Patents

Literature

164 results about "Wheel chock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wheel chocks (or chocks) are wedges of sturdy material placed closely against a vehicle's wheels to prevent accidental movement. Chocks are placed for safety in addition to setting the brakes. The bottom surface is sometimes coated in rubber to enhance grip with the ground. For ease of removal, a rope may be tied to the chock or a set of two chocks. One edge of the wedge has a concave profile to contour to the wheel and increase the force necessary to overrun the chock. Most commonly, chocks are seen on aircraft and train cars.

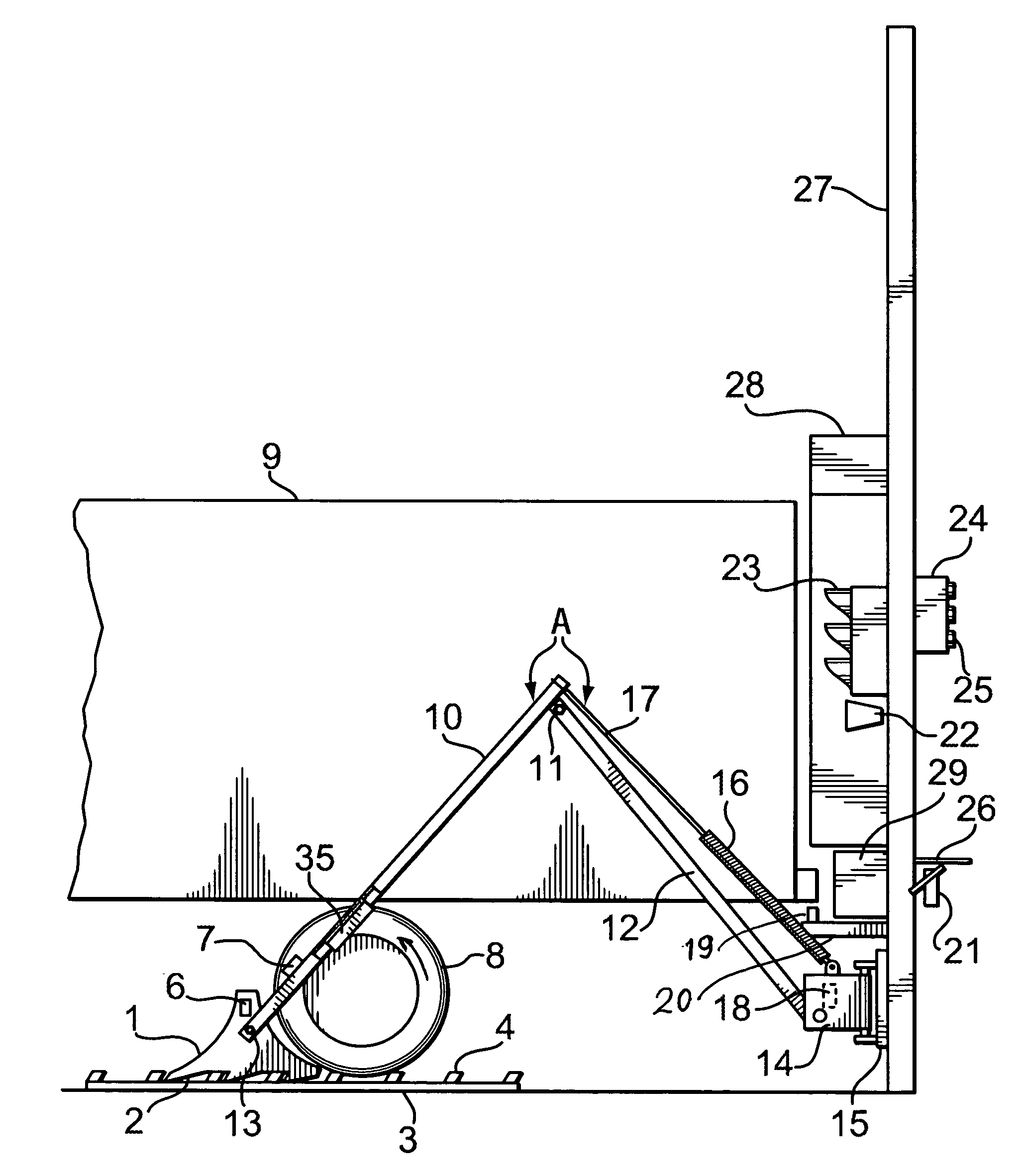

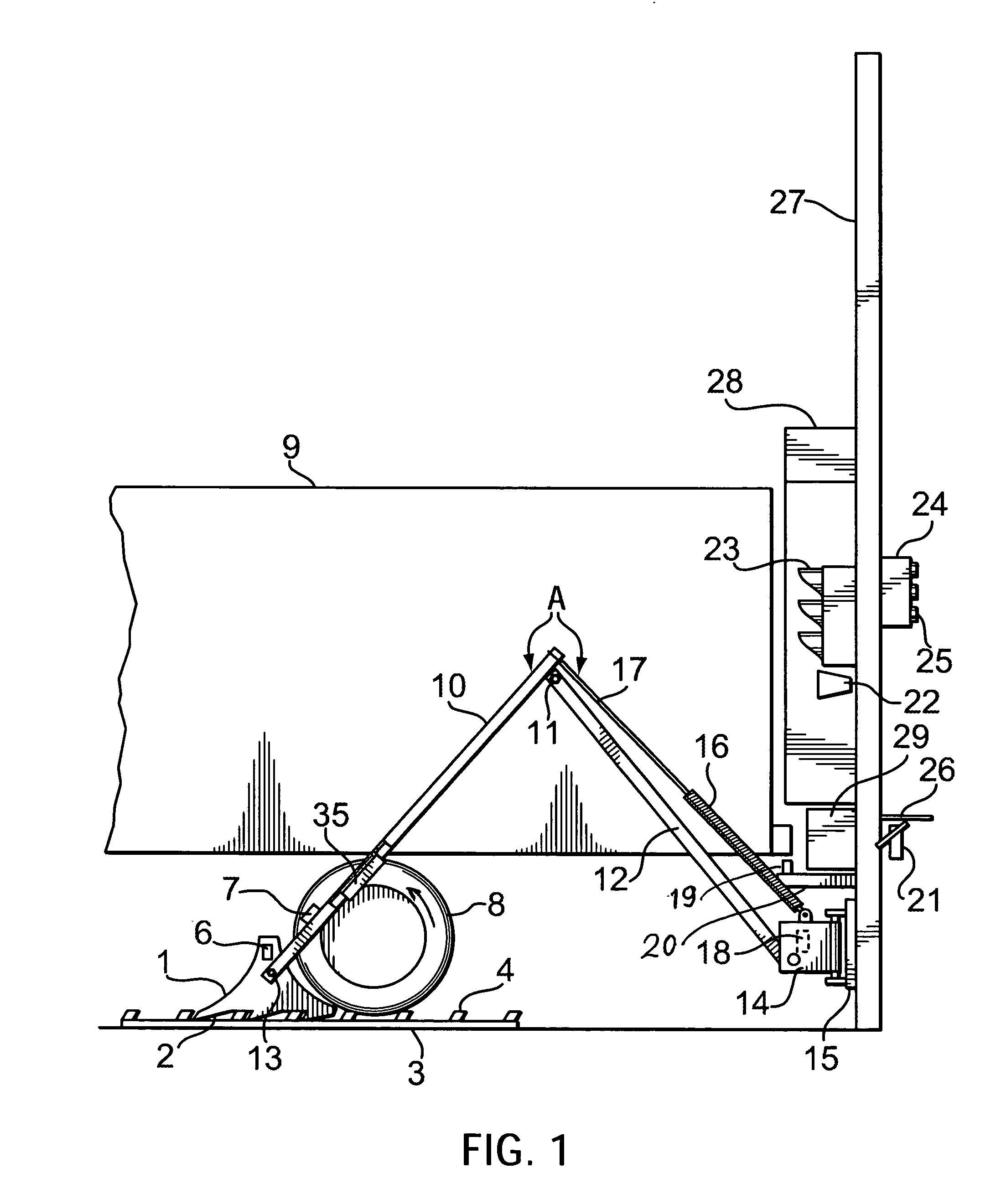

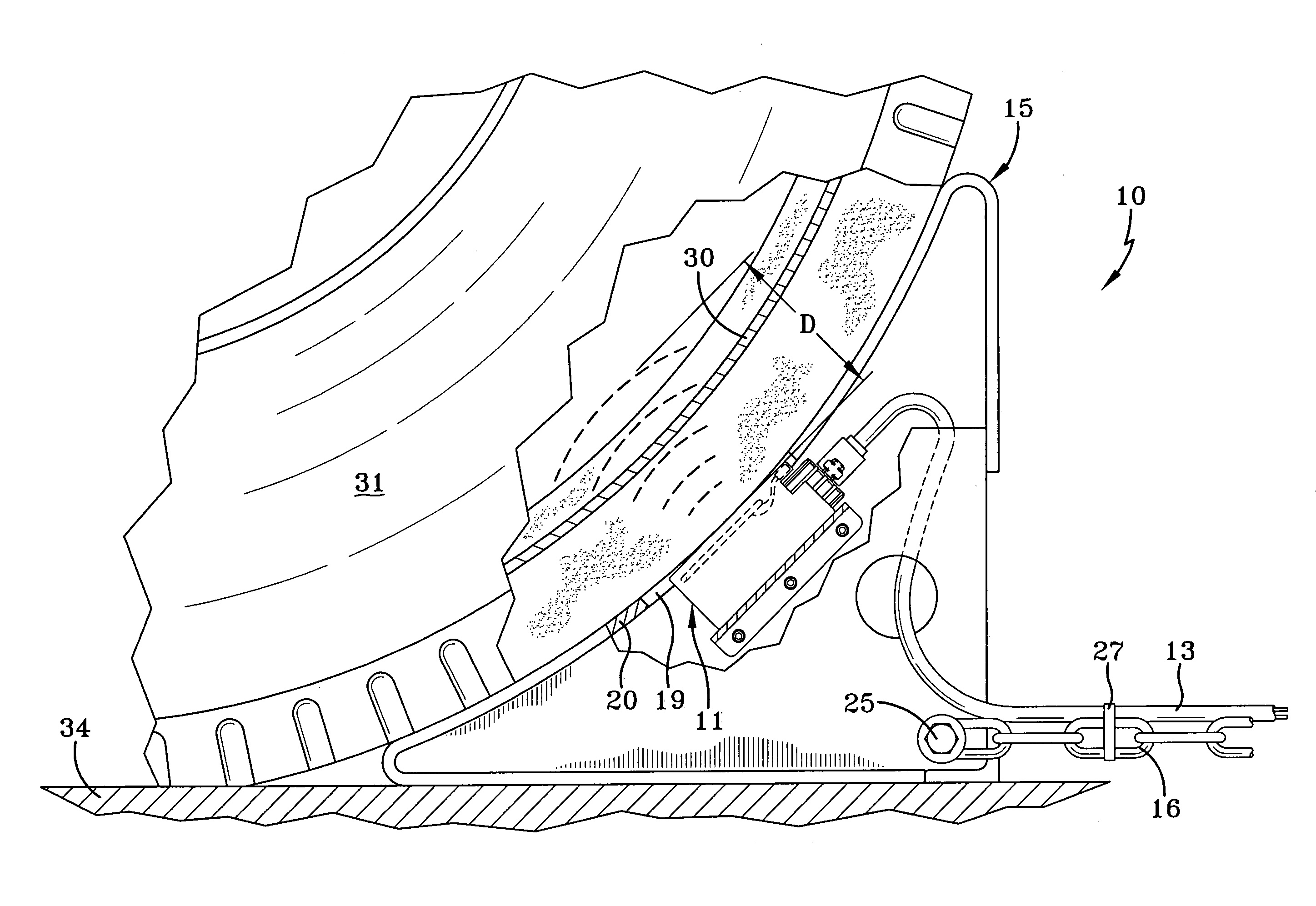

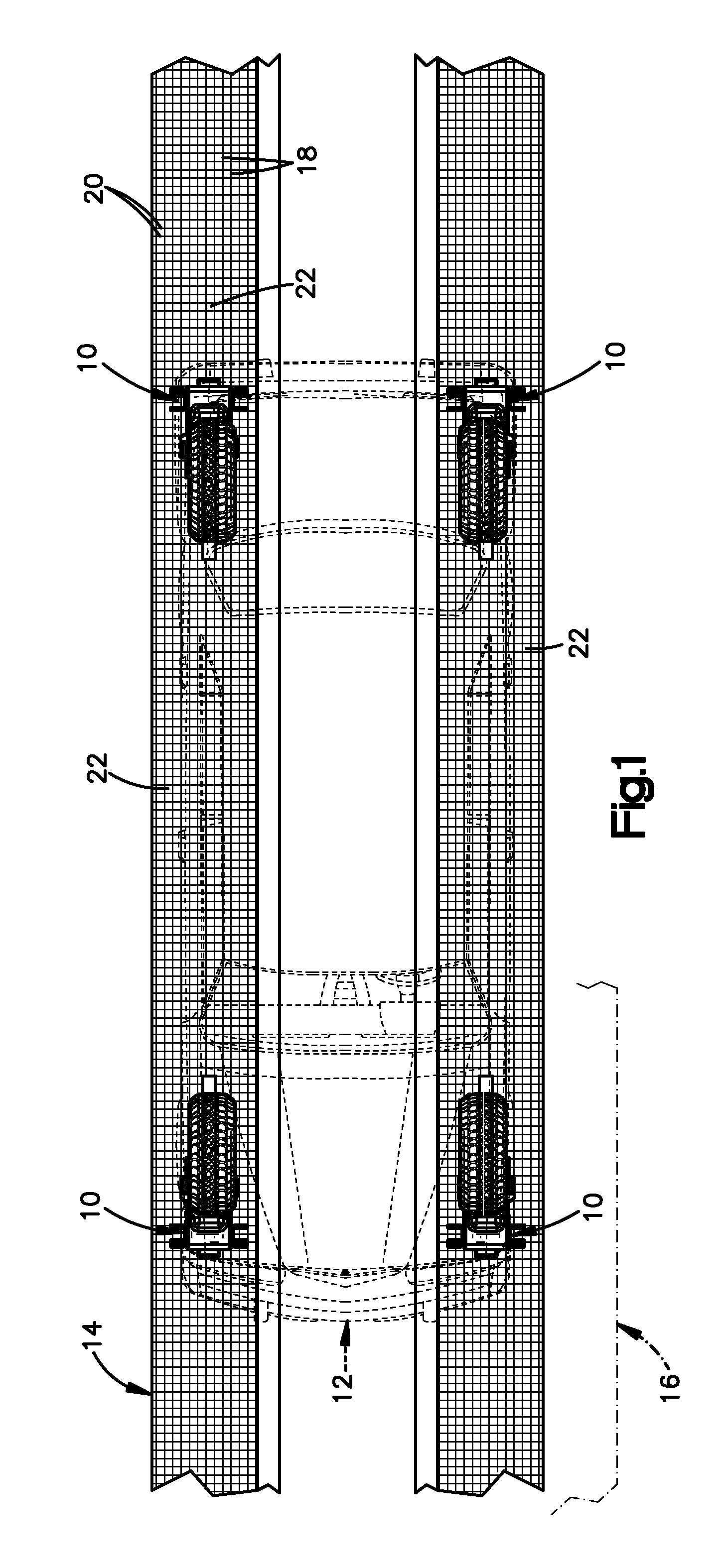

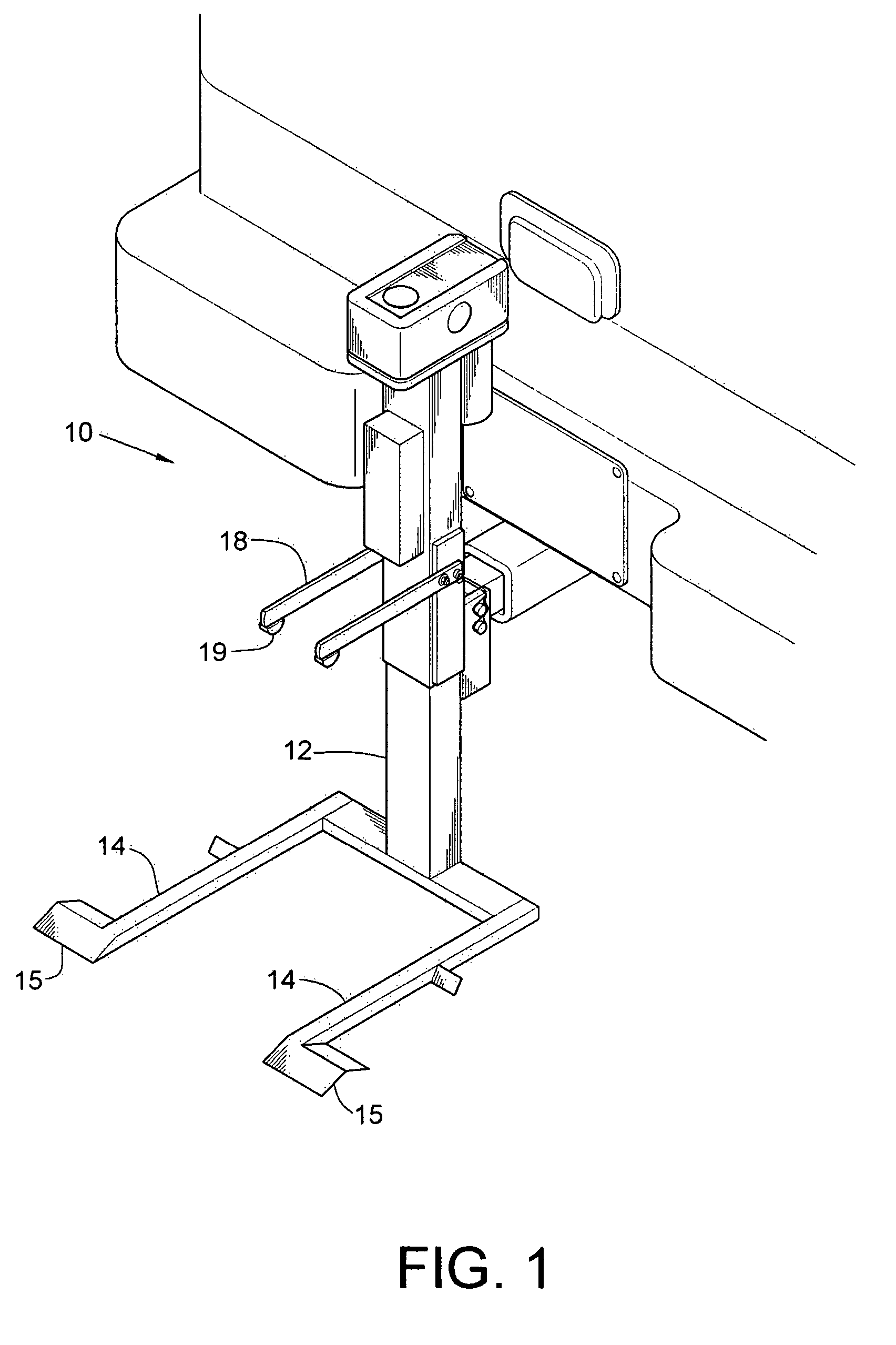

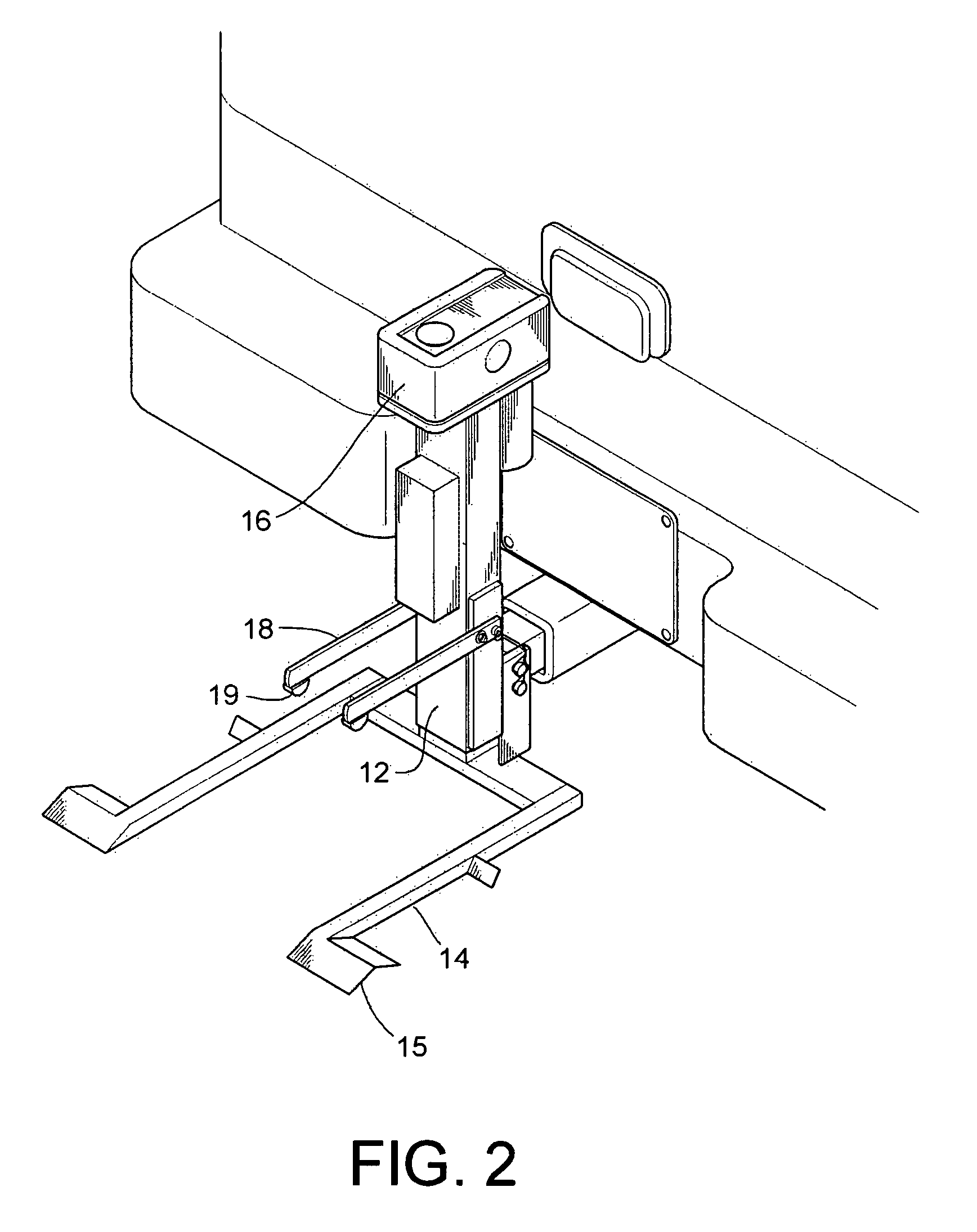

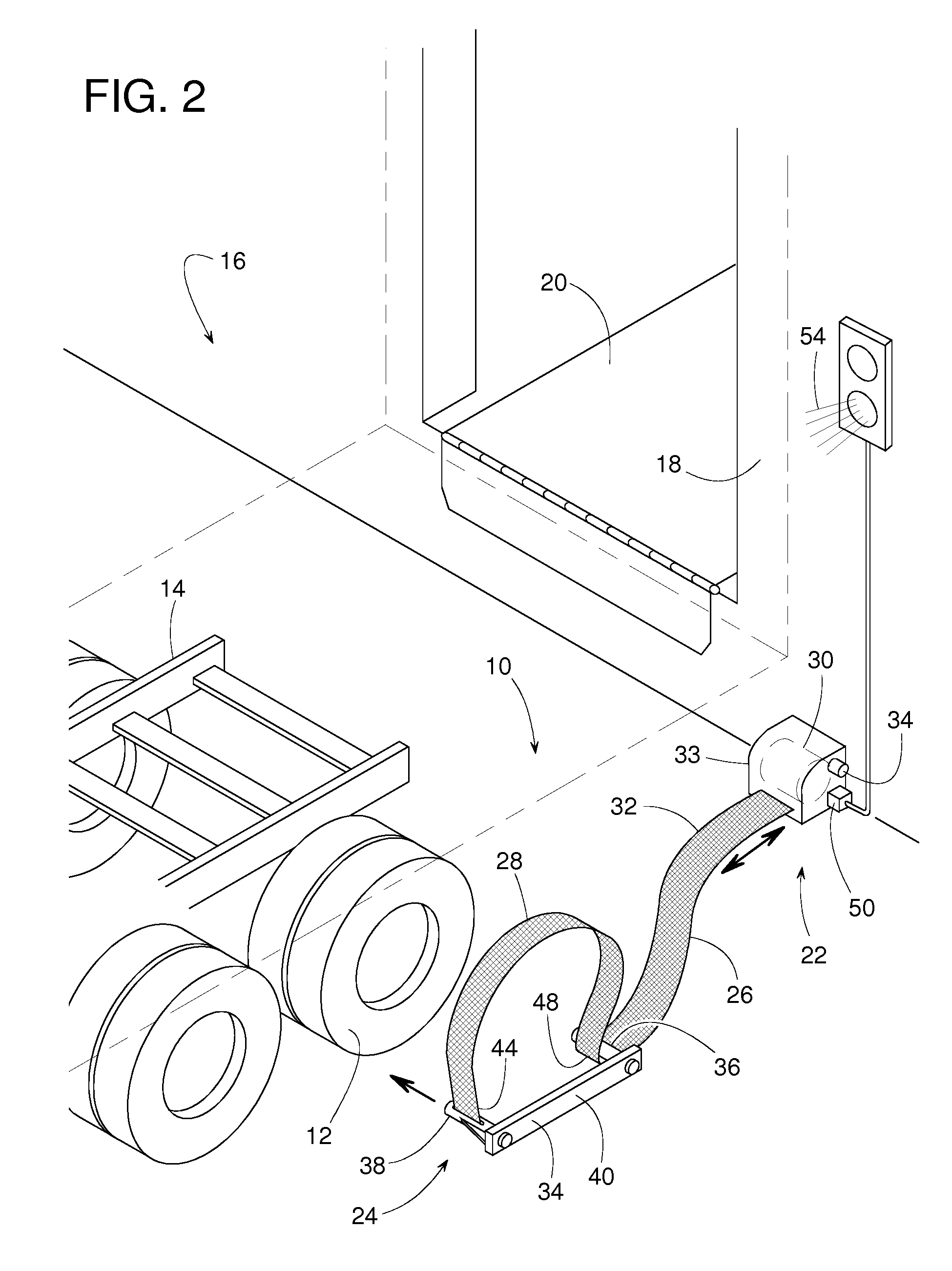

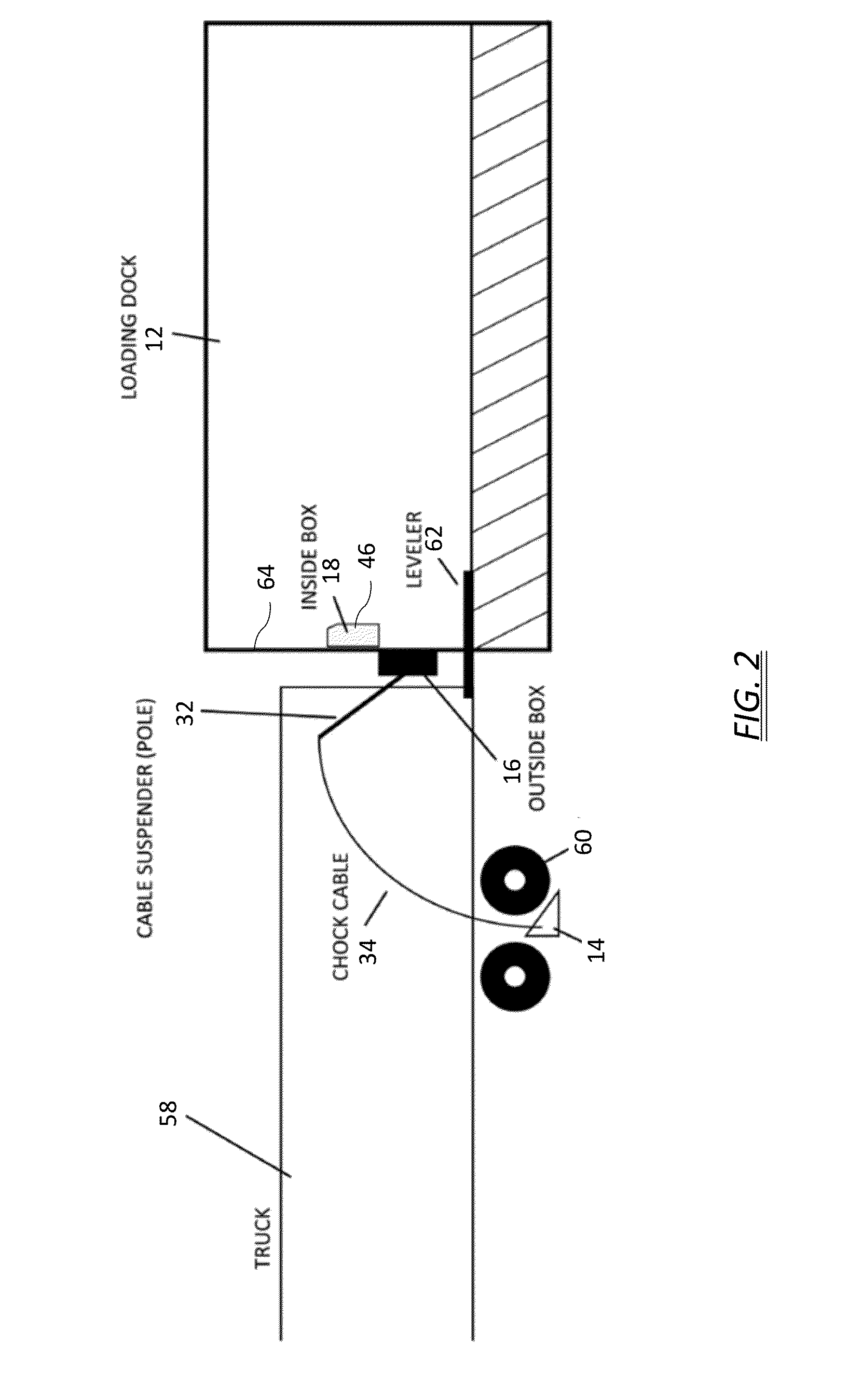

Wheel chock restraint system

InactiveUS7032720B2Simple methodEliminate the problemPortable braking systemRail brake actuationMechanical engineeringWheel chock

