Gluing tool

A glue dispensing and fixture technology, applied in installation, optics, instruments, etc., can solve the problems of difficult precise glue dispensing, assembly yield bottleneck, and difficult precise fixing of lens modules, etc., to achieve simple structure, improve production efficiency, The effect of improving dispensing accuracy and assembly yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings.

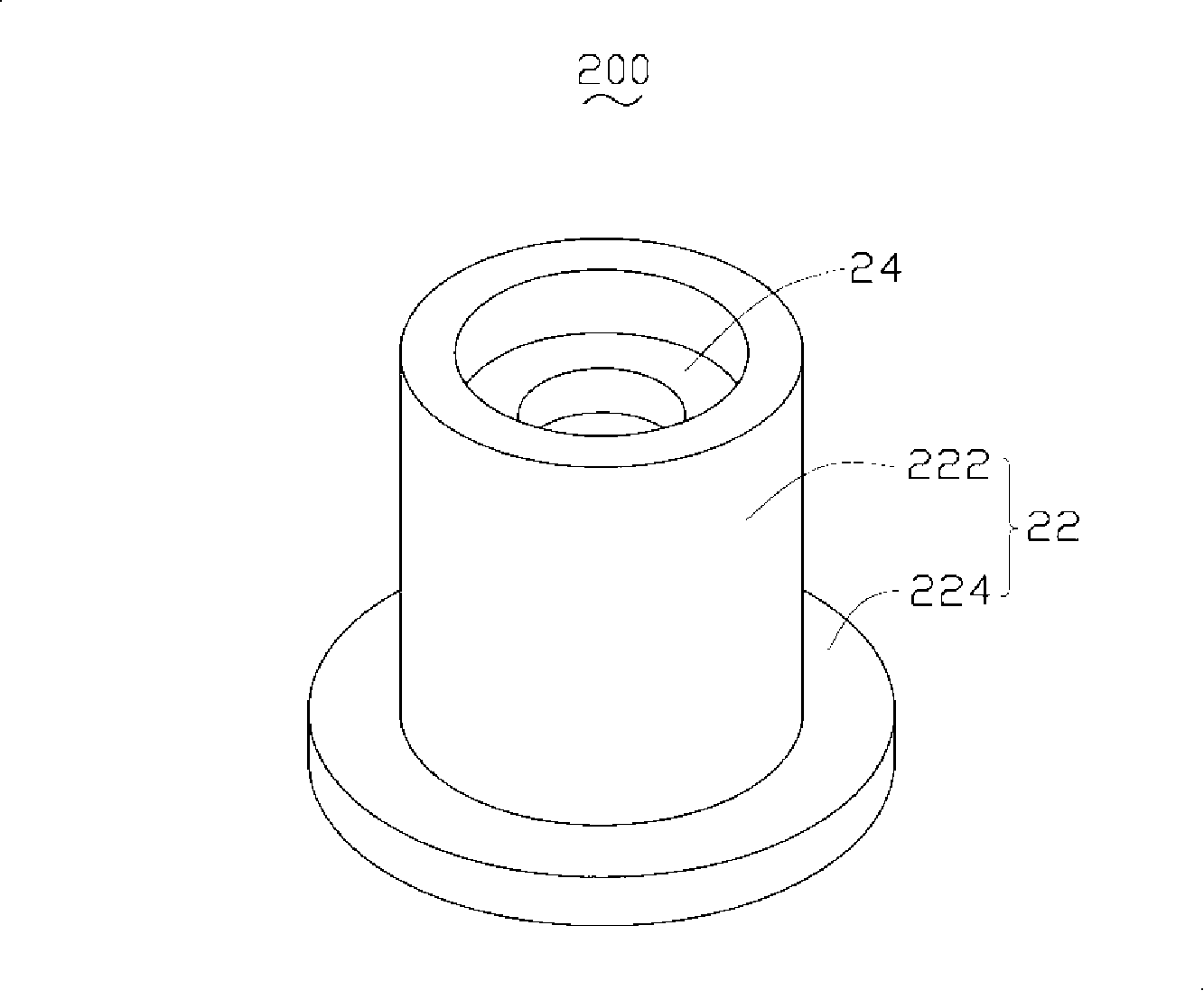

[0012] see figure 1 , is a schematic diagram of the lens module 200 to be dispensed. The lens module 200 includes a lens barrel 22 and a plurality of optical elements disposed inside the lens barrel 22 , such as lenses (not shown), spacers 24 and the like. The lens barrel 22 includes a barrel body 222 and an end portion 224 disposed at one end of the barrel body 222 .

