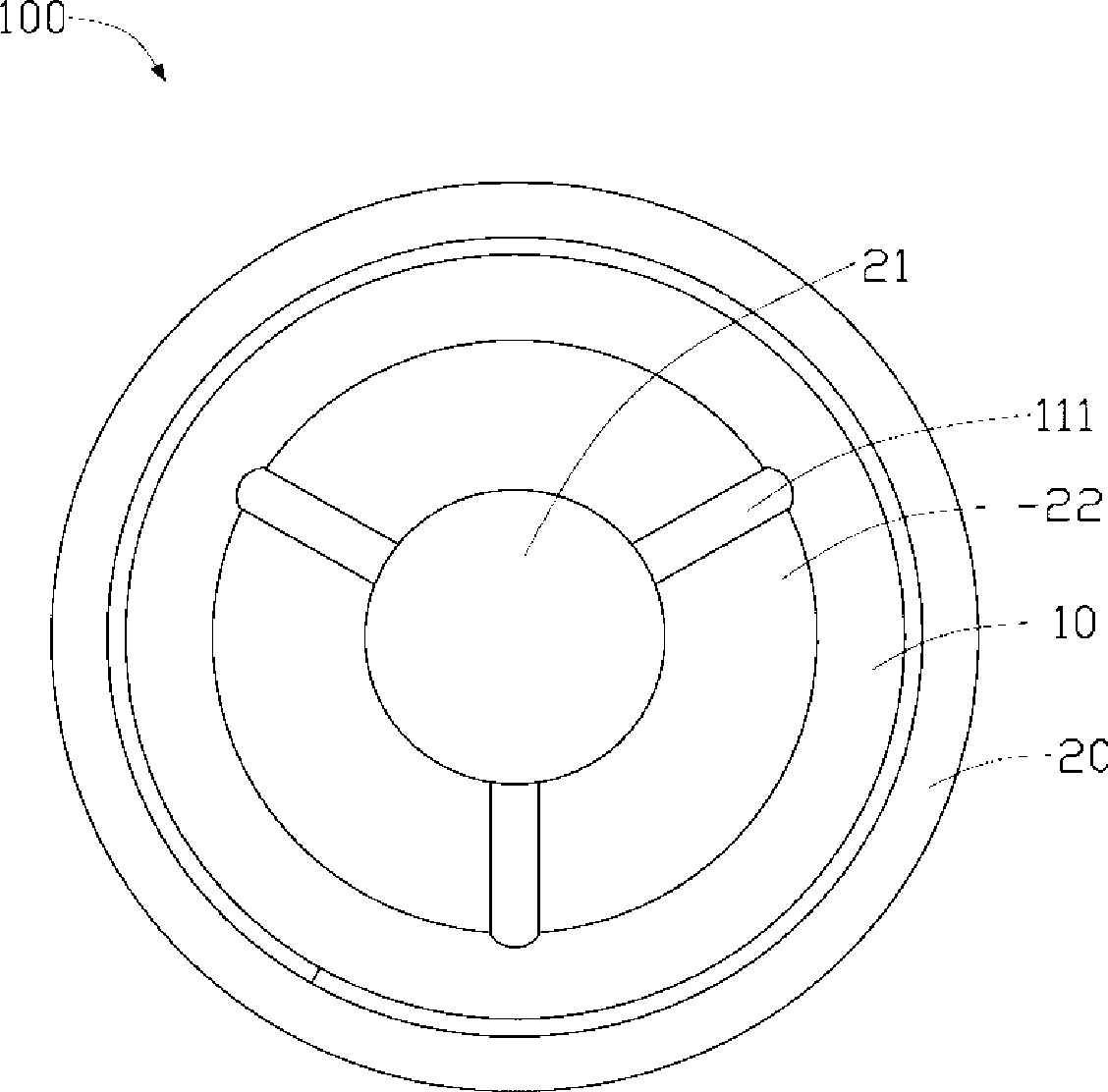

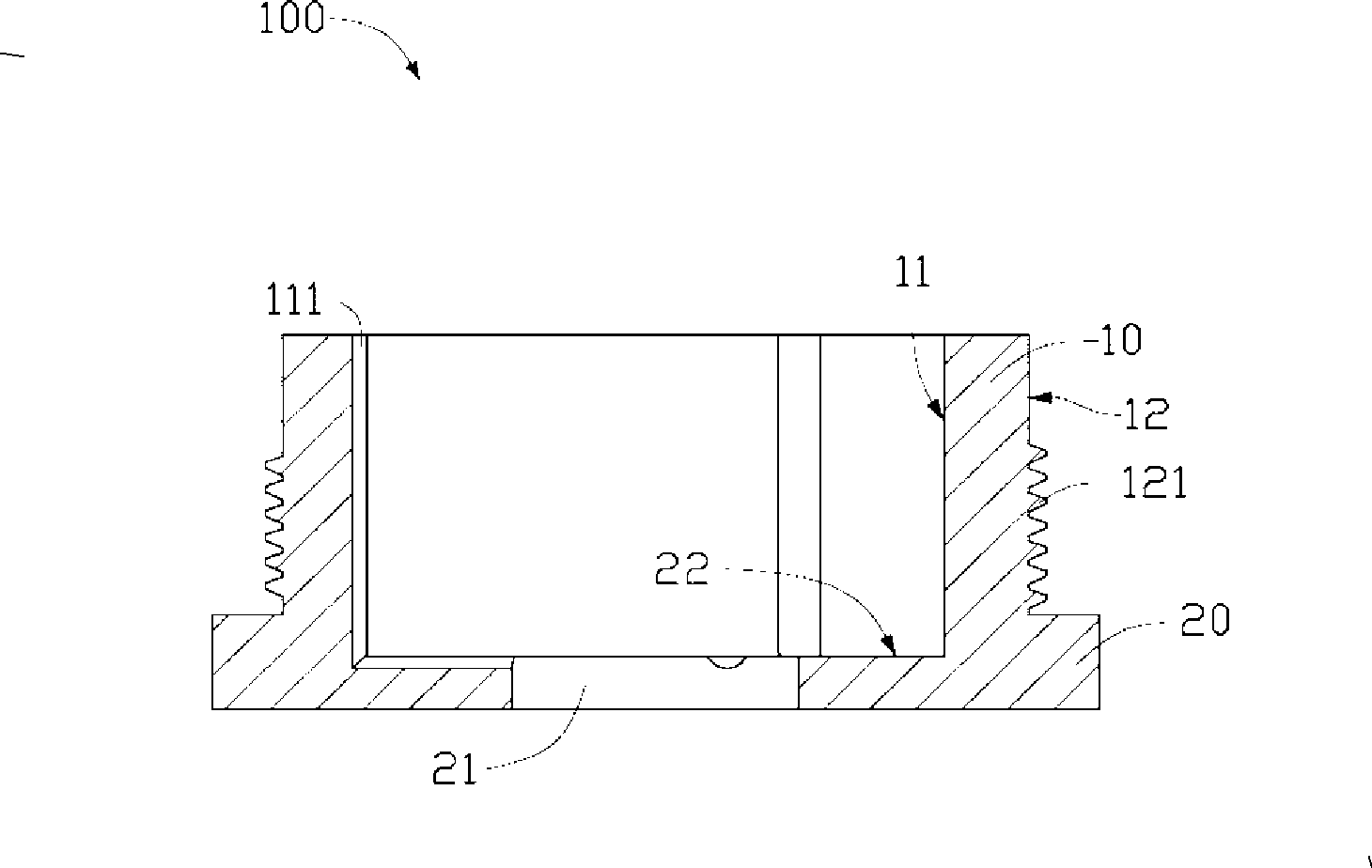

[0015] see figure 1 , figure 2 and image 3 , is the lens barrel 100 provided by the embodiment of the present invention. The lens barrel 100 is used to accommodate optical elements such as lenses and filters, and its material can be engineering plastics such as polyethylene, polypropylene, polyvinyl chloride or polystyrene. The lens barrel 100 includes a lens barrel sidewall 10 and a lens barrel bottom 20 .

[0016] The lens barrel sidewall 10 has an inner surface 11 and an outer surface 12 . The outer surface 12 is formed with external threads 121 .

[0017] The lens barrel bottom 20 is located at the bottom of the lens barrel side wall 10 , and the lens barrel bottom 20 and the lens barrel side wall 10 are integrally formed. The barrel bottom 20 has an inner surface 22 . A center of the lens barrel bottom 20 has an aperture 21 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com