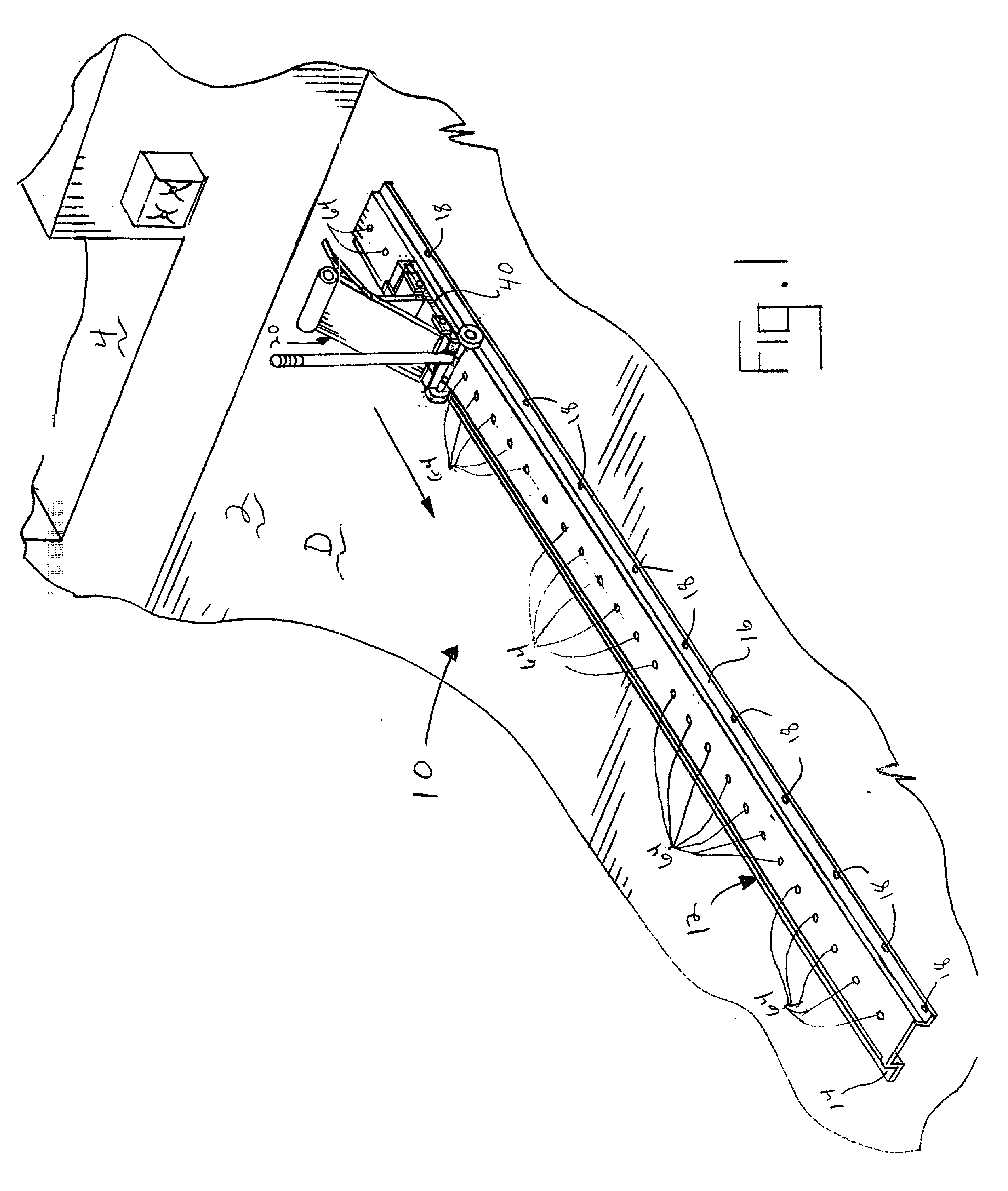

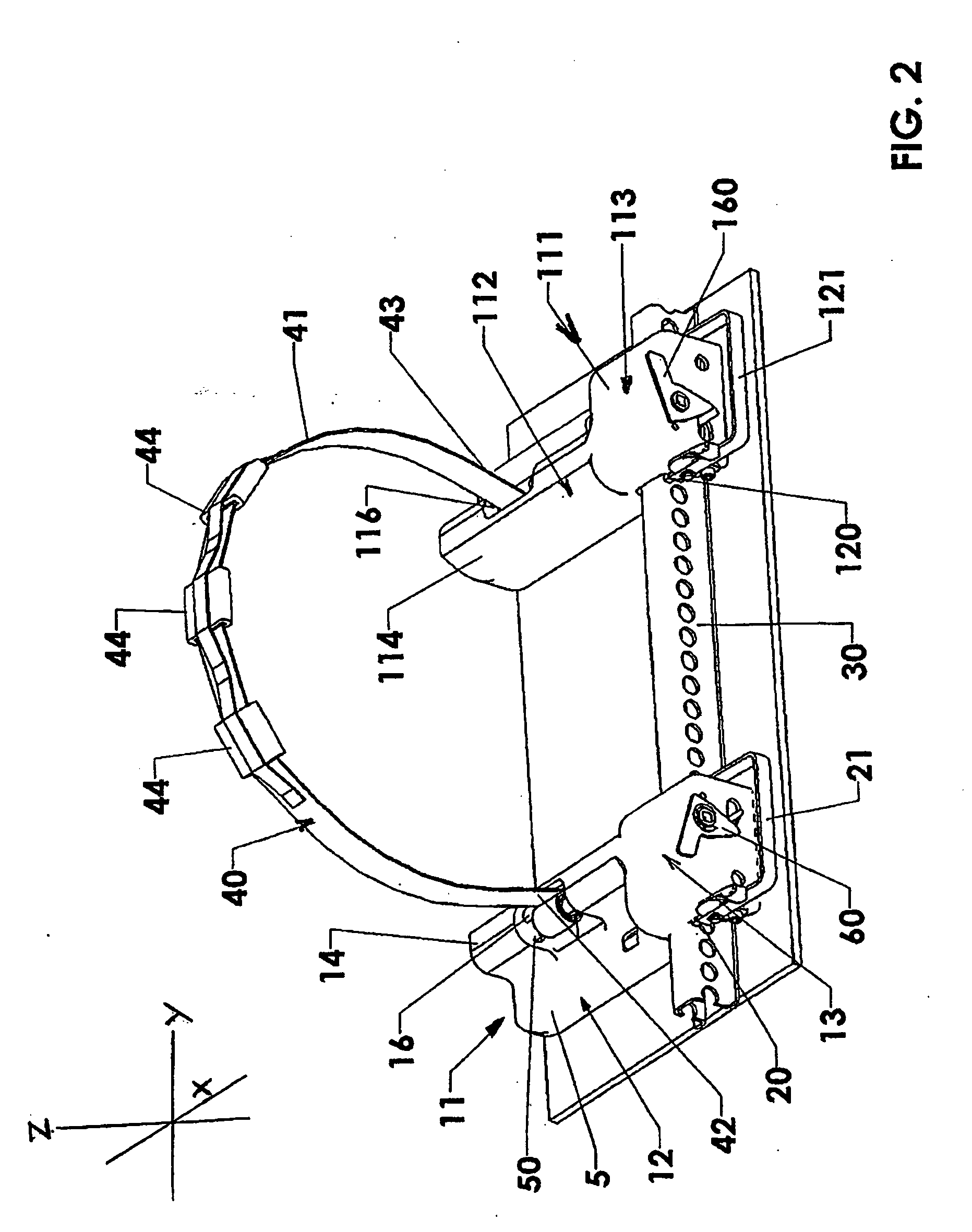

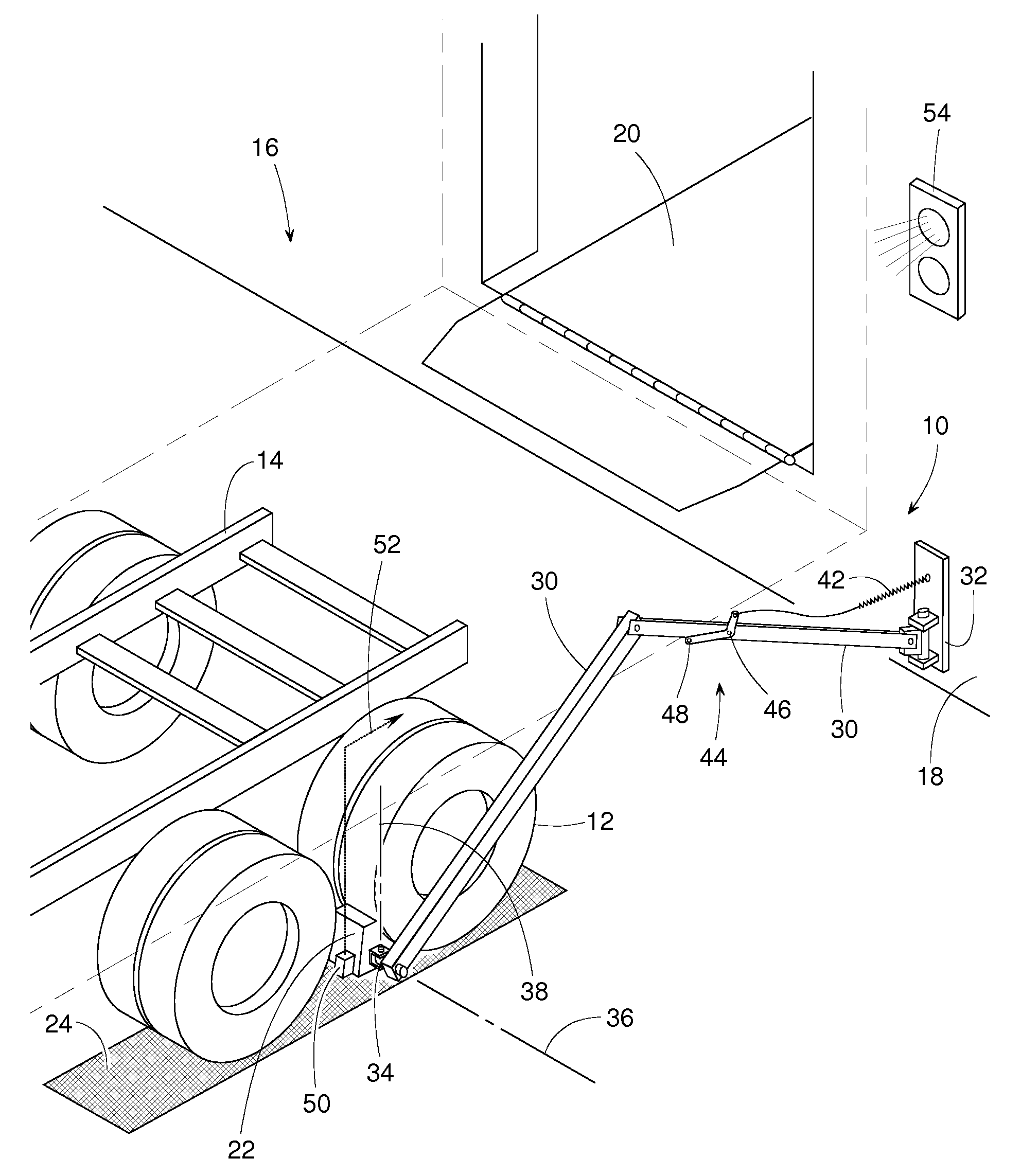

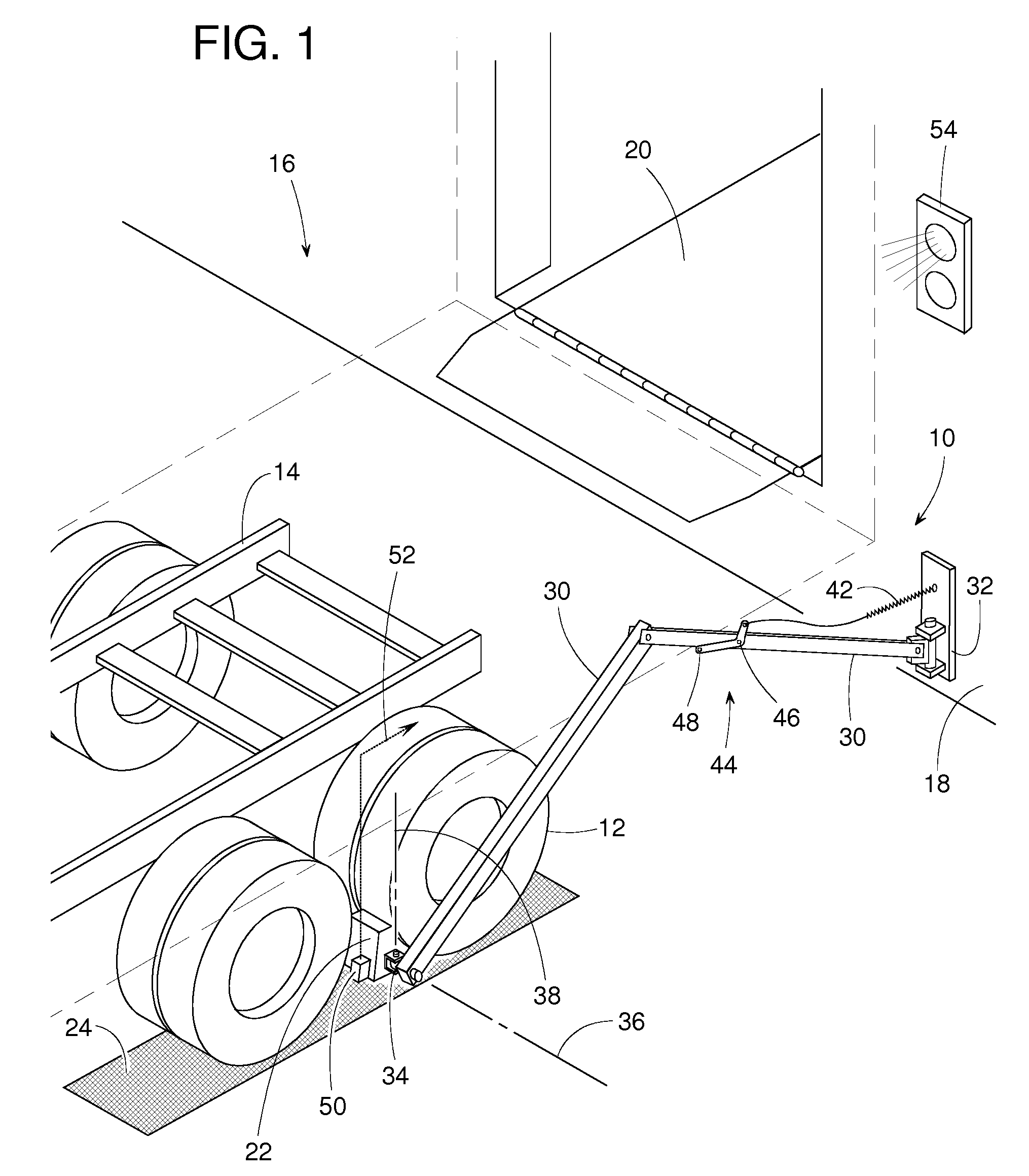

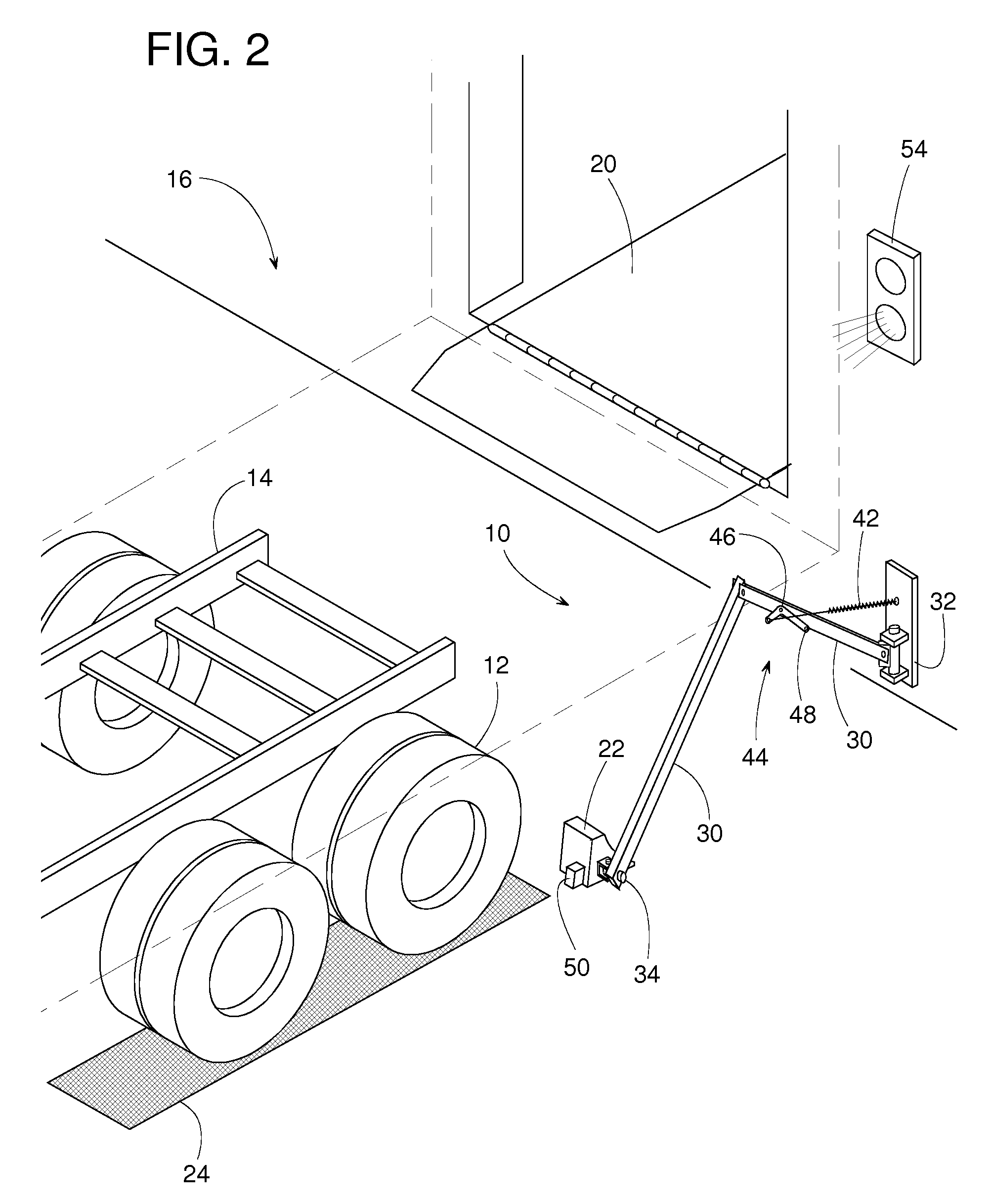

Wheel chock restraint system comprising a wheel chock, a supporting element mounted on the ground in vicinity of a loading dock and a wheel chock support assembly connected by one end to the wheel chock and by another end in vicinity of the loading dock. A base portion of the chock is provided with first engagement elements and the supporting elements are provide with corresponding second engagement elements. The first engagement elements are adapted to cooperate with the second engagement elements, thus creating a retention force directed away from the loading dock and preventing the chock from sliding away from the wheel of a vehicle making an attempt to depart prematurely from the loading dock. Wheel chock support assembly is adapted to ensure a secure positioning of the chock under the wheel of the vehicle during loading and unloading operation by creating an engagement force directed towards the loading dock and pressing the chock against the wheel. The first engagement elements comprise a plurality of teeth extending downwardly from the base portion of the chock under a predetermined angle and the second engagement elements are a plurality of stoppers extending upwardly from the supporting element.

Owner:9172 9863 QUEBEC

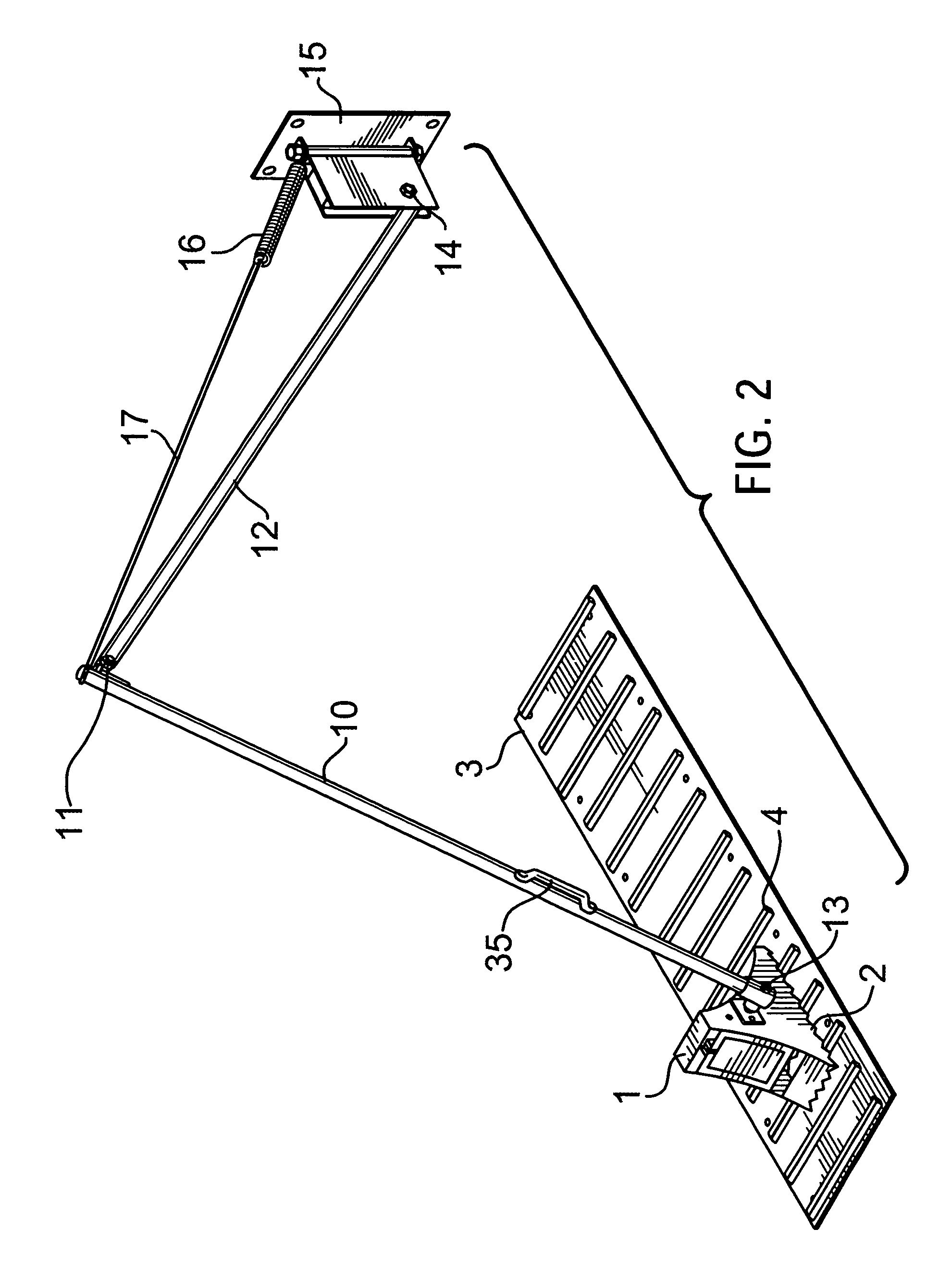

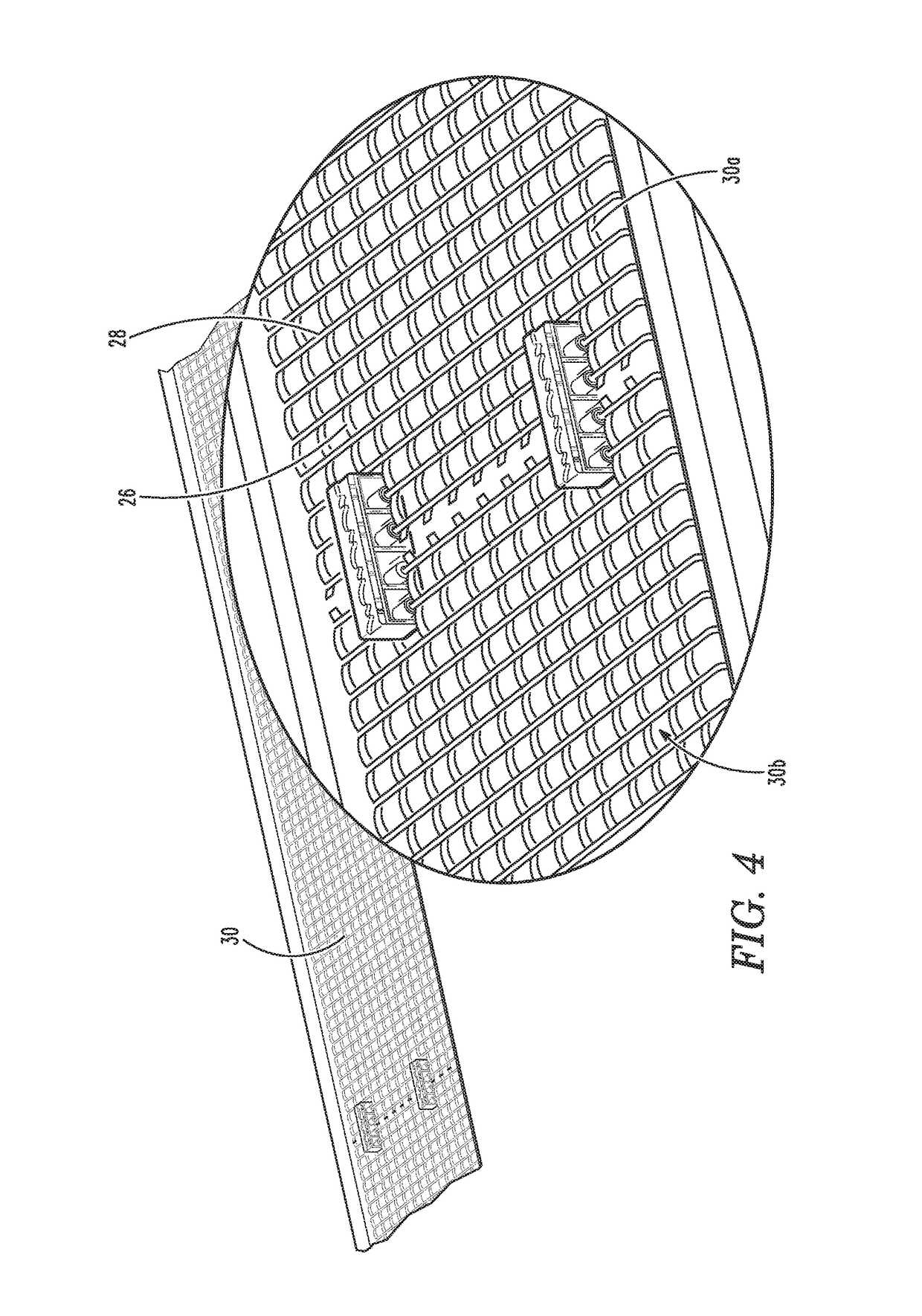

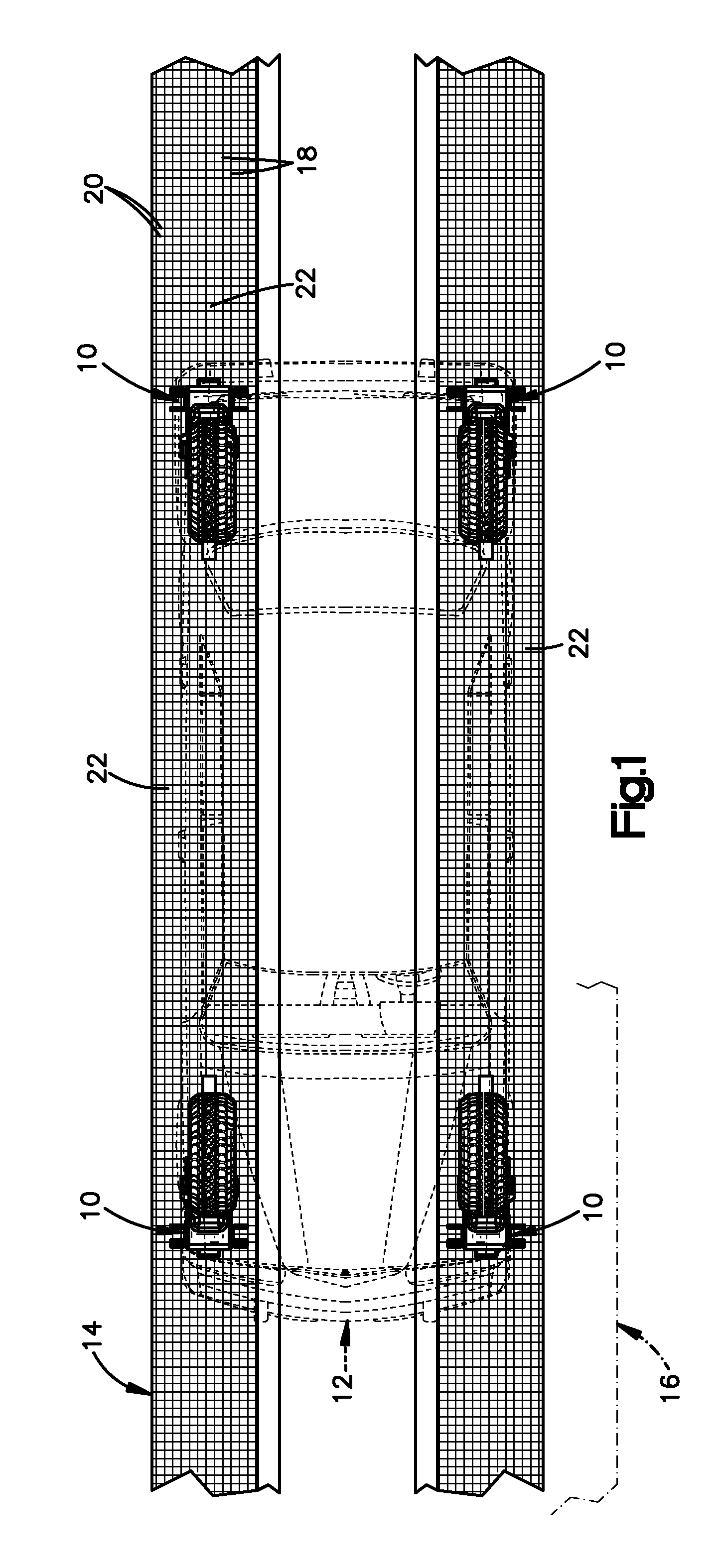

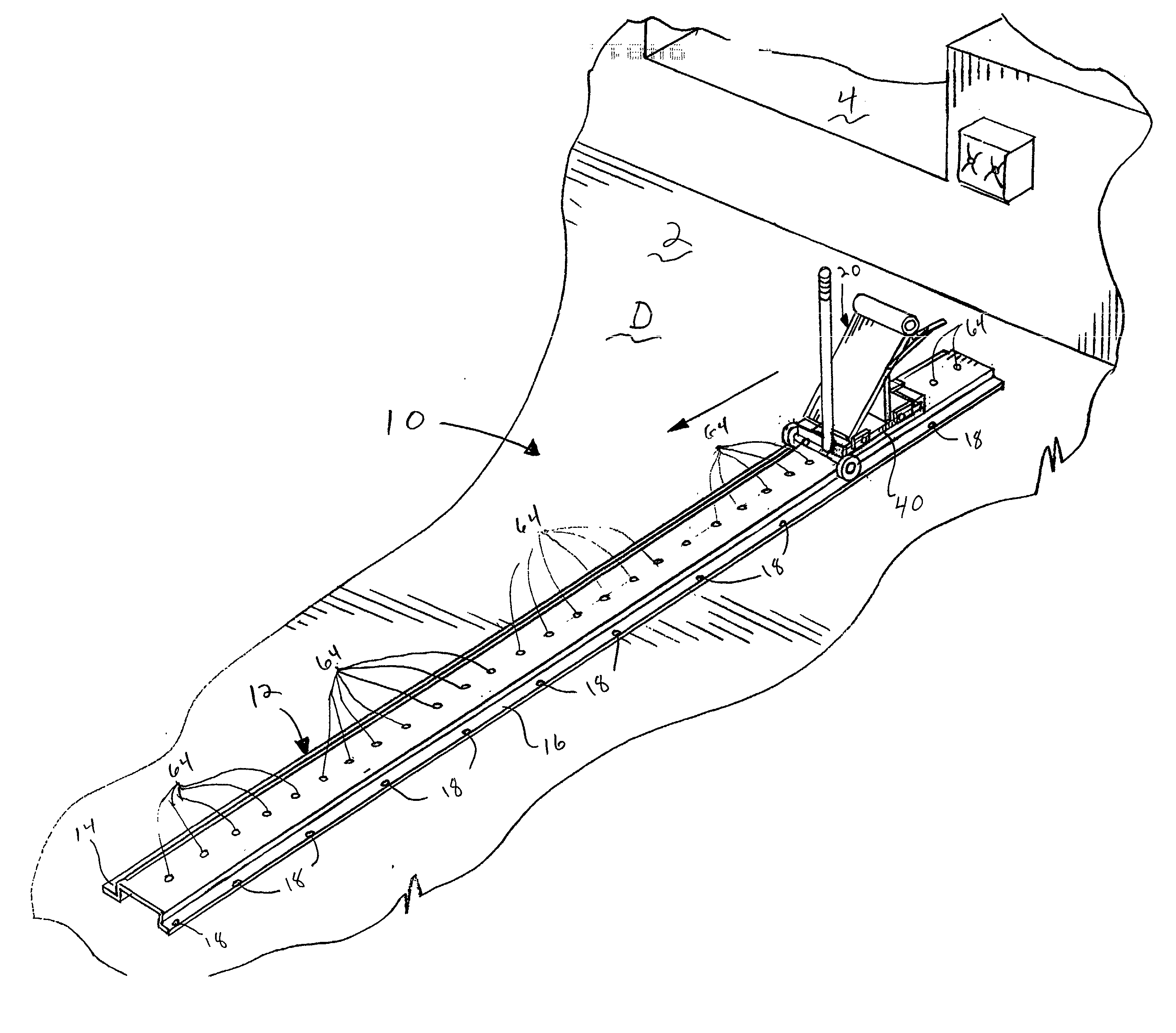

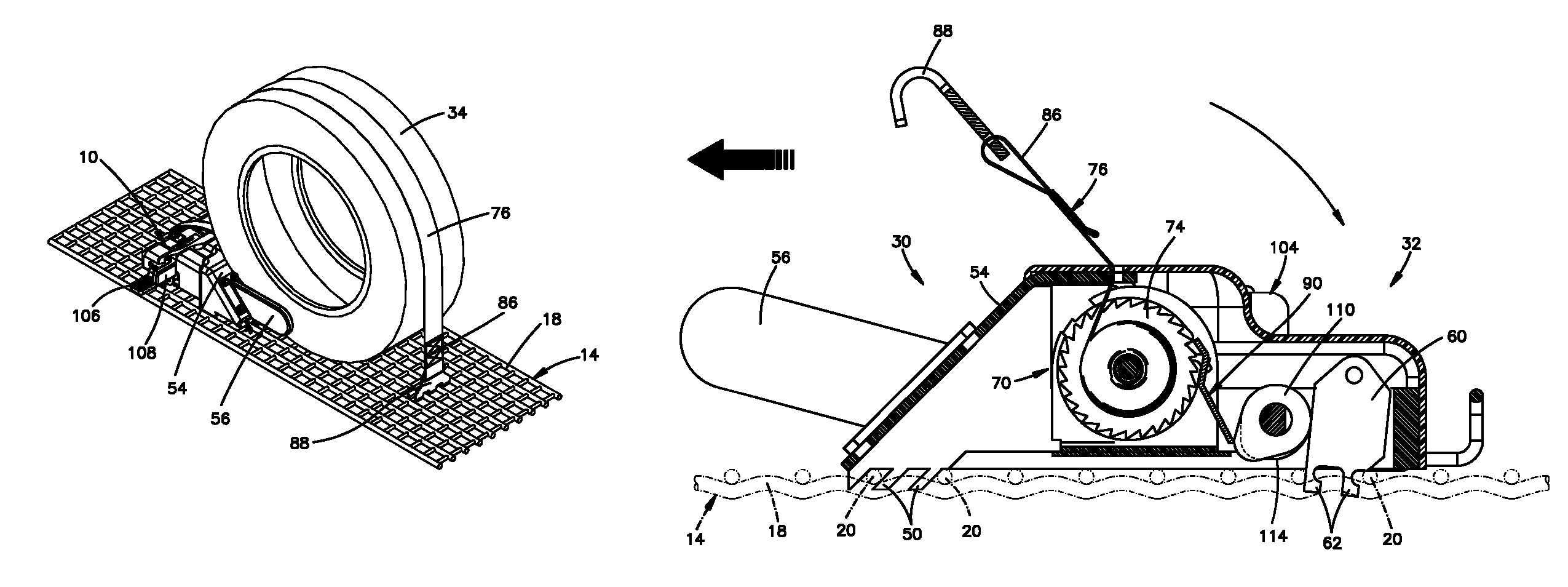

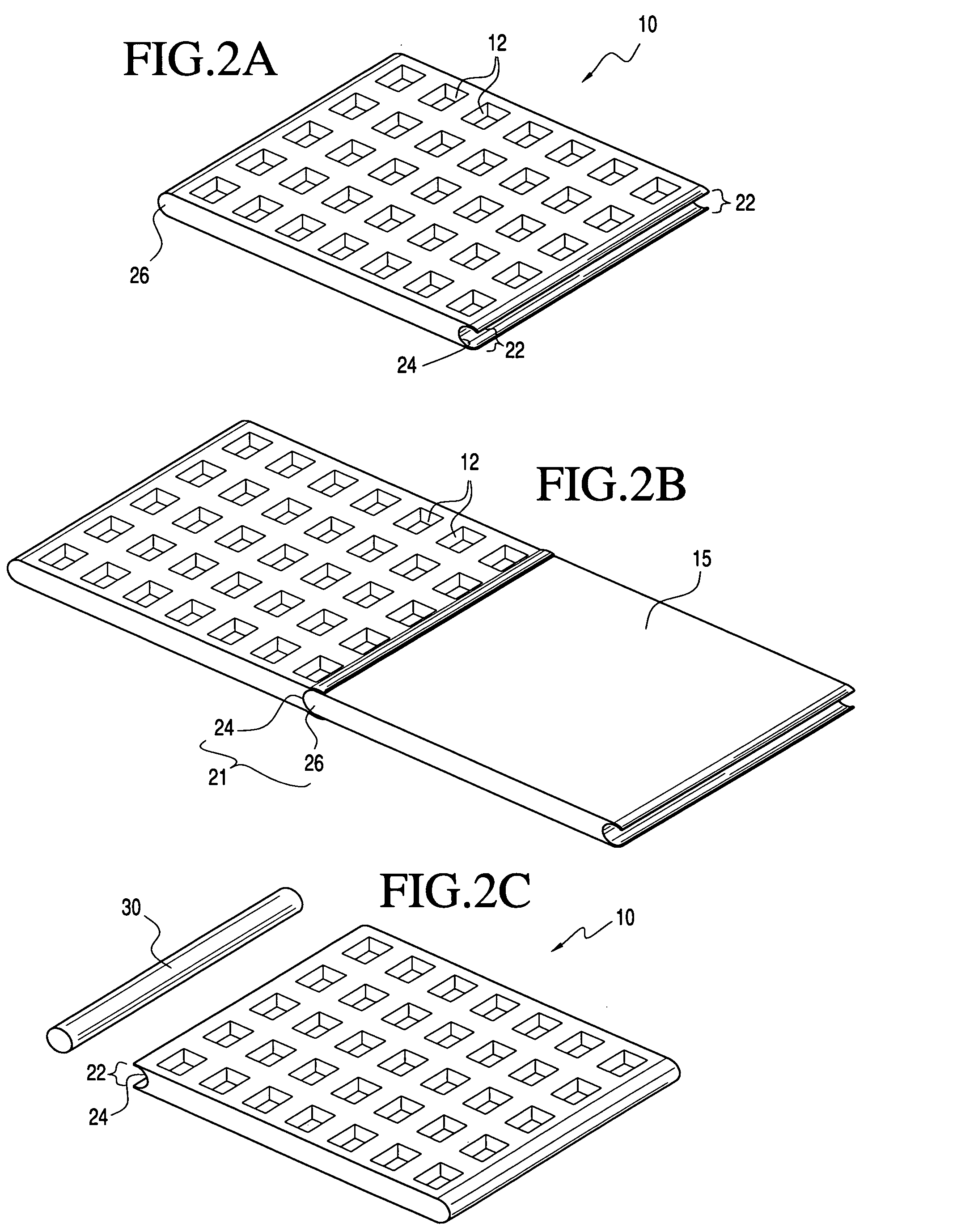

Grating connector and spacer apparatus, system, and methods of using the same

ActiveUS9731730B2Length of may varyAccurate spacingAngles/taper measurementsWagons/vansGratingEngineering

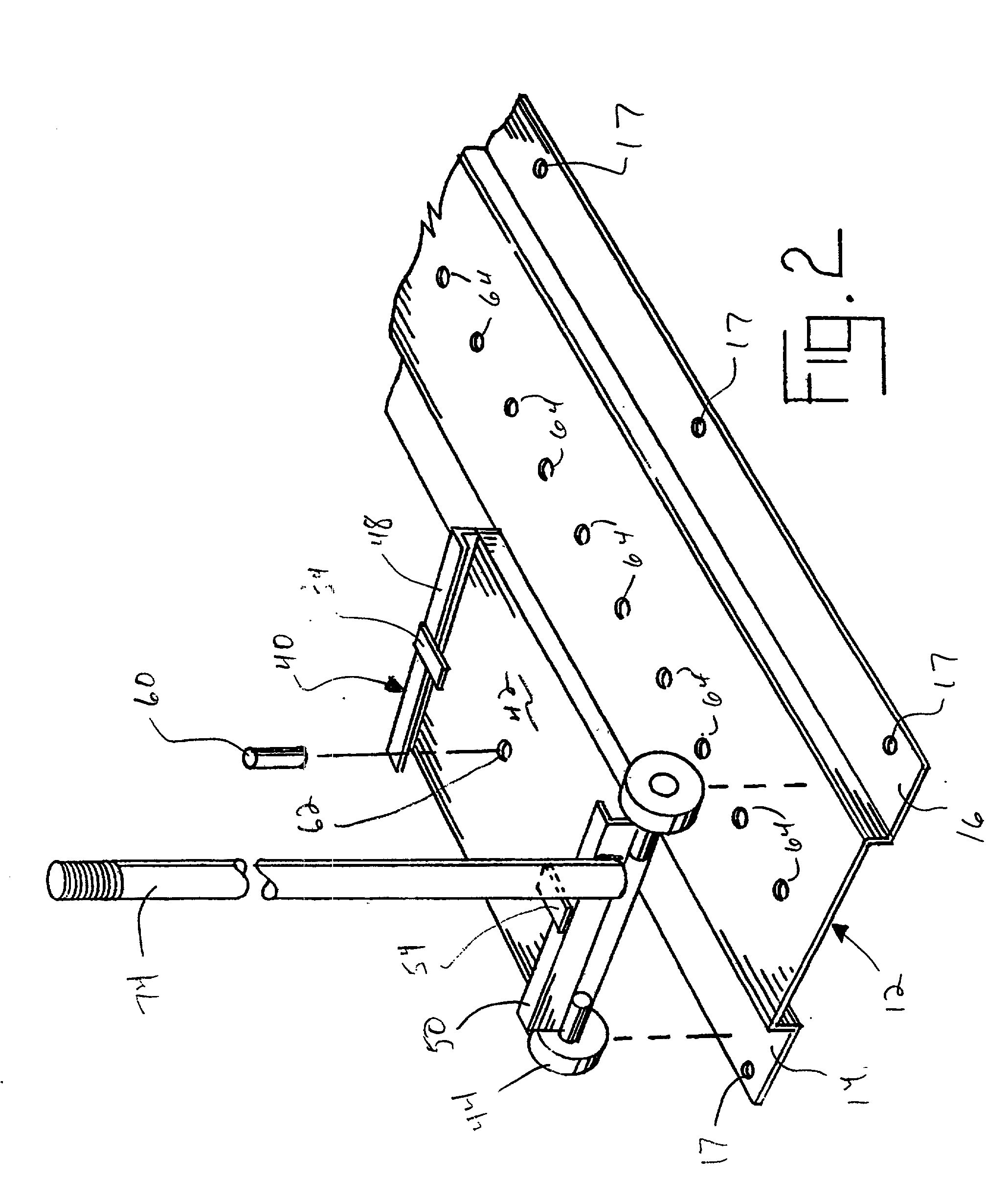

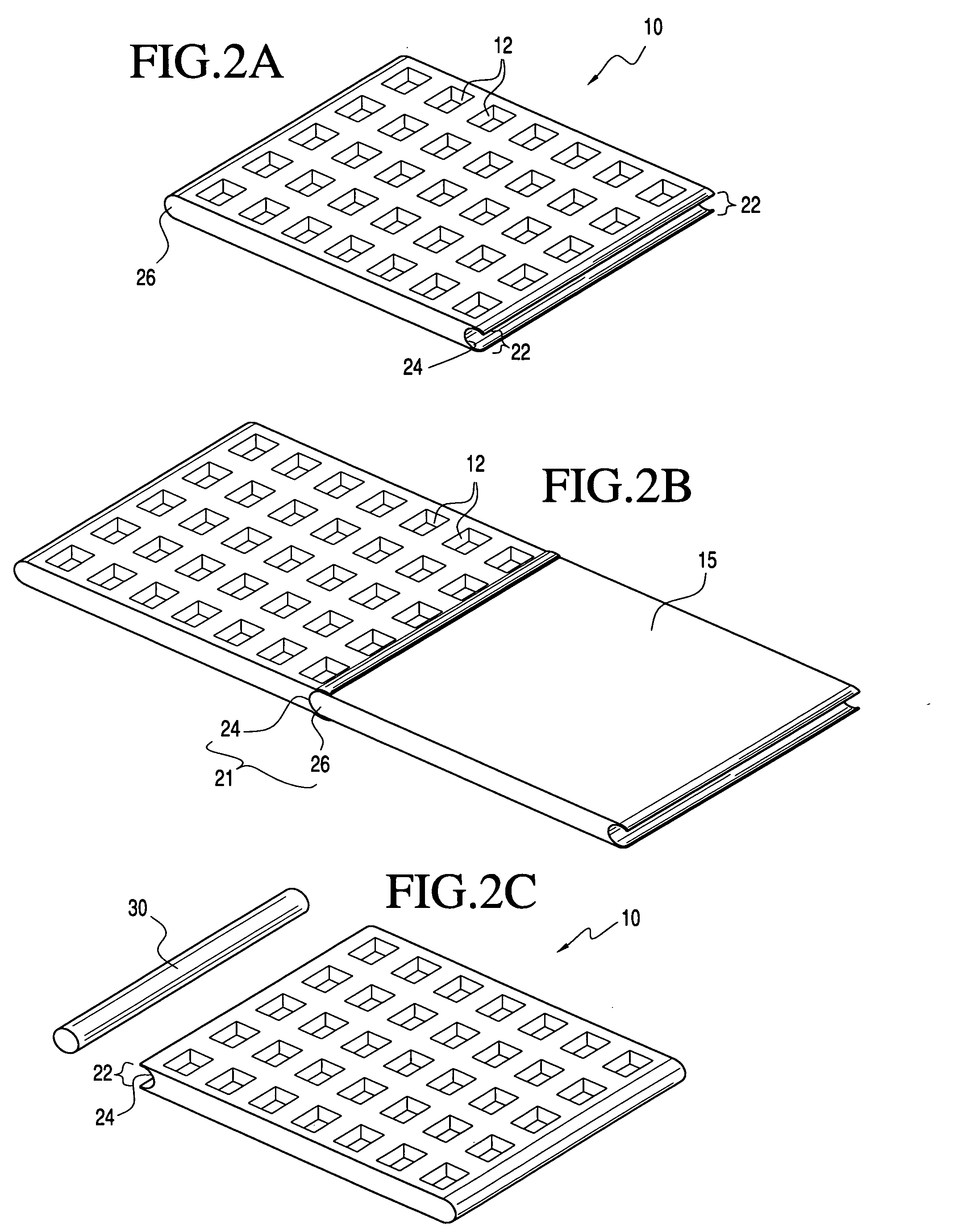

The present invention relates to an apparatus, system, and method of using the same for connecting and spacing grating and the like. Specifically, the present invention relates to connecting and spacing wire gratings, for example wire gratings used as vehicle tire support material or for mounting wheel chocks thereon in the transportation of automobiles. Even more specifically, the present invention may be used to connect a plurality of wire gratings together and to space in a first direction the plurality of gratings apart from each other at multiple selectable distances in one configuration. In a second configuration, the present invention may be used to space in a second direction the plurality of gratings from other objects, such as a wall or guard rail. The second configuration may be used in multiple orientations in order to provide multiple different spacing distances.

