Electro-hydraulic flat-pushing clamping device

A technology of clamping device and driving device, which is applied in the field of fixtures and can solve problems such as poor synchronization performance of clamping blocks and uncontrollable clamping force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

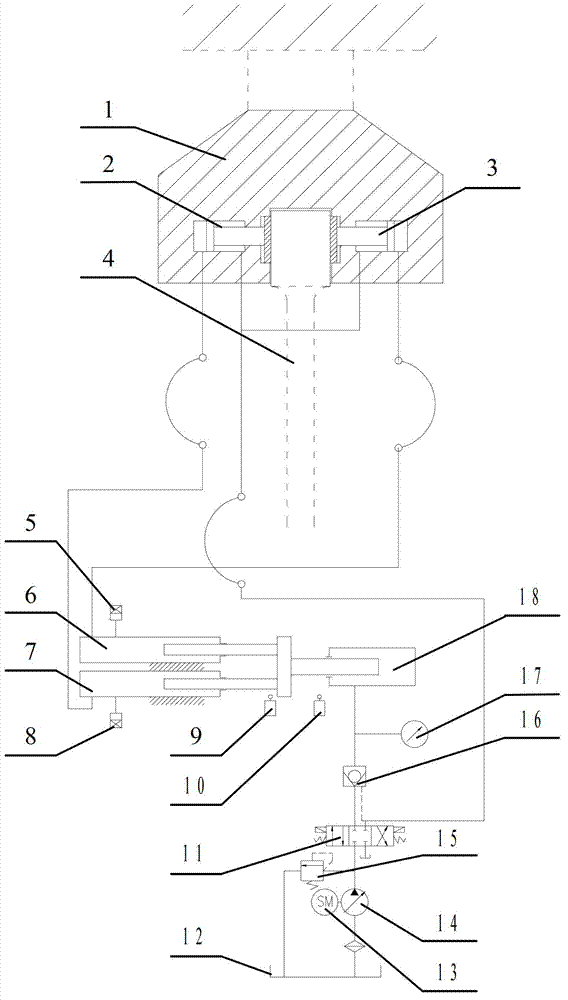

[0038] See attached figure 1 and attached Figure 5 , 6 , the flat push type clamping device of the present invention comprises collet body 1, piston cylinder A2, piston cylinder B3, plunger cylinder A7, plunger cylinder B6 and drive device composition; Described collet body 1 comprises body 101, rear end Cover A102, piston A103, front end cover A104, transition plate A105, snap ring A106, clamp block A107, clamp block B108, snap ring B109, transition plate B110, front end cover B111, piston B112, rear end cover B113; The block A107 is connected to the piston A103 through the transition plate A105; the front end cover A104 is close to the clamp block A107, and the rear end cover A102 is located at the outer end of the body 101; the clamp block B108 is connected to the piston B112 through the transition plate B110; the front end cover B111 is close to the clamp Block B108, the rear end cover B113 is located at the outer end of the body 101; the piston rod of the piston cylind...