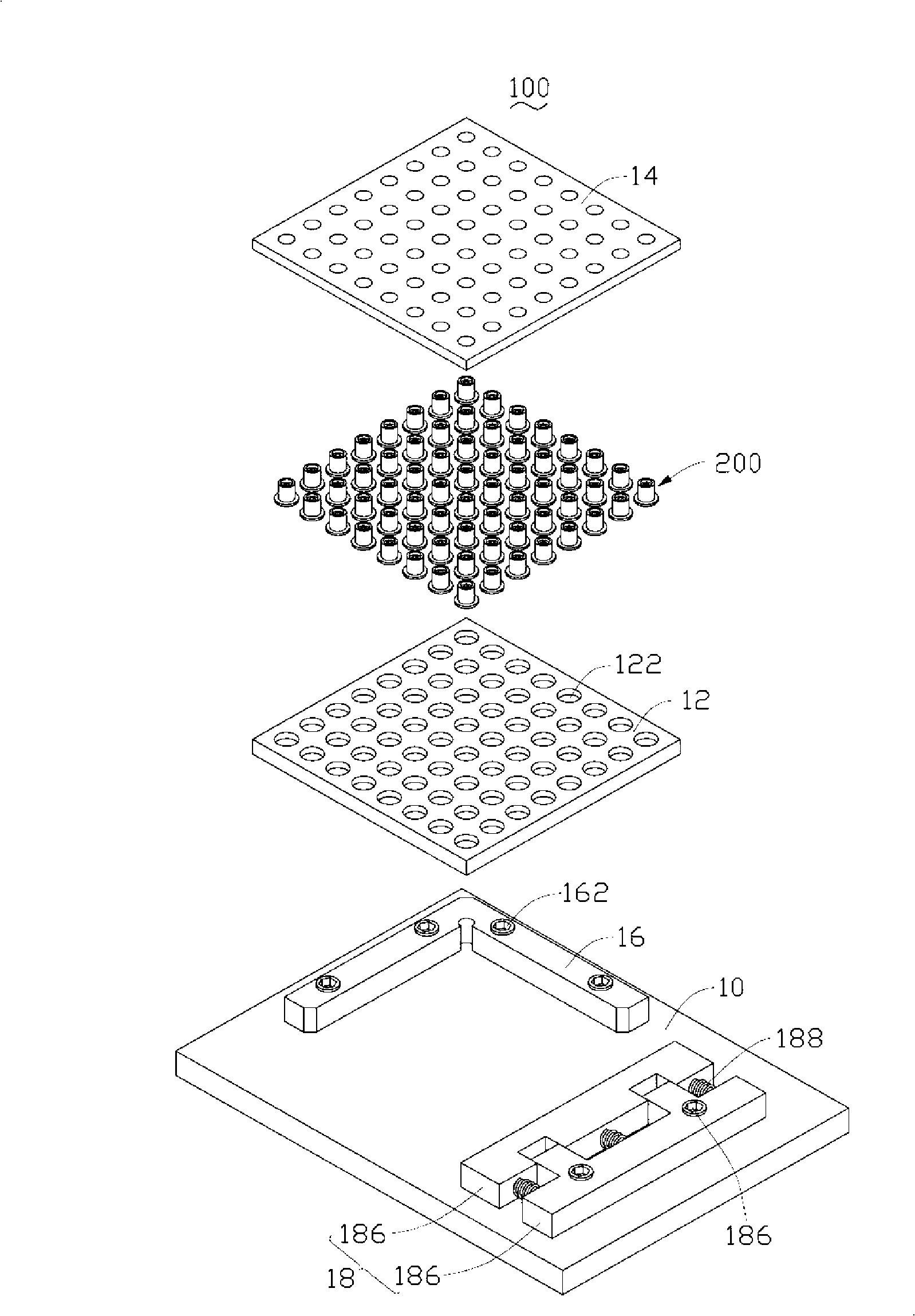

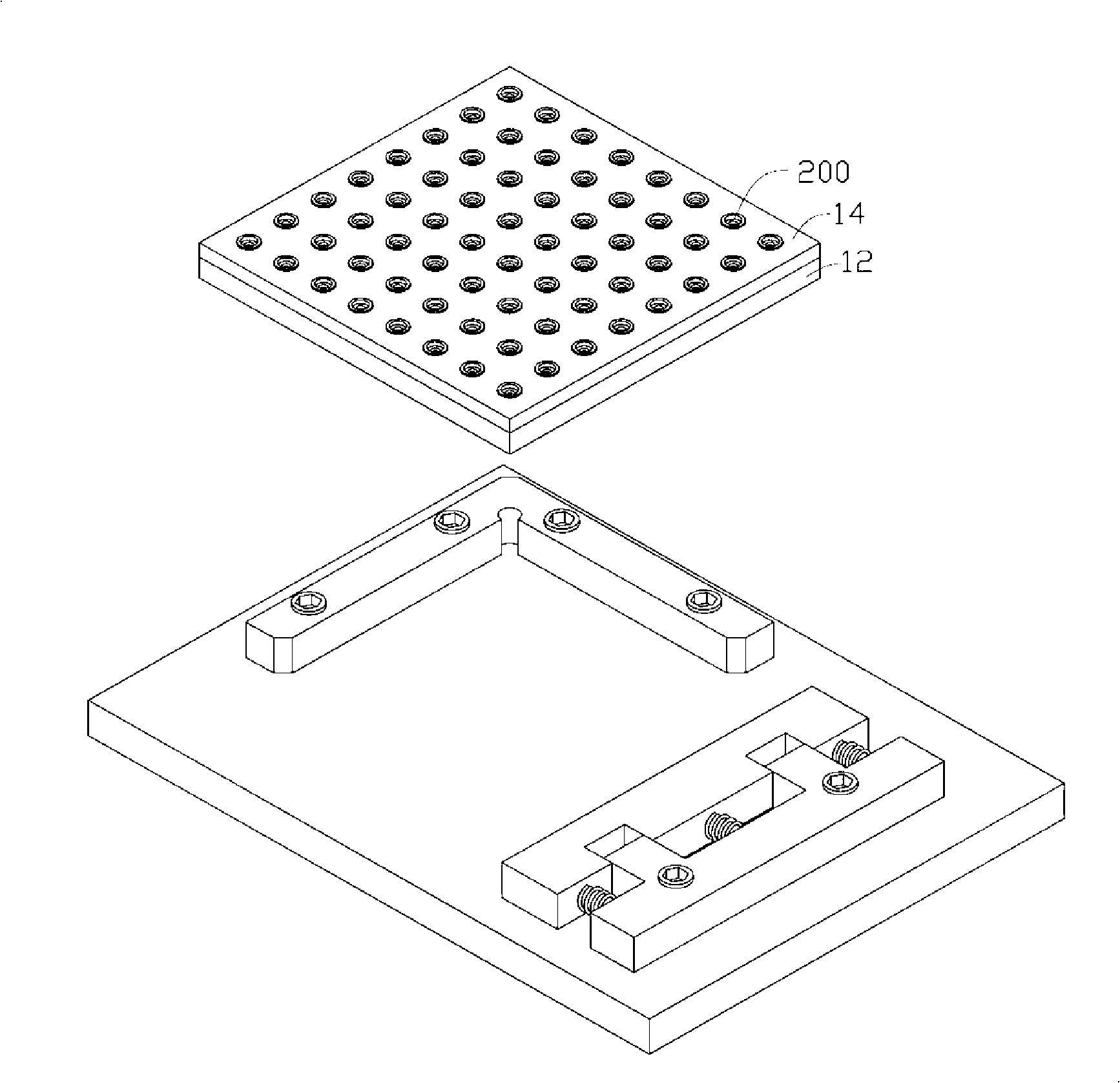

[0013] see figure 2 , is a schematic diagram of a dispensing fixture 100 according to a preferred embodiment of the present invention. The dispensing fixture 100 includes a platform 10 , a tray 12 , a cover 14 , an L-shaped block 16 , and a push block 18 .

[0014] The tray 12 is provided with a plurality of recesses 122 for placing the lens module 200 . The depressions 122 are respectively arranged at equal intervals along the sides of the tray 12 , and in this embodiment, the depressio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com