Clamping device with pressure sensor

A technology of pressure sensor and clamping device, which is applied in the direction of workpiece clamping device, manufacturing tools, etc., can solve problems such as troublesome, inconvenient, and difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

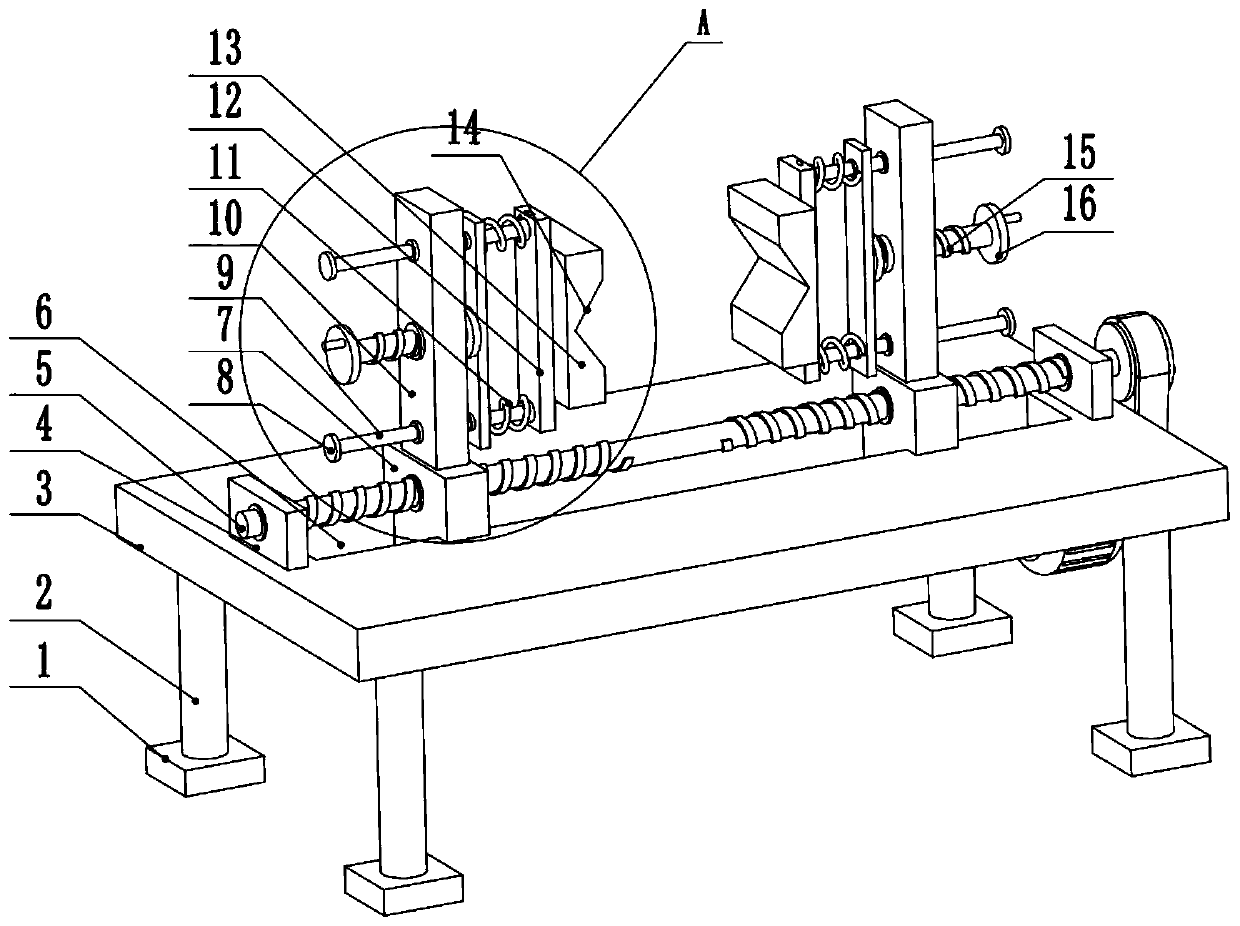

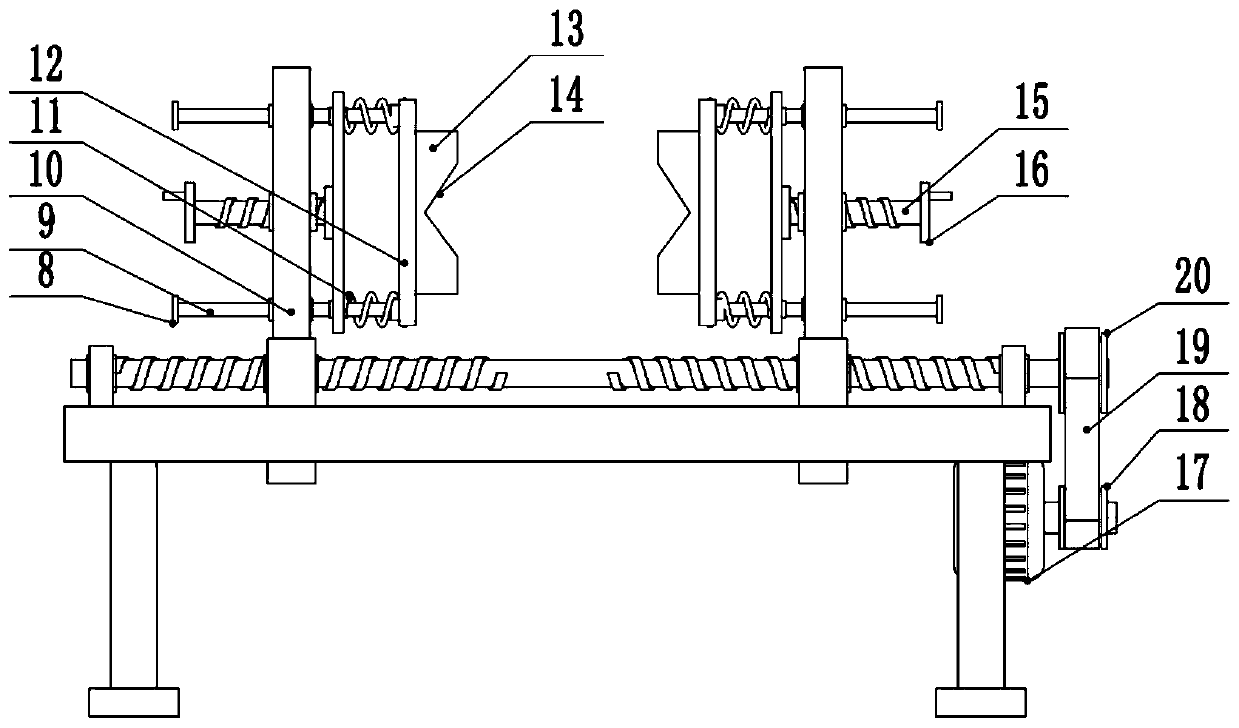

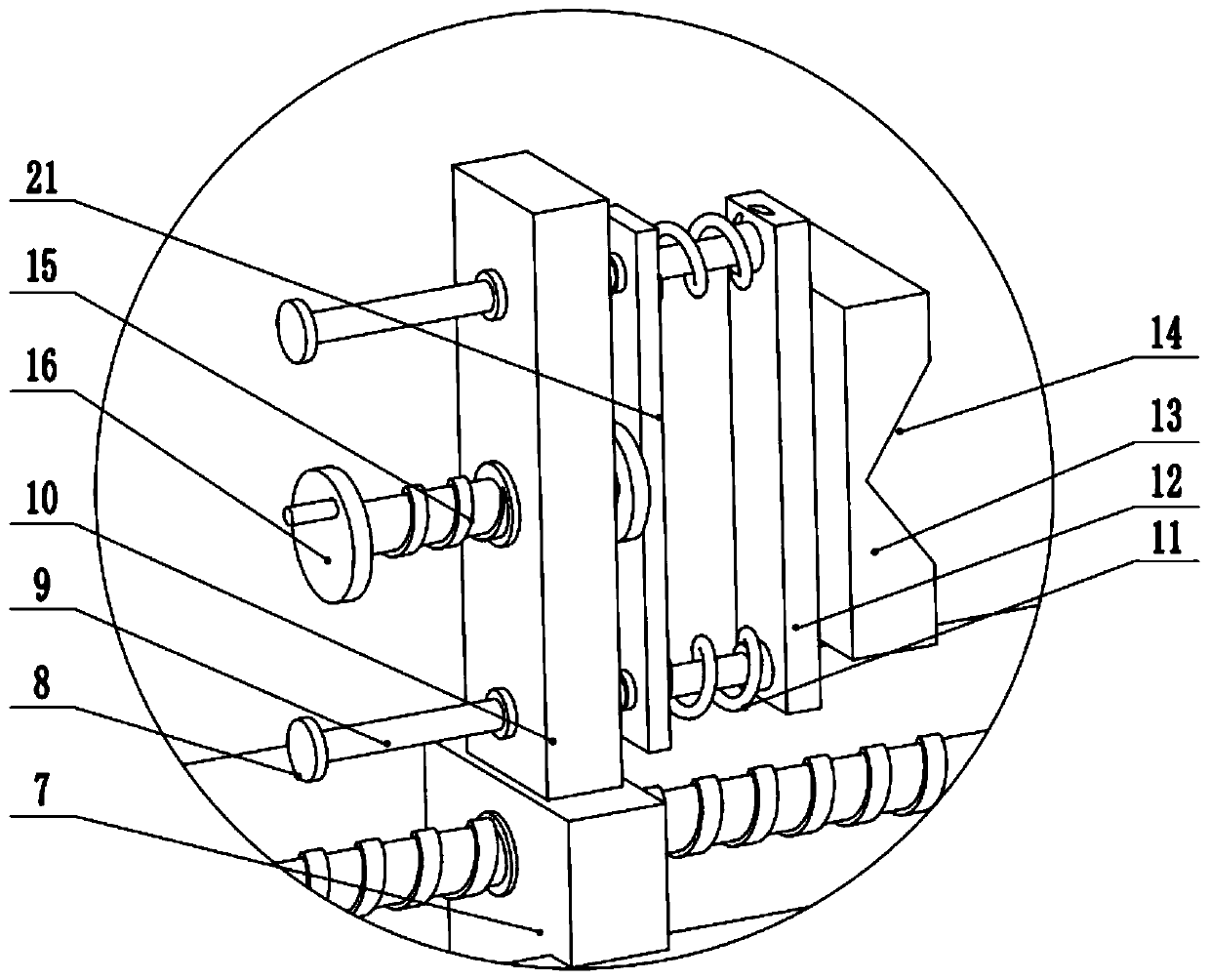

[0024] see Figure 1-3 , a clamping device with a pressure sensor, comprising a workbench 3, four corners of the lower surface of the workbench 3 are provided with support columns 2, the lower end of the support column 2 is provided with a pad 1, and the middle of the workbench 3 is provided with There is a chute 6, the chute 6 is slidably connected to the slider 7, the upper part of the slider 7 is