Owner:HOLLAND CO

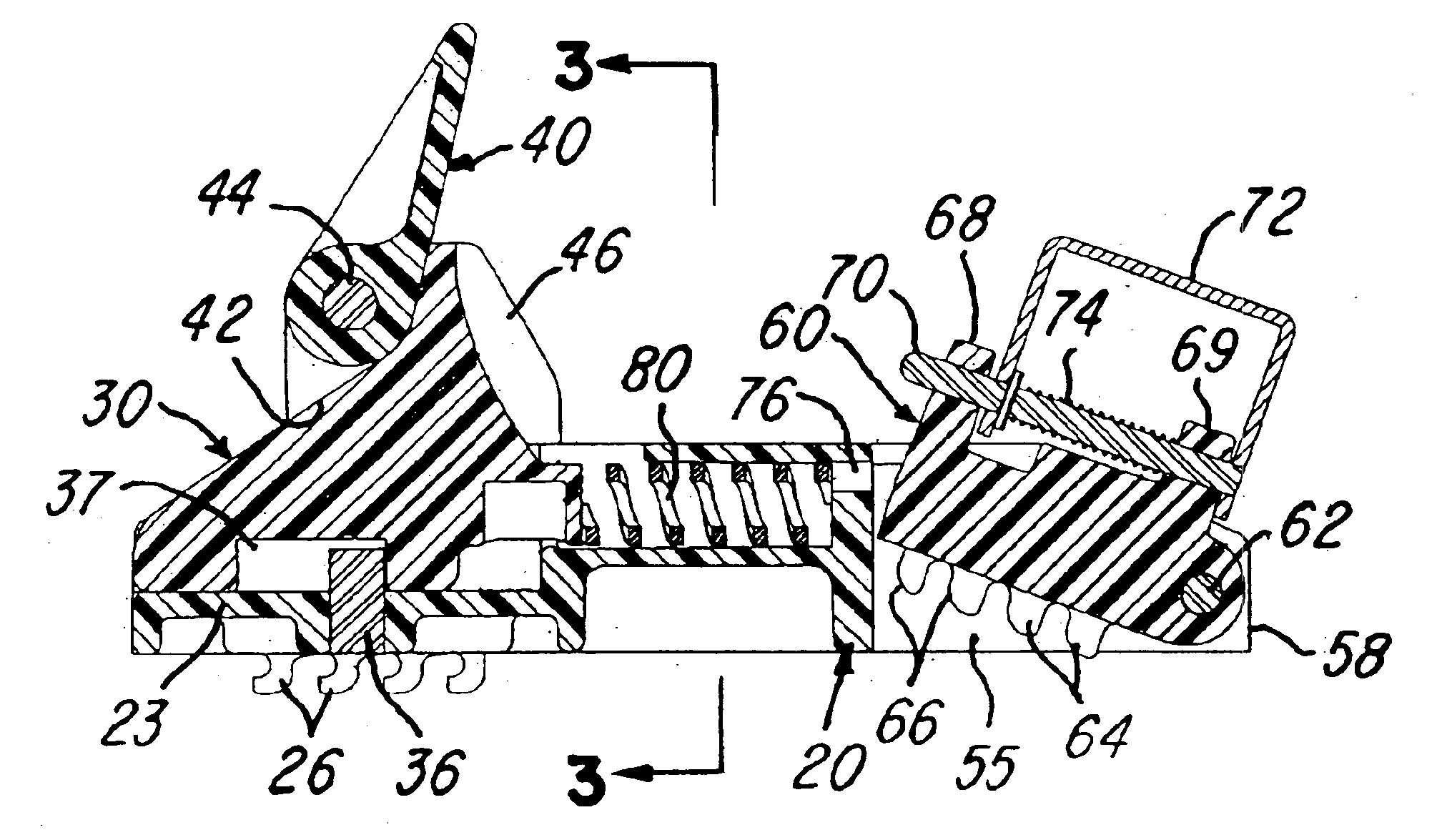

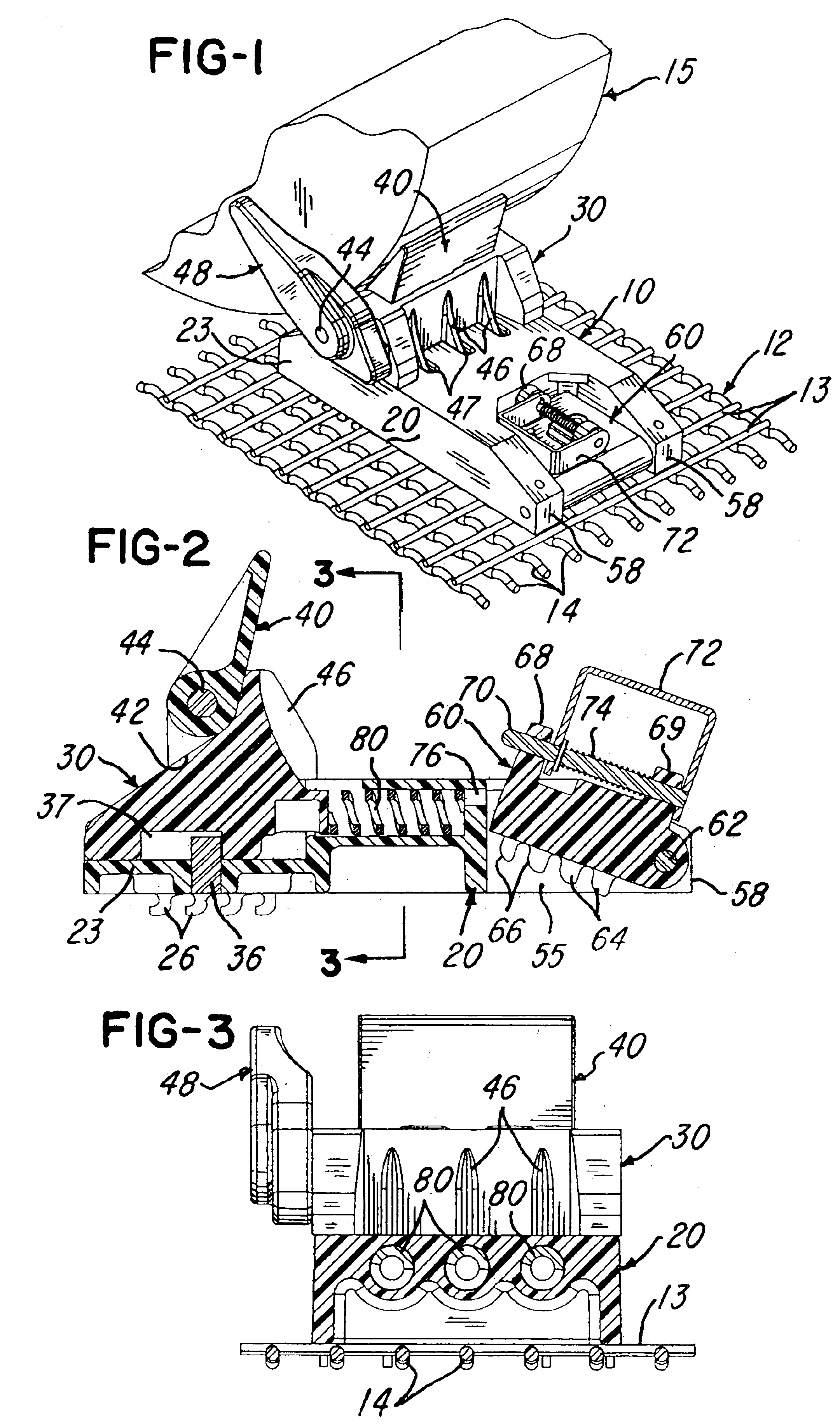

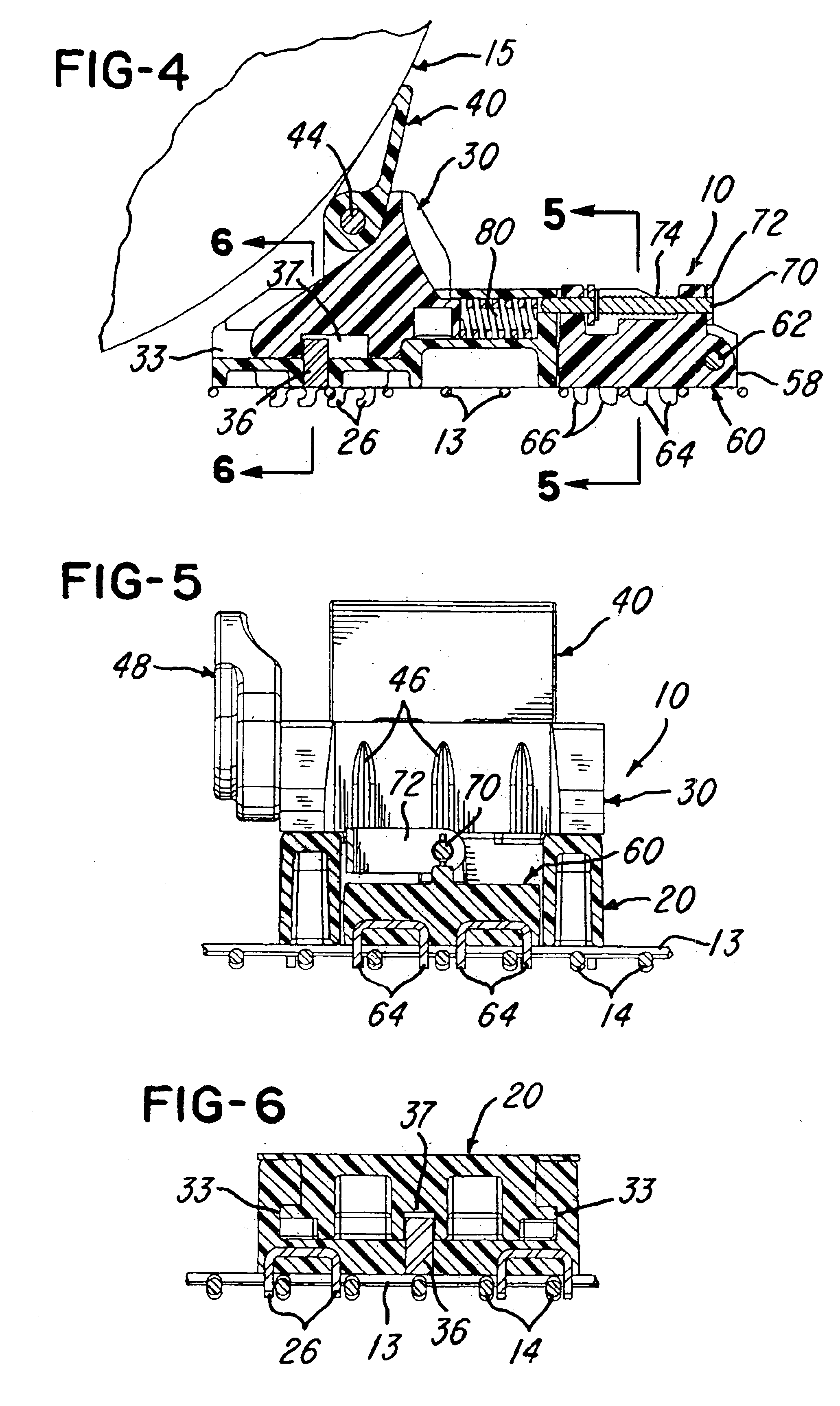

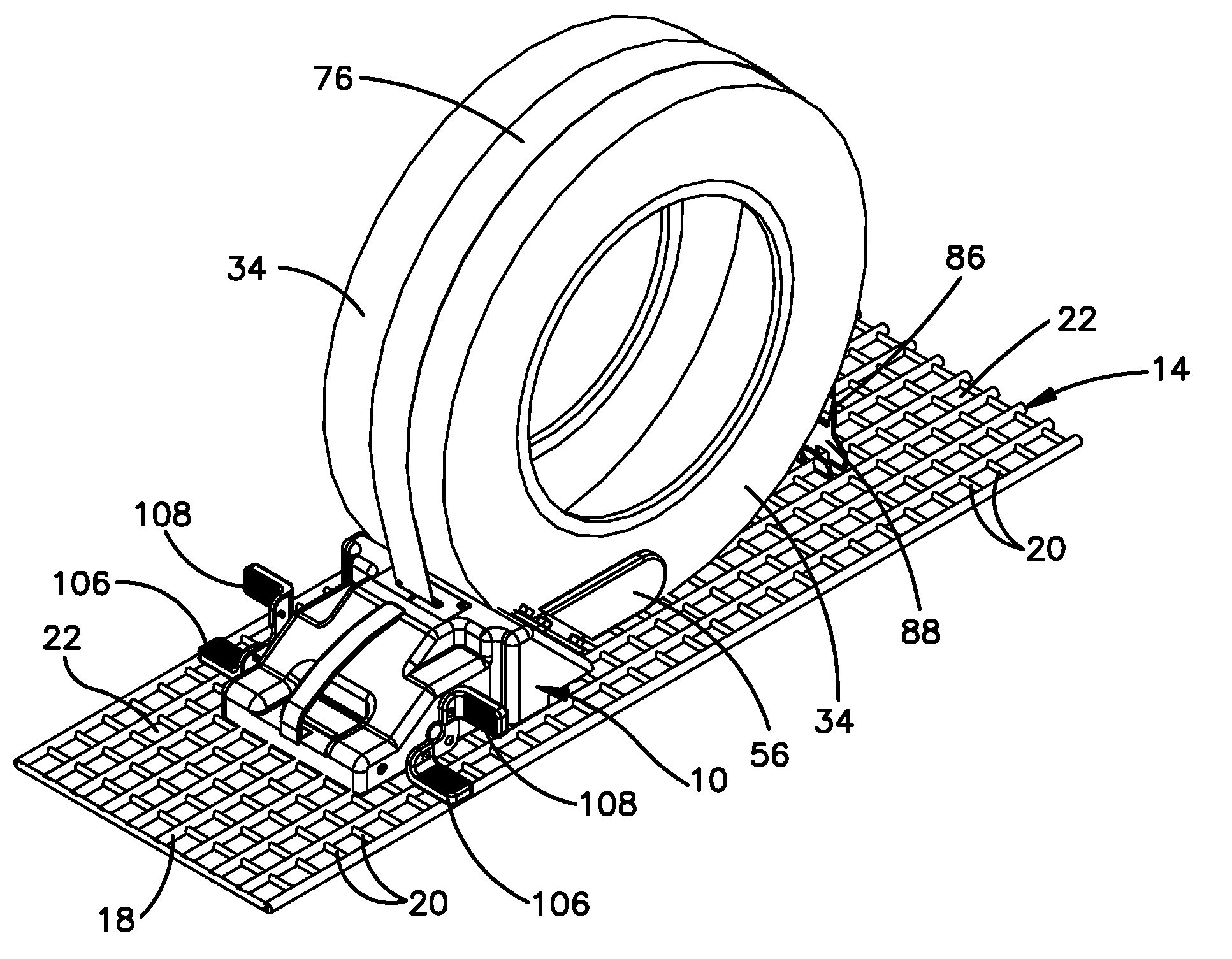

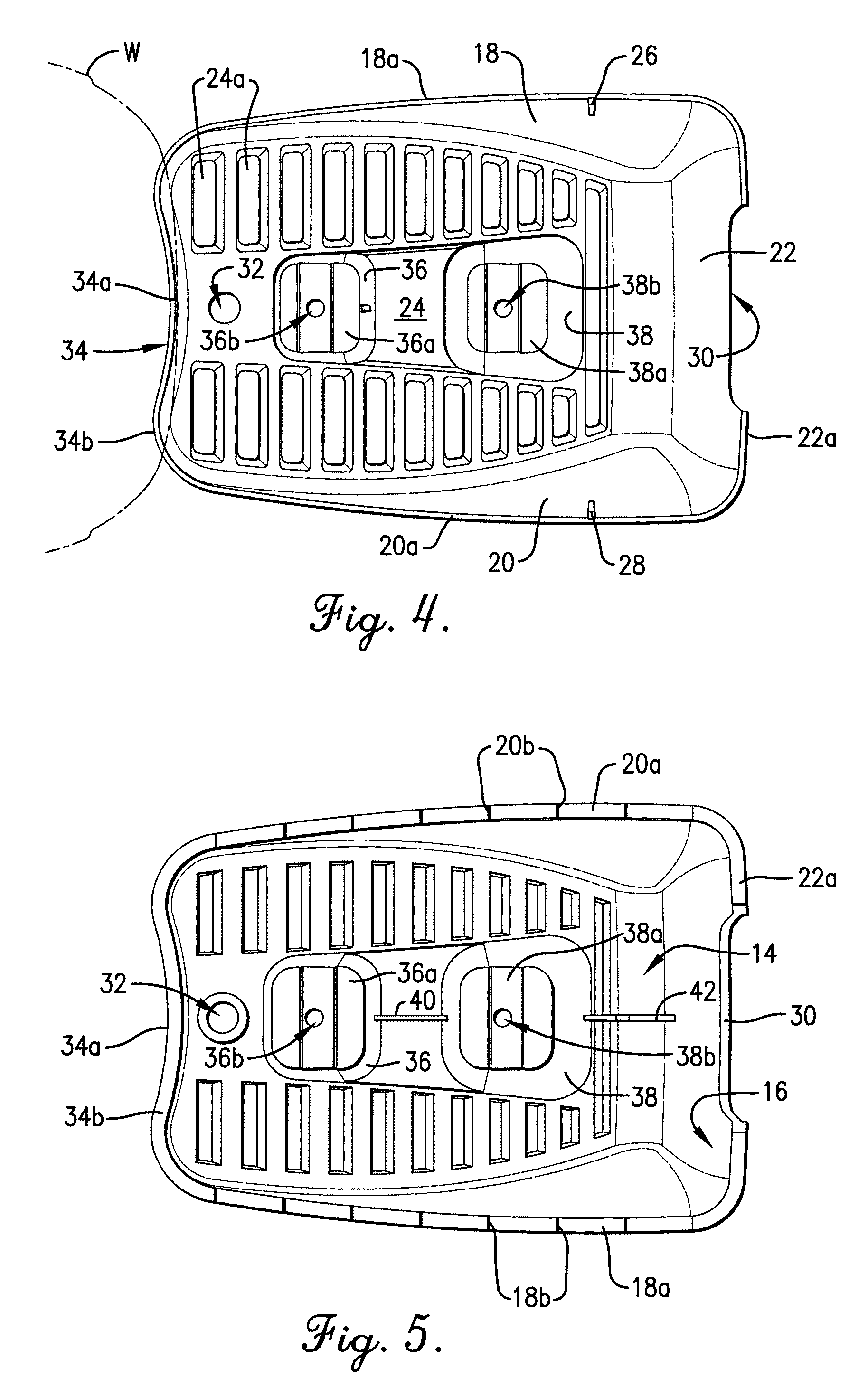

Shock absorbing vehicle wheel chock

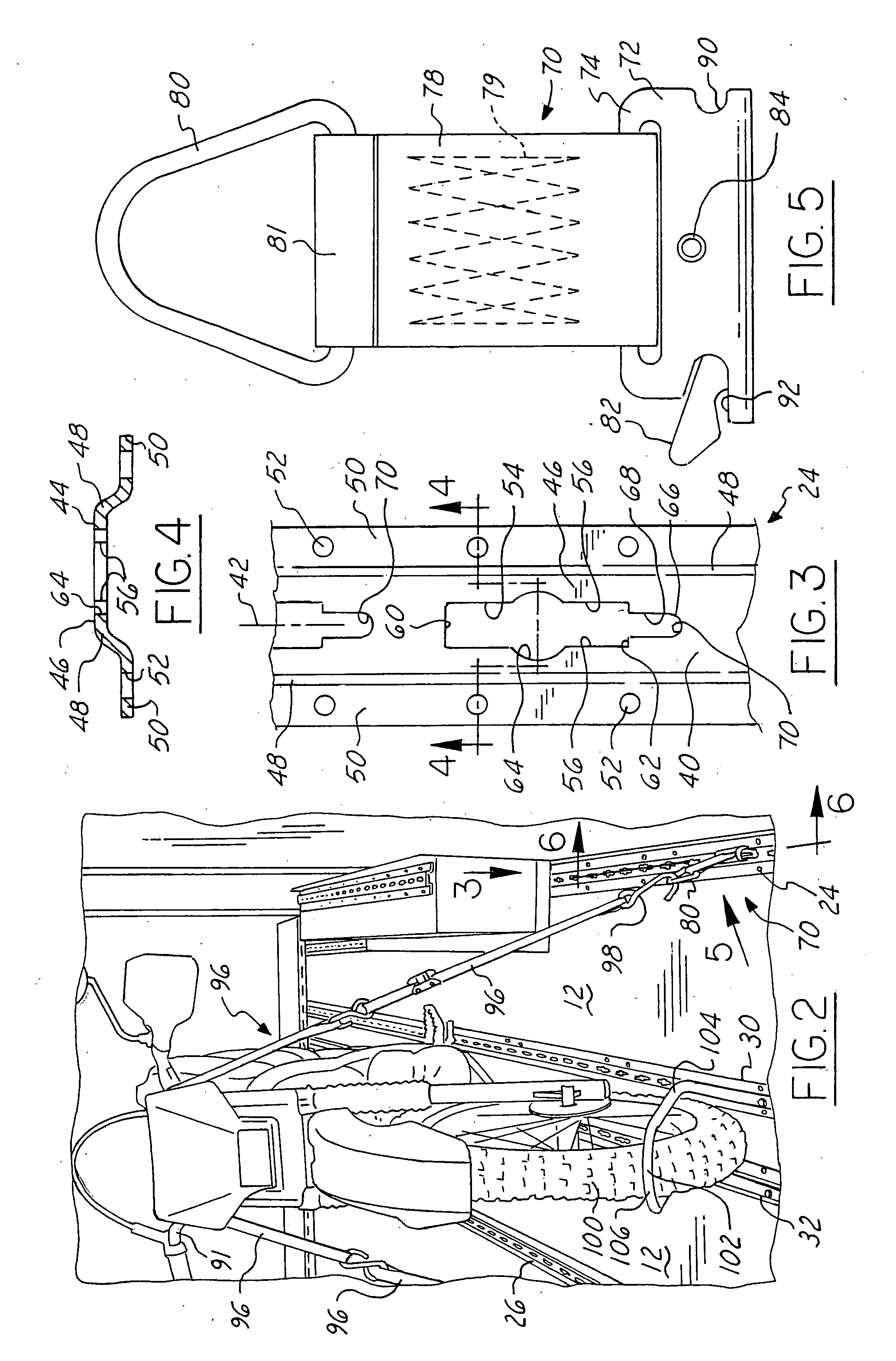

InactiveUS6851523B1Eliminates time costReduces the financial lossPortable braking systemItem transportation vehiclesWire gridPlastic materials

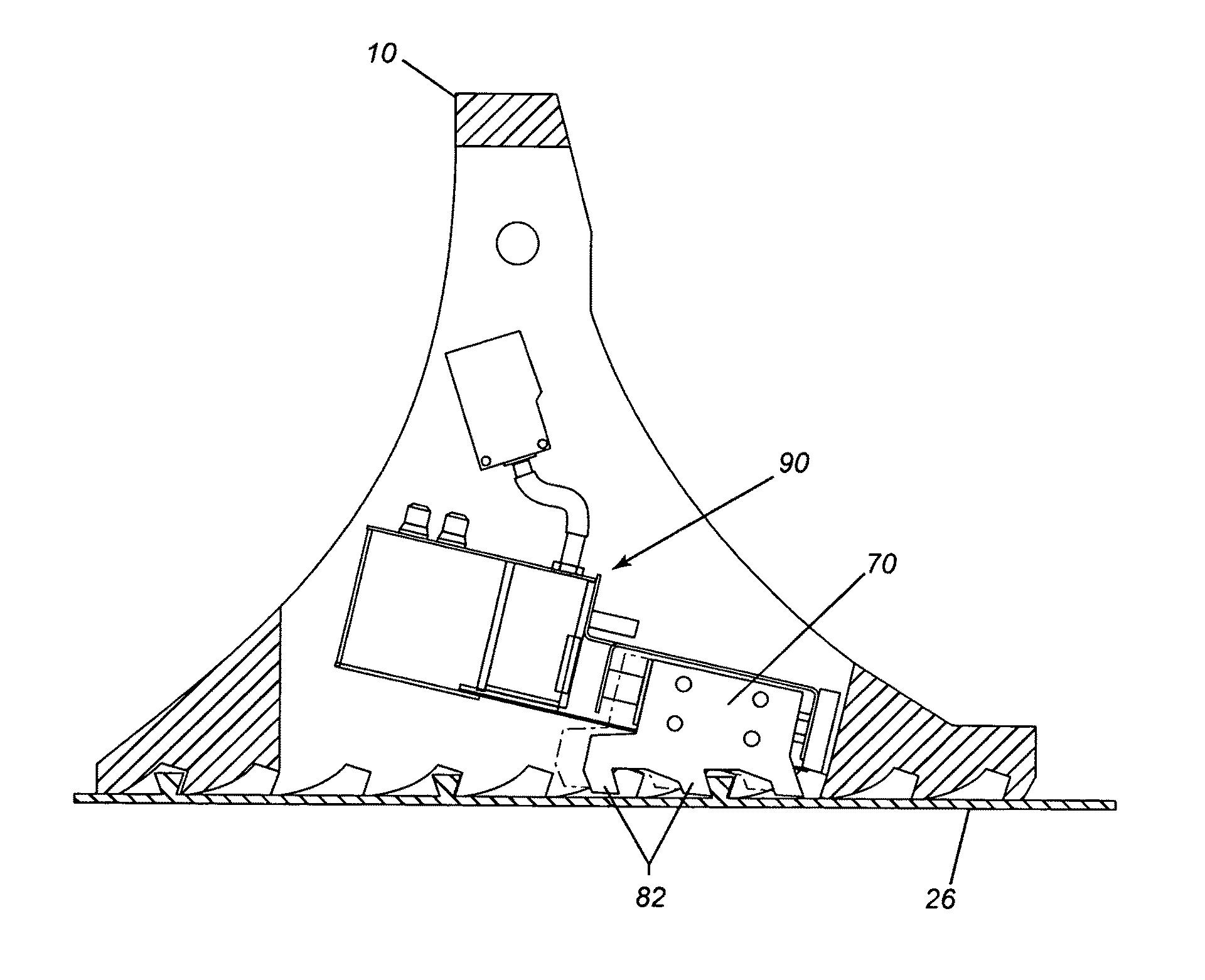

A horizontally extending body or base member includes a forward portion and a rearward portion and has downwardly projecting teeth for engaging a wire grid mounted on a bed or floor. The forward portion of the base member supports a wheel engaging head member for relative horizontal movement between extended and retracted positions, and compression springs bias the head member to its extended position. A lock member is supported by the rearward portion of the base member for pivotal movement between released and locked positions and also has downwardly projecting teeth for engaging the wire grid. The head member carries a wheel engaging extension member for pivotal movement between retracted and extended positions. A side paddle member is also carried by the head member to resist lateral movement of the wheel, and preferably all of the members are each molded of a liquid thermoset plastics material.

