Semi-gear

A technology of half gears and teeth, which is applied in the field of film laminating machine series, and can solve problems such as instability, looseness, and inability to film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

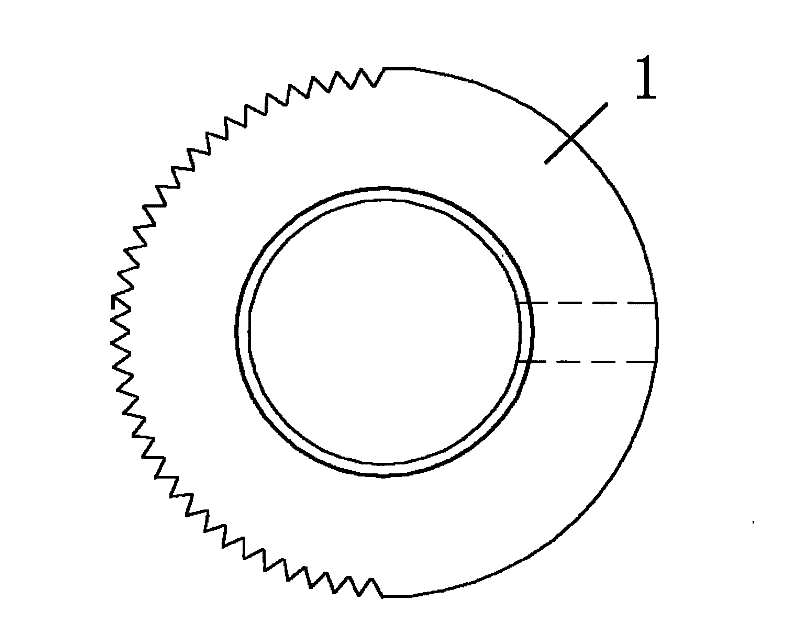

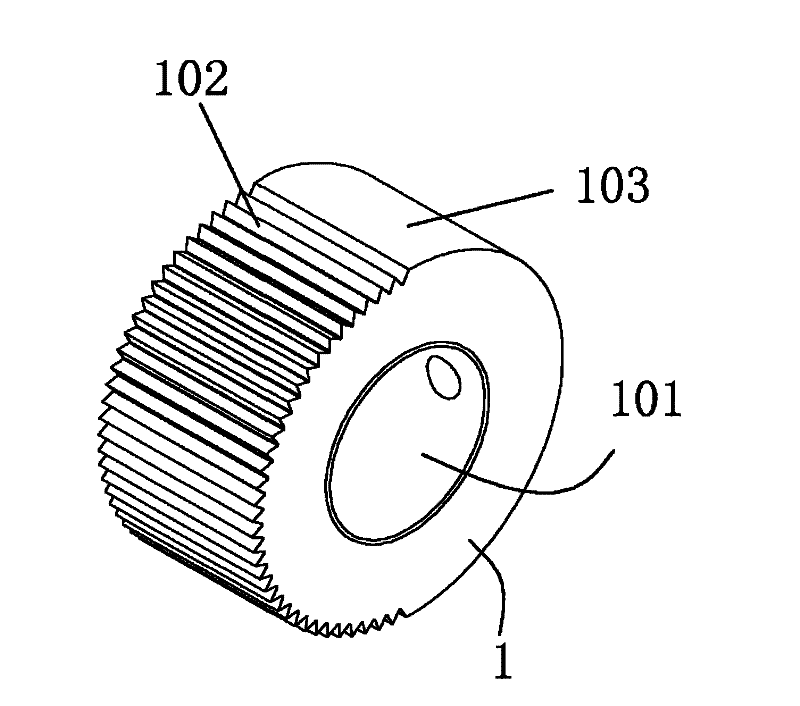

[0017] Examples, see attached Figure 1~3 ; A half gear, including a cylinder 1, the cylinder has a through hole 101; the outer circumference of the cylinder has teeth 102.

[0018] Half of the outer peripheral surface of the cylinder has teeth, and the other half is a smooth surface 103 .

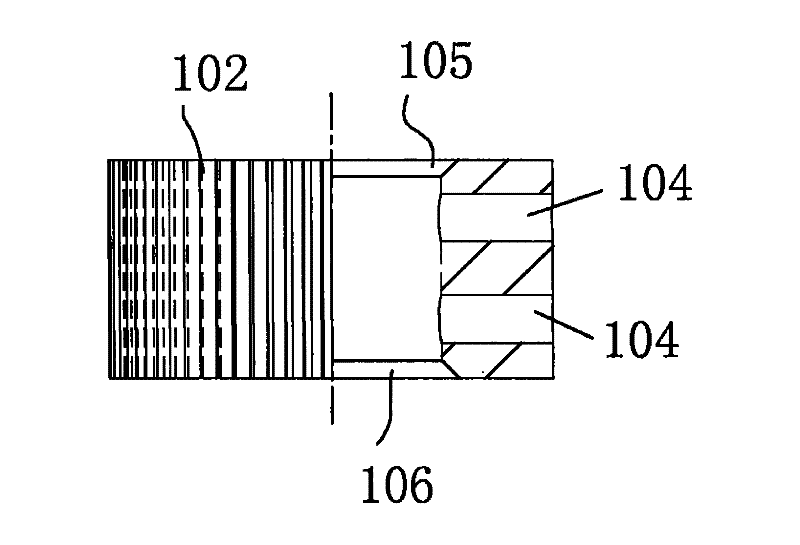

[0019] A pin hole 104 is provided on the smooth surface of the outer peripheral surface of the cylinder, and the pin hole communicates with the through hole.

[0020] There are two pin holes.

[0021] There are chamfers 105 and 106 at both ends of the through hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com