Method for producing yarn and apparatus thereof

A yarn manufacturing and yarn technology, applied in the field of yarn manufacturing and its devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

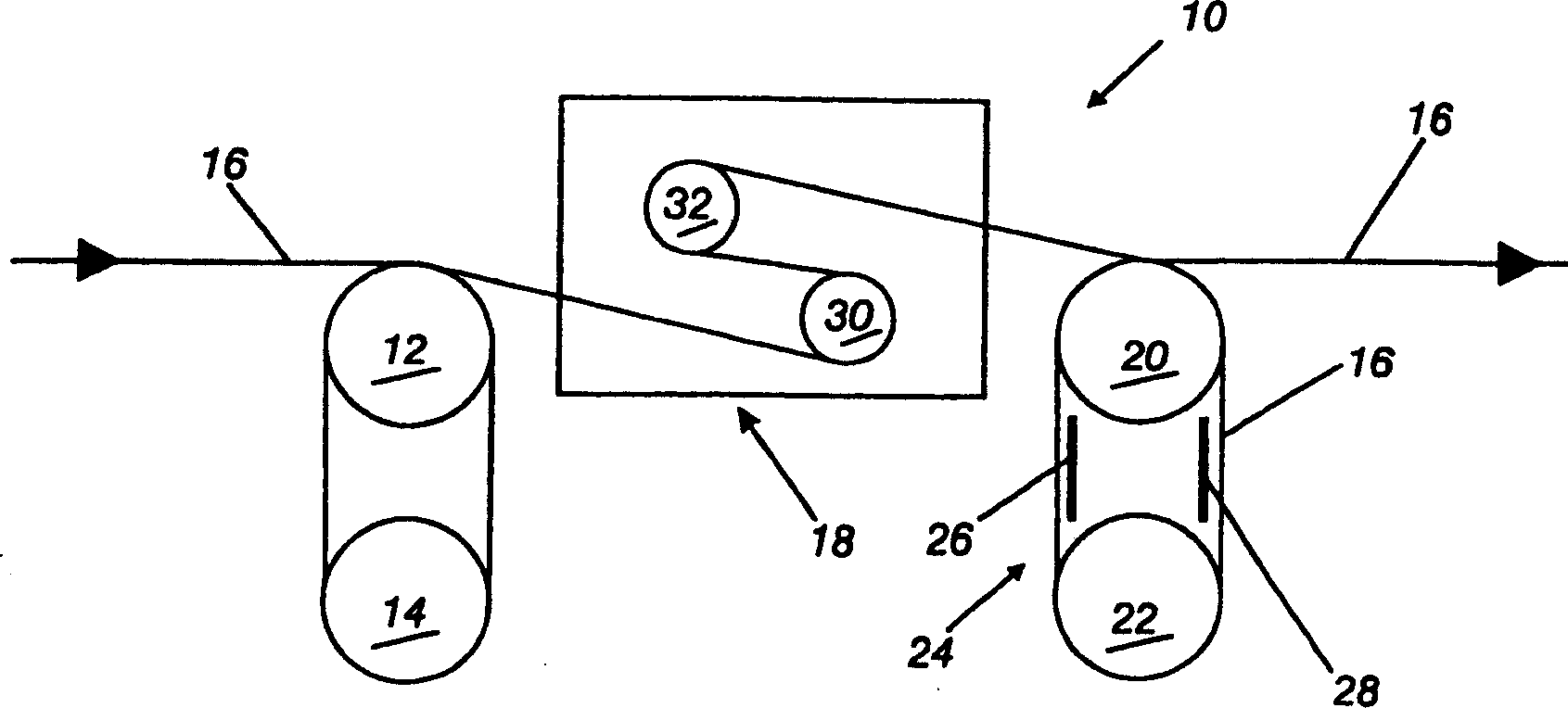

Examples

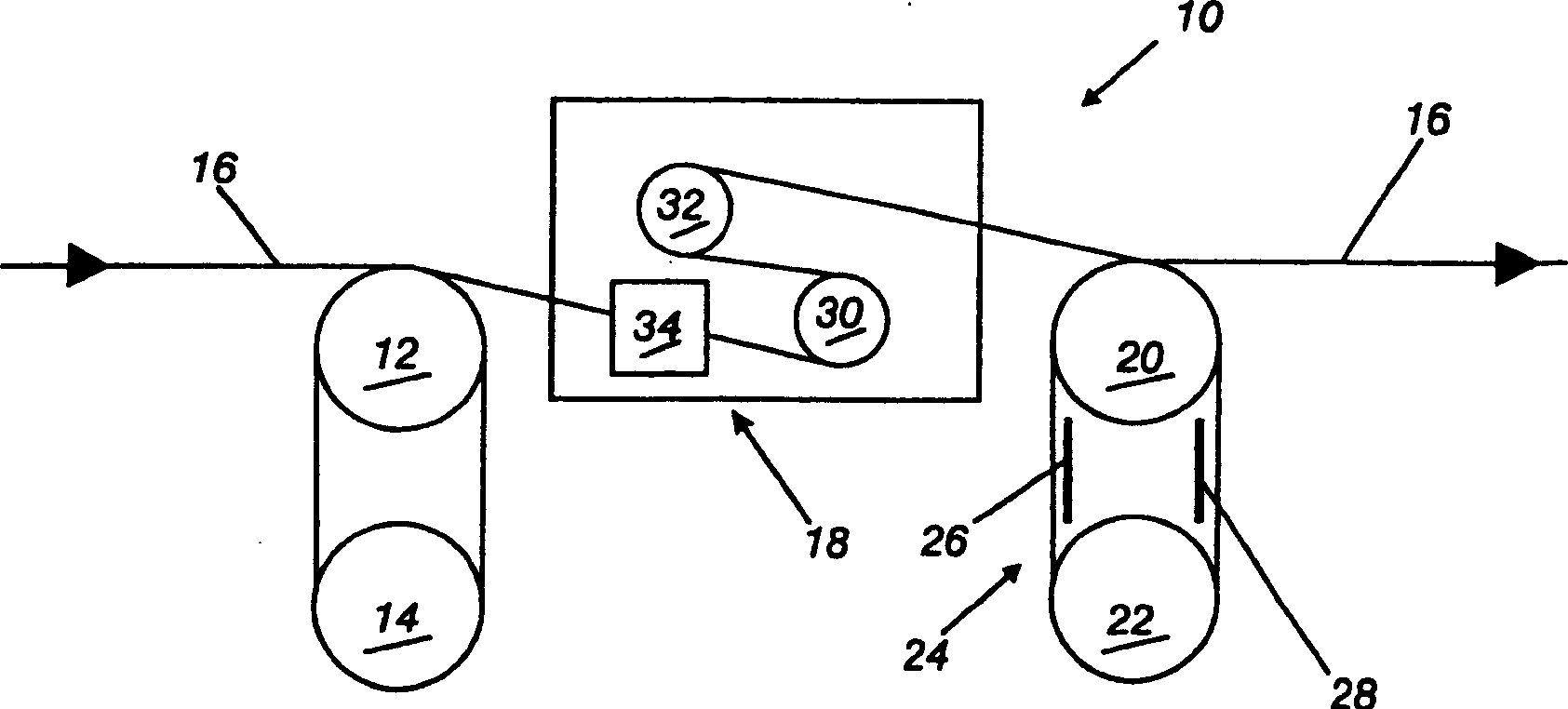

example 2

[0048] Using the configuration of Example 1, Test 4, an additional tension gate is added before the two roller tension gates, such as figure 2 shown. The tension gate is an air intermingler operating at a pressure of 30 psig. Using a draw speed of 5000 mpm, the relaxation rate on the relax roll was 8.91% at a temperature of 150°C (draw roll held at 242°C).

[0049] At 5,000 mpm, the spinning stability improved from 3.0 to 2.75 when air was supplied to the mixing element.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com