Owner:TITAN IND SERVICES

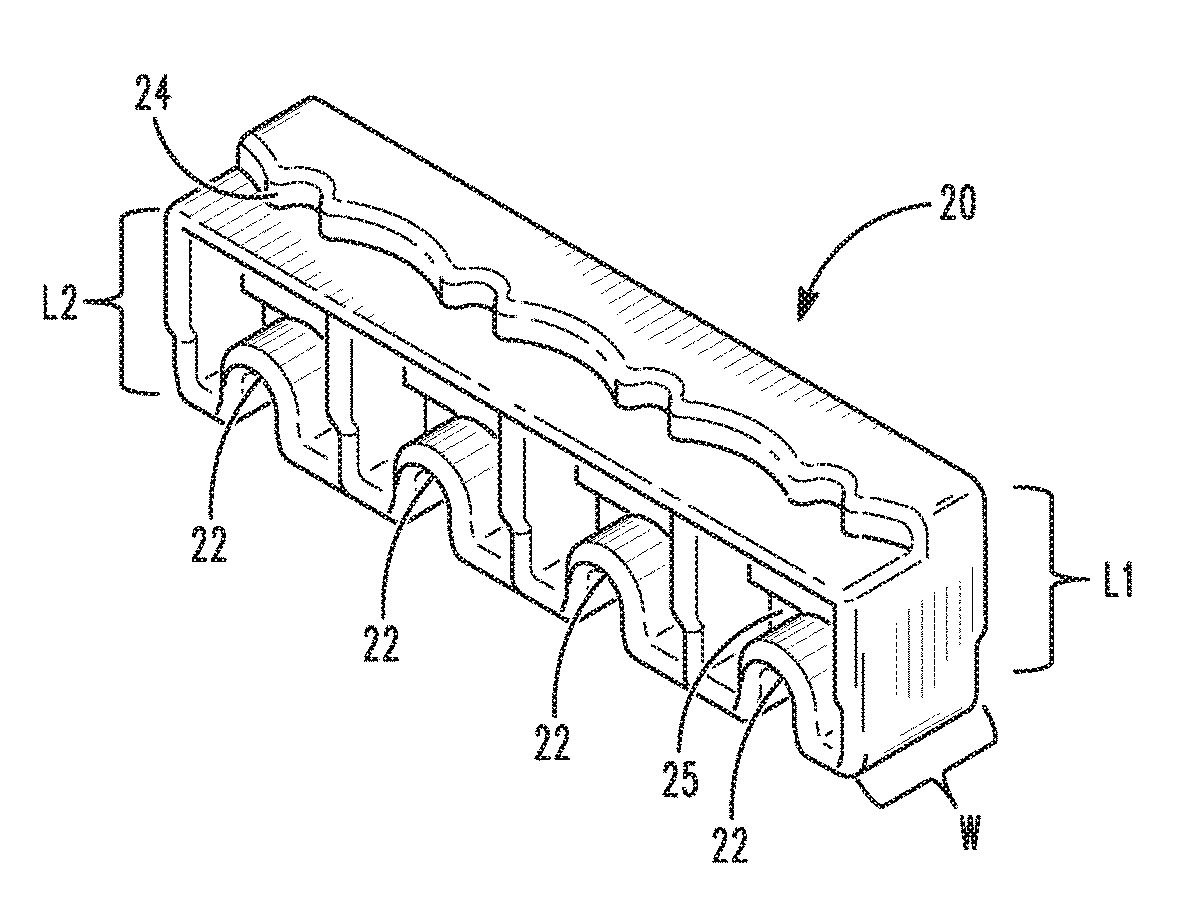

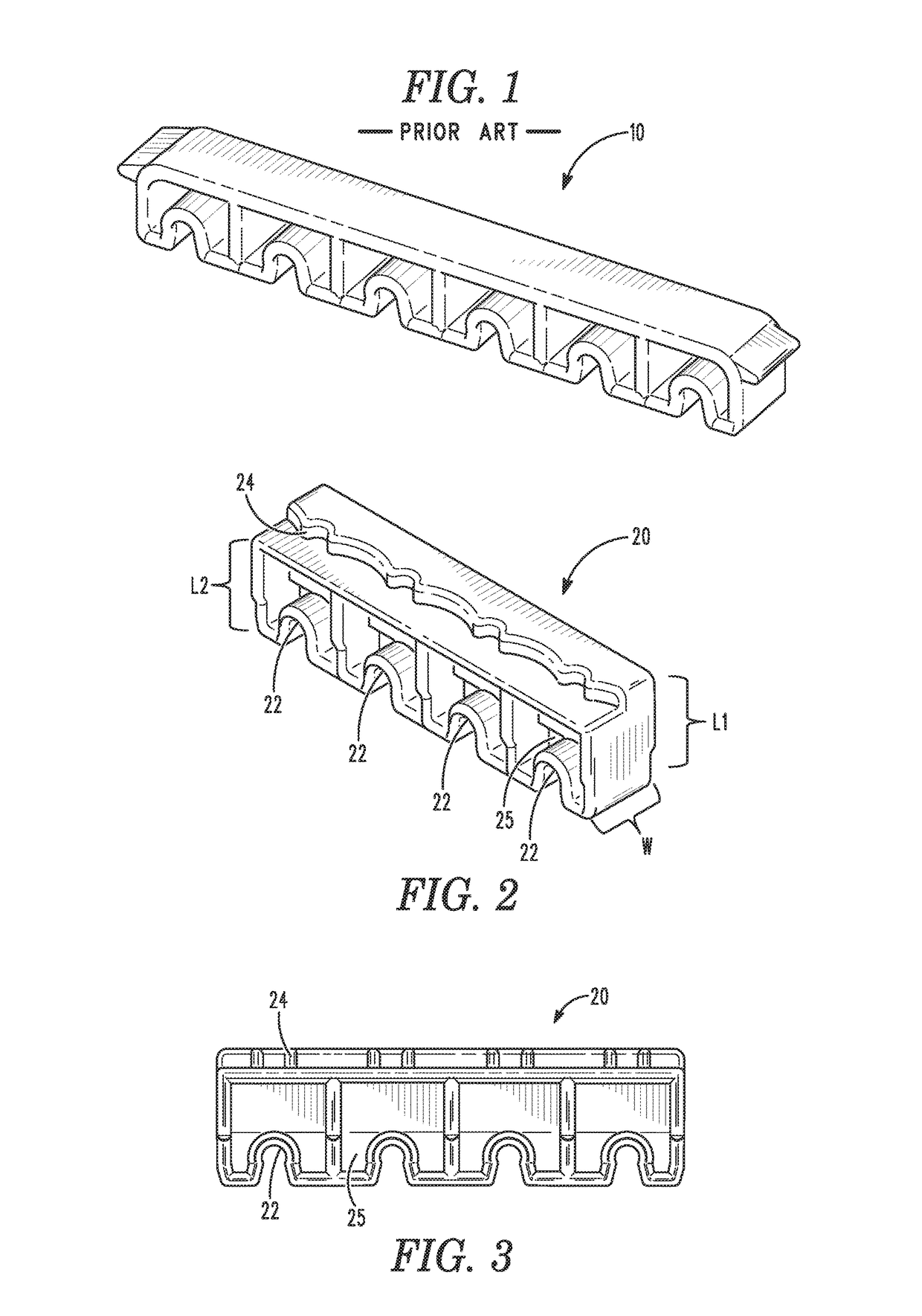

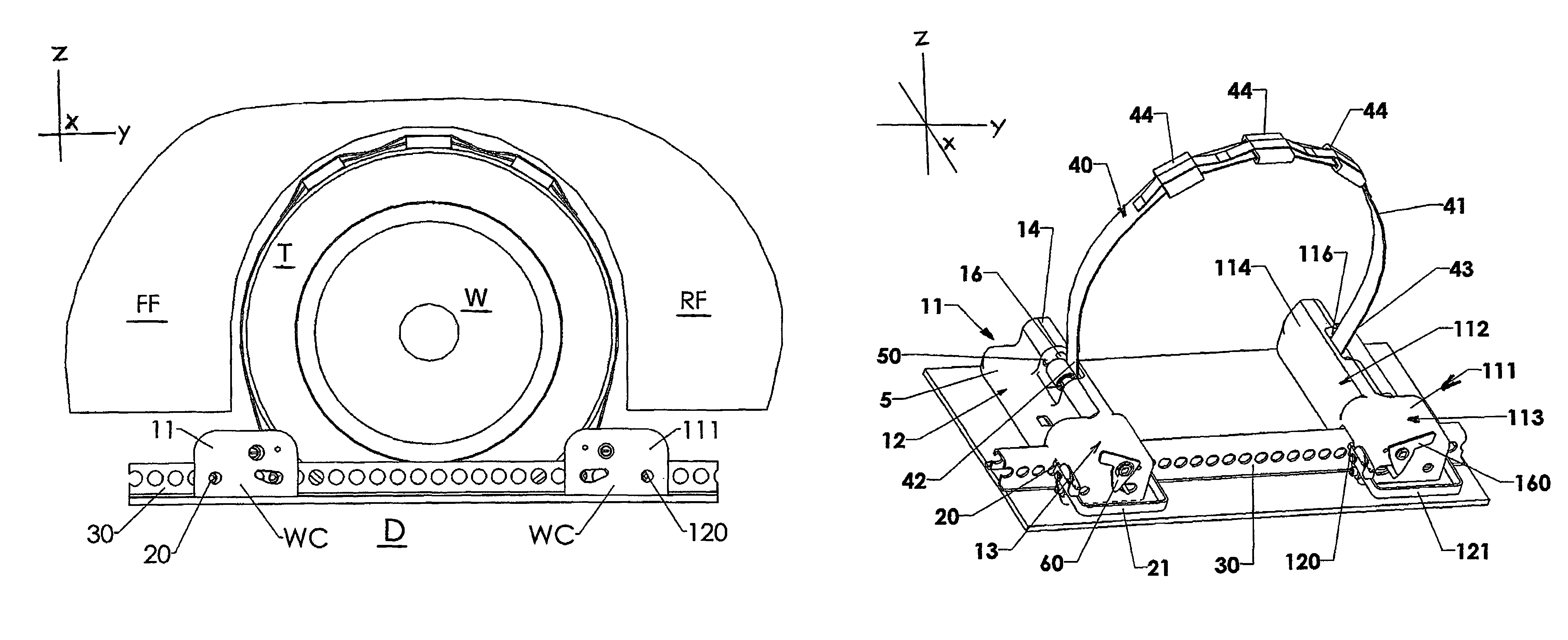

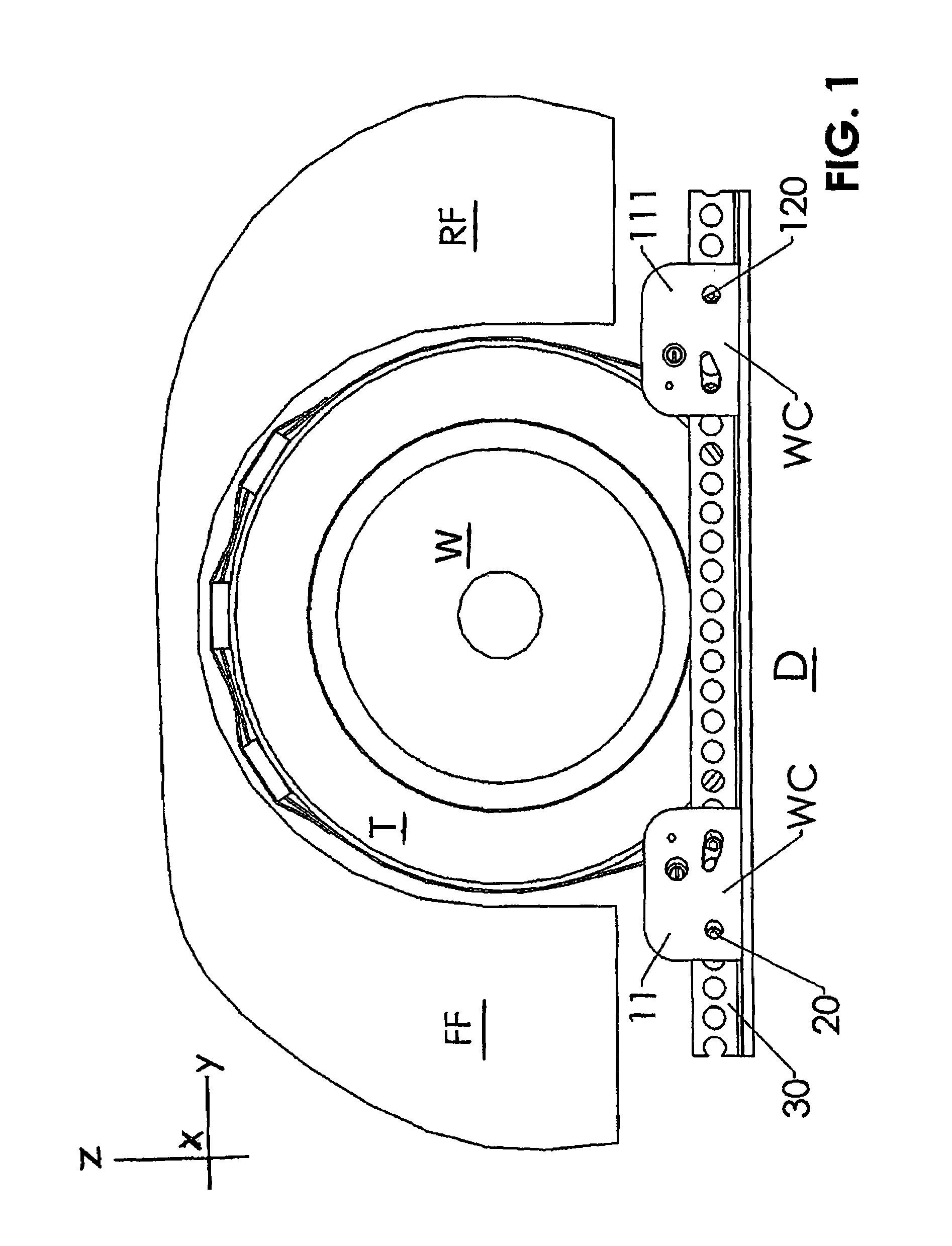

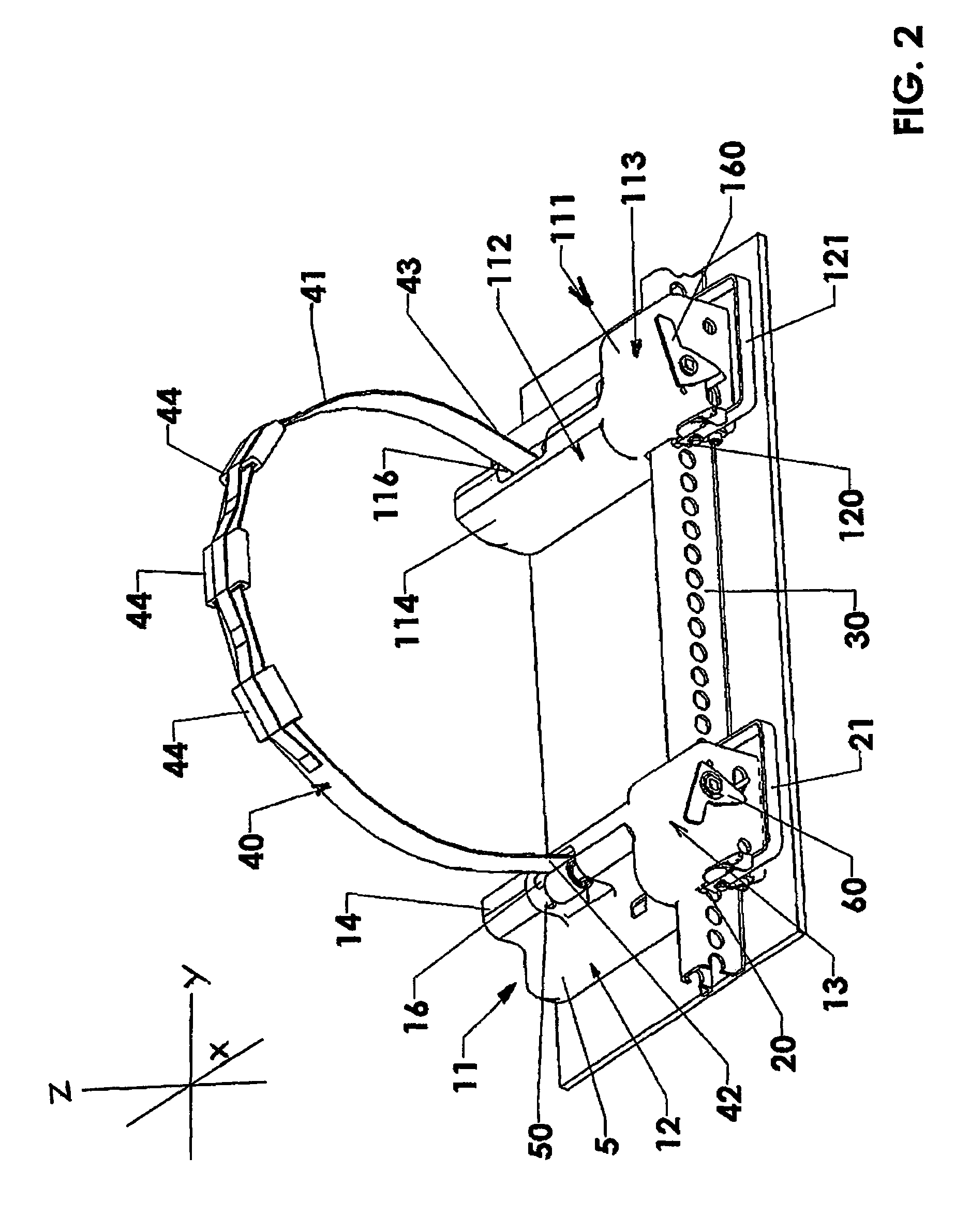

Low-profile wheel chock assembly

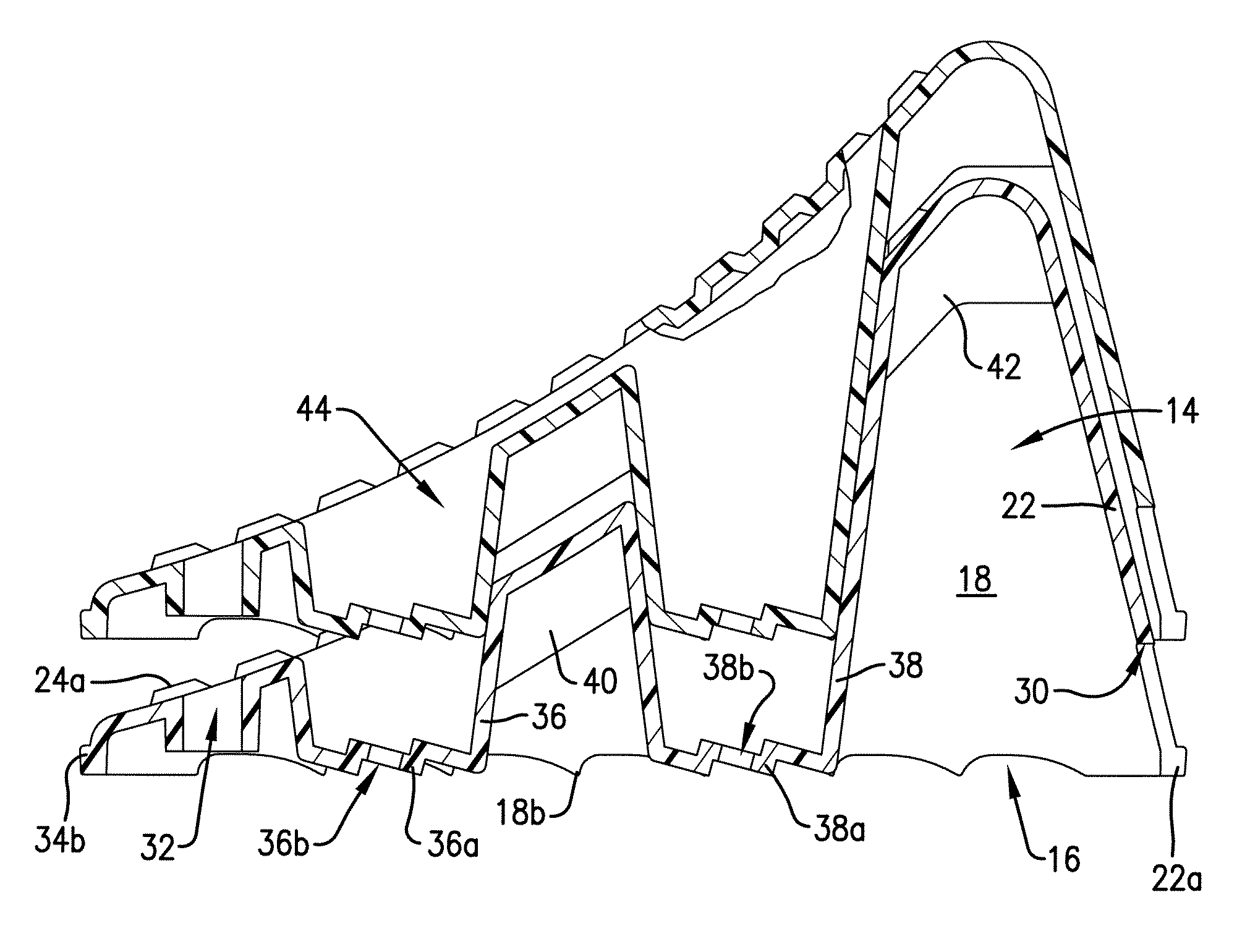

ActiveUS7513725B1Improve rigidityHigh strengthLoad securingItem transportation vehiclesEngineeringMirror image

A low elevational profile of each of a pair of first and second wheel chocks for restraining a current “low-drag” motor vehicle in a carrier, such as a railway car, is derived from each wheel chock having an internally webbed, elongated stepped-box body terminated with a relatively short rectangular box having its inner wall integrally formed with the stepped-box body. The body of the first chock is essentially a mirror-image of the second chock body. The low profile of a wheel chock allows each to be positioned under a vehicle the rocker panel of which has its lower edge only 148 mm (5.82 inches) above the surface upon which the vehicle's tire rests, so that the installed chock height is reduced to 47.6 mm (1.87″) under the components of the vehicle's body. The assembly may include a pair of “active” chocks; or, one active chock and one anchor chock. A single window in the upper portion of the stepped-box provides access for a strap of a wheel harness, which strap is wrapped around a torque tube in an active chock. The torque tube in one chock is rotatable in a direction opposite to that of the torque tube of the other chock. With a pair of active chocks, hooks on straps of a prior art harness are eliminated because it is difficult and time-consuming to manipulate a tire harness with its straps and hooks to secure the tire between the wheel chocks. When one chock is an anchor chock, one end of the strap is provided with a hook which is anchored to a rod or tube which is substituted for the rotatable torque tube.

Owner:GE GLOBAL SOURCING LLC

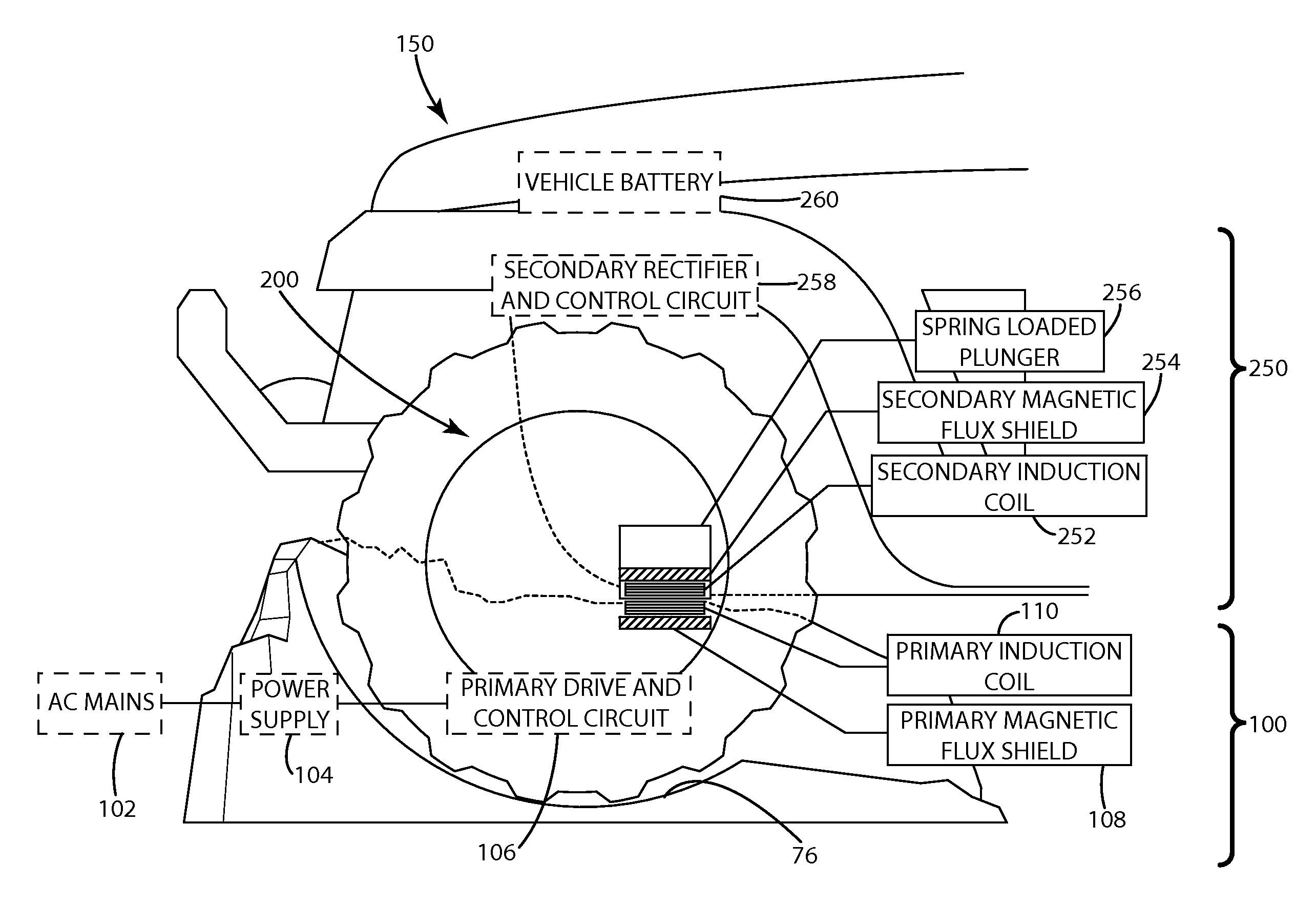

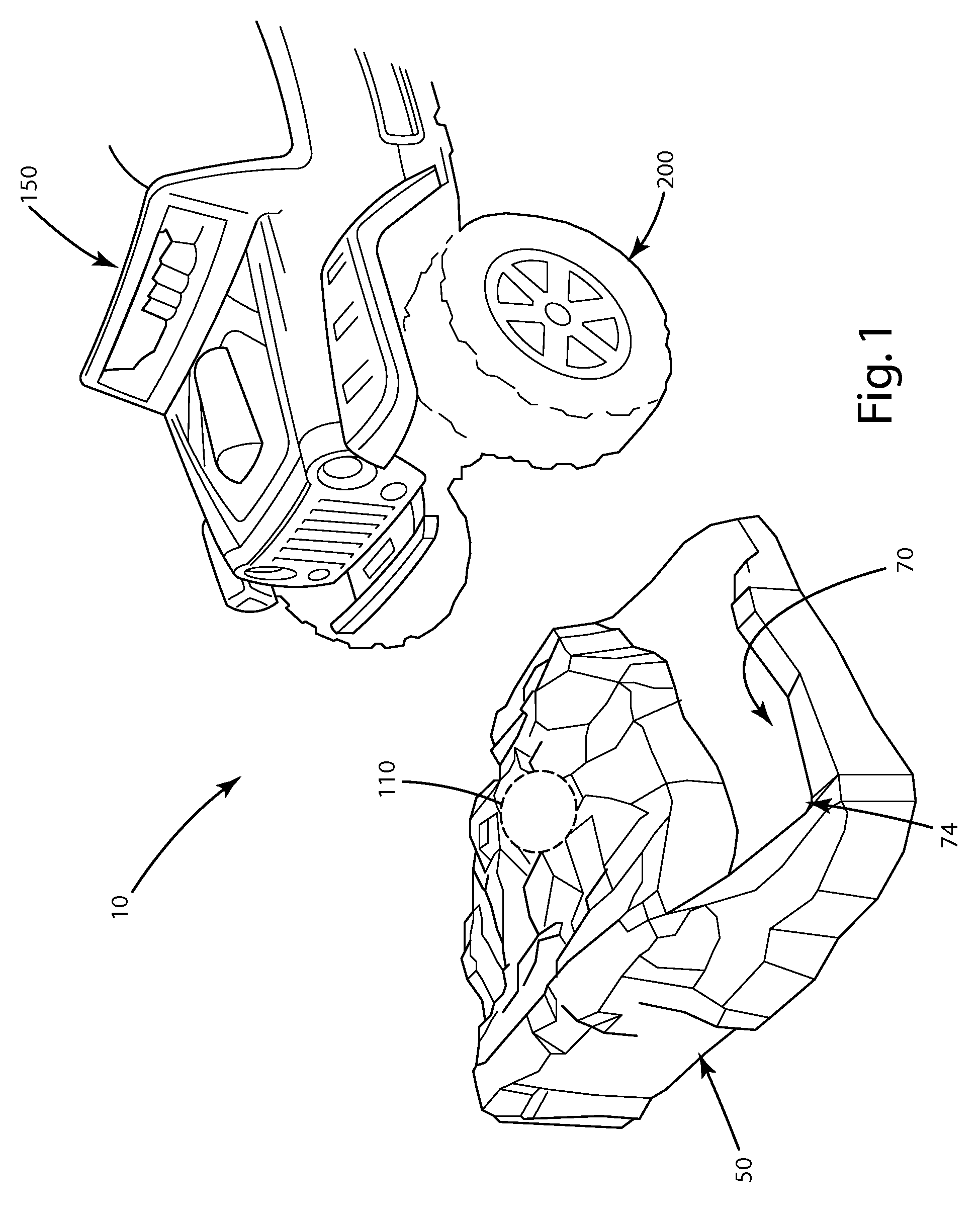

Inductive charging system for electric vehicle

ActiveUS8937454B2Facilitate damage-free coupling and decouplingNear-field transmissionRailway vehiclesElectricityEngineering

Owner:PHILIPS IP VENTURES BV

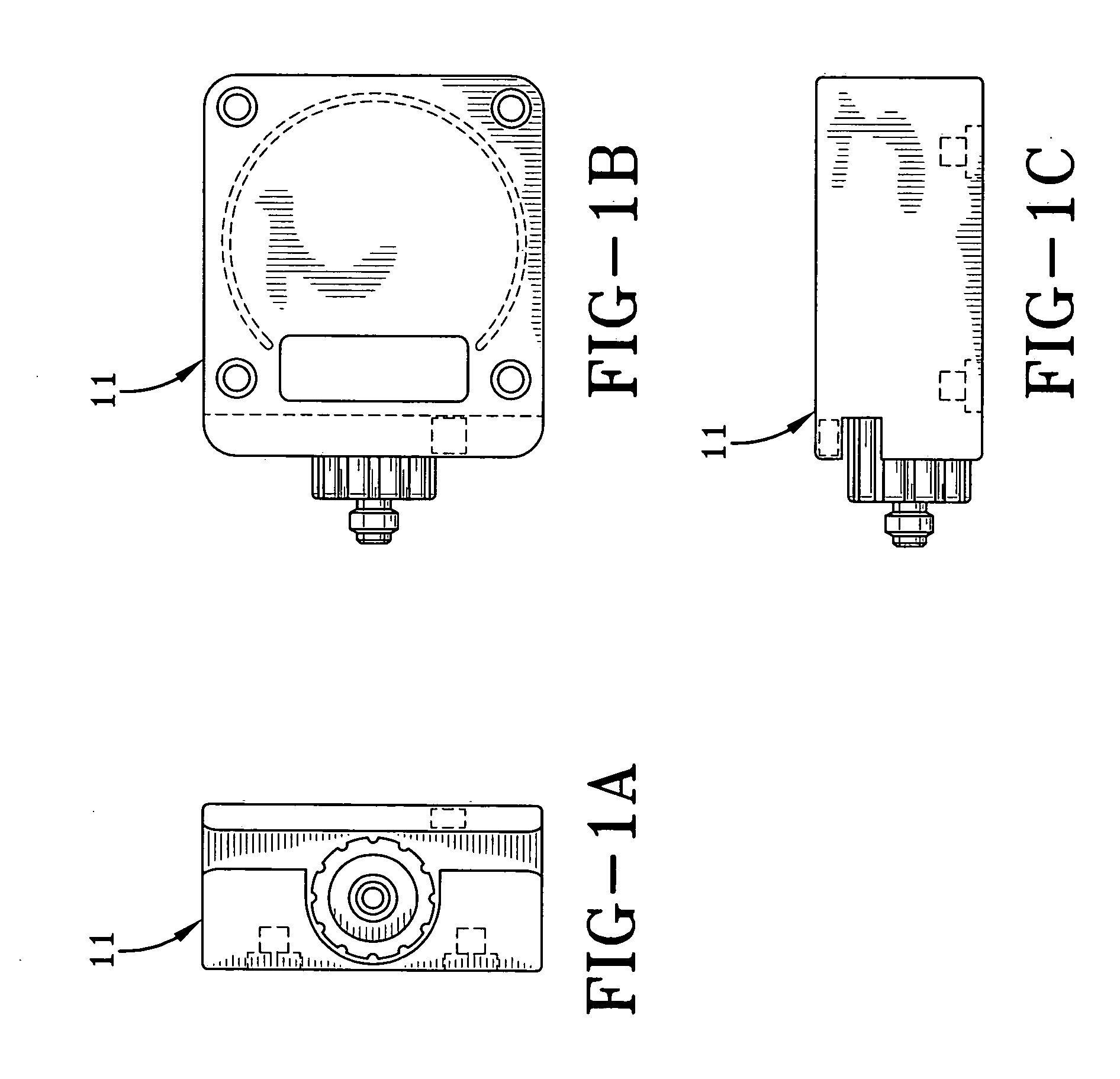

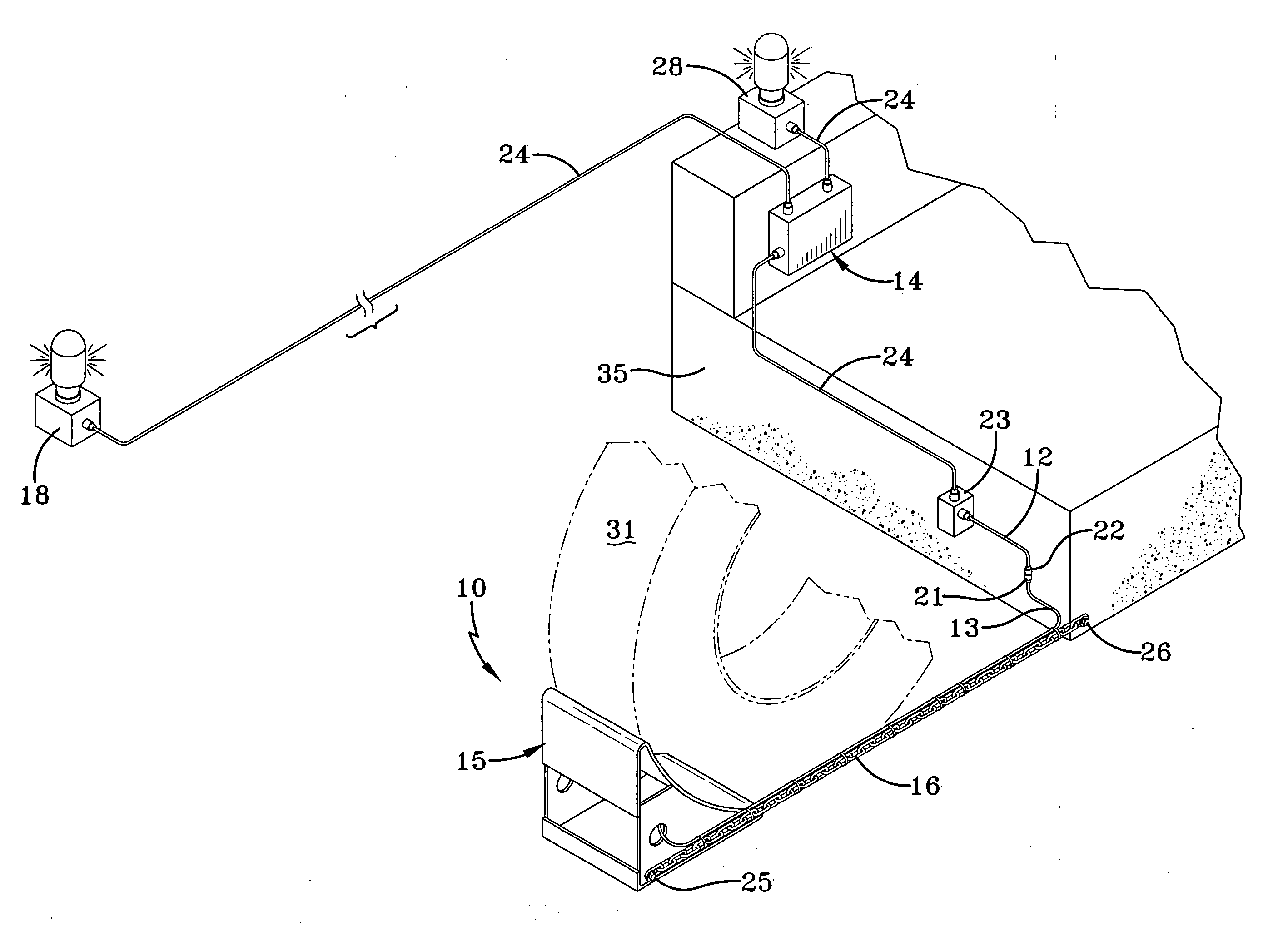

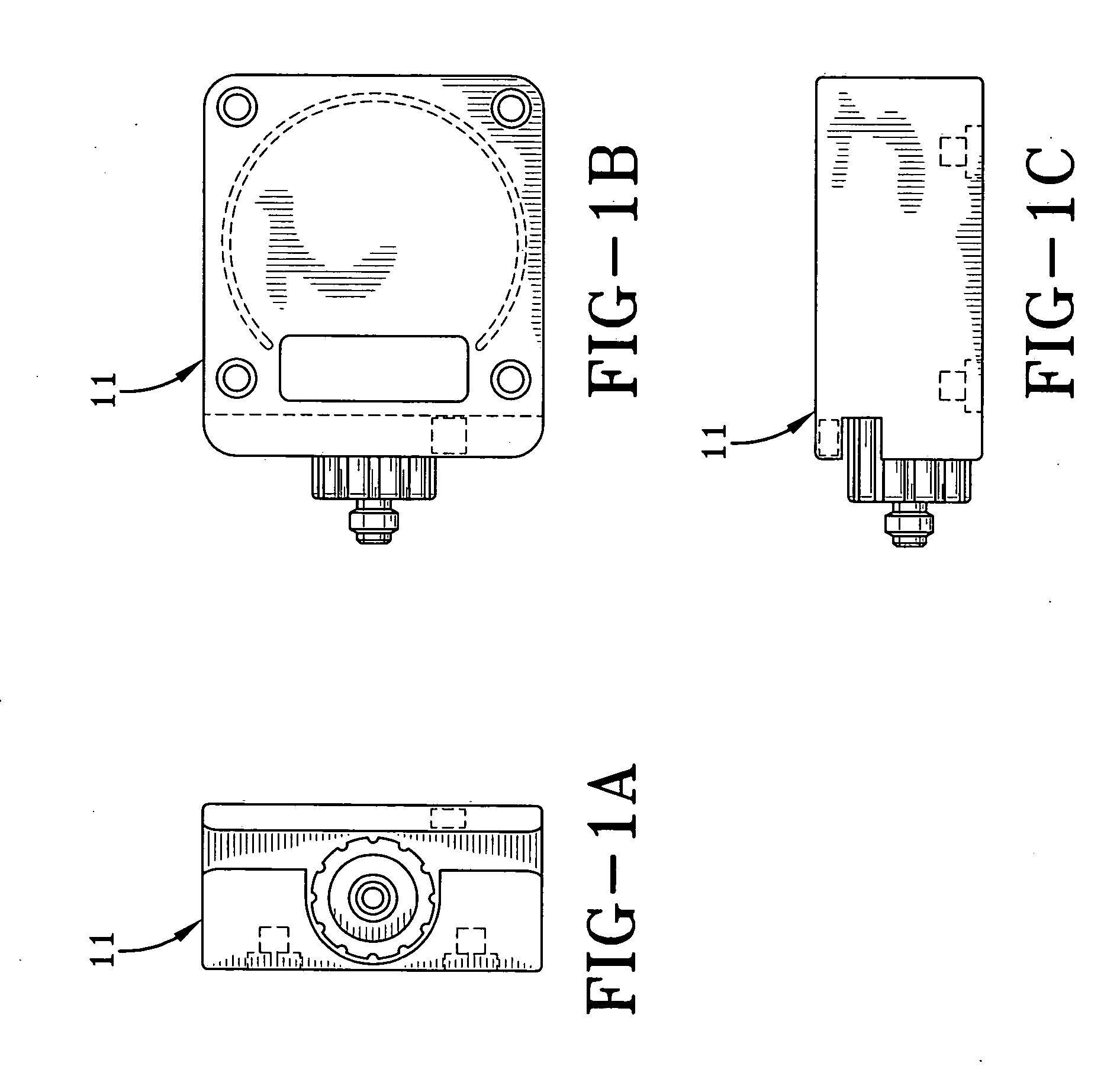

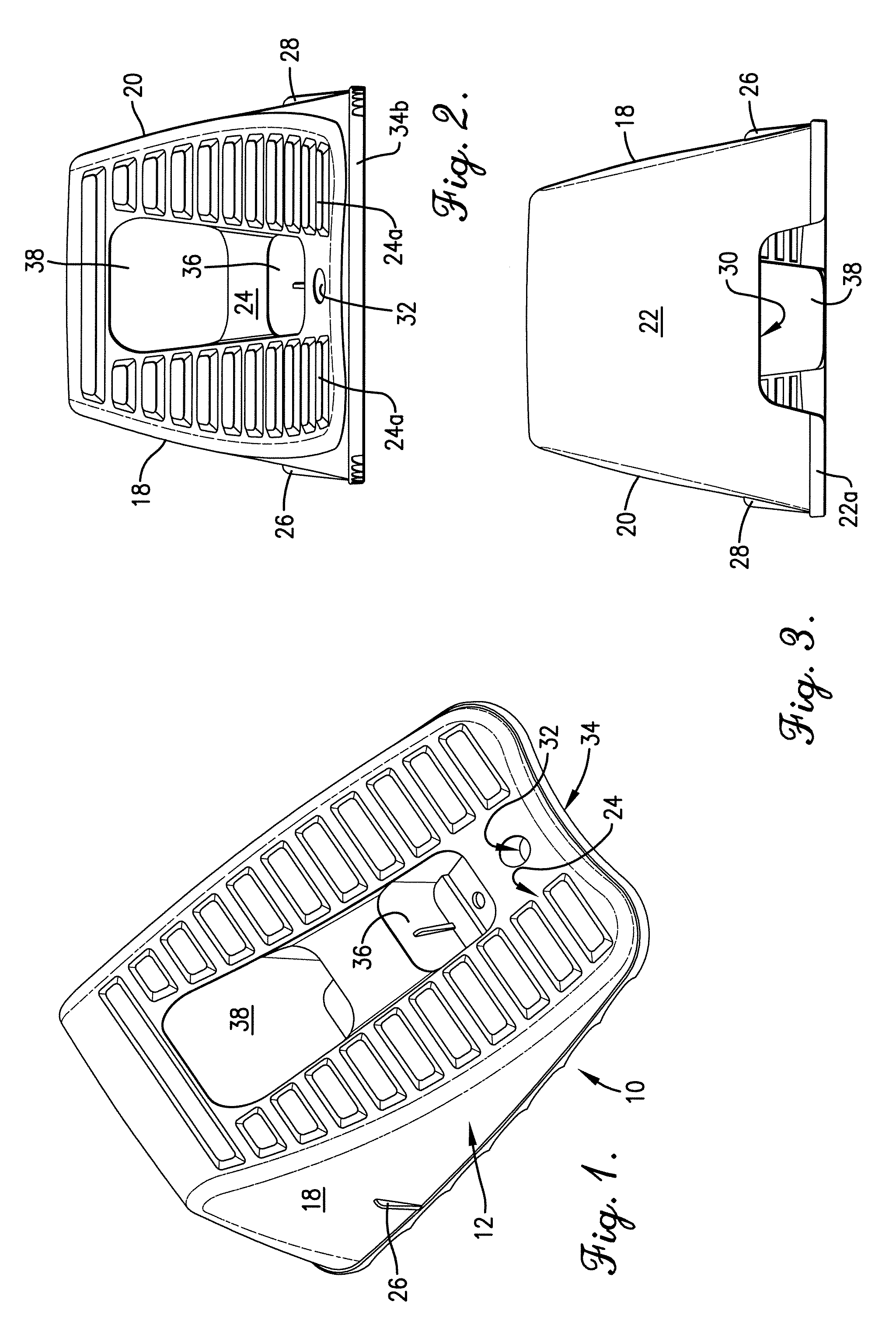

Tire-detecting wheel chock apparatus

InactiveUS7226265B2Precise positioningEasy maintenanceConveyorsPortable braking systemMicrocontrollerDriver/operator

A wheel chock apparatus includes a chock body for chocking a tire of a vehicle such as a semi-trailer prior to loading or unloading the trailer by a towmotor at a docking bay. When properly positioned, the chock body prevents movement of the vehicle away from the docking bay during the loading or unloading operation. Such movement poses a possible hazard to the cargo being loaded or unloaded, to the equipment performing the loading / unloading operations, and to the operator of such equipment. The chock body includes a sensor mounted on or embedded in the body, which is capable of detecting a properly chocked tire. The sensor is electrically connected to a microcontroller programmed to control an indicator, such as a visual light or audible alarm, that will alert an equipment operator on the docking bay as to whether the driver of the vehicle has properly chocked the tires.

