Tension-adjusting type shrink film heating mechanism

A heating mechanism and tension adjustment technology, used in packaging paper shrinkage, external support, transportation packaging, etc., can solve the problems of heating efficiency, uneven heating of shrink film, etc., to ensure efficiency and uniformity, flexible use, and guaranteed stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The content of the present invention will be described in further detail below with reference to the accompanying drawings.

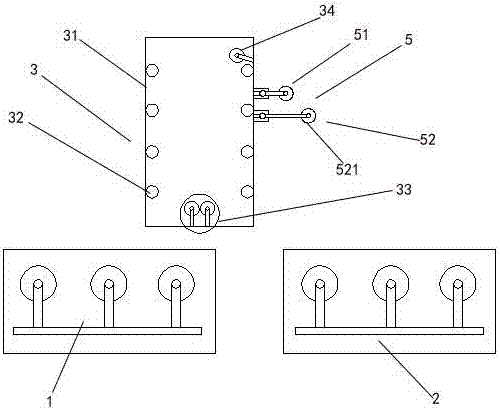

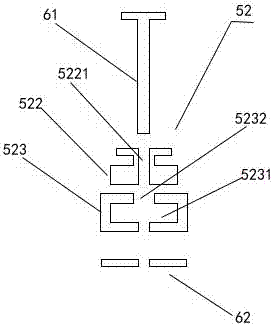

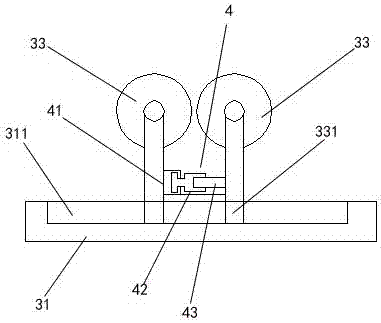

[0018] like figure 1 As shown, a tension-adjustable shrink film heating mechanism includes a feeding device 1 , a discharging device 2 , a heating device 3 , a clamping mechanism 4 , and a tension-adjusting mechanism 5 . The feeding device 1 and the heating device 3 are located on the same horizontal line. The heating device 3 is installed above the feeding device 1 . The heating device 3 includes a heating box 31 , a heating tube 32 , two positioning rollers 33 and a limiting roller 34 . The heating box 31 is provided with a plurality of heating pipes 32 on both sides thereof. The bottom of the heating box 31 is provided with two positioning rollers 33 . The two positioning rollers 33 are arranged in parallel. A limit roller 34 is arranged above the heating box 31 . like image 3 and 4 As shown, the bottom of the heating box 31 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com