Preparation method of novel thread guide wheel

A godet, a new type of technology, used in rayon support, textiles and papermaking, etc., can solve the problems of peeling off, reducing the practicality of the godet, and the surface coating being easily oxidized, and achieving excellent yarn guiding performance, The effect of low preparation cost and reasonable process arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

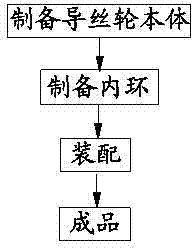

Image

Examples

Embodiment

[0019] Concrete preparation steps are as follows:

[0020] a) Preparation of the godet wheel body, the godet wheel body is made of silicon carbide ceramic particles as the main material, combined with a certain amount of additives, and sintered by hot isostatic pressing; wherein, the particle size of the silicon carbide ceramic particles is 0.8- 1.2um, the sintering temperature is controlled at 1550-1650°C, the pressure is 120-125MPa, the main additive is alumina or magnesia, which can effectively reduce the sintering temperature and increase the sintering density;

[0021] b) Prepare the inner ring. The main raw material of the inner ring is flake graphite, the carbon content of which is 99.5%-99.9%, and the maximum scale size is 0.2-0.4mm; the inner ring is prepared by molding process, and the prepared inner ring The thickness is 1-1.5mm, the inner surface roughness is 0.8-0.2, and the outer surface roughness is slightly larger than the inner surface roughness value;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com