Owner:HENDRICKSON USA L L C

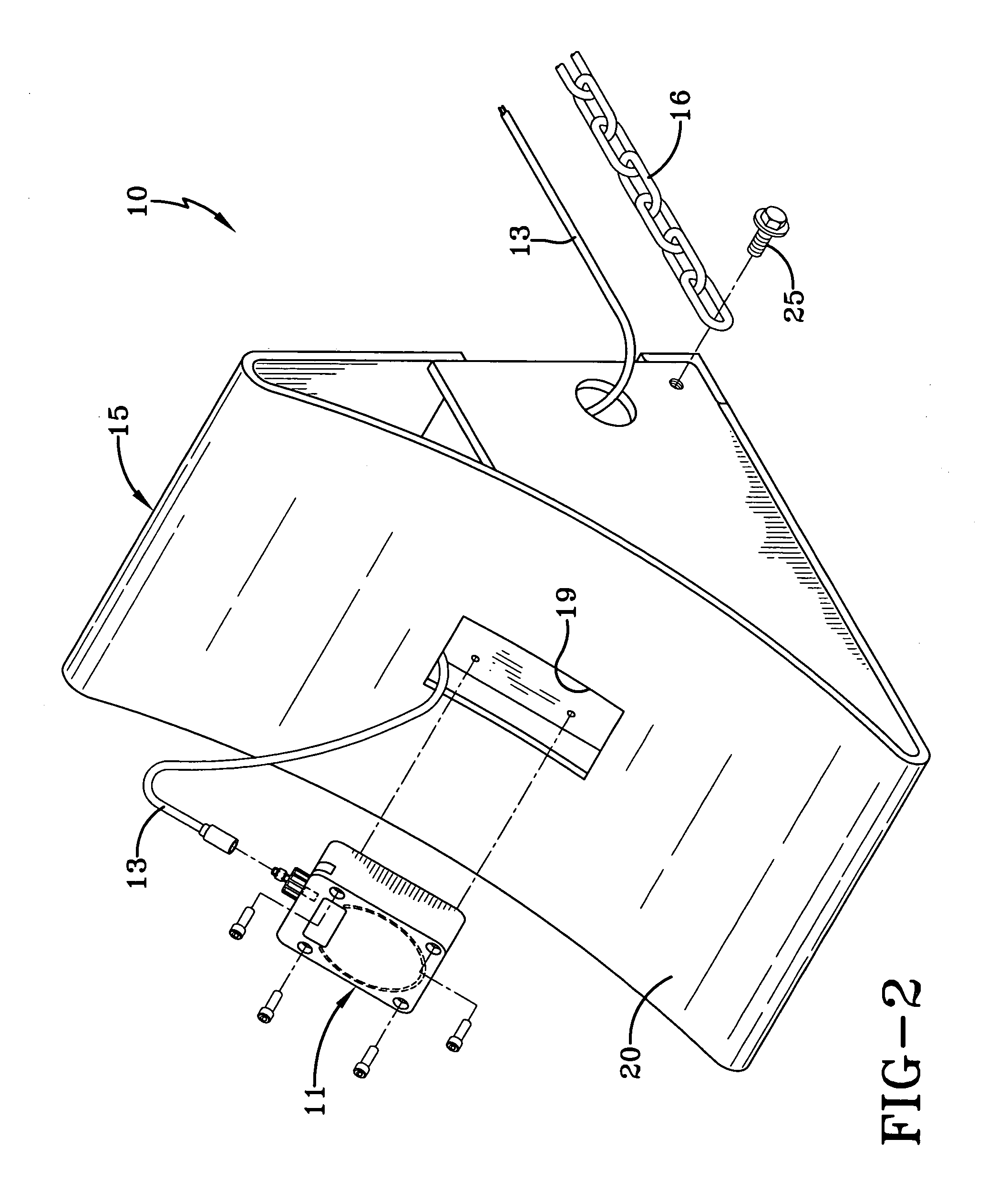

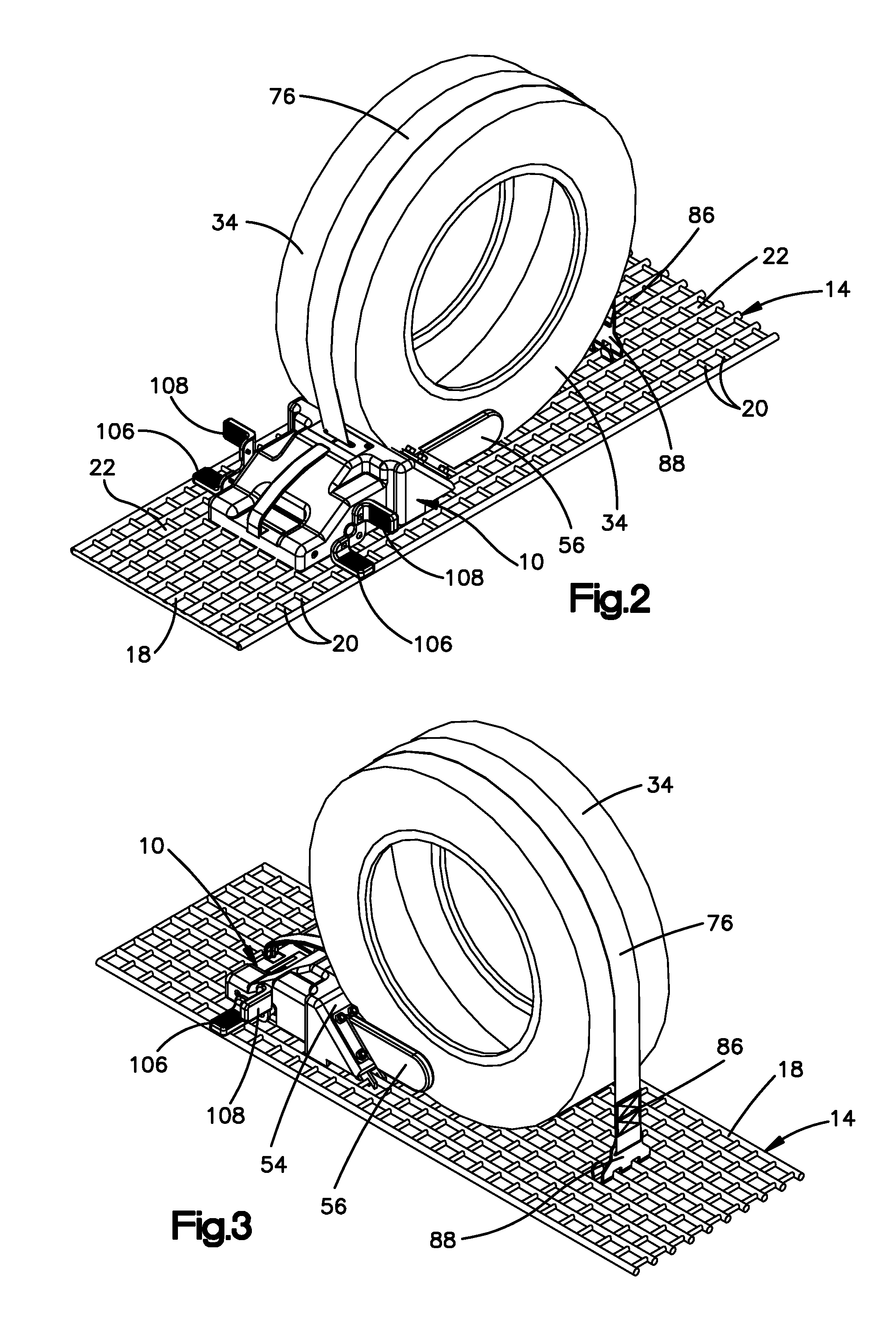

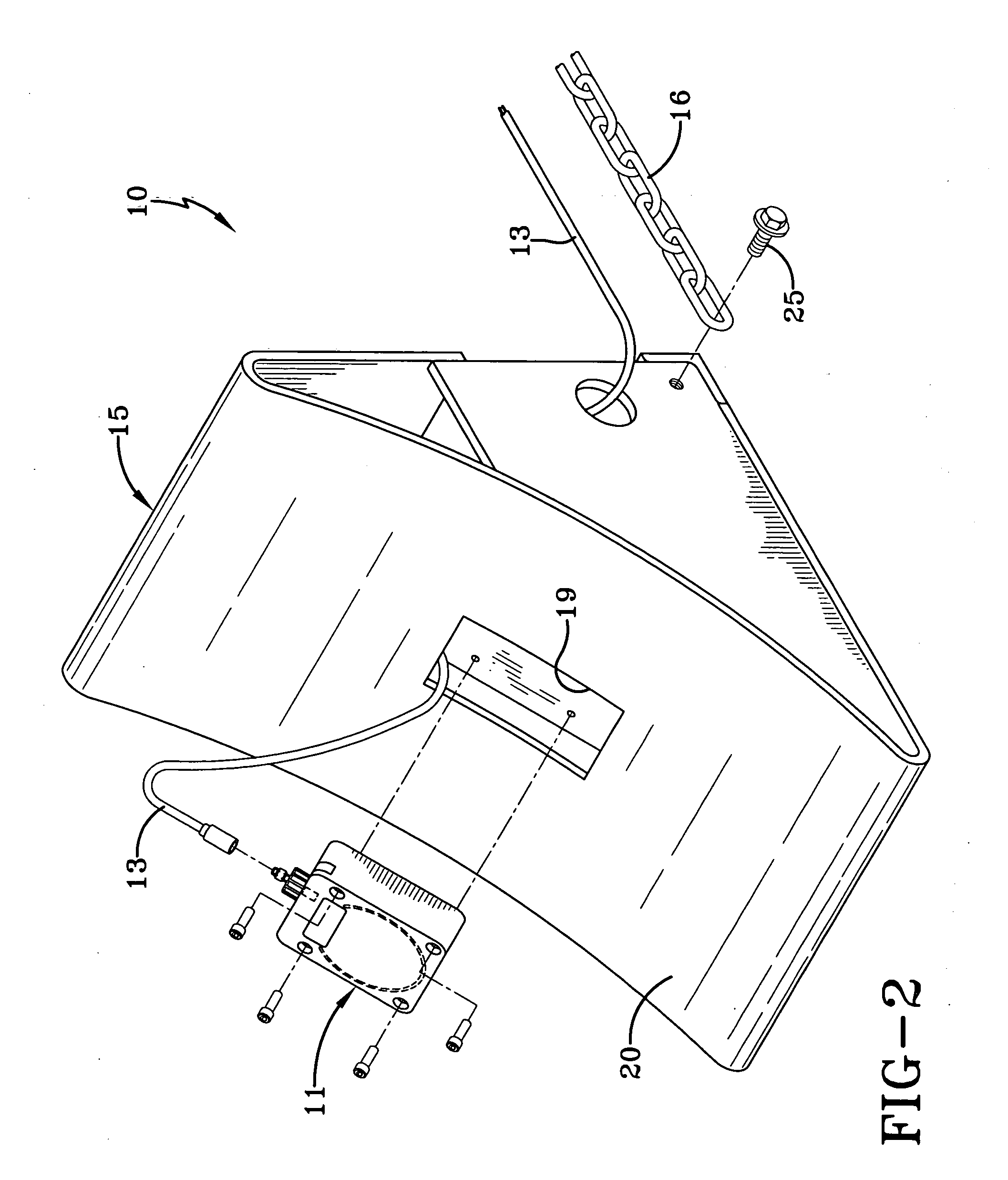

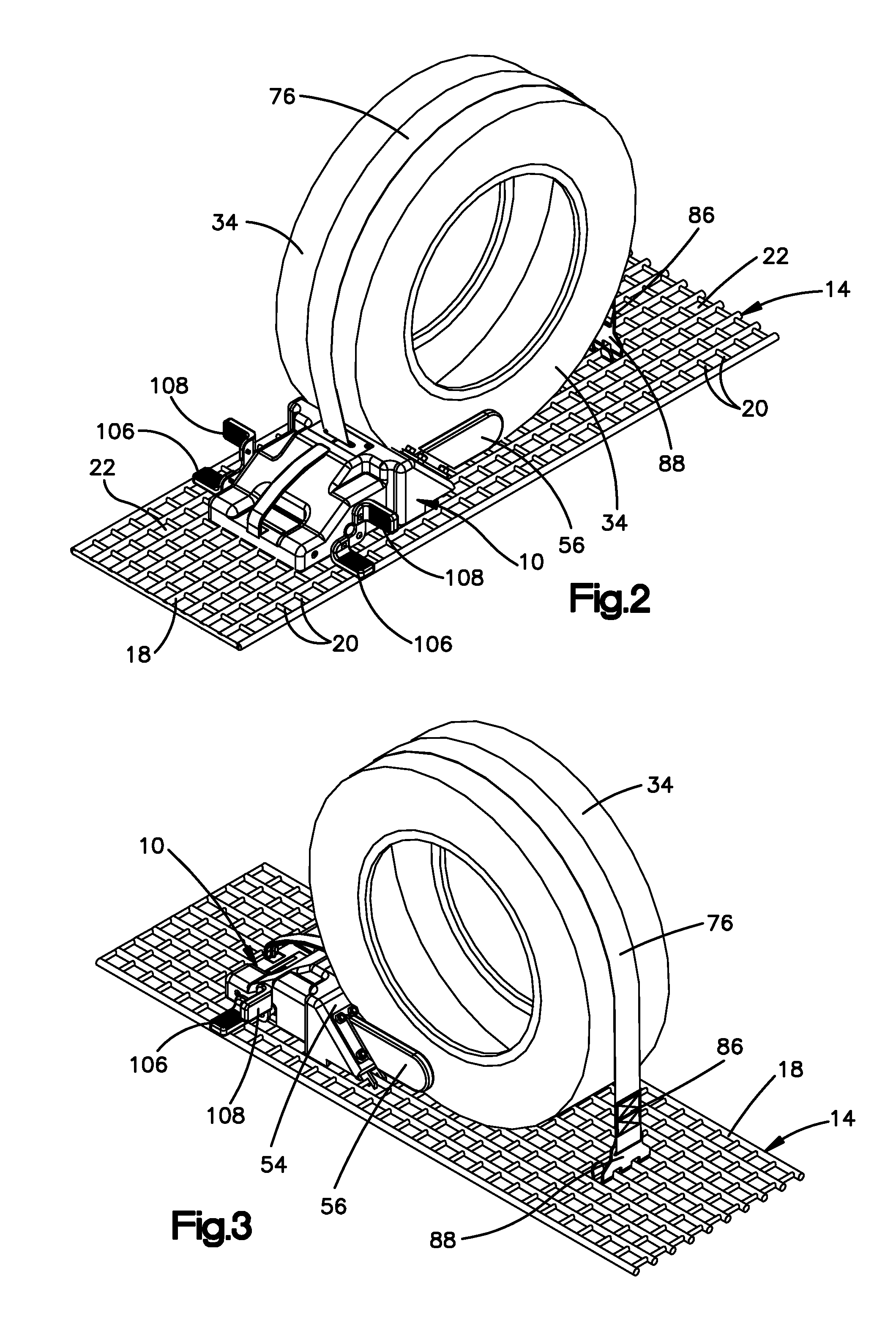

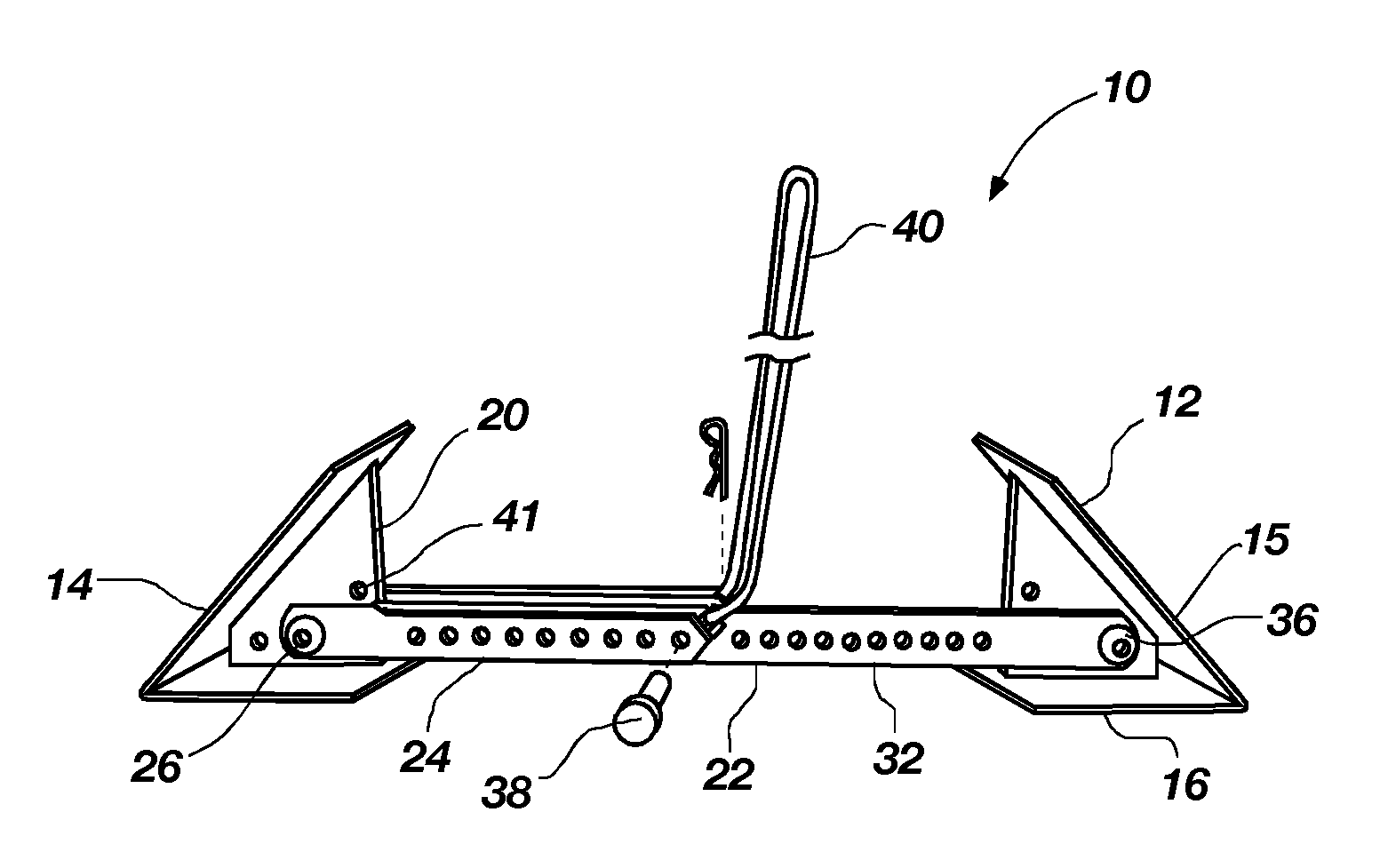

Wheel chock With Restraint

A wheel chock for restraining movement of a vehicle tire on a supporting grating during transit includes a base, a grate lock mechanism for locking the base to the grating, and a ramp on the base for engagement with a circumference of a vehicle tire. A strap connected with the base is extensible around the vehicle tire to help restrain movement of the tire on the grating. The chock includes a retractor for retracting the strap and for taking up slack that forms in the strap during transit.

Owner:MIDWEST PRECISION PRODS

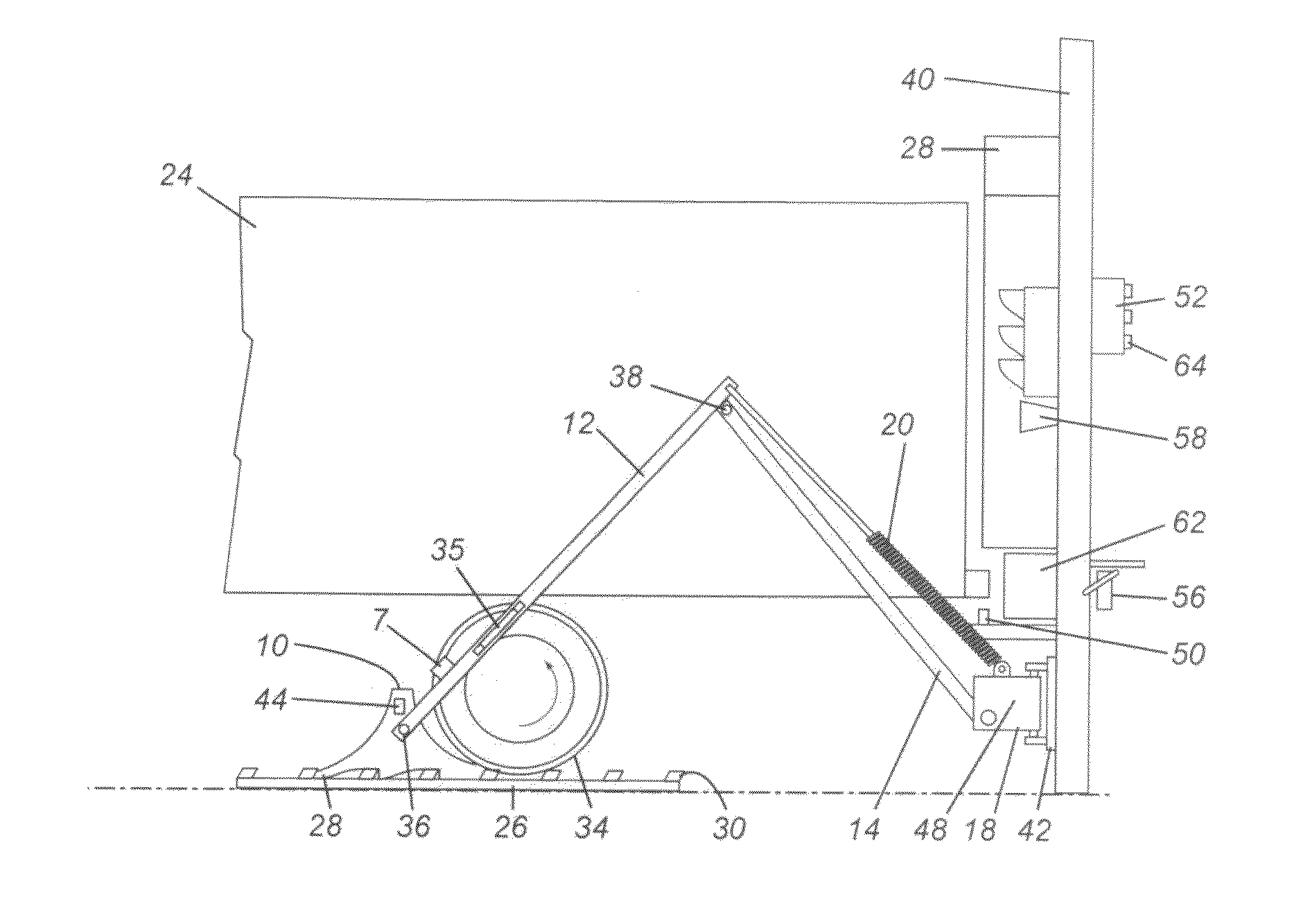

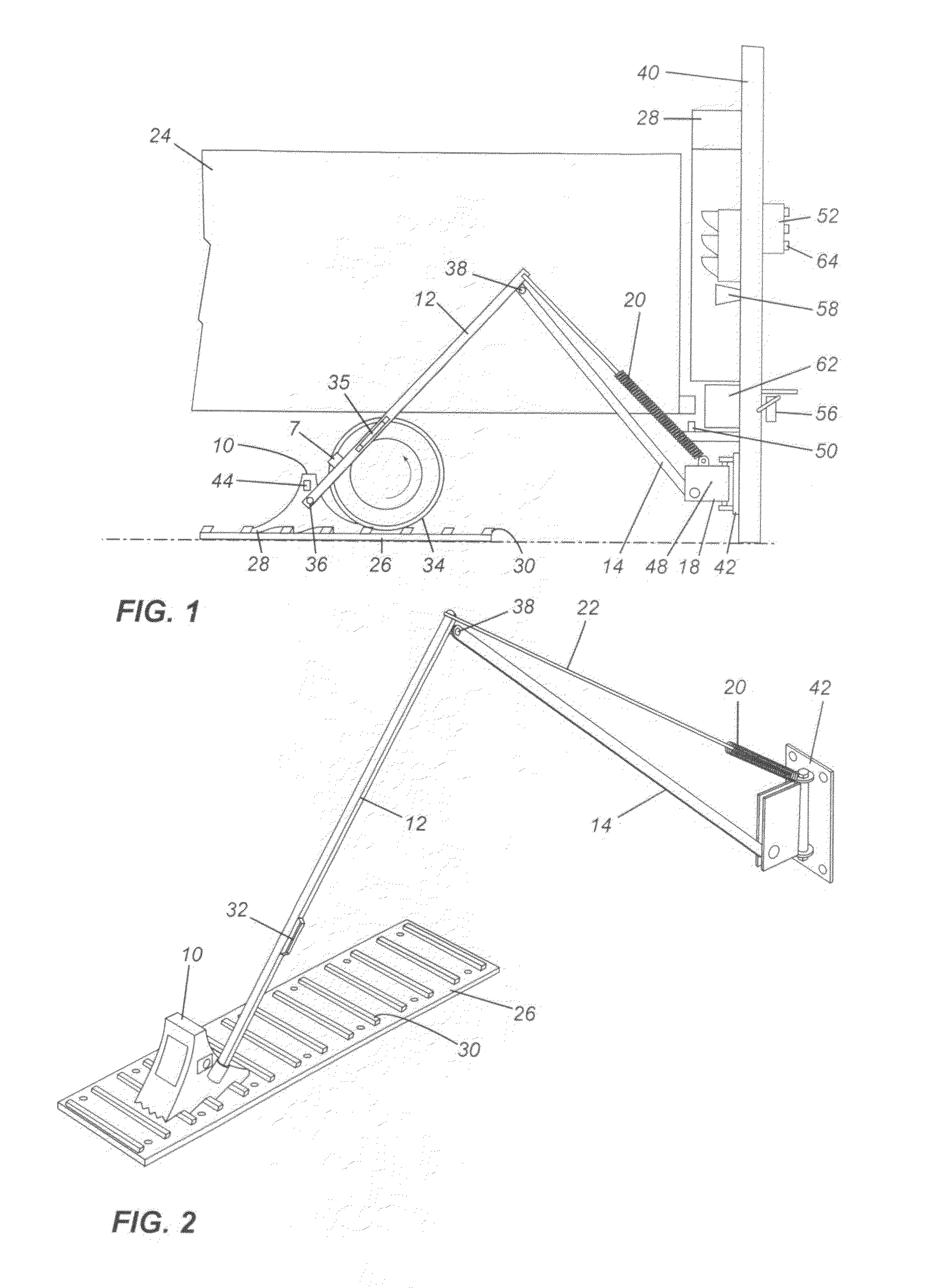

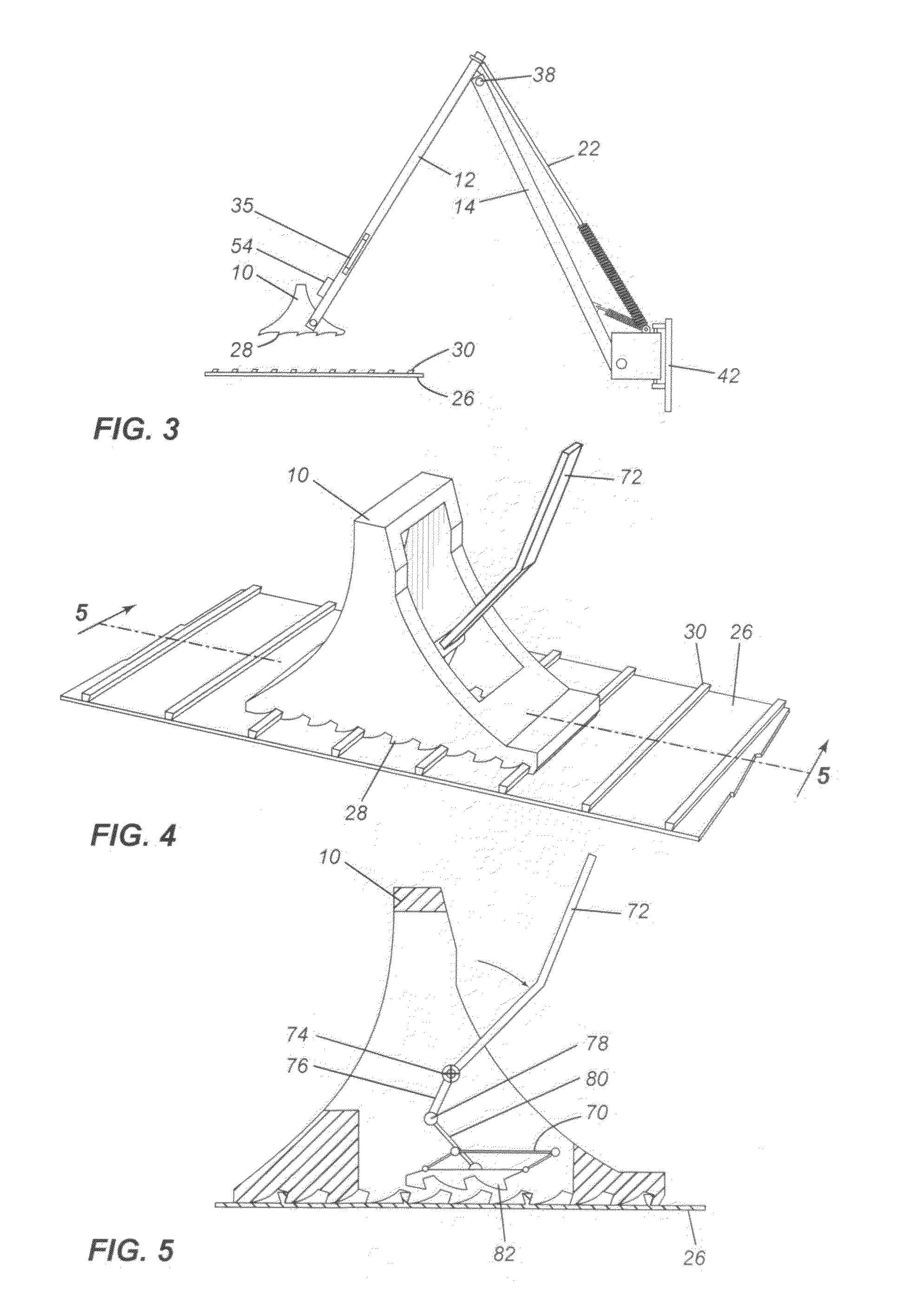

Wheel chock system

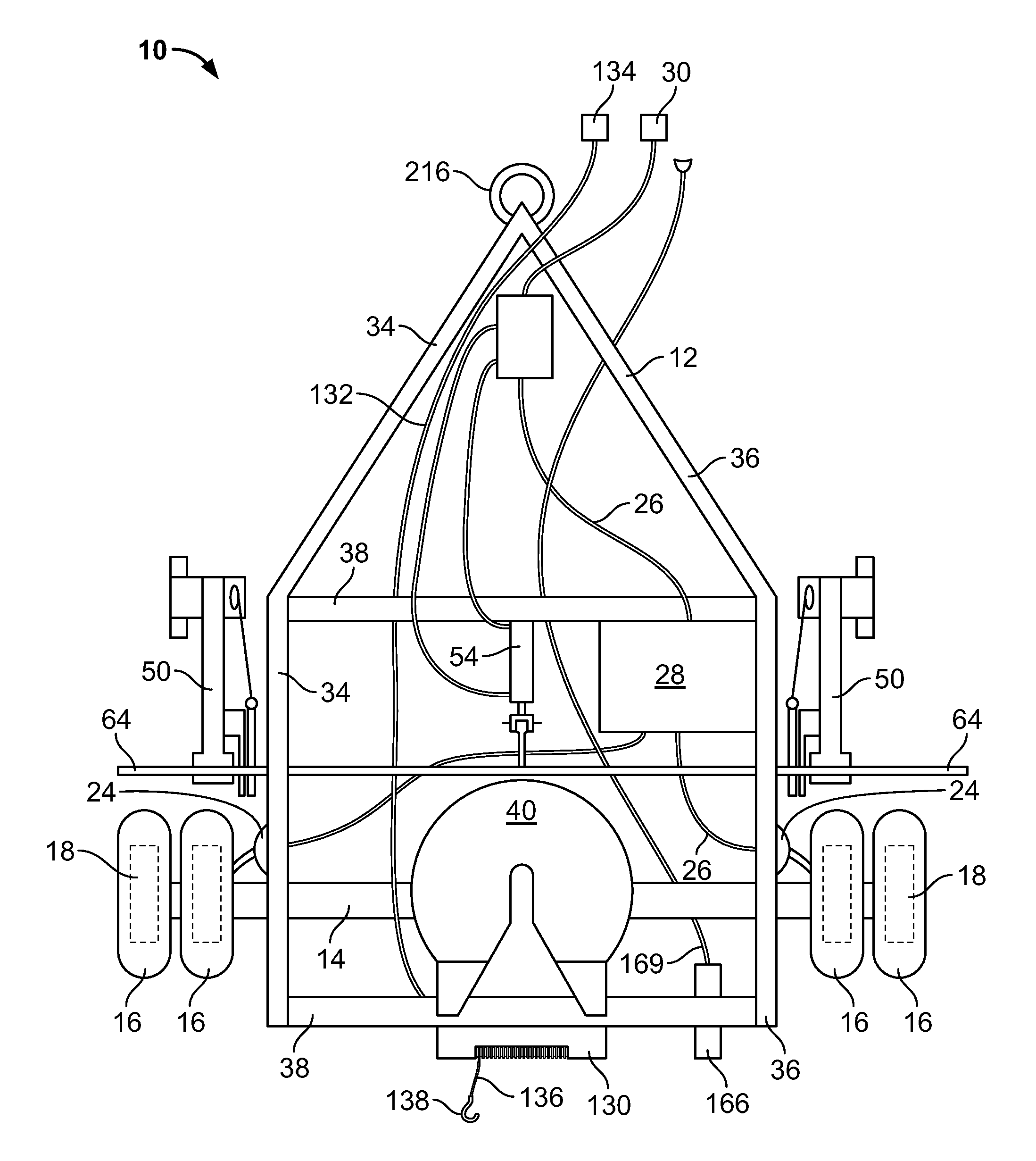

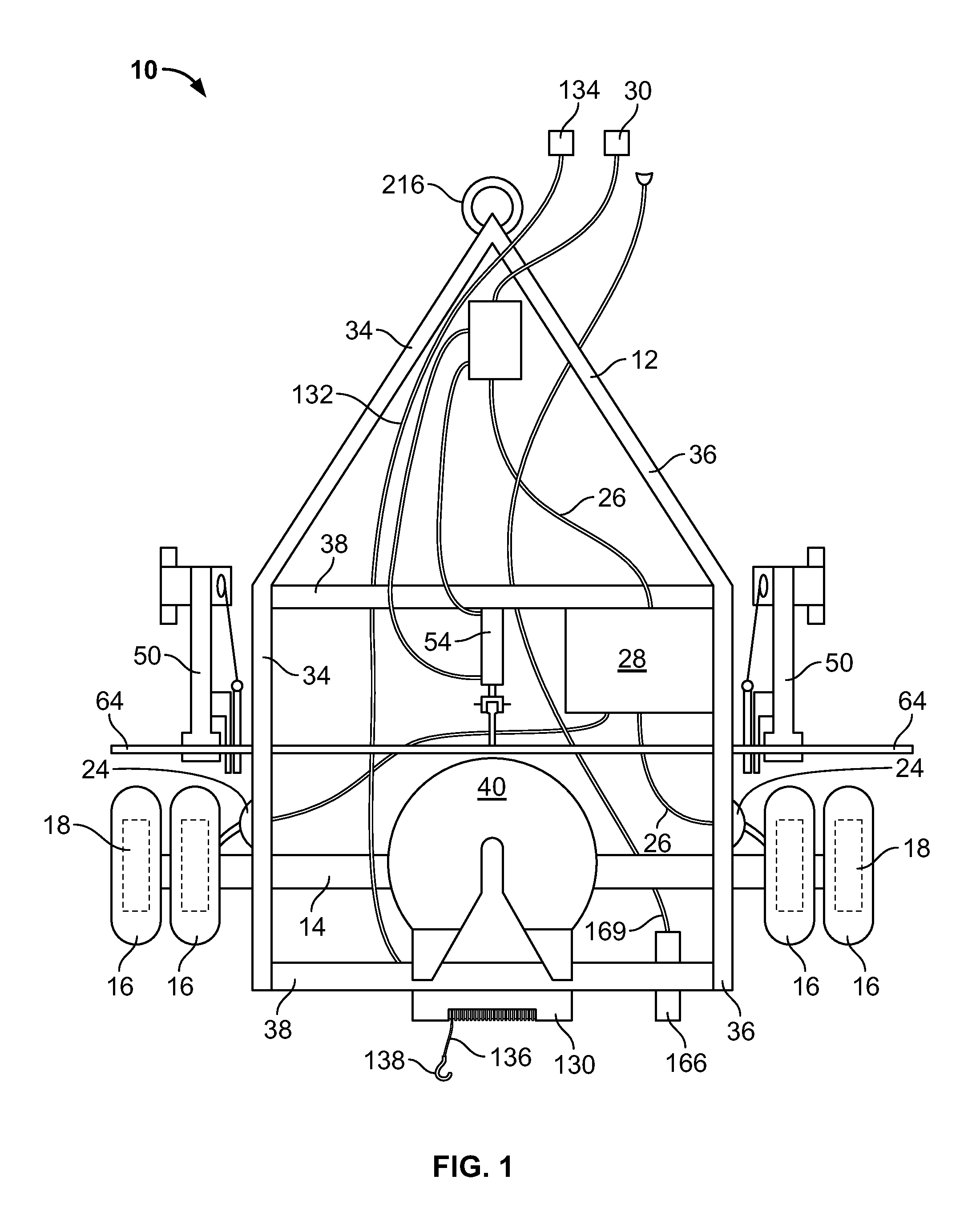

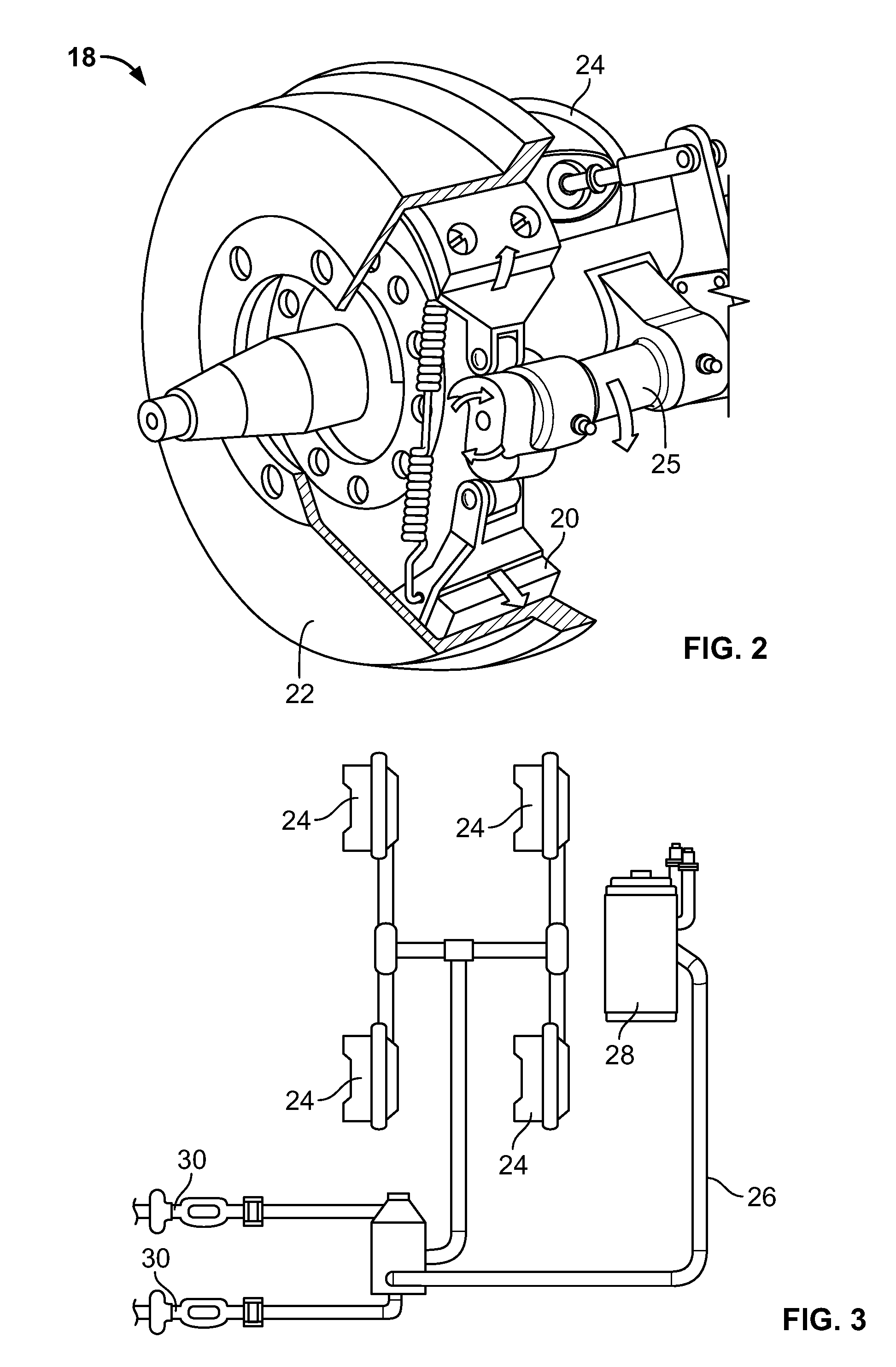

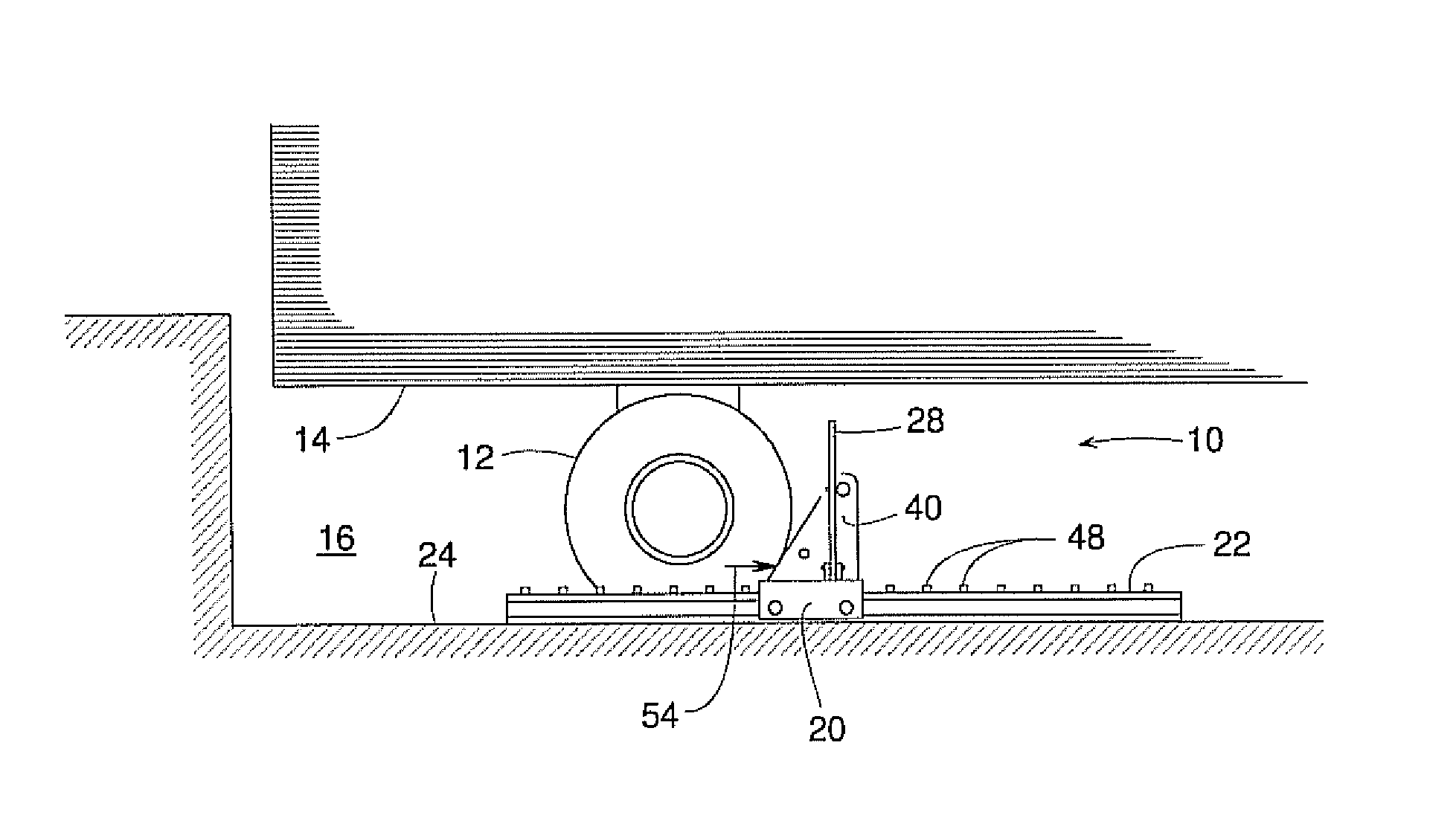

ActiveUS8307956B2Braking element arrangementsPortable braking systemSpray nozzleMechanical engineering

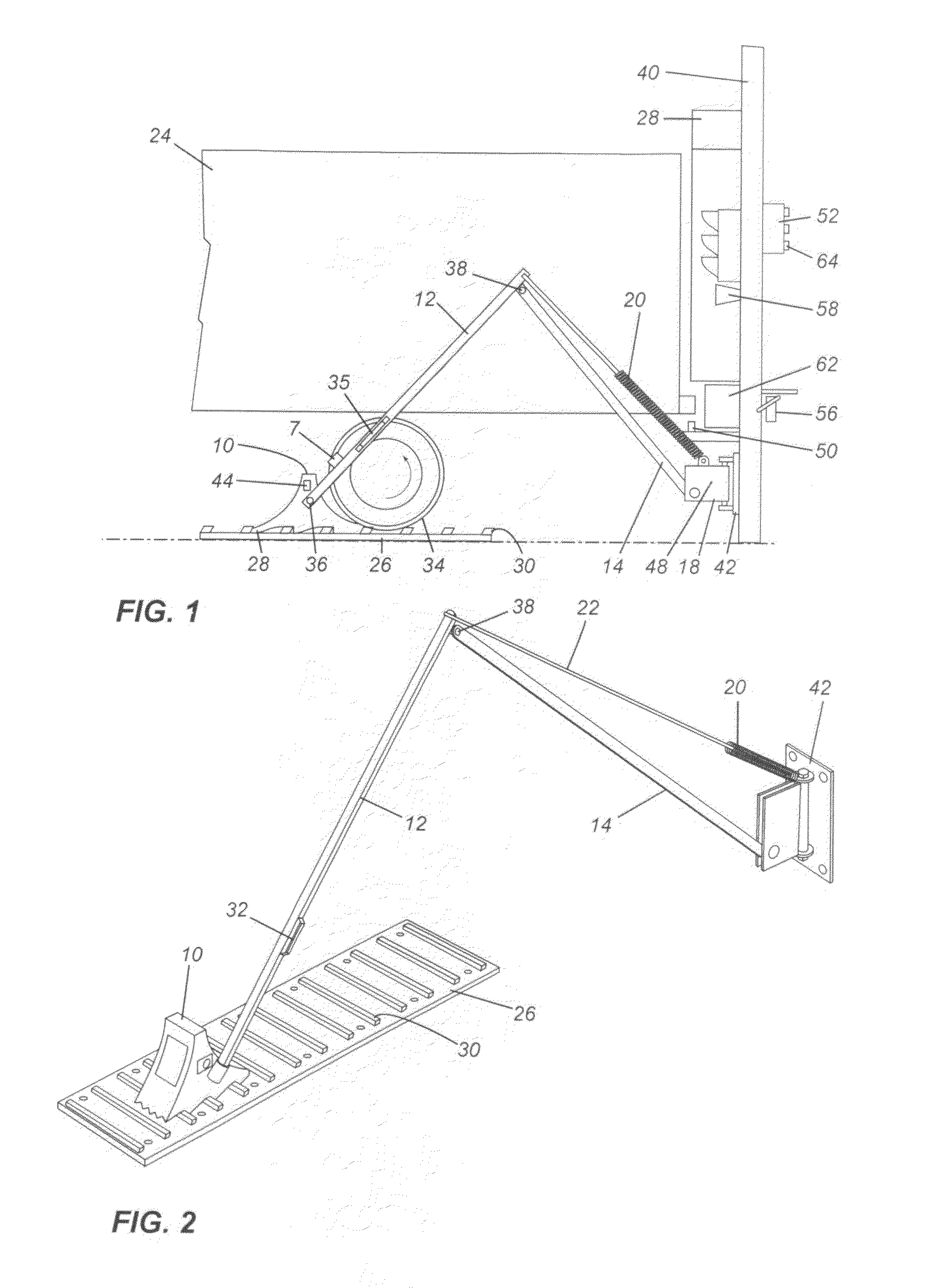

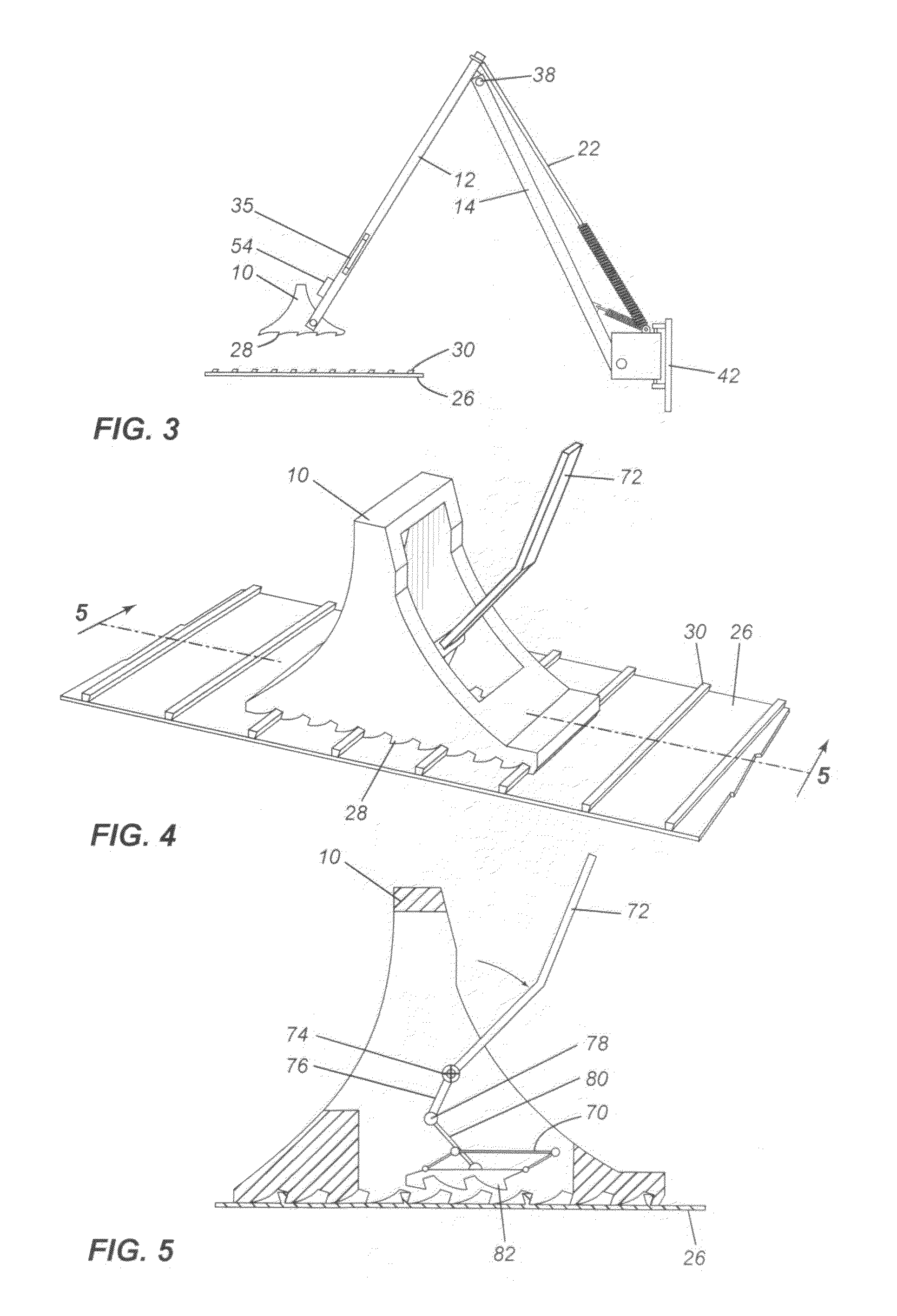

A wheel restraint for restraining a vehicle at a loading dock includes various features such as, a wheel chock supported by a spring loaded articulated arm with a spring that can be selectively tightened or released, a sensor that detects whether the chock is solidly against a base plate or floor, a bi-directional pivotal joint between the articulated arm and the wheel chock to ensure that the chock can sit squarely on a mating base plate, a wheel chock that meshes with a hydraulically actuated base plate, pivotal or otherwise movable backstops that prevent a wheel chock from sliding out of position, and a base plate cleaning system. The cleaning system might include a vehicle-actuated brush, fluid spray nozzles, electric heater and removable cover plates.

