Complex fiber processing follow-up production device

A production equipment and composite fiber technology, applied in fiber processing, spinneret assemblies, textiles and papermaking, etc., can solve problems such as unsatisfactory precision, weak toughness, affecting work efficiency, etc., to achieve coherent process steps, spraying The effect of uniform silk speed, clean and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

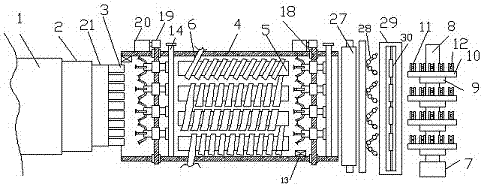

[0012] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

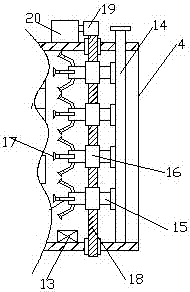

[0013] A composite fiber processing follow-up production equipment device, including a spinneret 1, a cooling device, a pre-shaping mechanism and a winding mechanism arranged in sequence, the spinneret 1 is provided with a spinneret assembly, and the spinneret assembly includes a vertical Type spray rack 2, protective device 21 and nozzle 3.

[0014] Described cooling device comprises cooling box 4, is provided with several channel pipes 5 in the case of described cooling box 4, and wherein cooling water pipe 6 is coiled on each described channel pipe 5, and the feeding port of described cooling box 6 and discharge port are all provided with induction air cooling device, described induction air cooling device comprises temperature sensor 13 and air cooling pipe 14, and described air cooling pipe 14 is provided with several extension pipes 15 rotating in sequence,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com