Backlight module and display module

A technology of backlight module and display module, which is applied in the directions of optics, electric light source, light source fixing, etc., can solve the problems of increasing production cost and assembly complexity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

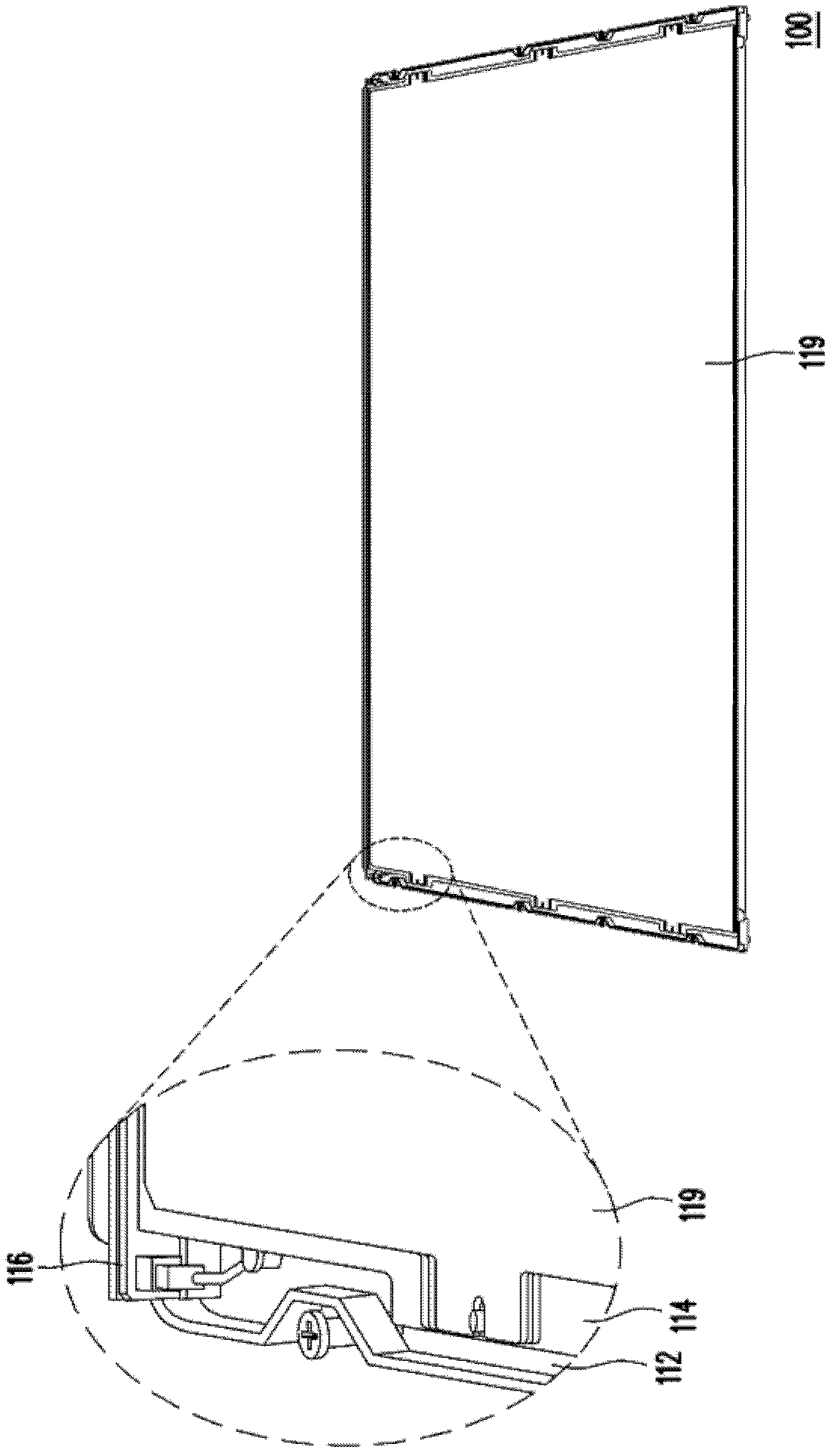

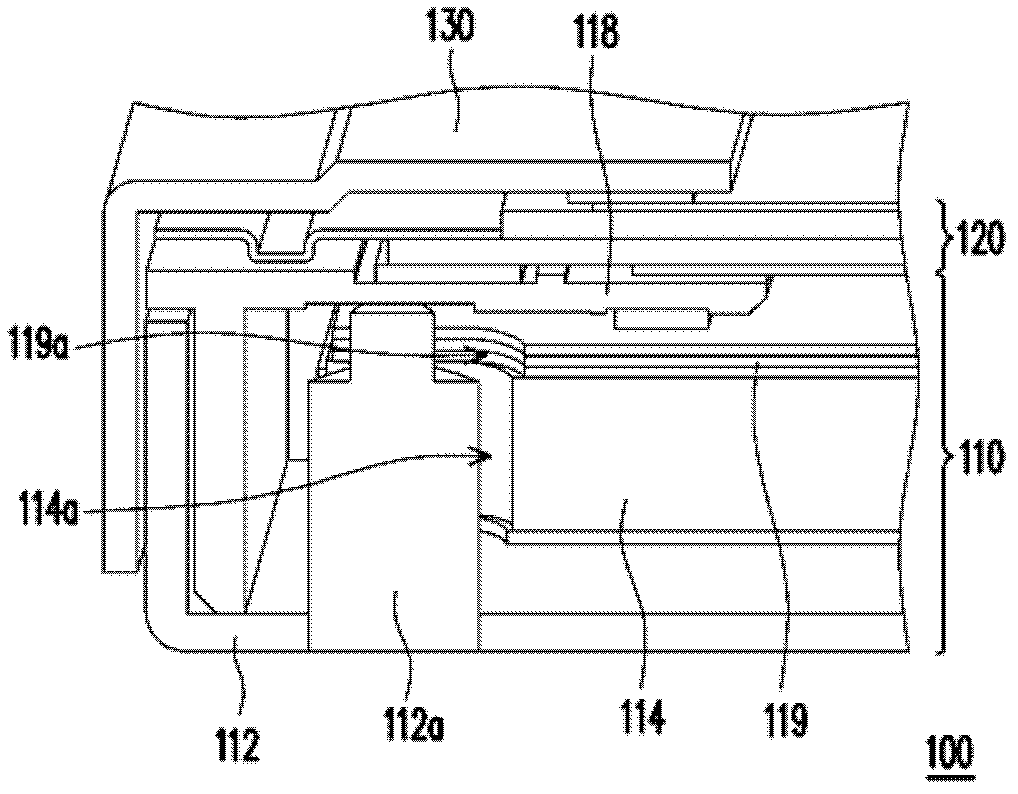

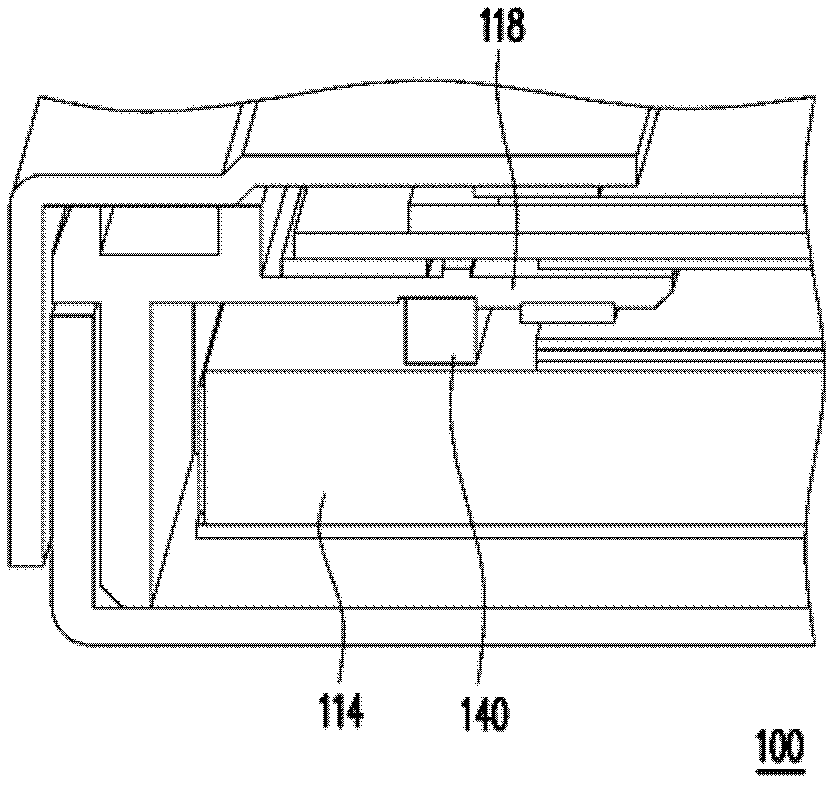

[0097] image 3 A display module according to an embodiment of the present invention is shown. Figure 4 is a cross-sectional view of the display module of this embodiment. In order to clearly express the structural characteristics, image 3 Components such as the front frame, the display panel, and the bearing frame are omitted, and the local structure is shown in a partially enlarged view.

[0098] Such as image 3 and Figure 4 As shown, the display module 200 of this embodiment mainly includes a display panel 400 and a backlight module 300 , wherein the backlight module 300 is mainly composed of a bottom plate 310 , a light guide plate 320 , a supporting frame 330 , a buffer material 340 and a baffle 350 . The light guide plate 320 is disposed on the bottom plate 310, and the light guide plate 320 includes a top surface 320a, a bottom surface 320b opposite to the top surface 320a, and a plurality of side surfaces 320c connected between the top surface 320a and the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com