Owner:RITE HITE HLDG CORP

Tire-detecting wheel chock apparatus

InactiveUS20050226705A1Precise positioningEasy maintenancePortable braking systemConveyorsMicrocontrollerEquipment Operator

A wheel chock apparatus includes a chock body for chocking a tire of a vehicle such as a semi-trailer prior to loading or unloading the trailer by a towmotor at a docking bay. When properly positioned, the chock body prevents movement of the vehicle away from the docking bay during the loading or unloading operation. Such movement poses a possible hazard to the cargo being loaded or unloaded, to the equipment performing the loading / unloading operations, and to the operator of such equipment. The chock body includes a sensor mounted on or embedded in the body, which is capable of detecting a properly chocked tire. The sensor is electrically connected to a microcontroller programmed to control an indicator, such as a visual light or audible alarm, that will alert an equipment operator on the docking bay as to whether the driver of the vehicle has properly chocked the tires.

Owner:HENDRICKSON USA L L C

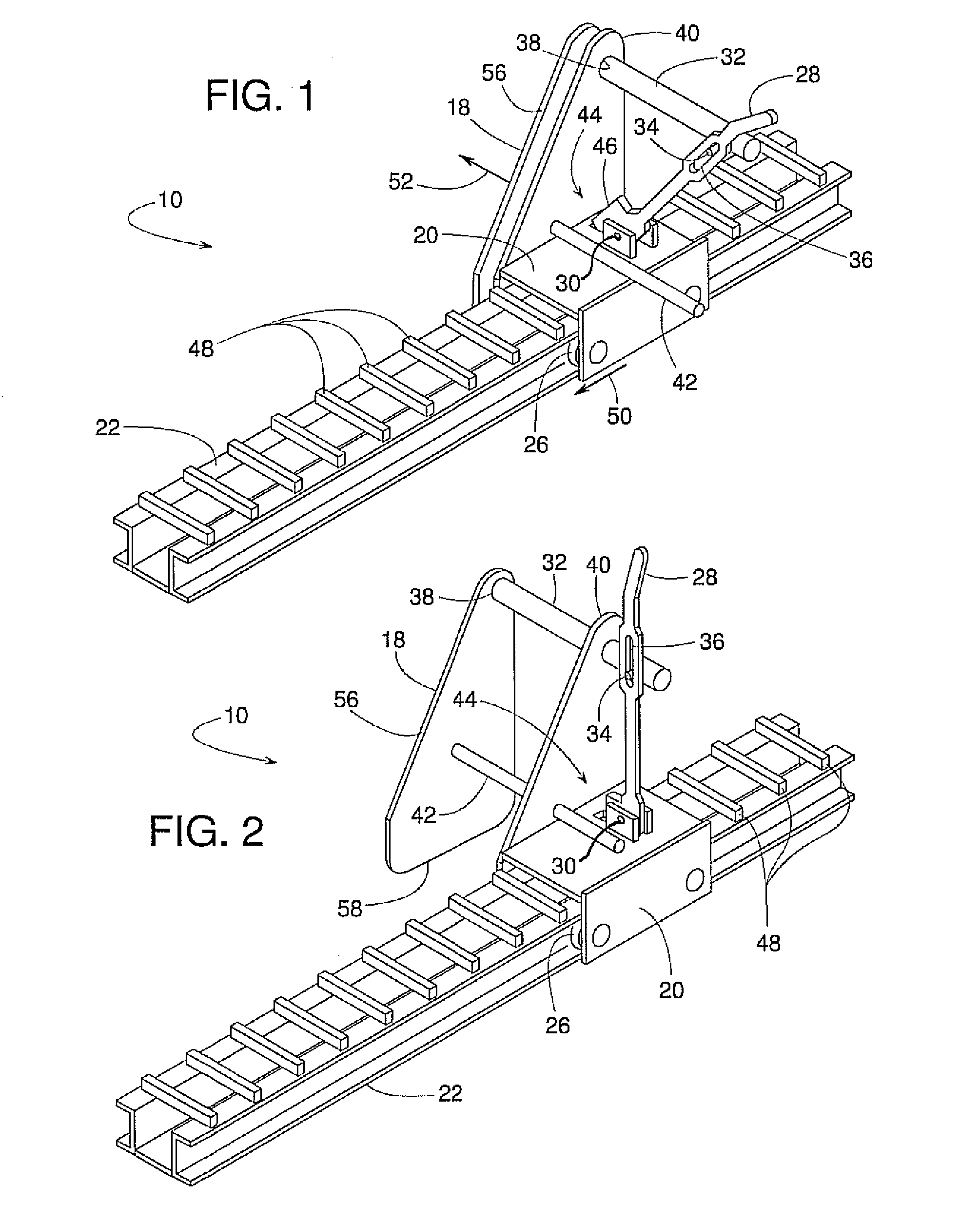

Manually positioned wheel chocking apparatus

InactiveUS20020141852A1Prevent movementRefuse transferringLoading/unloadingParking areaParking space

Manually positioned wheel chocking apparatus are disclosed. In a preferred embodiment, the chocking apparatus includes a track secured adjacent a parking area; a movable chock; and means for temporarily fixing the chock to the track to substantially prevent the chock from moving. The movable chock has a surface which can be selecidvely positioned within the parking space at a location for engaging a tire of a vehicle. It also includes an extension for operatively engaging the track. The fixing means may optionally comprise a pin sized to mate with a bore in a track or a, frictional lock, preferably constructed as an over-center toggle.

Owner:RITE HITE HLDG CORP

Chock system

ActiveUS8590674B2Strong securityPrevent movementBraking element arrangementsPortable braking systemMechanical engineeringWheel chock

A wheel chock restraint system which comprises a wheel chock having a base, a plurality of teeth extending outwardly from the base, the teeth extending in a first direction, and a locking member mounted within the chock, the locking member having a plurality of locking member teeth extending from a bottom thereof, the locking member teeth extending in a second direction generally opposed to the first direction, and an arrangement for moving the locking member in a generally vertical direction.

Owner:9172 9863 QUEBEC

Dual purpose track for holding wheel chocks and strap clips to tie down dirt bikes to trailers

ActiveUS20050238455A1Improve reliabilityInexpensive to manufacturerPortable braking systemFlexible elementsEngineeringDual purpose

The dual purpose track comprises a unitary elongated body having a longitudinal axis and a raised center section extending along the axis from one end to the other. The center section includes a flat base with downwardly tapering sides terminating in laterally outwardly extending flanges. The flat base which extends along the longitudinal axis is provided with longitudinally spaced apart elongated slots, as an example, spaced every four inches, which extend lengthwise along the axis. Each slot is configured to receive either the head of the bolt of a wheel chock used to retain a dirt bike along the floor of a trailer or a tie down fastening device. A strap is connected between the tie down device and the handle bar of the dirt bike to assist in retaining the bike in a fixed position. Thus, the track serves two purposes, namely, it holds the wheel chocks and the anchoring devices for the straps.

Owner:TOTEFF THOMAS S

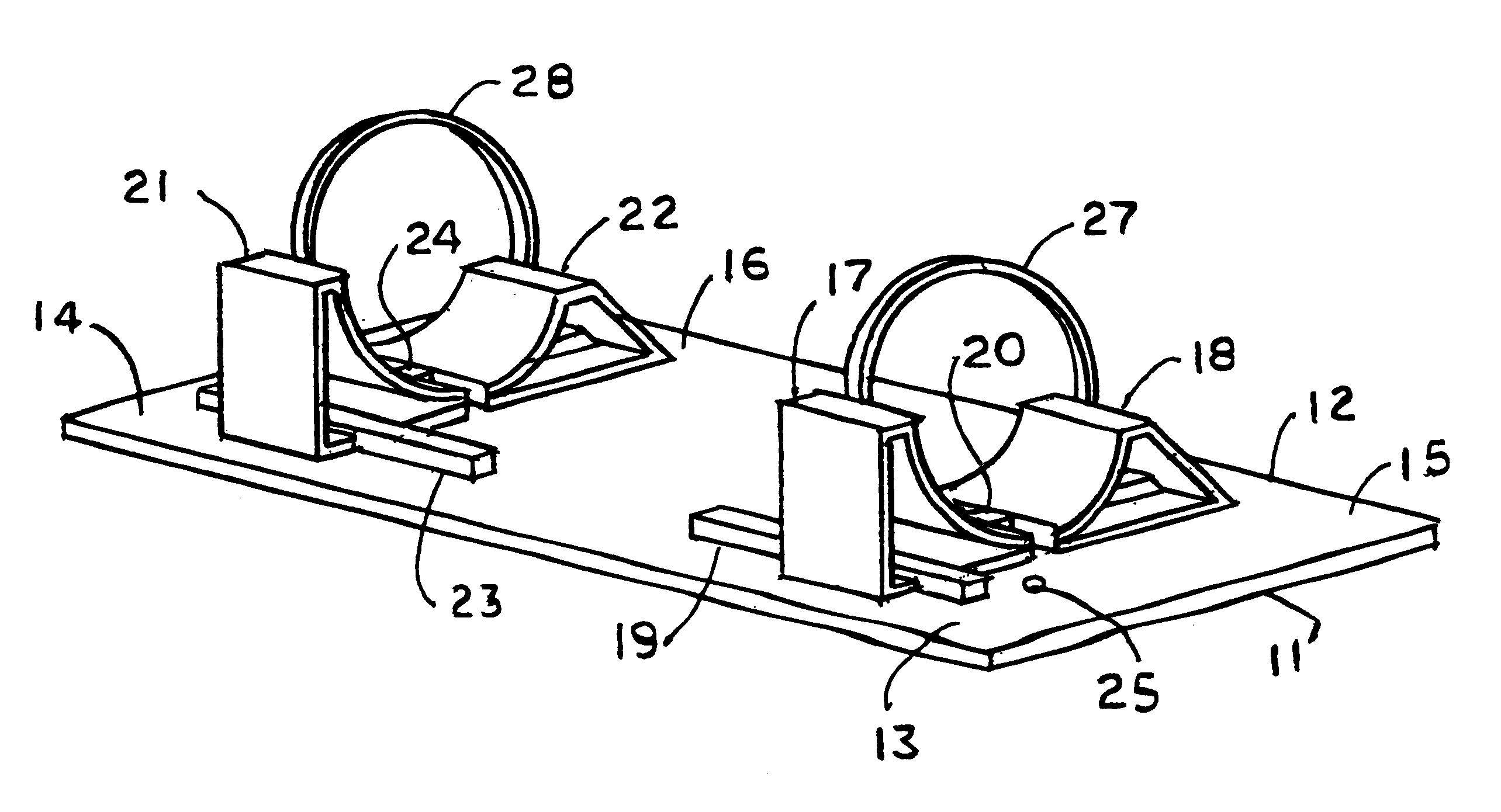

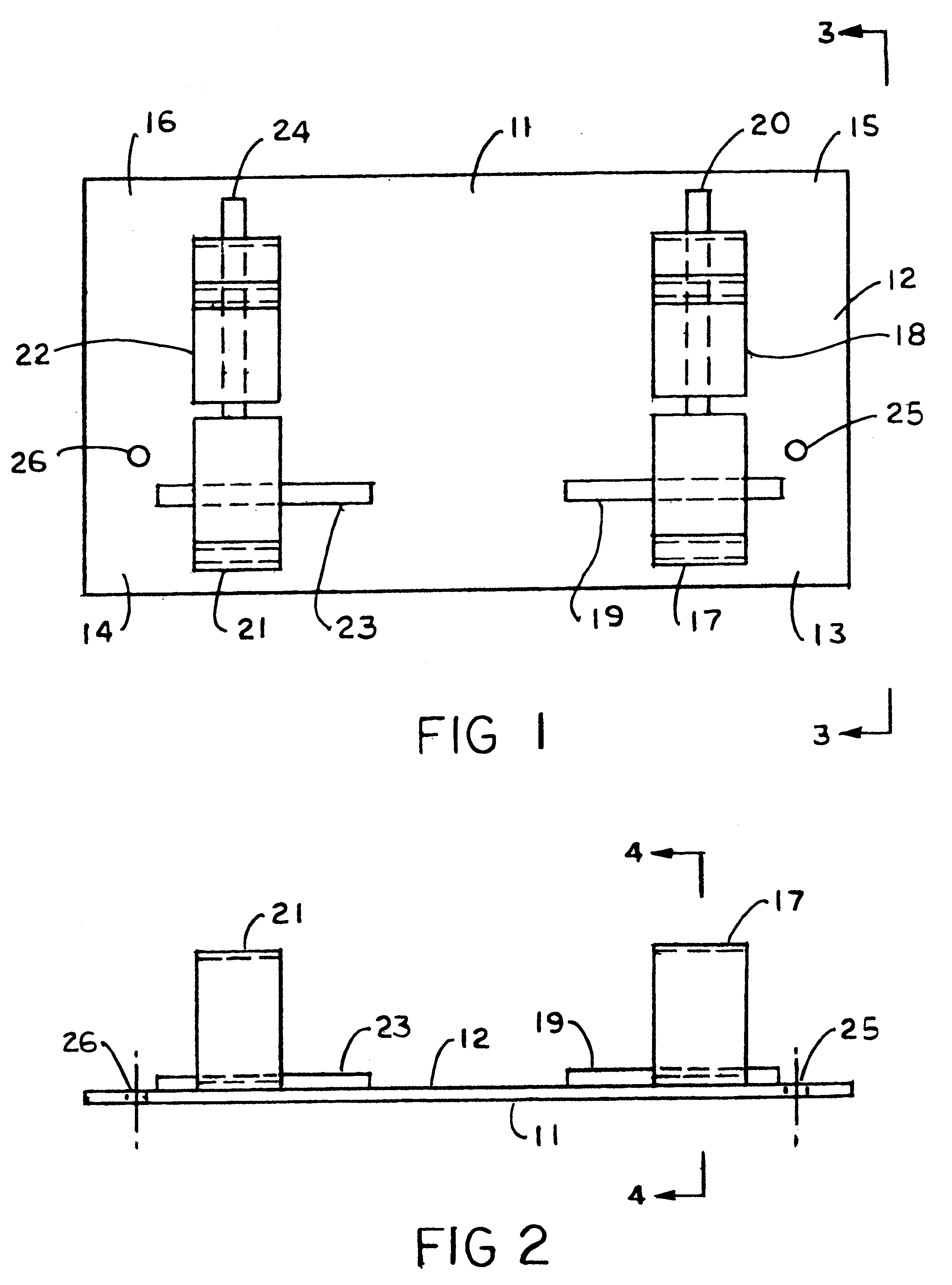

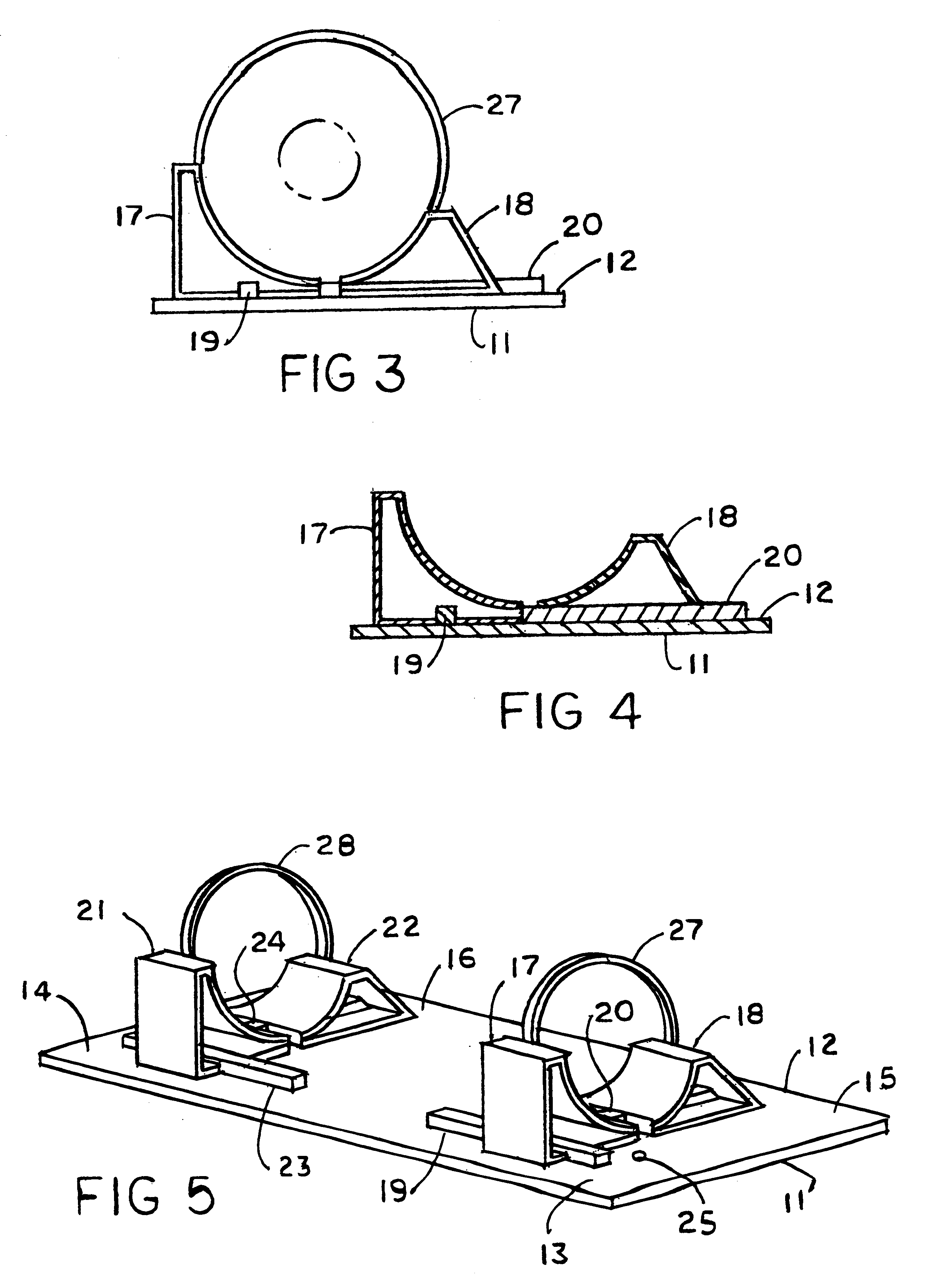

Compact adjustable wheel chock assembly for retainment of multi-size wheels

A novel compact adjustable wheel chock assembly for retainment of multi-size wheels (11) comprising of a one-piece flat rigid base plate (12) having a front-right surface (13), a front-left surface (14), a rear-right surface (15), a rear-left surface (16), a front-right wheel chock (17), mounted on the front-right surface (13) having a sideways adjustment device (19), a rear-right wheel chock (18) located on the rear-right surface (15), having a forward-backward adjustment device (20), a front-left wheel chock (21), mounted on the front-left surface (14), having a sideways adjustment device (23), a rear-left wheel chock (22) located on the rear-left surface (16), having a forward-backward adjustment device (24), an attachment hole (25) located on the front-right surface (13) and an attachment hole (26) located on the front-left surface (14) both having a mechanical device to attach the one-piece flat rigid base plate (12) to a supporting substructure surface, a tie-down strap (27) having a mechanical device to attach the tie-down strap (27) to the top of the front-right wheel chock (17) and attach opposite end of the tie-down strap (27) to the top of the rear-right wheel chock (18), a tie-down strap (28)having a mechanical device to attach the tie-down strap (28)to the top of the front-left wheel chock (21) and attach opposite end of the tie-down strap (28) to the top of the rear-left wheel chock (22).

Owner:GUBLER TYLER WILSON +1

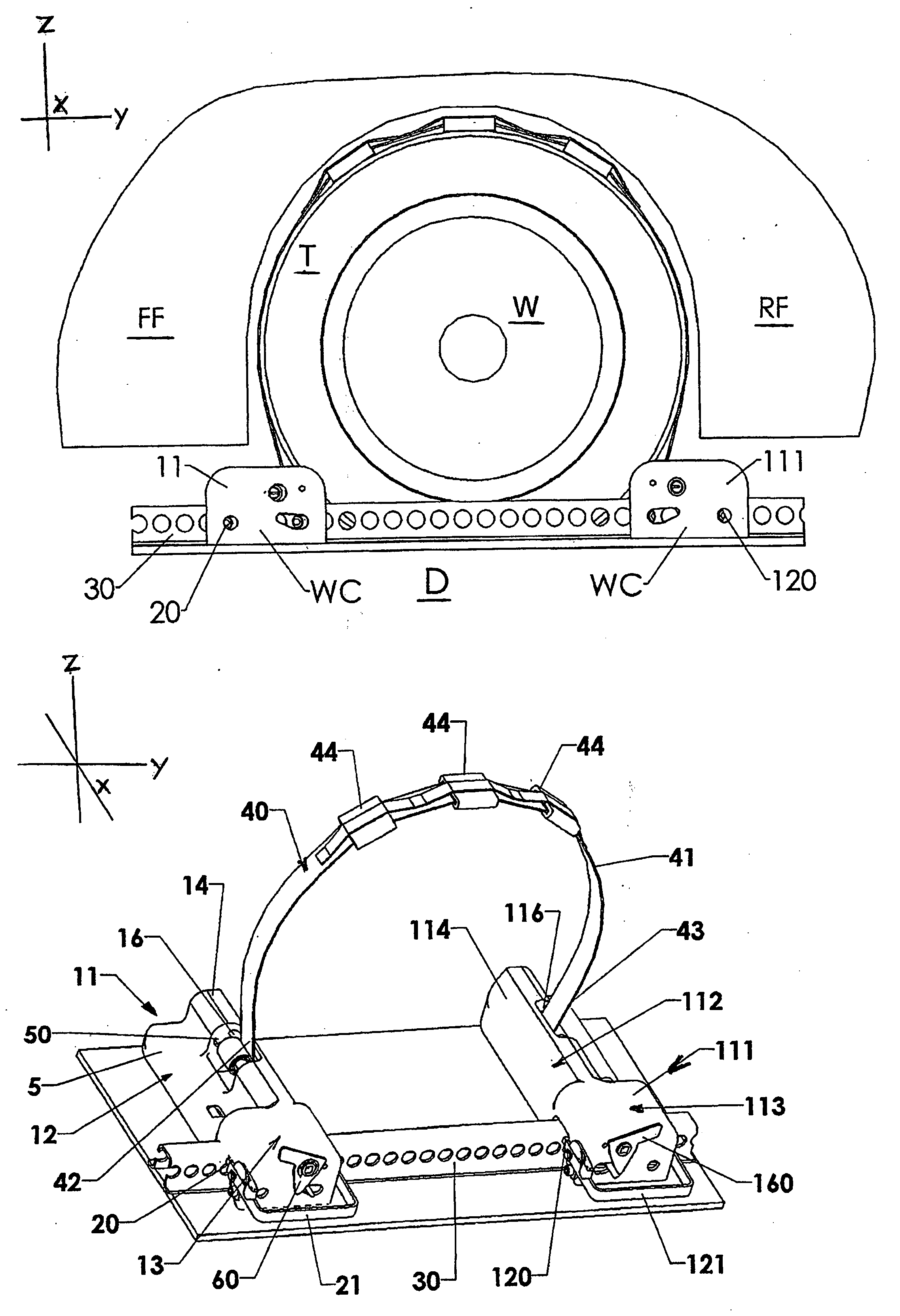

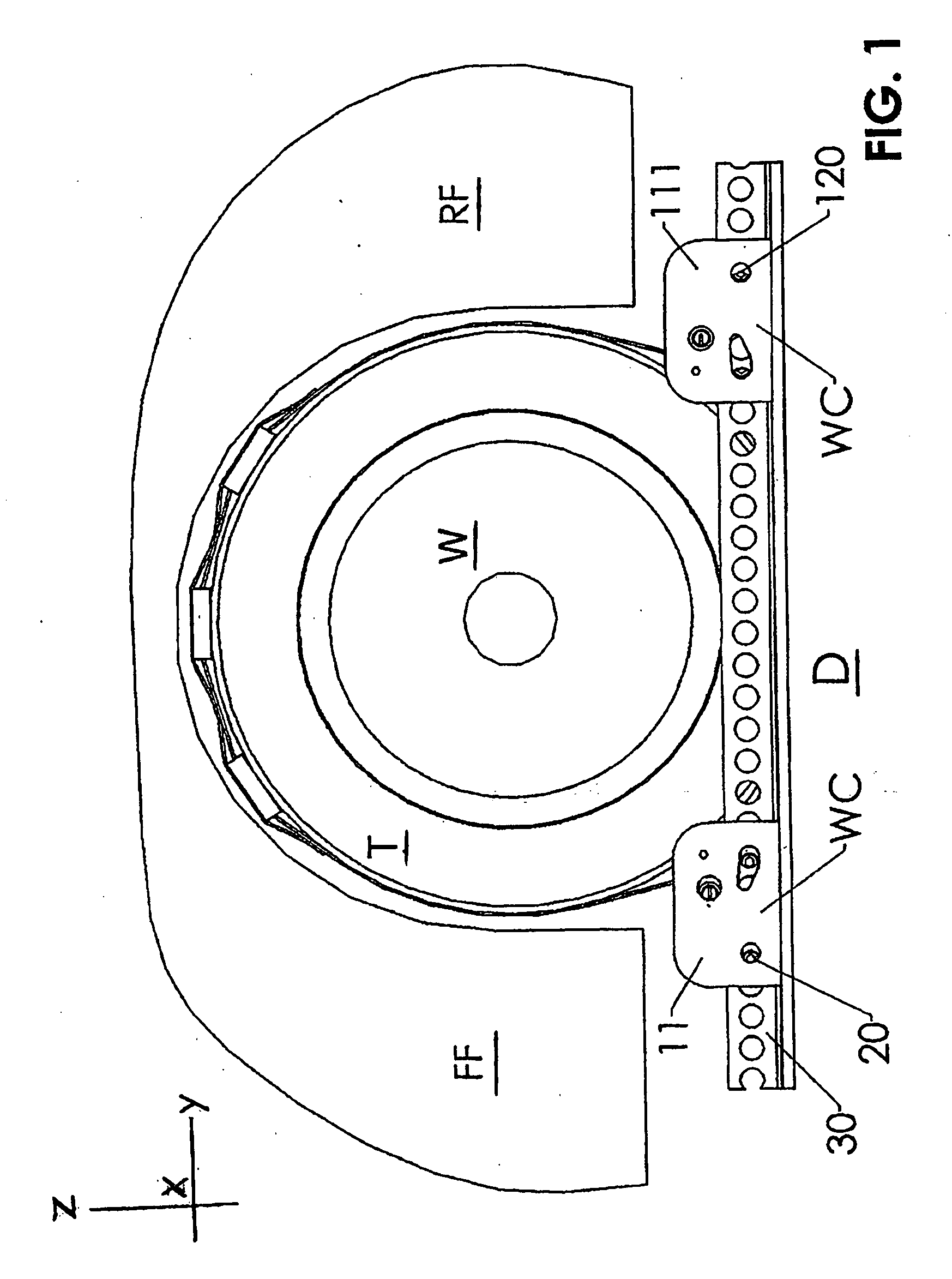

Wheel chock

InactiveUS7040461B2Effective and easy to useEfficient storagePortable braking systemLeading edgeEngineering

A wheel chock (10) configured for placement under a resting rubber tired wheel (W), such as a wheel found on a powered vehicle, to maintain the wheel (W) at rest is disclosed. The wheel chock (10) broadly includes a body (12) that defines an internal chamber (14) in communication with an open face (16) presented by the body (12). The body (12) presents a prism-like configuration having a generally triangular shape and includes a pair of oppositely spaced sidewalls (18, 20), a rear wall (22) extending between and adjoining the sidewalls (18,20), and a wheel-supporting surface (24) extending between and thereby enclosing the walls (18,20,22). The wheel-supporting surface (24) presents a low profile, arcuate leading tire-engaging edge (34). The arcuate leading edge (34) substantially complements the contour of the tire and enables the chock (10) to be easily placed under the wheel (W) in an optimal operating position i.e., in close adjacent alignment with the wheel (W) so that at least a portion of the majority of the circumferentially extending treads of the rubber tire of the wheel (W) engage at least a portion of the chock (10) with a minimal exertion of force and effort by the user. The internal chamber (14) in communication with the open face (16) enables the body (12) of the chock (10) to be stackably nested within another similarly configured wheel chock to provide a compact, space-efficient storage of the chocks that facilitates ready portability for transportation of a pair or more of the chocks in the vehicle.

Owner:HOPKINS MFG

Wheel chock with restraint

A wheel chock for restraining movement of a vehicle tire on a supporting grating during transit includes a base, a grate lock mechanism for locking the base to the grating, and a ramp on the base for engagement with a circumference of a vehicle tire. A strap connected with the base is extensible around the vehicle tire to help restrain movement of the tire on the grating. The chock includes a retractor for retracting the strap and for taking up slack that forms in the strap during transit.