provided with a fixed seat 10, the left and right ends of the workbench 3 are provided with a bearing seat 4, and the middle part of the bearing seat 4 is rotatably connected to the first wire Rod 5, the left and right sides of the first screw mandrel 5 are screwed to the middle part of the slide block 7, the left and right sides of the first screw mandrel 5 are provided with opposite threads, and the right side of the lower surface of the workbench 3 is provided with a drive motor 17 , the output shaft of the drive motor 17 is fixedly connected to the first pulley 18, the first pu...

Embodiment 2

[0027] see figure 1 , the other content of this embodiment is the same as that of Embodiment 1, except that: the opposite side of the clamping block 13 is provided with a jaw 14 . In order to facilitate the clamping of various types of workpieces, jaws 14 of different sizes can be provided on the opposite surfaces of the clamping block 13, and the workpieces can be fixed through the jaws 14, and the workpieces will be more stable after being clamped. shaking.

[0028] In the implementation process of the present invention, the workpiece to be clamped is placed between the two clamping blocks 13. At this time, the drive motor 17 is started, and the drive motor 17 drives the first screw mandrel 5 to rotate through the belt 19 transmission. The left and right sides of the rod 5 are provided with threads with opposite rotations, so when the first screw rod 5 rotates, the two sliders 7 move close to each other, thereby driving the clamping blocks 13 to move close to each other, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com