Pinch roll in front of rolling mill

A technology of pinch rolls and front clamps, used in metal rolling, metal rolling, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

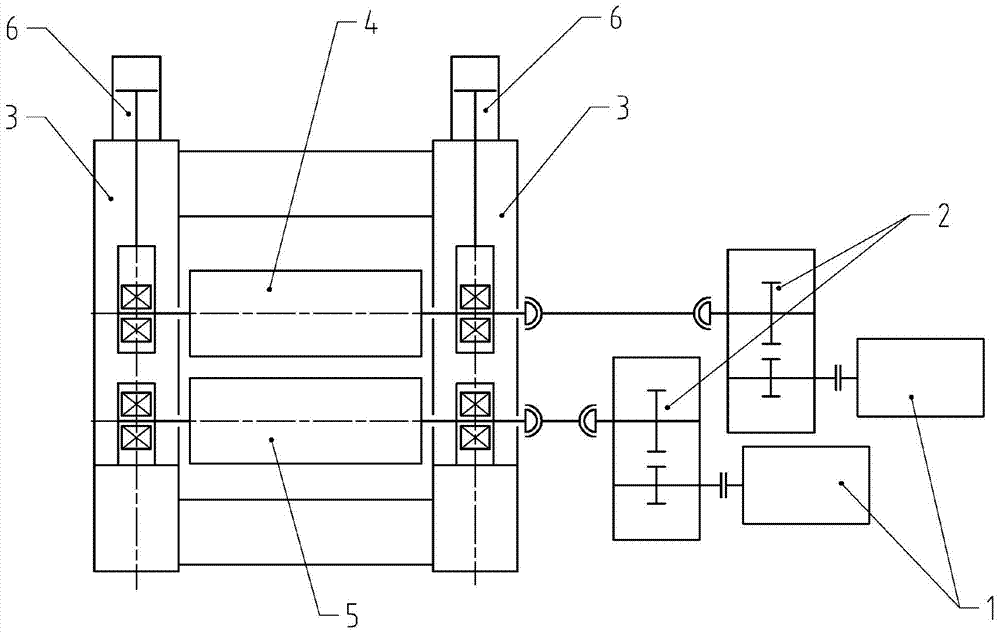

[0014] figure 2 It is a structural schematic diagram of the front pinch roll of the rolling mill of the present invention. Including frame 3, rollers, transmission device, hydraulic cylinder 6 and body piping, frame 3 includes two left and right side frame pieces and the upper beam fixedly connected between the left and right side frame pieces and the left and right side frame pieces The lower beam at the lower part of the room, the left and right frame pieces and the upper and lower beams form a frame window, and the inner walls of the frame windows of the left and right frame pieces are provided with slide plates and lower pinch roller bearing seats, and the lower pinch roller bearing seats are fixed. In the lower part of the inner wall of the frame window; there are two hydraulic cylinders 6, which are respectively fixed on the top of the left and right side frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com