Owner:MIDWEST PRECISION PRODS

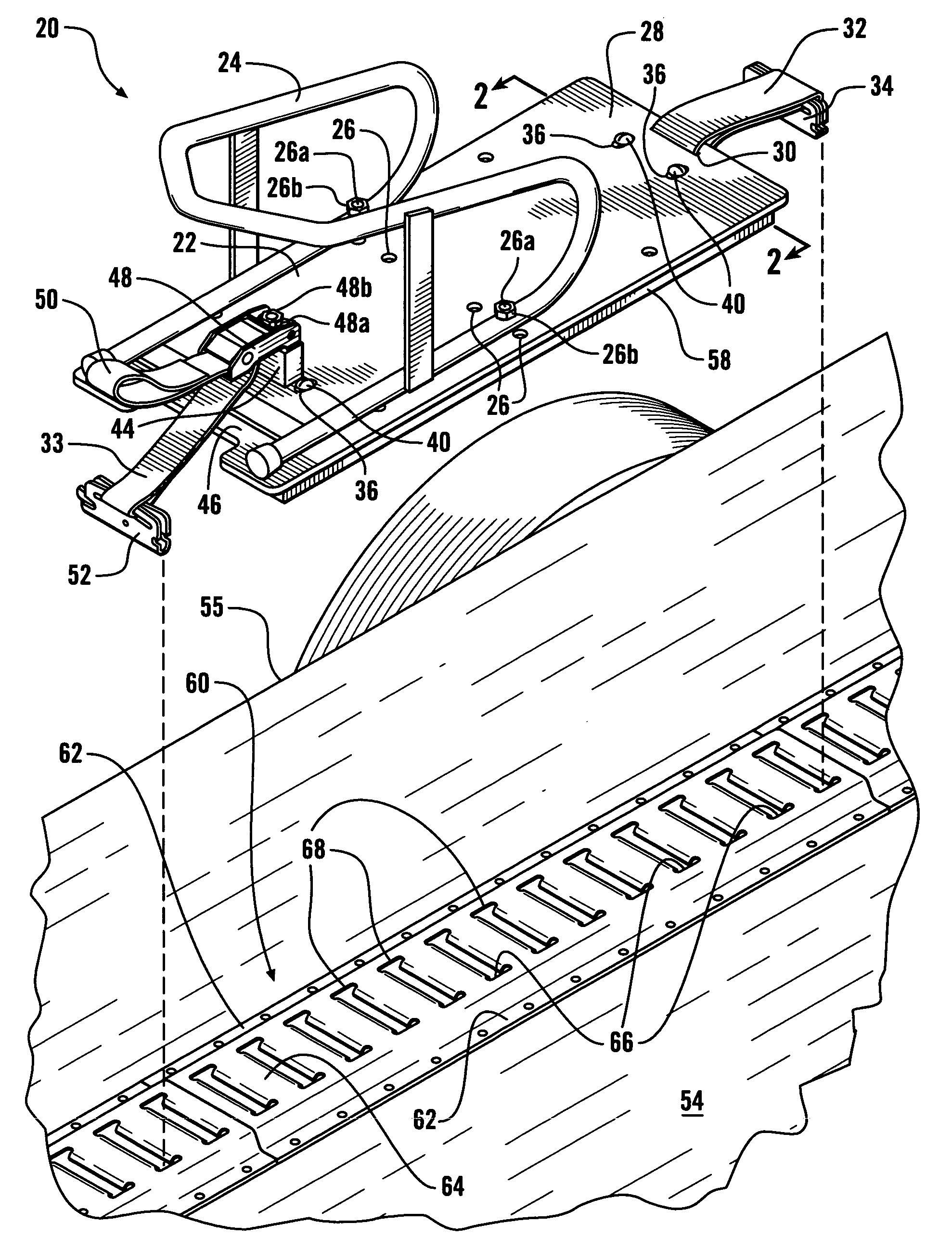

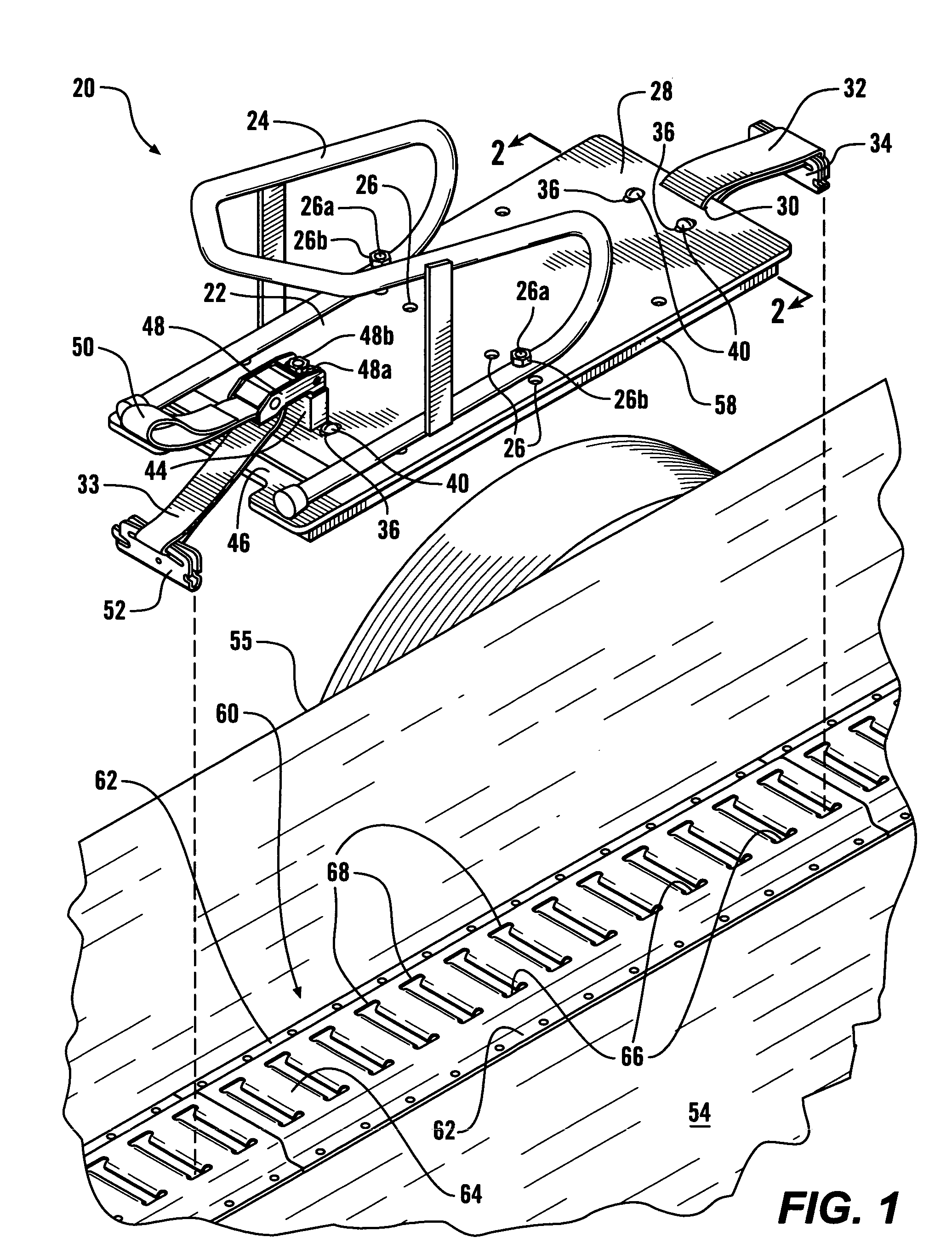

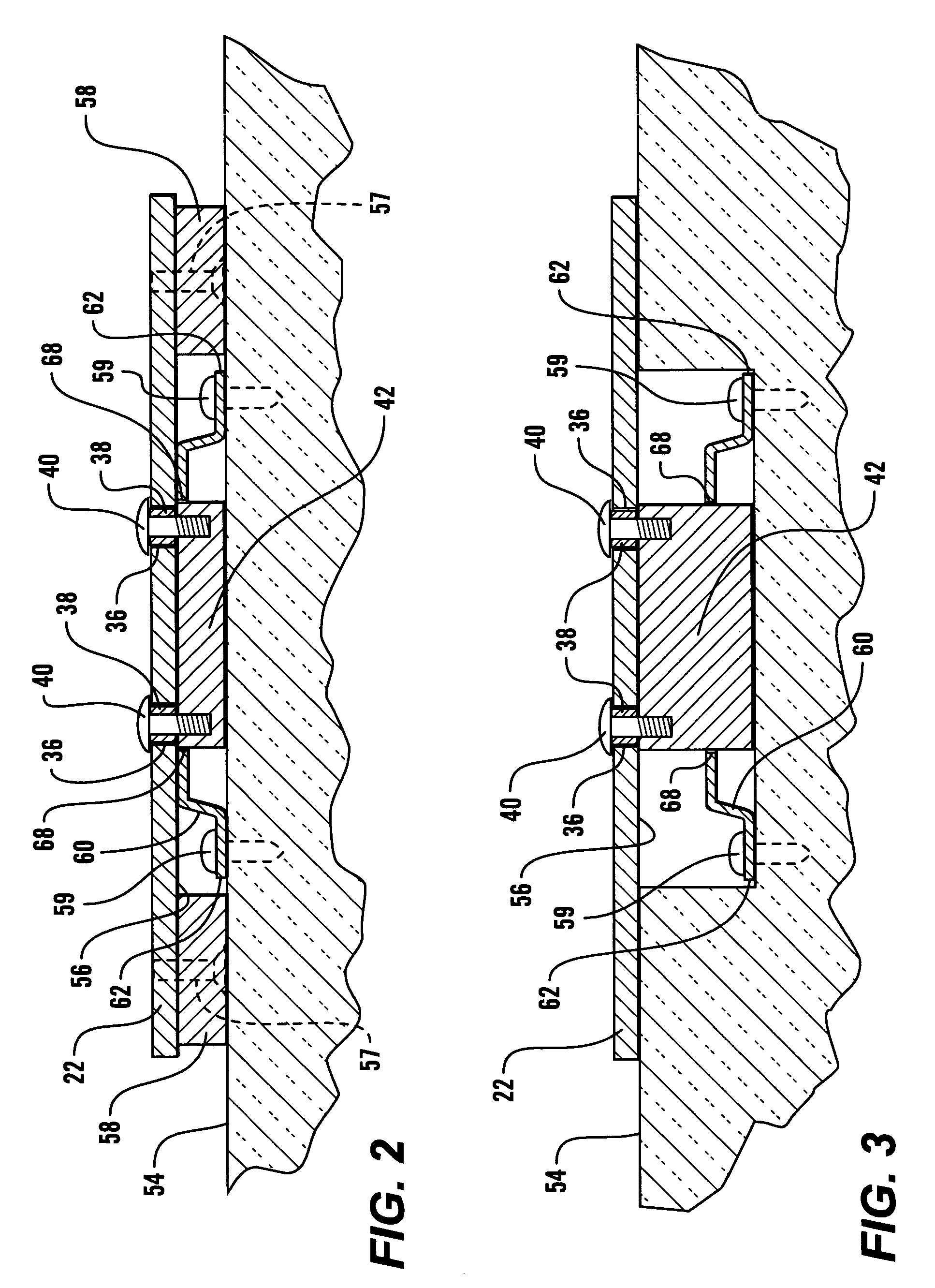

Wheel chock mounting plate assembly

InactiveUS6863481B2Easy to disassembleTravelling carriersPortable braking systemControl systemEngineering

A wheel chock mounting plate assembly that can be easily attached to and removed from the load surface of a trailer or other transporting vehicle. The wheel chock mounting plate assembly attaches to a logistic track, standard in the field of cargo control systems, that is fixed to the load surface. The wheel chock mounting plate is precisely drilled and machined to receive a wheel chock. The mounting plate assembly has a fitting adapted to engage the logistic track attached with a logistic strap to the rear end of the mounting plate. At least one longitudinally slideable key is adapted to extend below the mounting plate to fit in a transverse opening of the logistic track to prevent the mounting plate from moving in a direction transverse to the length of the logistic track. The front of the mounting plate has a fitting adapted to engage the logistic track and secure the mounting plate assembly in the longitudinal direction of the logistic track.

Owner:PINGEL ENTERPRISE

Trailer docking repositionable support

ActiveUS8528929B2Braking element arrangementsVehicle fittings for lifting and manoeuvringEngineeringMechanical engineering

Owner:STABILOCK

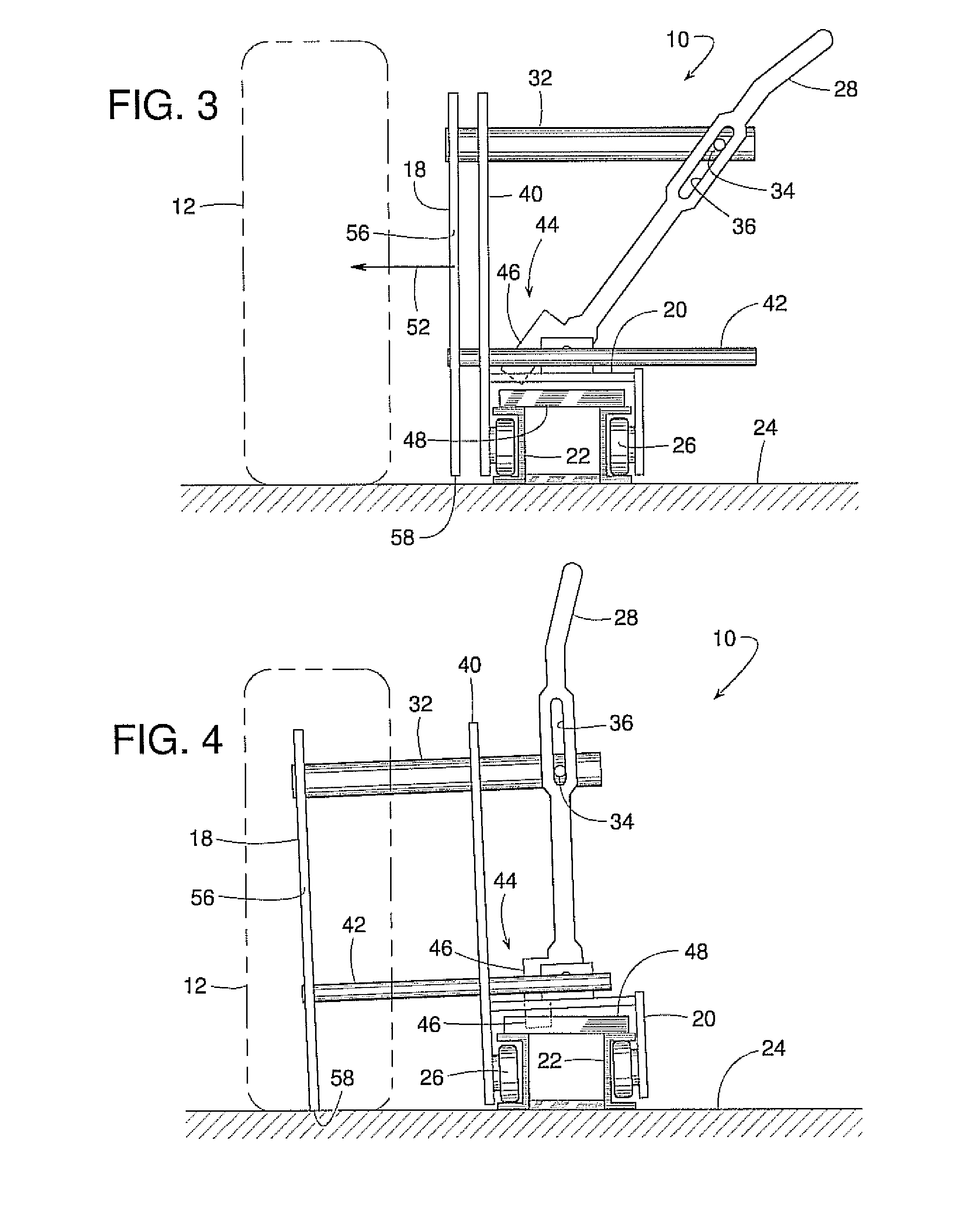

Manual wheel chocks with automatic positive locking

ActiveUS20090194375A1Braking element arrangementsPortable braking systemEngineeringMechanical engineering

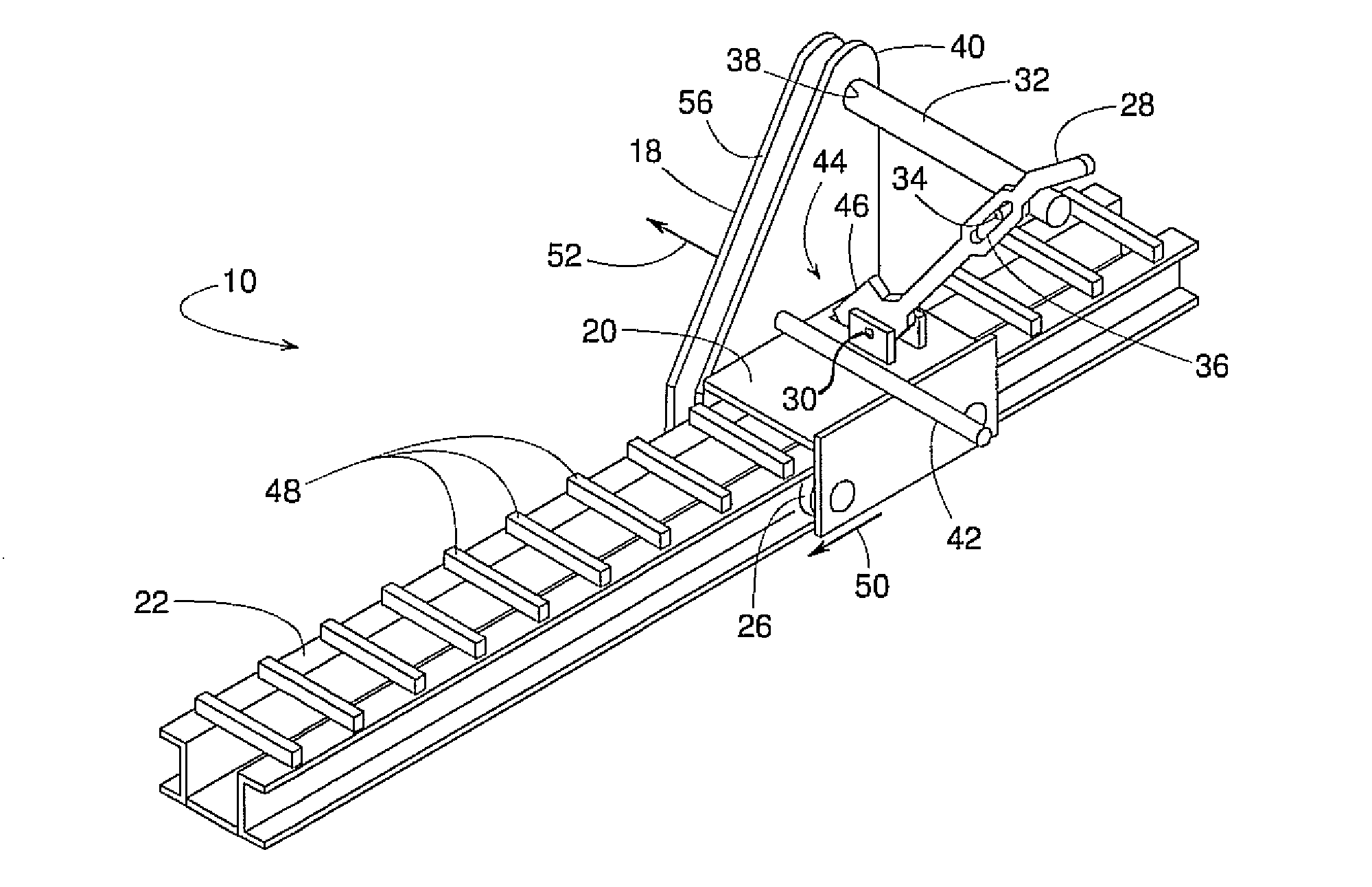

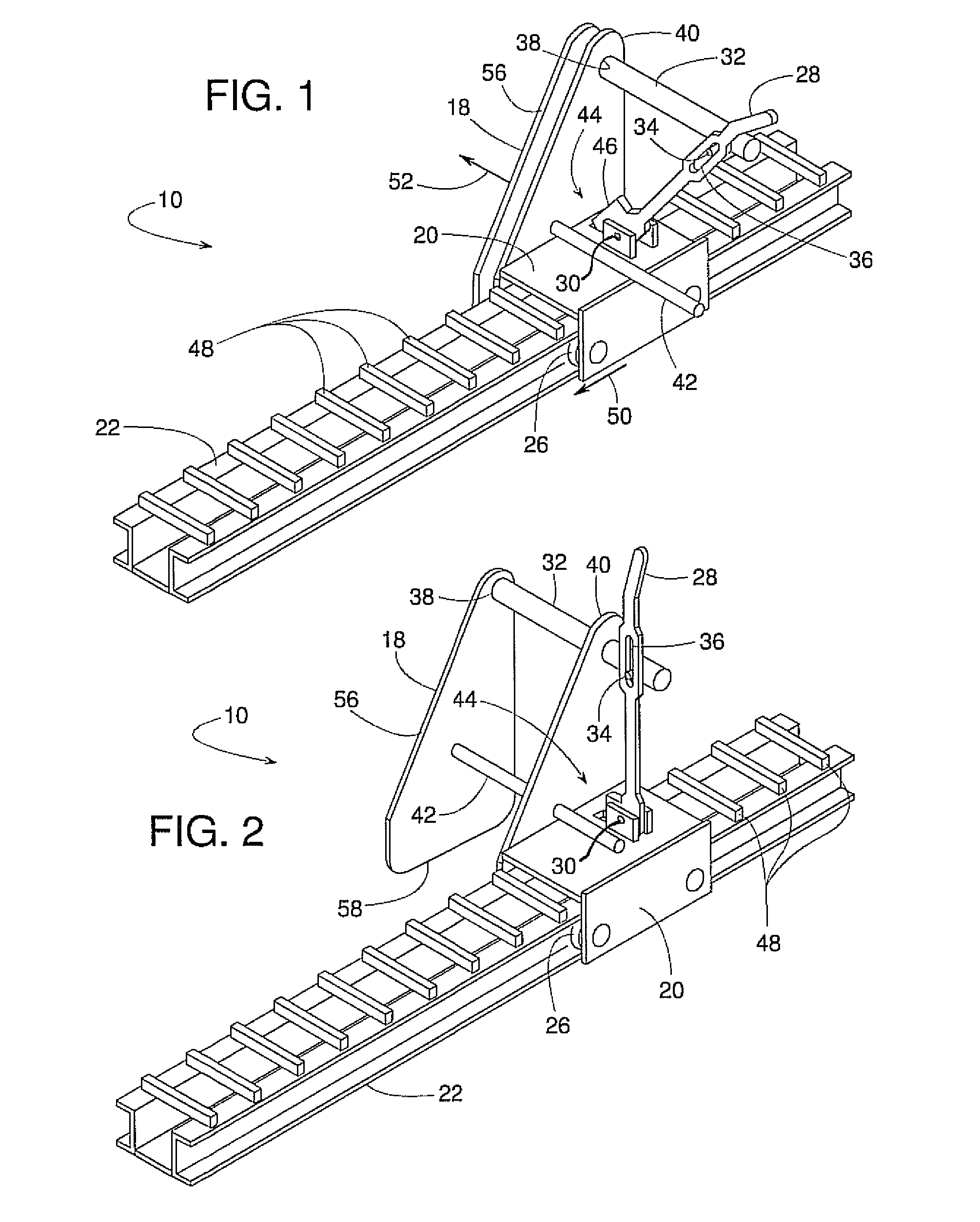

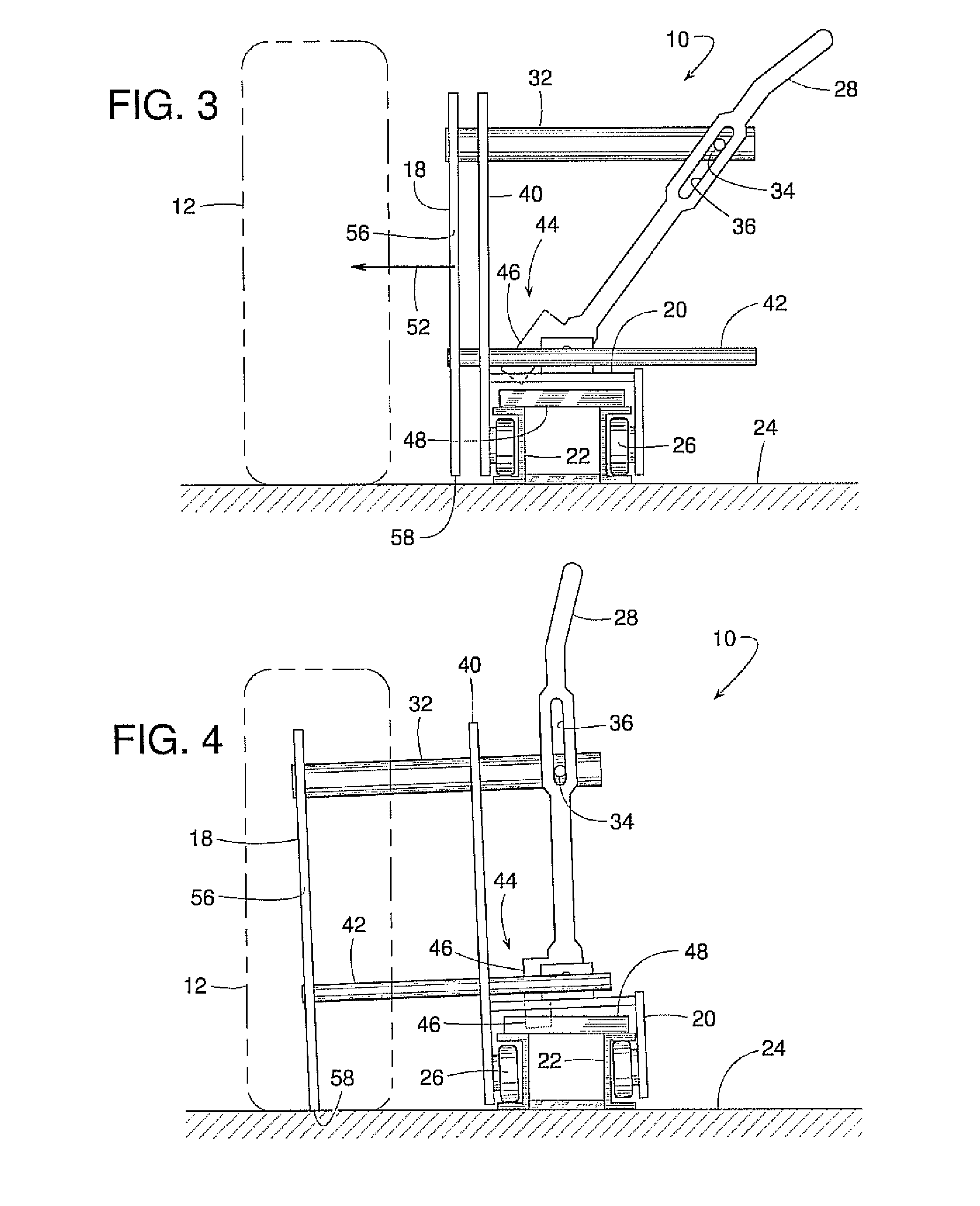

A wheel restraint includes a wheel chock that is manually movable between a retracted position clear of a wheel of a vehicle at a loading dock and an operative position to block the path of the wheel. In the retracted position, the chock can be manually moved freely along a track that is mounted to a driveway of the dock. When the chock is manually moved from its retracted position to its operative position, a locking feature automatically restricts the movement of the chock relative to the track. When the chock is manually moved back to its retracted position, the locking feature automatically disengages. Although the wheel chock is connected to a track, most of the force exerted by the wheel against the chock is transmitted directly from the chock to the driveway.

Owner:RITE HITE HLDG CORP

Low-profile wheel chock assembly

ActiveUS20090208304A1Avoid damageMore roomItem transportation vehiclesWagons/vansControl theoryMotorized vehicle

A low elevational profile of each of a pair of first and second wheel chocks for restraining a current “low-drag” motor vehicle in a carrier, such as a railway car, is derived from each wheel chock having an internally webbed, elongated stepped-box body terminated with a relatively short rectangular box having its inner wall integrally formed with the stepped-box body. The body of the first chock is essentially a mirror-image of the second chock body. The low profile of a wheel chock allows each to be positioned under a vehicle the rocker panel of which has its lower edge only 148 mm (5.82 inches) above the surface upon which the vehicle's tire rests, so that the installed chock height is reduced to 47.6 mm (1.87″) under the components of the vehicle's body. The assembly may include a pair of “active” chocks; or, one active chock and one anchor chock. A single window in the upper portion of the stepped-box provides access for a strap of a wheel harness, which strap is wrapped around a torque tube in an active chock. The torque tube in one chock is rotatable in a direction opposite to that of the torque tube of the other chock. With a pair of active chocks, hooks on straps of a prior art harness are eliminated because it is difficult and time-consuming to manipulate a tire harness with its straps and hooks to secure the tire between the wheel chocks. When one chock is an anchor chock, one end of the strap is provided with a hook which is anchored to a rod or tube which is substituted for the rotatable torque tube.

Owner:GE GLOBAL SOURCING LLC

Manual wheel chocks with automatic positive locking

ActiveUS8590673B2Braking element arrangementsPortable braking systemEngineeringMechanical engineering

A wheel restraint includes a wheel chock that is manually movable between a retracted position clear of a wheel of a vehicle at a loading dock and an operative position to block the path of the wheel. In the retracted position, the chock can be manually moved freely along a track that is mounted to a driveway of the dock. When the chock is manually moved from its retracted position to its operative position, a locking feature automatically restricts the movement of the chock relative to the track. When the chock is manually moved back to its retracted position, the locking feature automatically disengages. Although the wheel chock is connected to a track, most of the force exerted by the wheel against the chock is transmitted directly from the chock to the driveway.