Embodiment 2

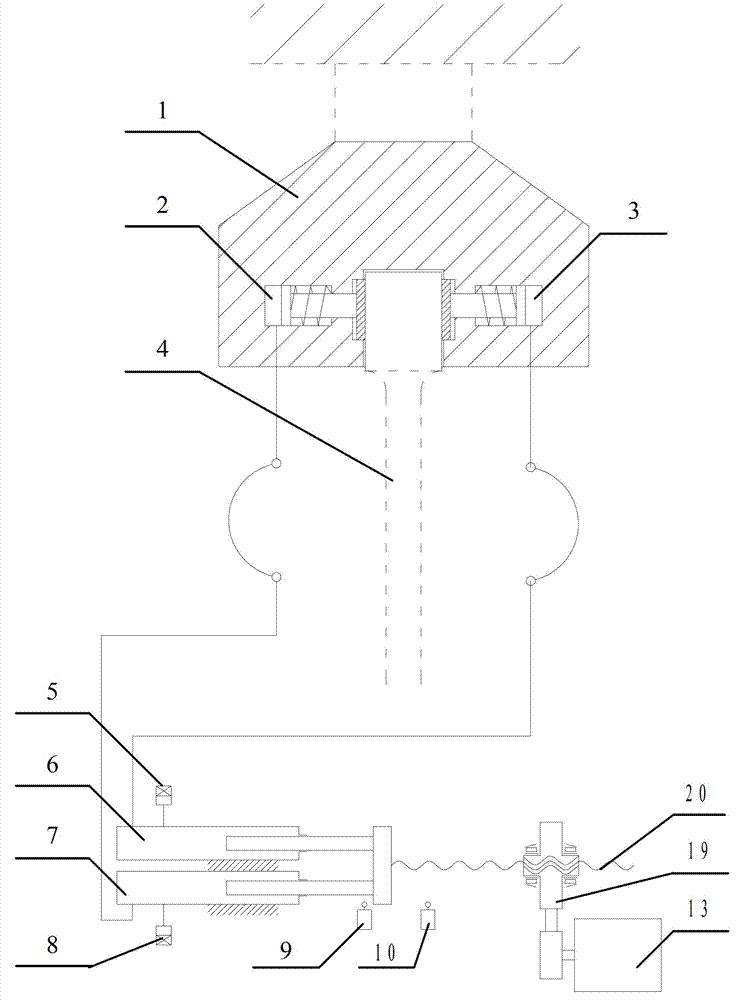

[0043] See attached figure 2 The difference between this embodiment and Embodiment 1 is that the driving device includes a servo motor 13, a reducer 19, and a ball screw 20, and the ball screw 20 is connected to the plunger cylinder A7 and the column of the plunger cylinder B6. The plug cylinder is connected, and the servo motor 13 drives the ball screw 20 to rotate through the reducer 19; the loosening system is that a spring is installed in the rod cavity of the piston cylinder A2 and the piston cylinder B3, and the clamping block is moved away from the test by the restoring force of the spring. Move in the direction of sample 4.

Embodiment 3

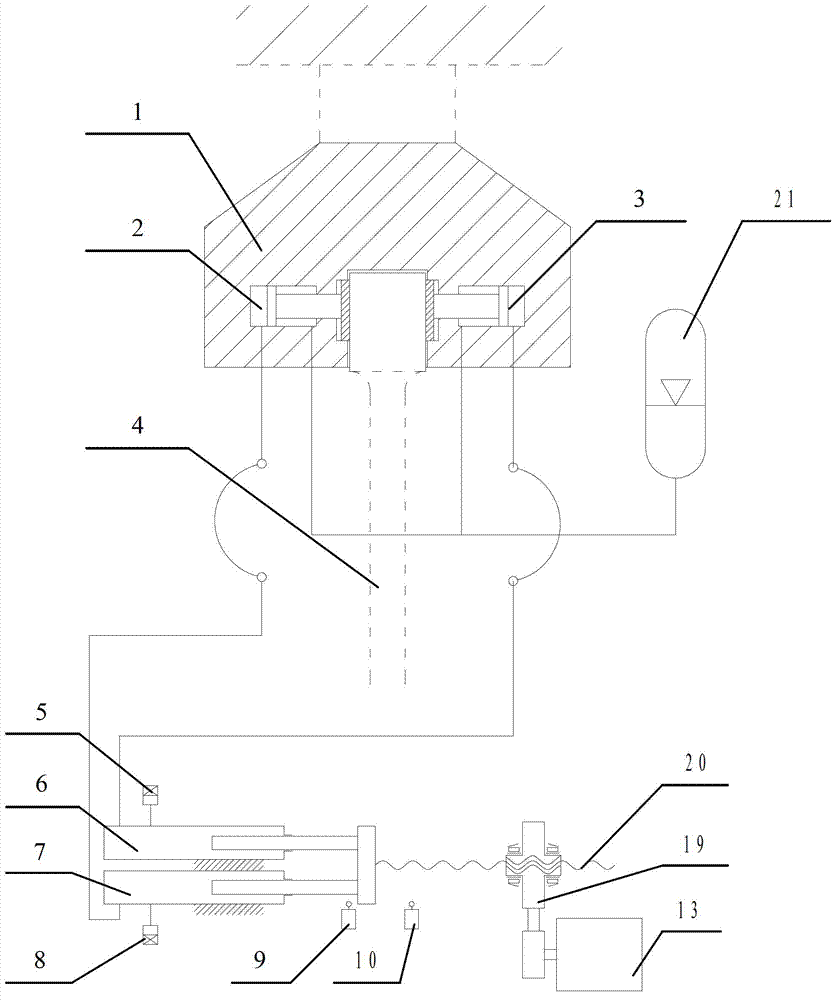

[0045] See attached image 3The difference between this embodiment and Embodiment 1 is that the driving device includes a servo motor 13, a reducer 19, and a ball screw 20, and the ball screw 20 is connected to the plunger cylinder A7 and the column of the plunger cylinder B6. The plug cylinder is connected, and the servo motor 13 drives the ball screw 20 to rotate through the reducer 19; the loosening system is that the piston cylinder A2 and the piston cylinder B3 have an accumulator 21 connected to the rod chamber, and when the sample 4 is loosened, through The accumulator 21 makes the pistons of the piston cylinder A2 and the piston cylinder B3 move away from the clamp block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com