Production method for complete extinction modified polyester

A production method and full extinction technology, applied in the field of polyester production, can solve the problems of easy color stripes, high hardware conditions, and high requirements for subsequent fabrics, and achieve the effect of improving the wool phenomenon and stabilizing the silk road

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with regard to specific embodiment:

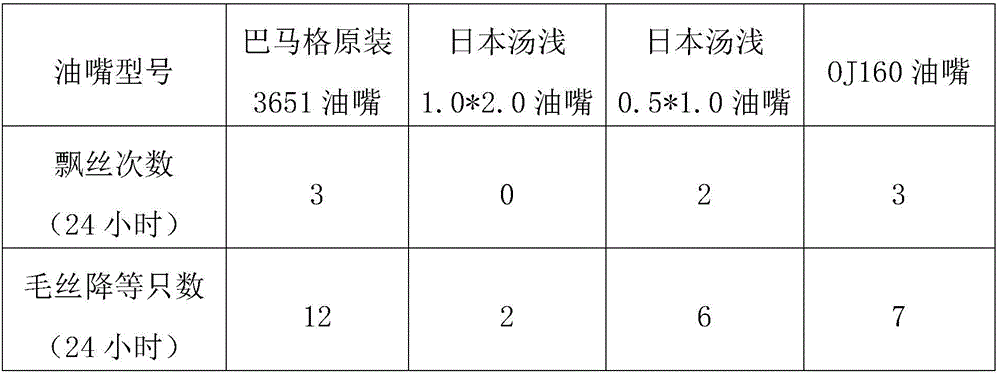

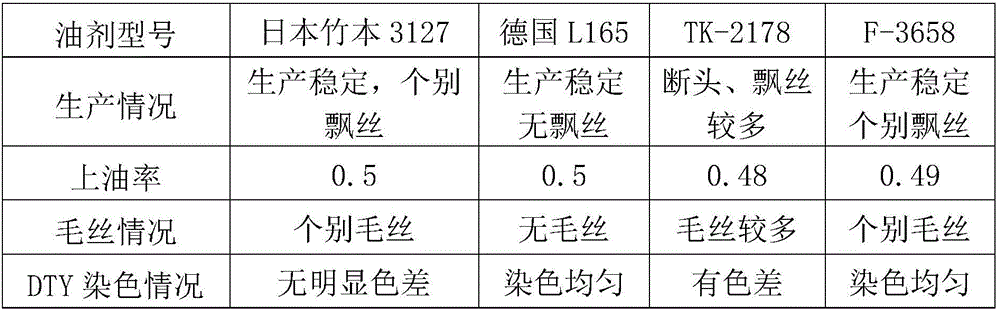

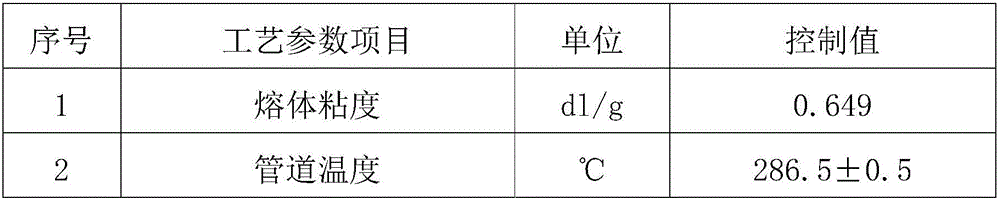

[0017] A production method of full-dull modified polyester, comprising the following steps: the masterbatch is transported to a drying system for crystallization and drying, and then passes through a masterbatch high-level silo, screw melt extrusion, a masterbatch metering pump, a melt dynamic mixer, After the melt static mixer enters the spinning box, at the same time, the polyester melt is transported through the pipeline, the booster pump enters the melt cooler to cool, and then is transported into the spinning box through the pipeline to polymerize with the masterbatch melt. Then go through the metering pump, spinneret, ring air cooling, nozzle oiling, wire guide, pre-network, GR1, GR2 winding forming, finished product inspection, and then pack into the warehouse. alcohol. Specifically, a melt injection system is designed and added in front of the spinning box of the POY spi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com