A centre mechanism and a semiconductor processing device

A technology of thimble and ring body, which is used in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of loose thimble, deformation of the clamping member 44, and inability to adjust, so as to avoid the loosening of the thimble, improve assembly efficiency, and improve The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order for those skilled in the art to better understand the technical solutions of the present invention, the ejector mechanism and semiconductor processing equipment provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

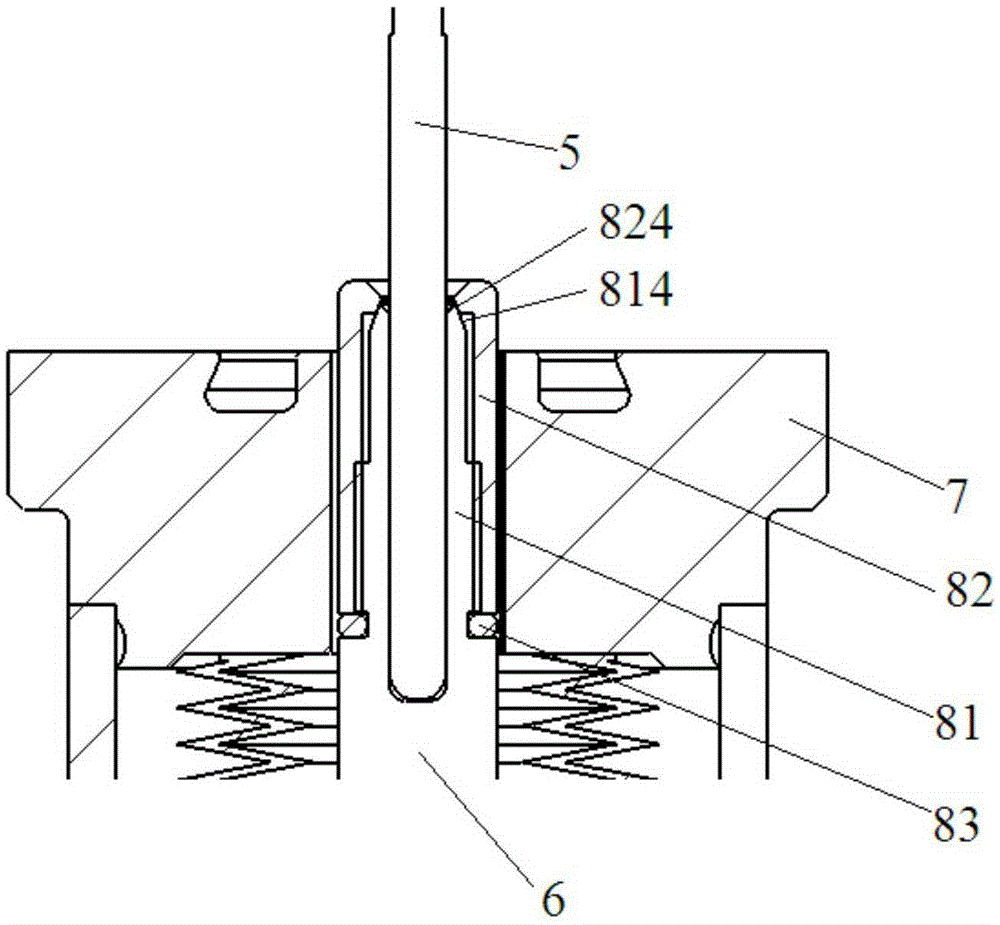

[0025] image 3 A partial sectional view of the ejector mechanism provided by the embodiment of the present invention. see image 3 , the thimble mechanism includes a thimble 5, a central shaft 6 and a fixed assembly, wherein the fixed assembly is used to fixedly connect the thimble 5 to the central shaft 6, and the fixed assembly includes a clamping deformation member 81 and a locking nut 82, wherein the clamping The deformation member 81 is arranged on the top of the central shaft 6 and sleeved on the lower part of the thimble 5 for clamping and fixing the thimble 5 . The locking nut 82 is sleeved on the clamping deformation member 81 and threadedly engaged with it. A first mating su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com