Filament winding tension adjusting device for moisture absorption and sweat releasing polyester filament feeding and winding machine

A tension adjustment device, moisture absorption and perspiration technology, applied in the direction of artificial filament support, artificial filament physical therapy, clustering of newly sprayed filaments, etc., can solve the problem of inconvenient adjustment of the godet roller position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

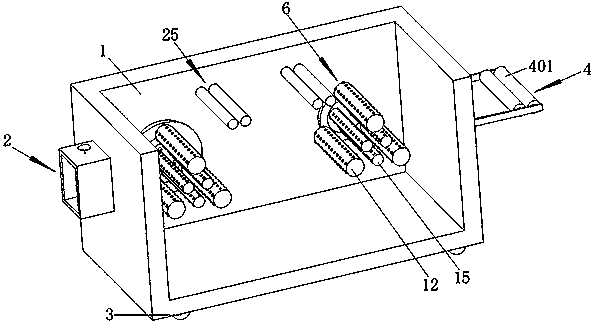

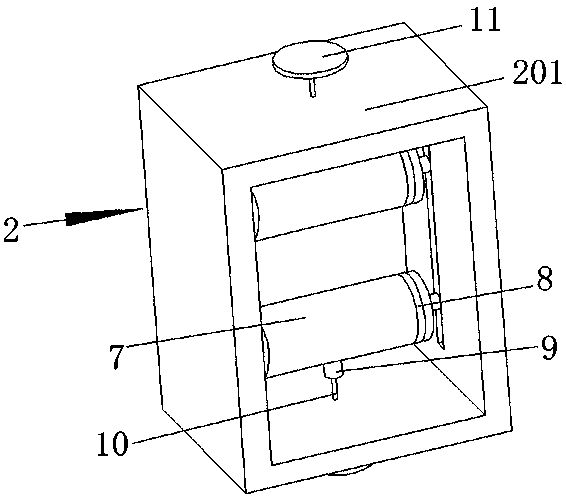

[0037] refer to figure 1 , Image 6 , a filament winding tension adjustment device in a moisture-absorbing and sweat-wicking polyester upper filament winding machine, comprising a box body 1, a pre-drawing mechanism 2, a runner 3, a traction mechanism 4, and a polyester filament 5, and the pre-drawing mechanism 2 is fixed Connected to the side wall of the box body 1, the runner 3 is rotatably connected to the bottom of the box body 1, the traction mechanism 4 is set on the outer side of the box body 1 away from the end of the pre-traction mechanism 2, and the inside of the box body 1 is connected with a symmetrically distributed winding mechanism 6. The winding mechanism 6 is provided with an adjustment component, and the polyester filament 5 bypasses the pre-drawing mechanism 2, the winding mechanism 6 and the traction mechanism 4 in turn; the polyester filament 5 output by the screw extruder is pulled by the traction mechanism 4 , the polyester filament 5 enters the winding...

Embodiment 2

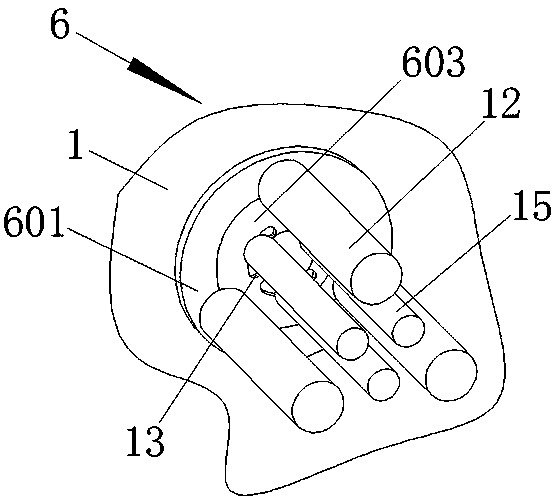

[0039] refer to Figure 1-4 , a filament winding tension adjustment device in a moisture-absorbing and sweat-wicking polyester upper filament winding machine, comprising a box body 1, a pre-drawing mechanism 2, a runner 3, a traction mechanism 4, and a polyester filament 5, and the pre-drawing mechanism 2 is fixed Connected to the side wall of the box body 1, the runner 3 is rotatably connected to the bottom of the box body 1, the traction mechanism 4 is set on the outer side of the box body 1 away from the end of the pre-traction mechanism 2, and the inside of the box body 1 is connected with a symmetrically distributed winding mechanism 6. The winding mechanism 6 is provided with an adjustment component, and the polyester filament 5 bypasses the pre-drawing mechanism 2, the winding mechanism 6 and the traction mechanism 4 in turn; the polyester filament 5 output by the screw extruder is pulled by the traction mechanism 4 , the polyester filament 5 enters the winding mechanis...

Embodiment 3

[0044] refer to Figure 1-4 with Figure 5 , a filament winding tension adjustment device in a moisture-absorbing and sweat-wicking polyester upper filament winding machine, which is basically the same as Embodiment 2, and furthermore, the inner wall of the sliding groove 13 is provided with a chute 16, and the chute 16 slides Be connected with slide block 17, be fixedly connected with back-moving spring between slide block 17 and chute 16 inwalls; By offering chute 16 at the inwall of slide groove 13, slide block 17 is slidably connected in chute 16, slide block 17 and A return spring is fixedly connected between the inner walls of the chute 16, and the sliding of the slider 17 in the chute 16 drives the sliding of the connecting column 14 in the chute 13, thereby driving the adjustment godet 15 to move in the chute 13, In order to realize the adjustment of the position of the godet roller 15 , the existence of the return spring is beneficial to realize the return of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com