Semi-gear tension conveying device

A conveying device and half-gear technology, applied in the field of film laminating machines, can solve problems such as conveying, instability, and looseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

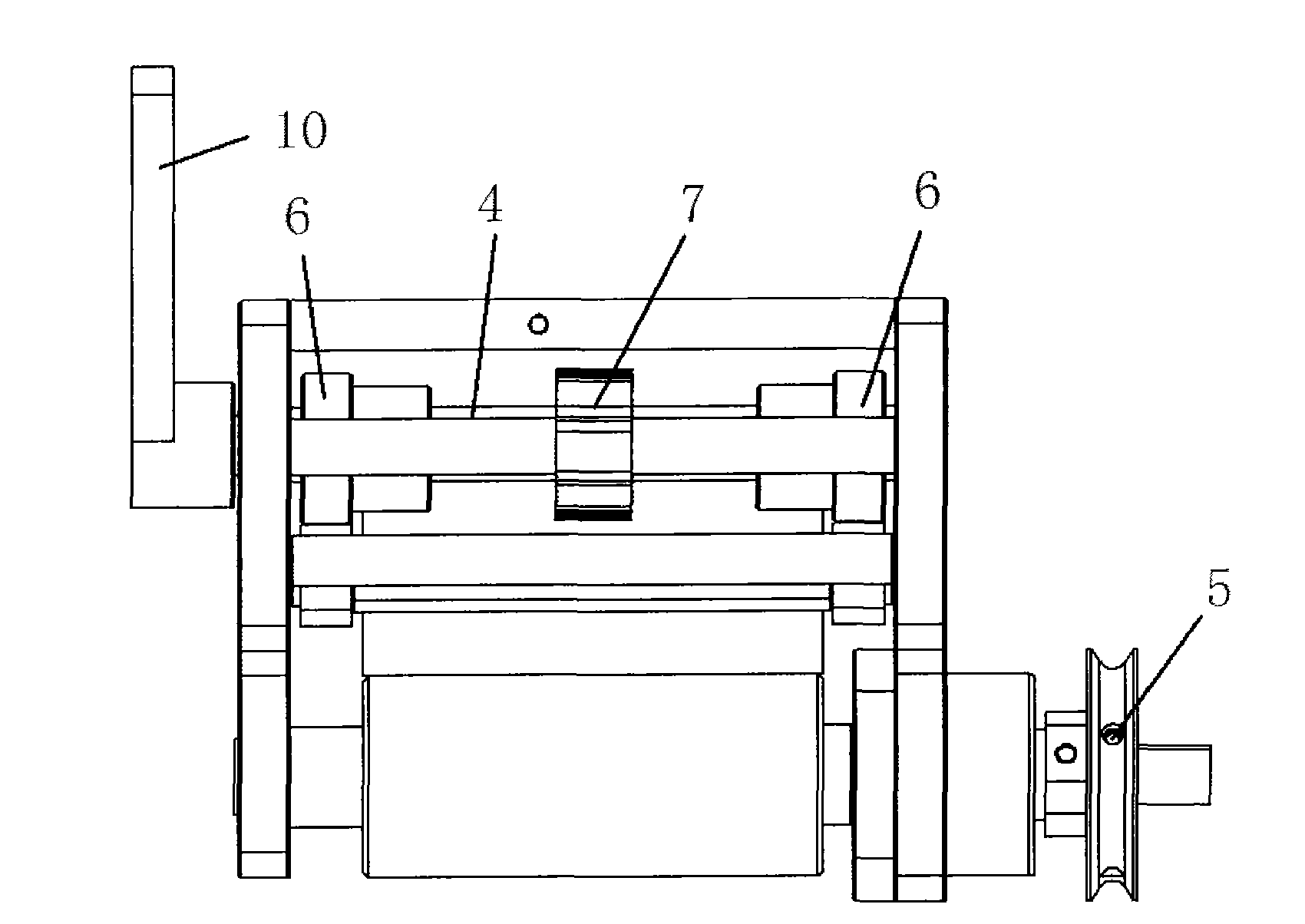

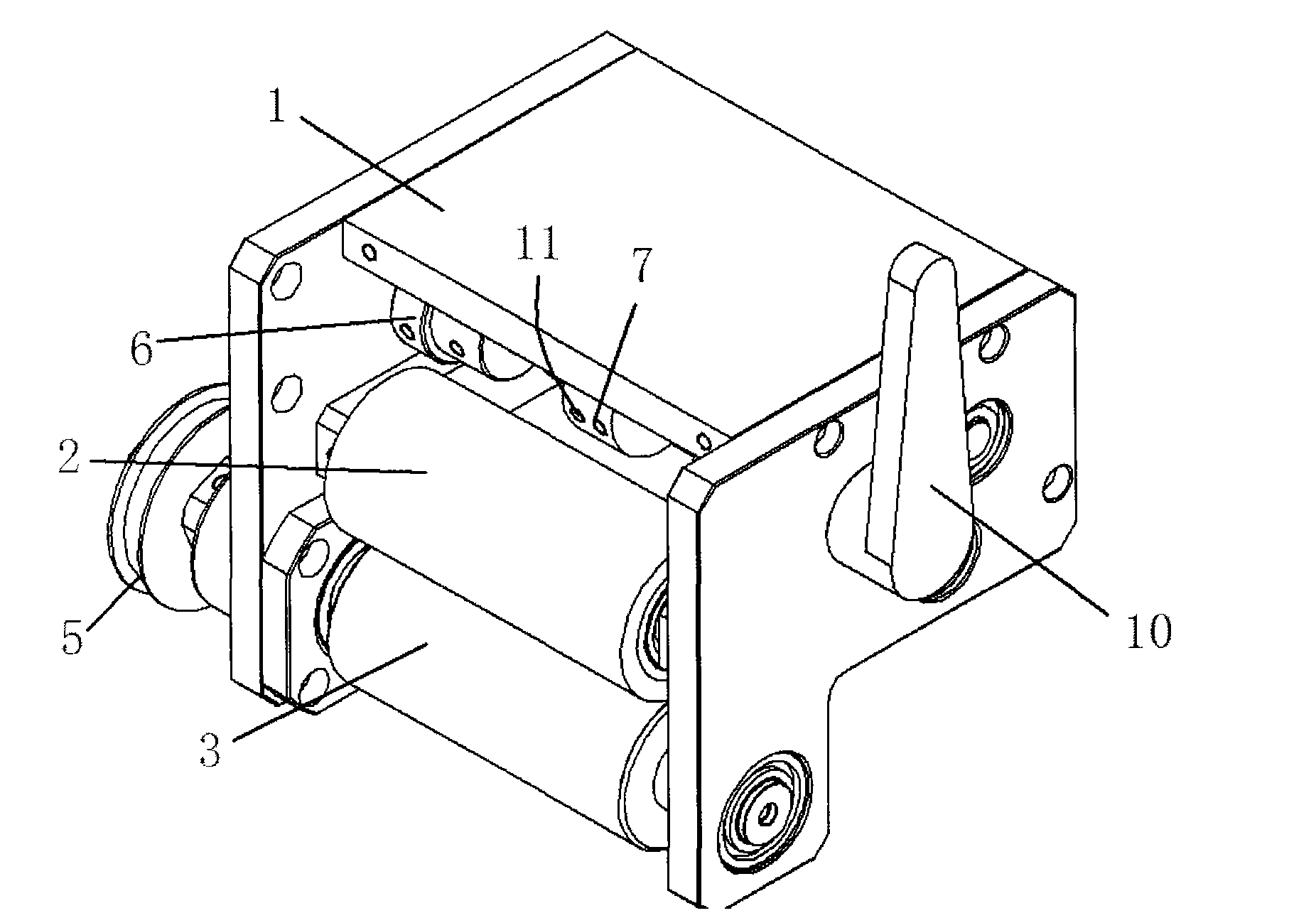

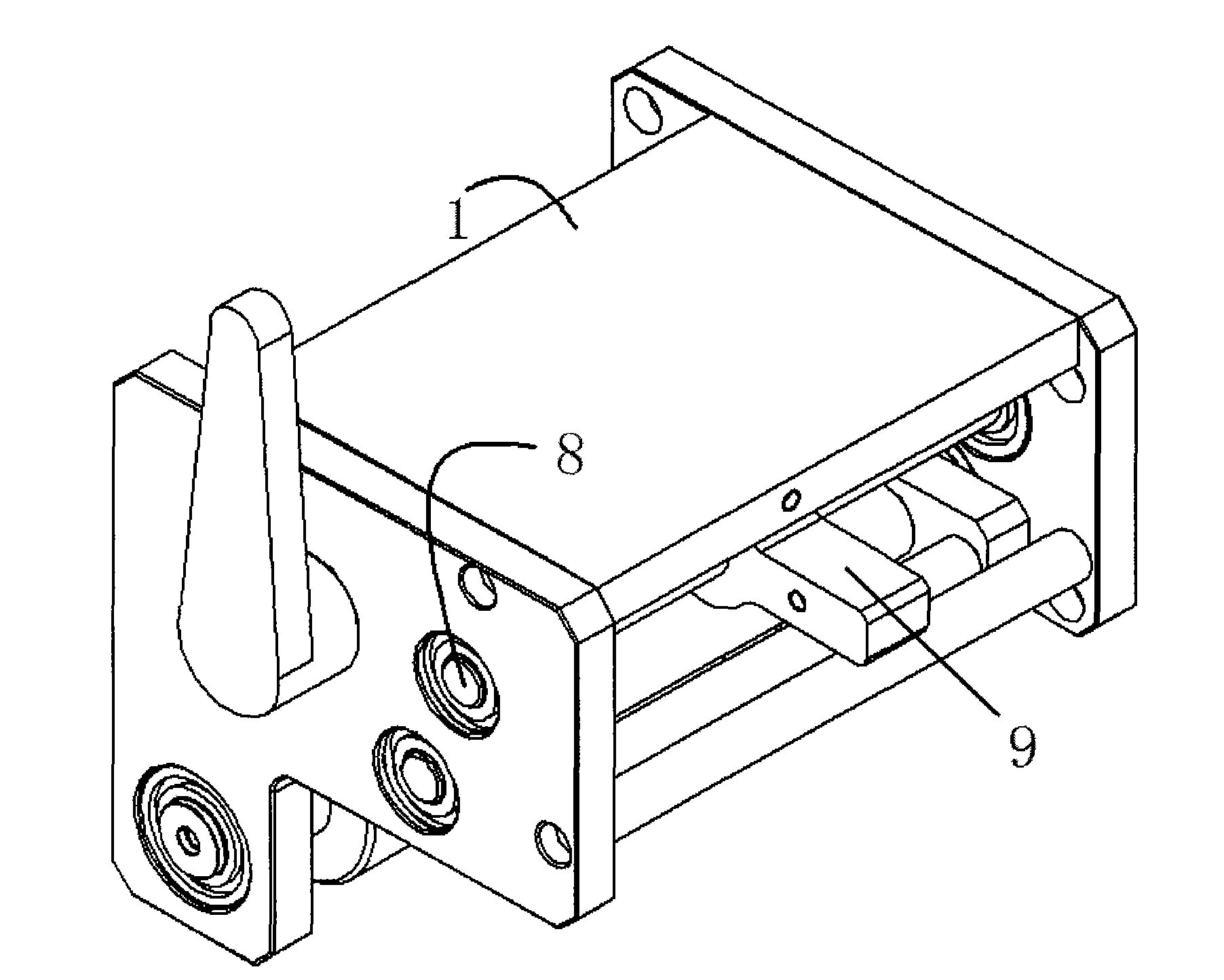

[0018] Examples, see attached Figures 1 to 5 The semi-gear tensioning conveying device includes a casing 1, a driven roller 2, a driving roller 3 and a drive shaft 4 are installed in the casing, a transmission pulley 5 is fixed at the end of the driving roller, and a transmission pulley 5 is fixed on the transmission shaft. There are two eccentric wheels 6; a half-gear 7 with half teeth 7a on the outer peripheral surface is fixed on the transmission shaft, and the casing also has a rotating shaft 8, which is mounted with clearance fit on the rotating shaft 8 The half gear handle 9, the size of the clearance is advisable that the half gear handle can rotate freely on the rotating shaft, and the front end of the half gear handle has a protrusion 9a that can be inserted into the teeth 7a of the half gear. The upper surface has an incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com