Owner:RITE HITE HLDG CORP

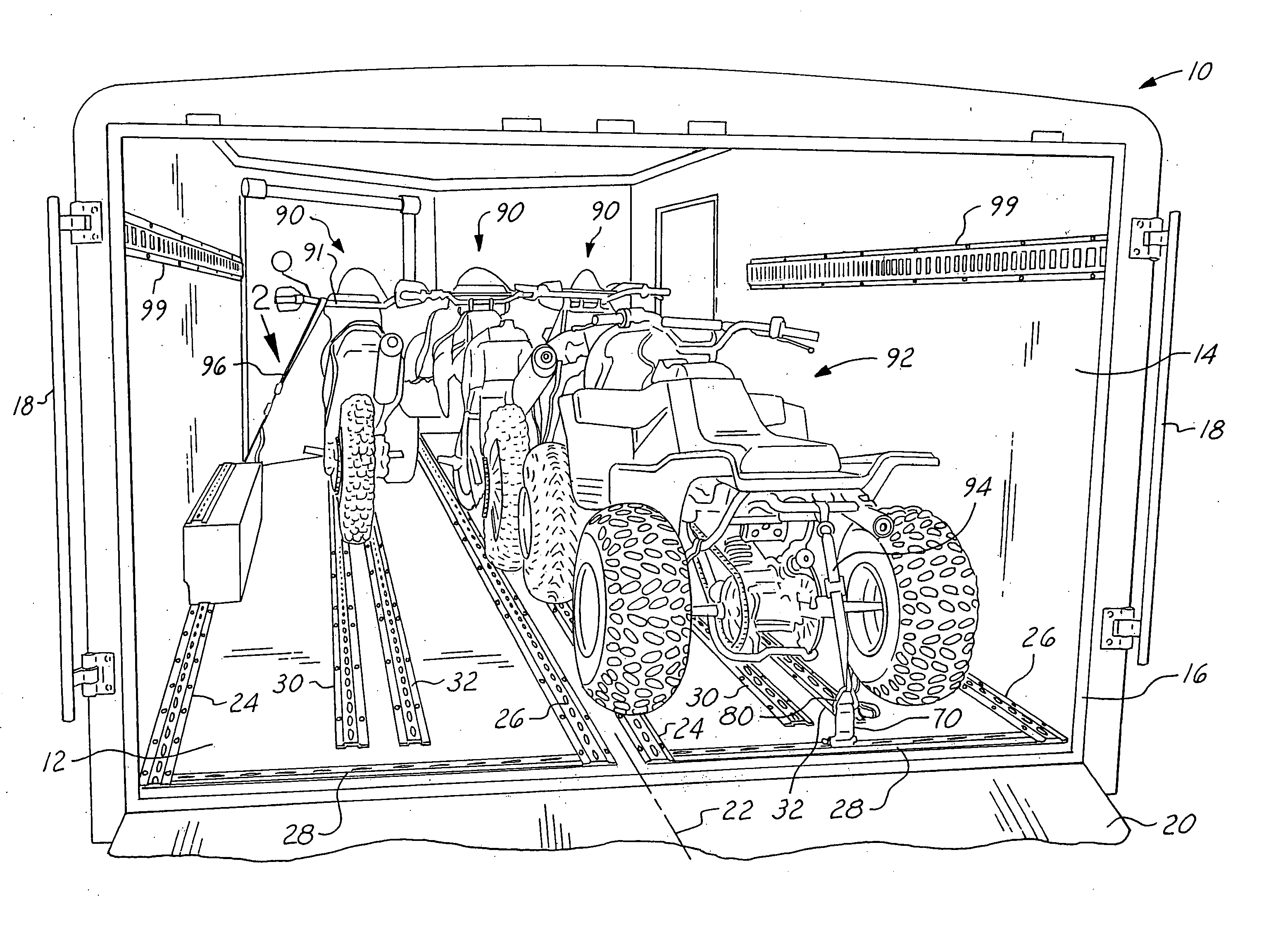

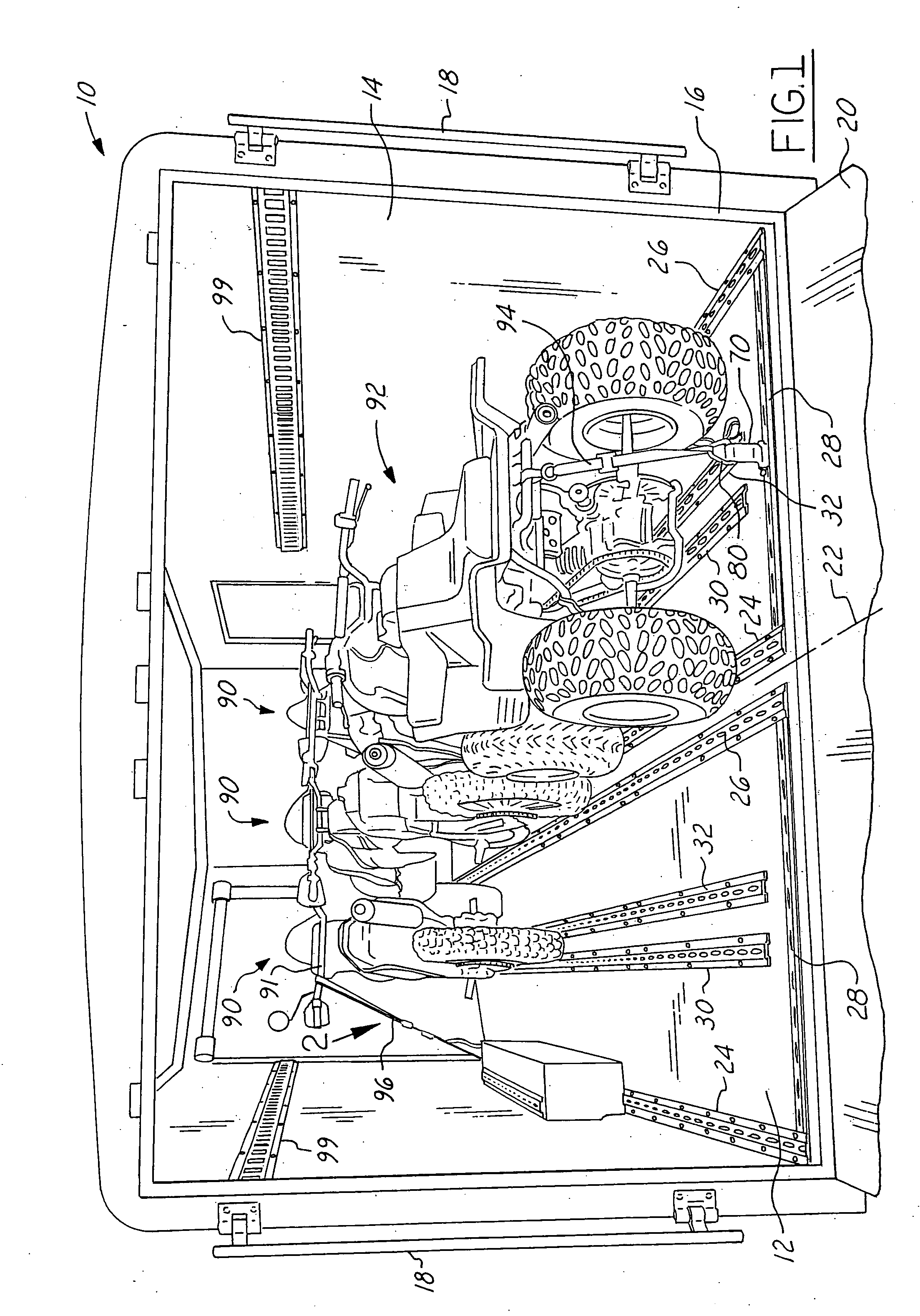

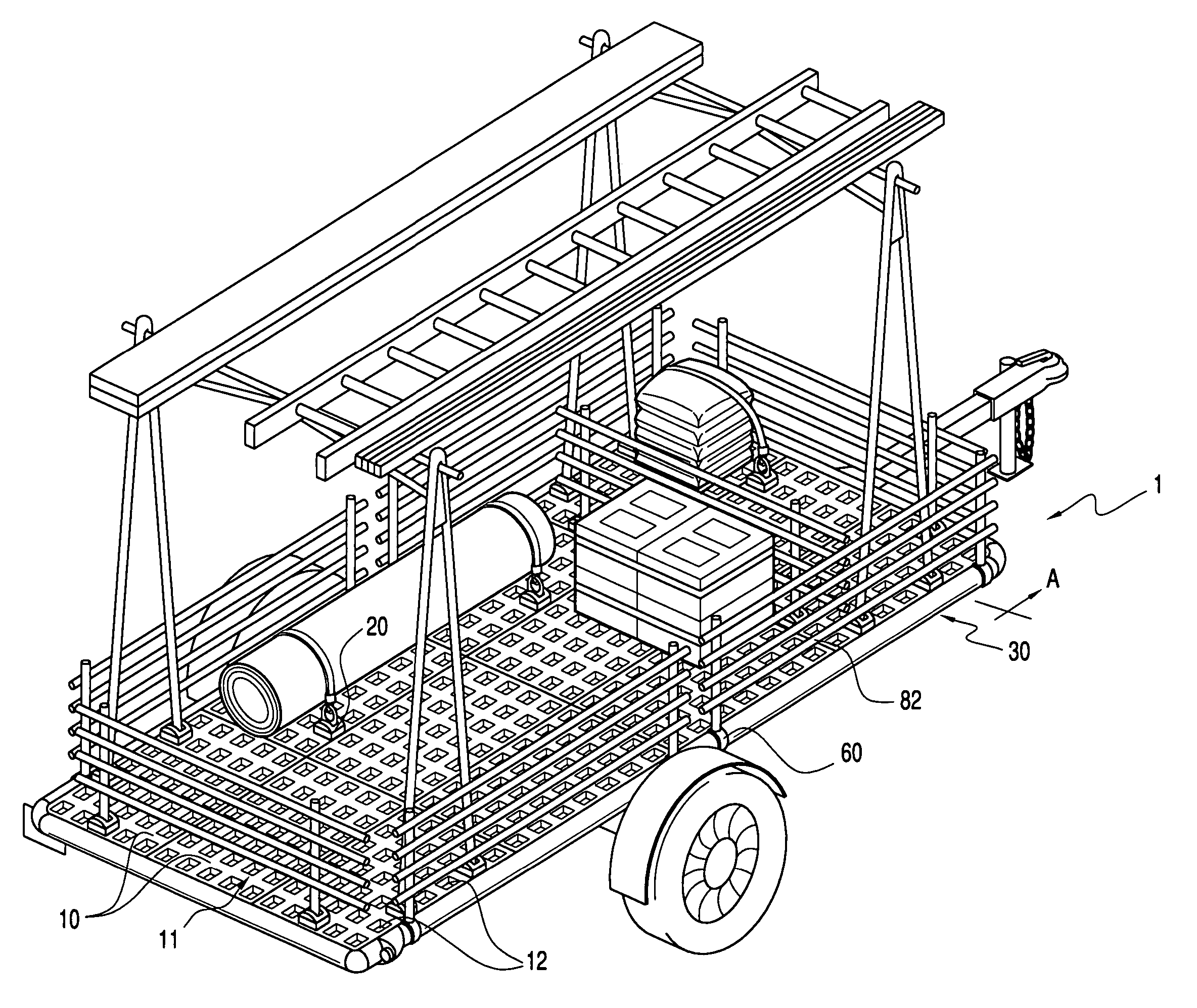

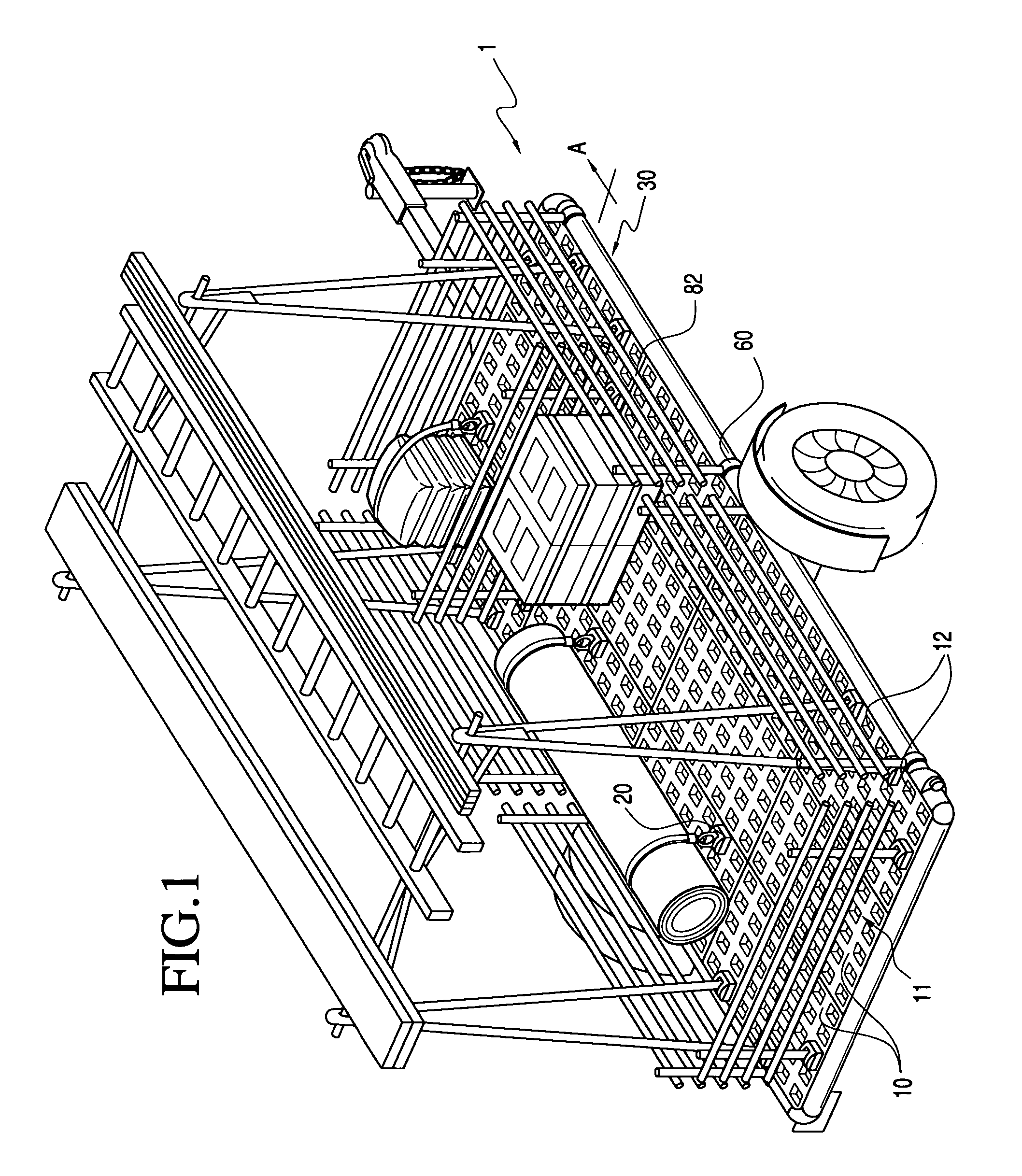

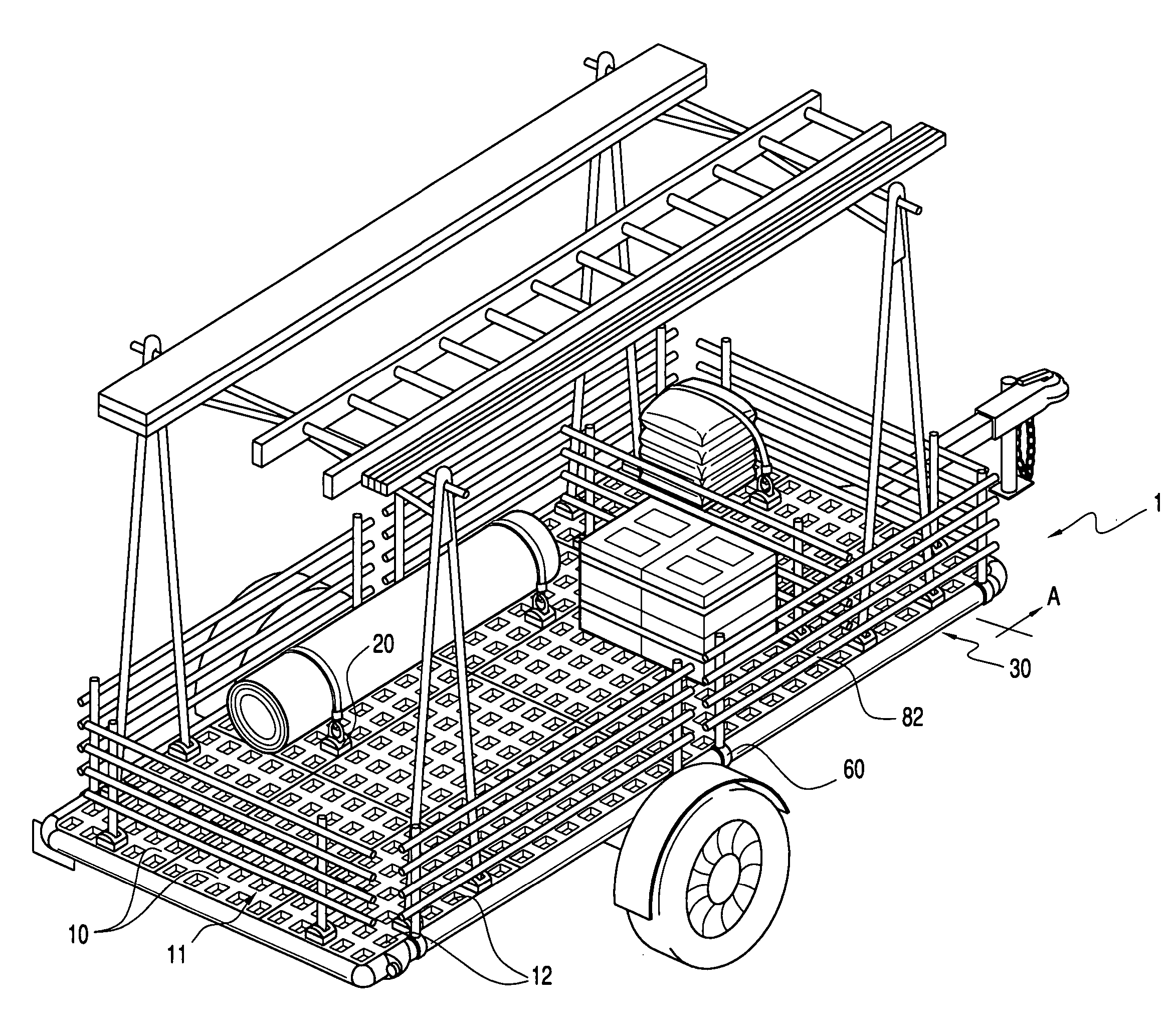

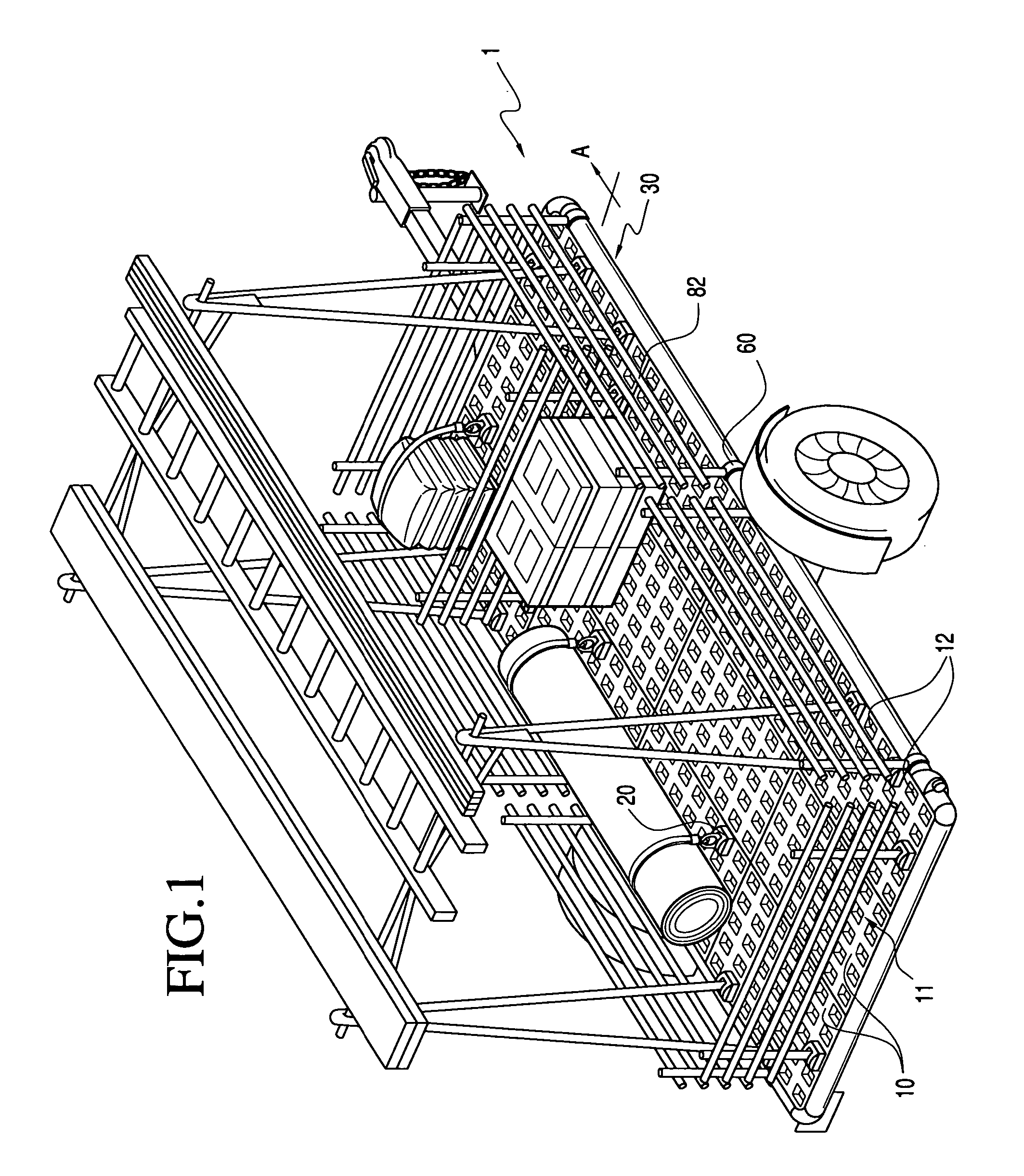

Cargo management system for trailers and truckbeds and method of use

InactiveUS7137764B2Improve securityFlexible elementsVehicle to carry long loadsEngineeringMechanical engineering

A configurable base is formed from a plurality of interlocking tiles that may fit within a frame. Anchoring tiles have receptacles for accepting anchors. Smooth panels support heavy items. Accessories are formed to either attach to the anchor or integrally with the anchor. Accessories include tie downs, sidewalls, cross frame and stanchions, and wheel-chocks. The anchor fits into the receptacles for placement anywhere desired on the base. An embodiment of the anchor has a lock for added security. A coupler provides at least one aperture for securing items, preferably positioned on the frame. An alternative configurable bed is formed by orthogonal cross members arranged within a frame. Open spaces between the orthogonal cross members accept anchors. Another alternative configurable bed is formed from a single tile having a plurality of receptacles. A method of configuring a cargo management system allows a dealer employee to compare customer needs to established footprints, alter the footprint design if needed, and generate a cost estimate for the configuration.

Owner:JOHNSON GARY

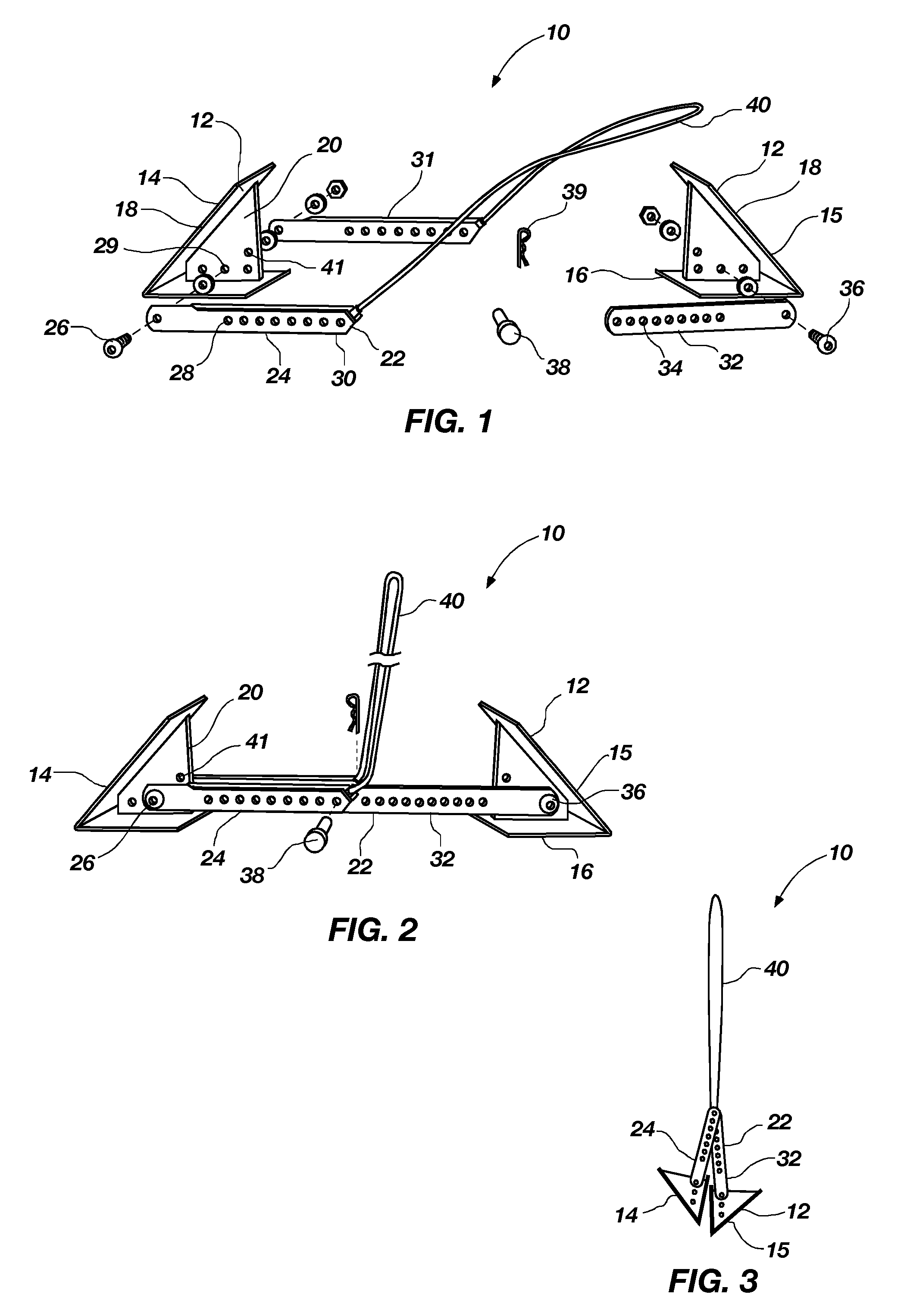

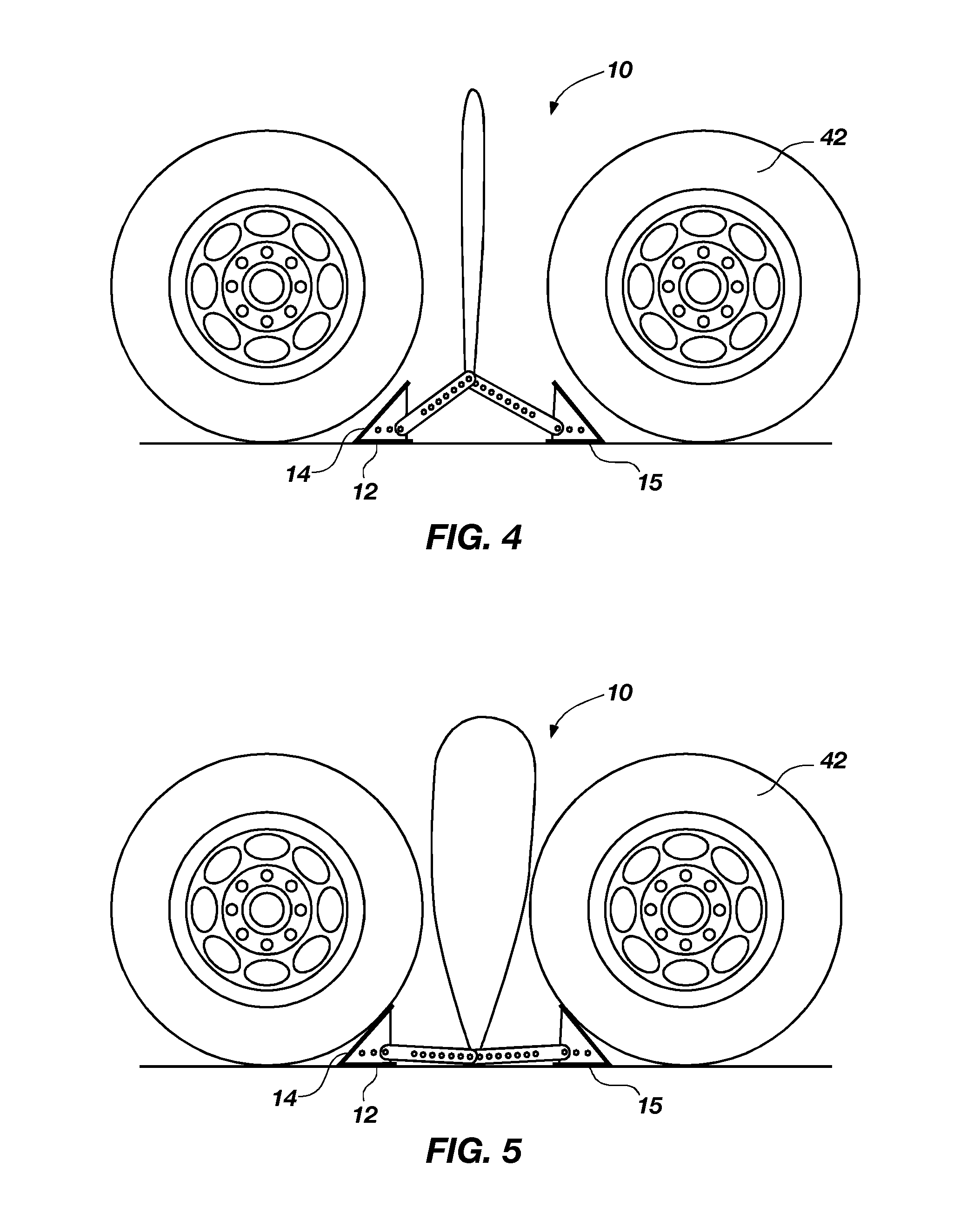

Over-center clamping wheel chocks

A wheel chock system for preventing movement of one or more wheels. The system may include a pair of chocks for clamping onto one or more wheels. The chocks may be connected through a linkage mechanism that can be rotated to draw the chocks together or move the chocks further apart. A handle may be attached to the linkage mechanism for moving the chock system from a blocking position to a released position. The handle may be configured to stand upright such that the chock system can be installed and removed by a user in a standing position without the need to bend or crouch. One embodiment of the chock system may be attachable to two different wheels in a tandem wheel arrangement, whereas another embodiment of the chock system may be configured to clamp onto a single wheel.

Owner:PROGRESS MFG LLC

Cargo management system for trailers and truckbeds and method of use

InactiveUS20060099044A1Improve securityFlexible elementsVehicle to carry long loadsFace sheetMechanical engineering

A configurable base is formed from a plurality of interlocking tiles that may fit within a frame. Anchoring tiles have receptacles for accepting anchors. Smooth panels support heavy items. Accessories are formed to either attach to the anchor or integrally with the anchor. Accessories include tie downs, sidewalls, cross frame and stanchions, and wheel-chocks. The anchor fits into the receptacles for placement anywhere desired on the base. An embodiment of the anchor has a lock for added security. A coupler provides at least one aperture for securing items, preferably positioned on the frame. An alternative configurable bed is formed by orthogonal cross members arranged within a frame. Open spaces between the orthogonal cross members accept anchors. Another alternative configurable bed is formed from a single tile having a plurality of receptacles. A method of configuring a cargo management system allows a dealer employee to compare customer needs to established footprints, alter the footprint design if needed, and generate a cost estimate for the configuration.

Owner:JOHNSON GARY

Wheel chock system

ActiveUS20090026022A1Avoid accumulationPortable braking systemRail brake actuationSpray nozzleMechanical engineering

A wheel restraint for restraining a vehicle at a loading dock includes various features such as, a wheel chock supported by a spring loaded articulated arm with a spring that can be selectively tightened or released, a sensor that detects whether the chock is solidly against a base plate or floor, a bi-directional pivotal joint between the articulated arm and the wheel chock to ensure that the chock can sit squarely on a mating base plate, a wheel chock that meshes with a hydraulically actuated base plate, pivotal or otherwise movable backstops that prevent a wheel chock from sliding out of position, and a base plate cleaning system. The cleaning system might include a vehicle-actuated brush, fluid spray nozzles, electric heater and removable cover plates.

Owner:RITE HITE HLDG CORP

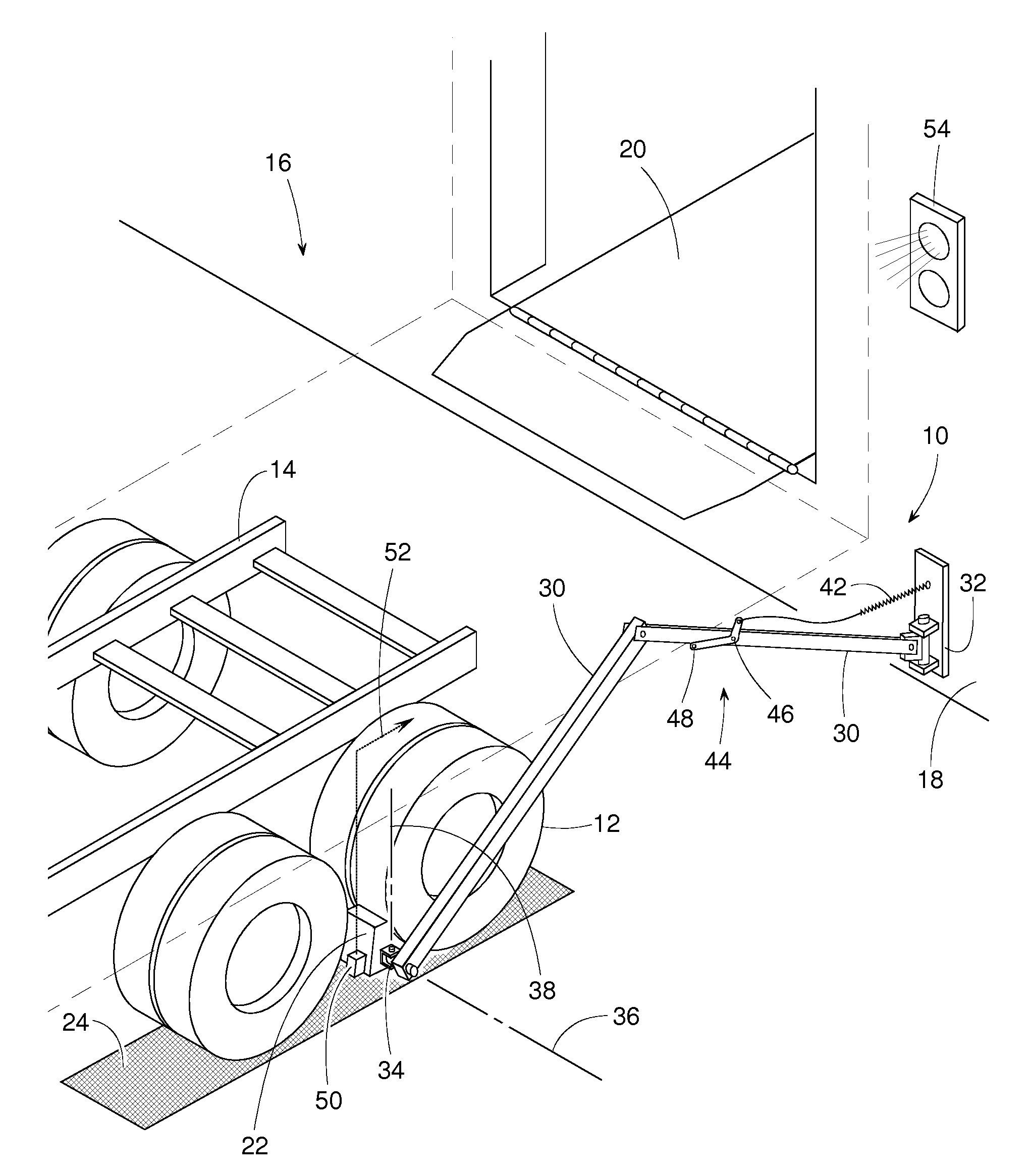

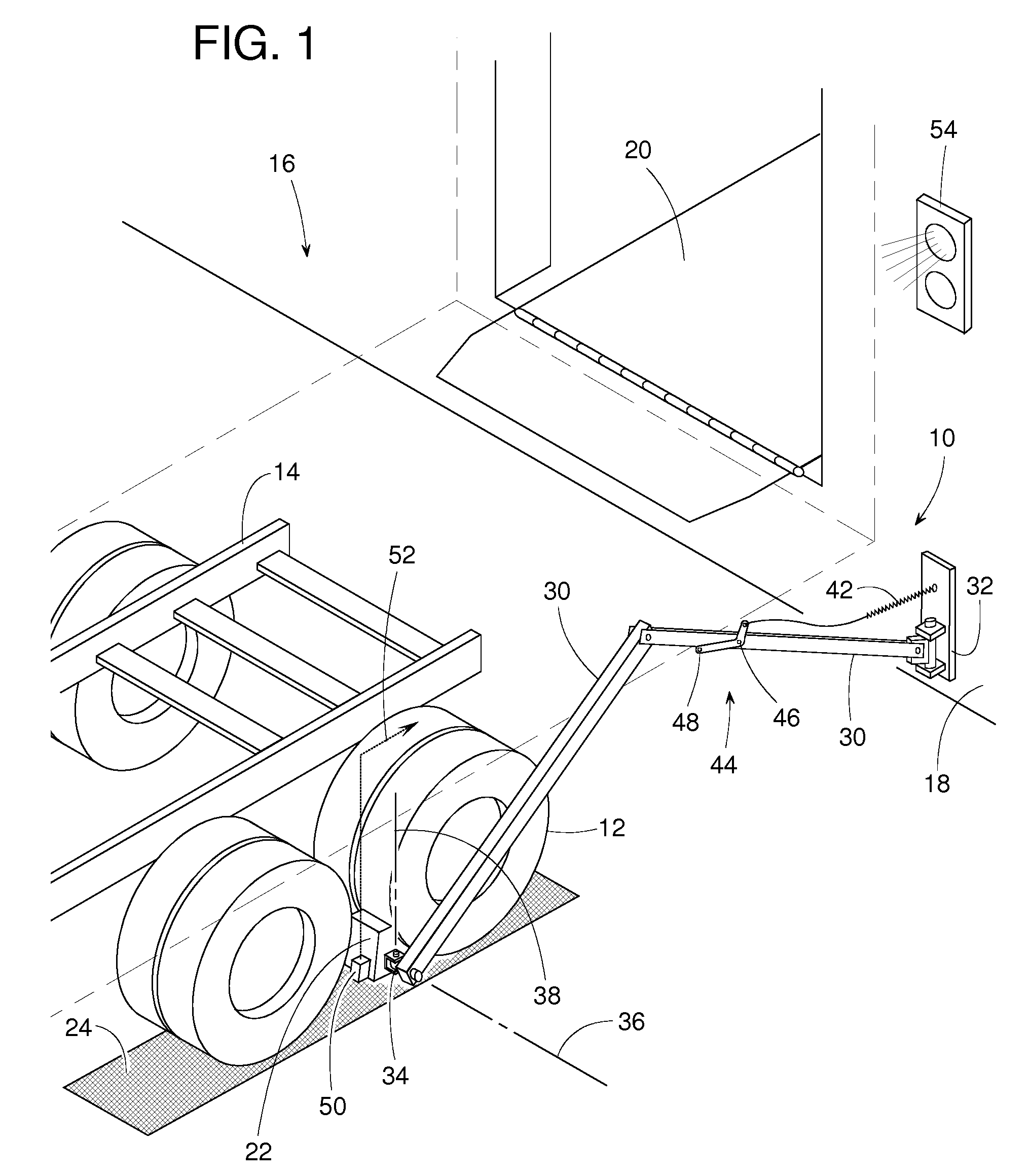

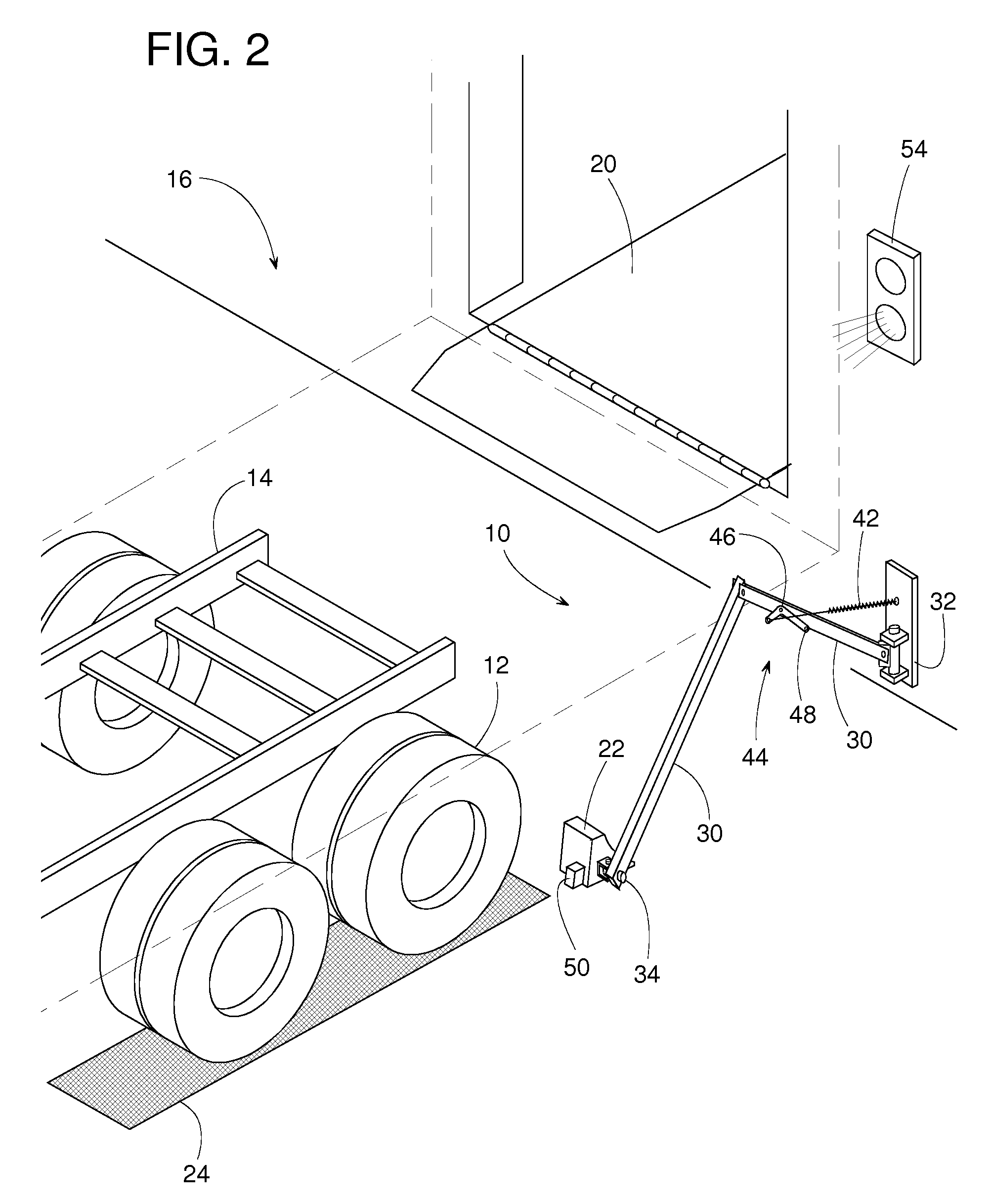

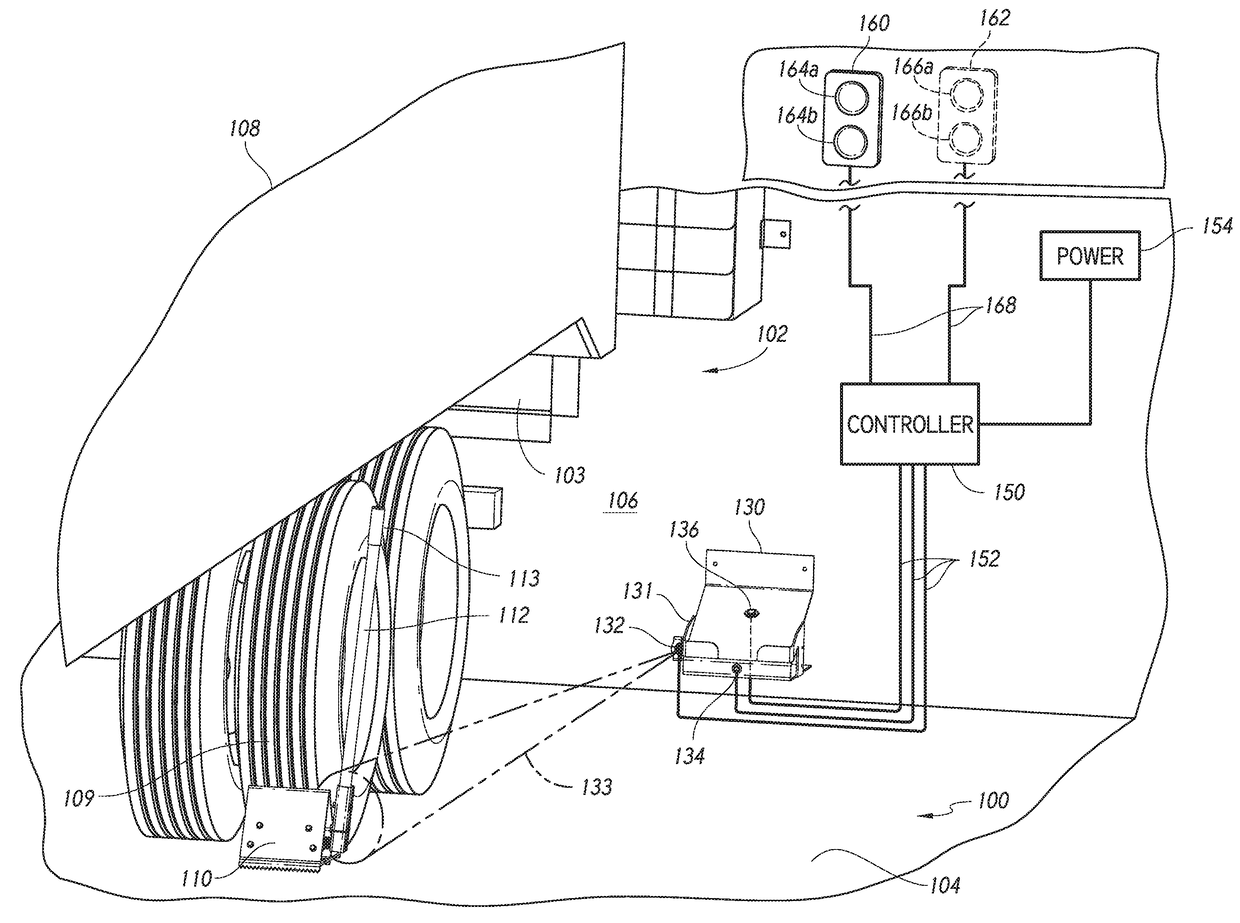

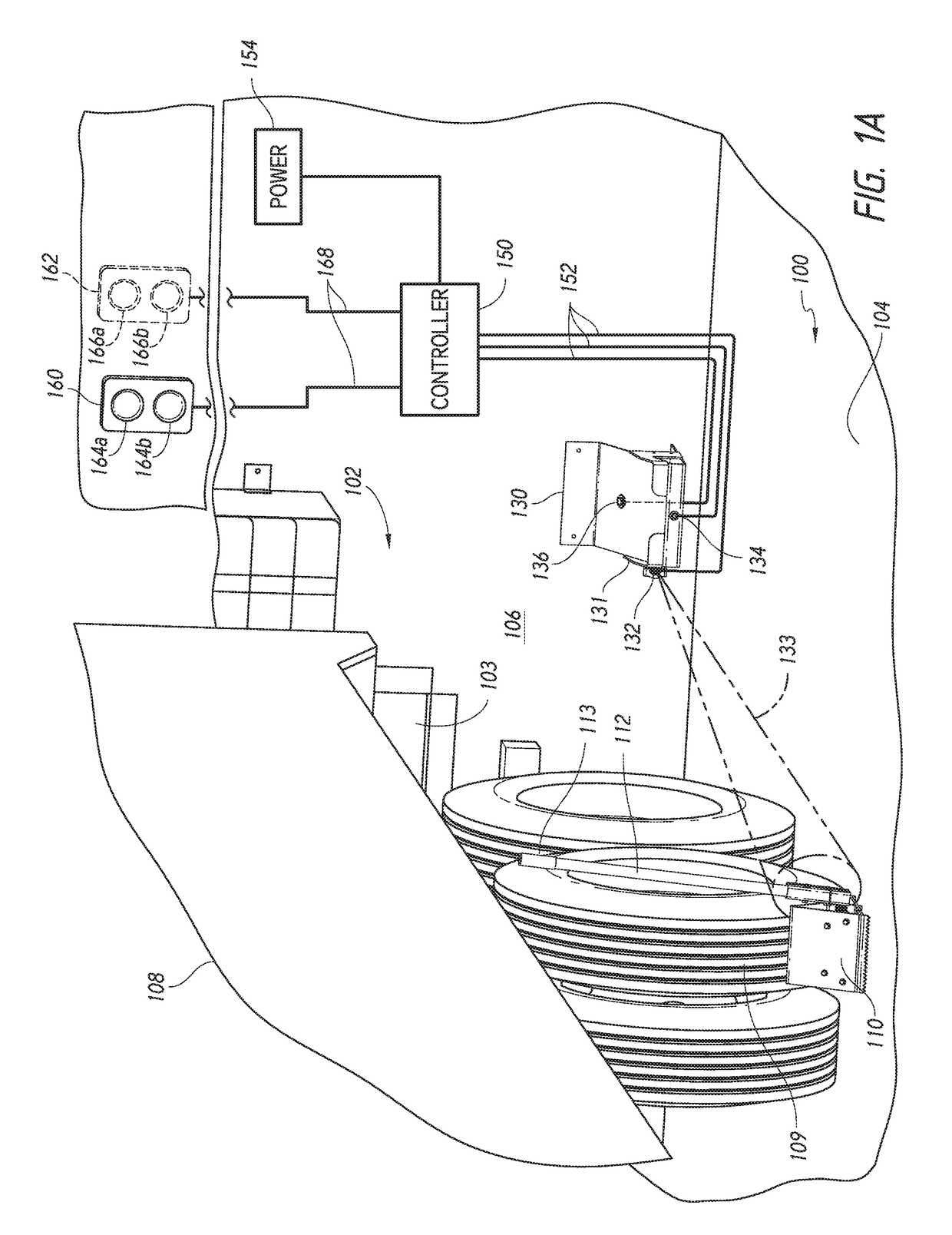

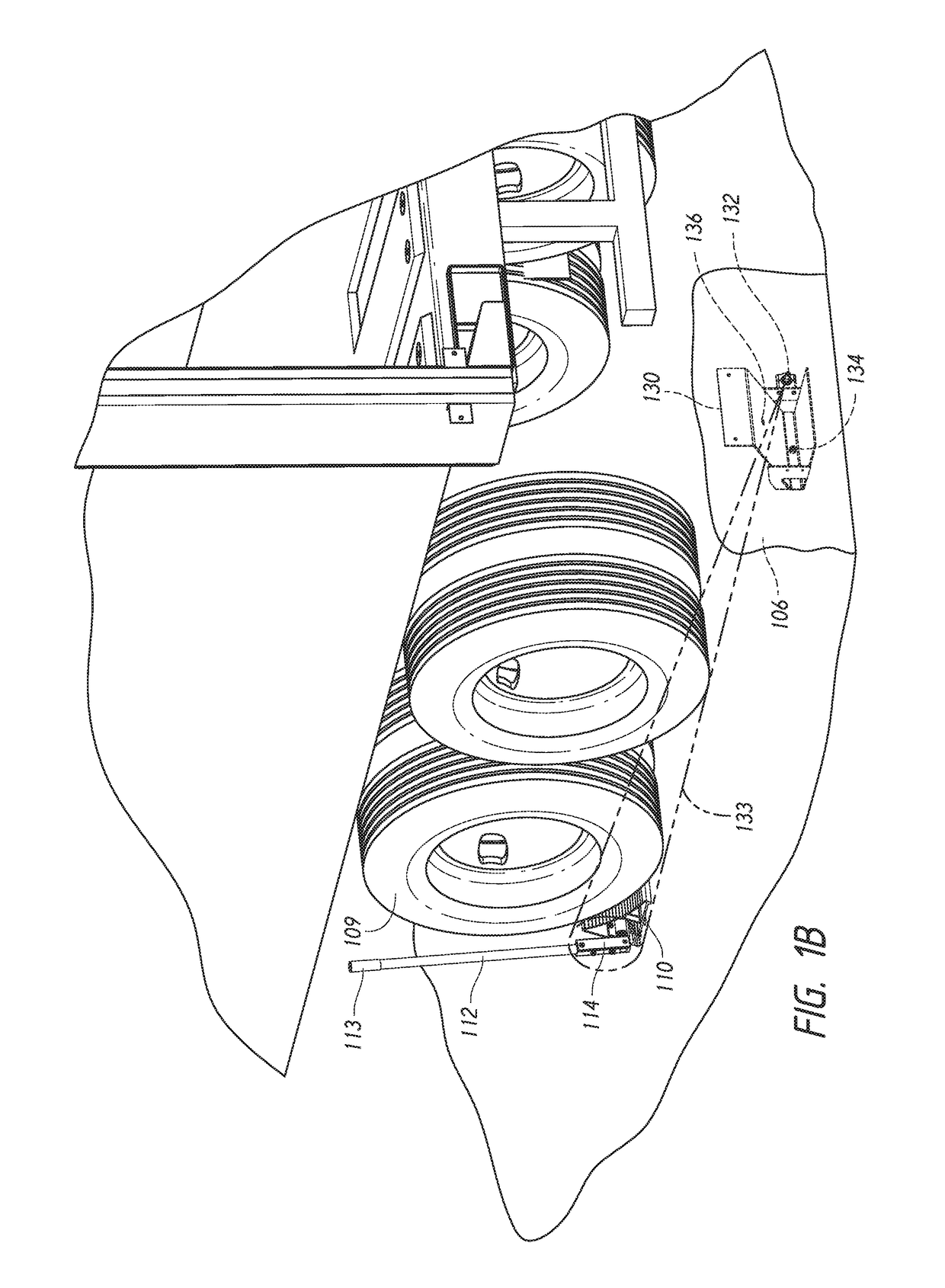

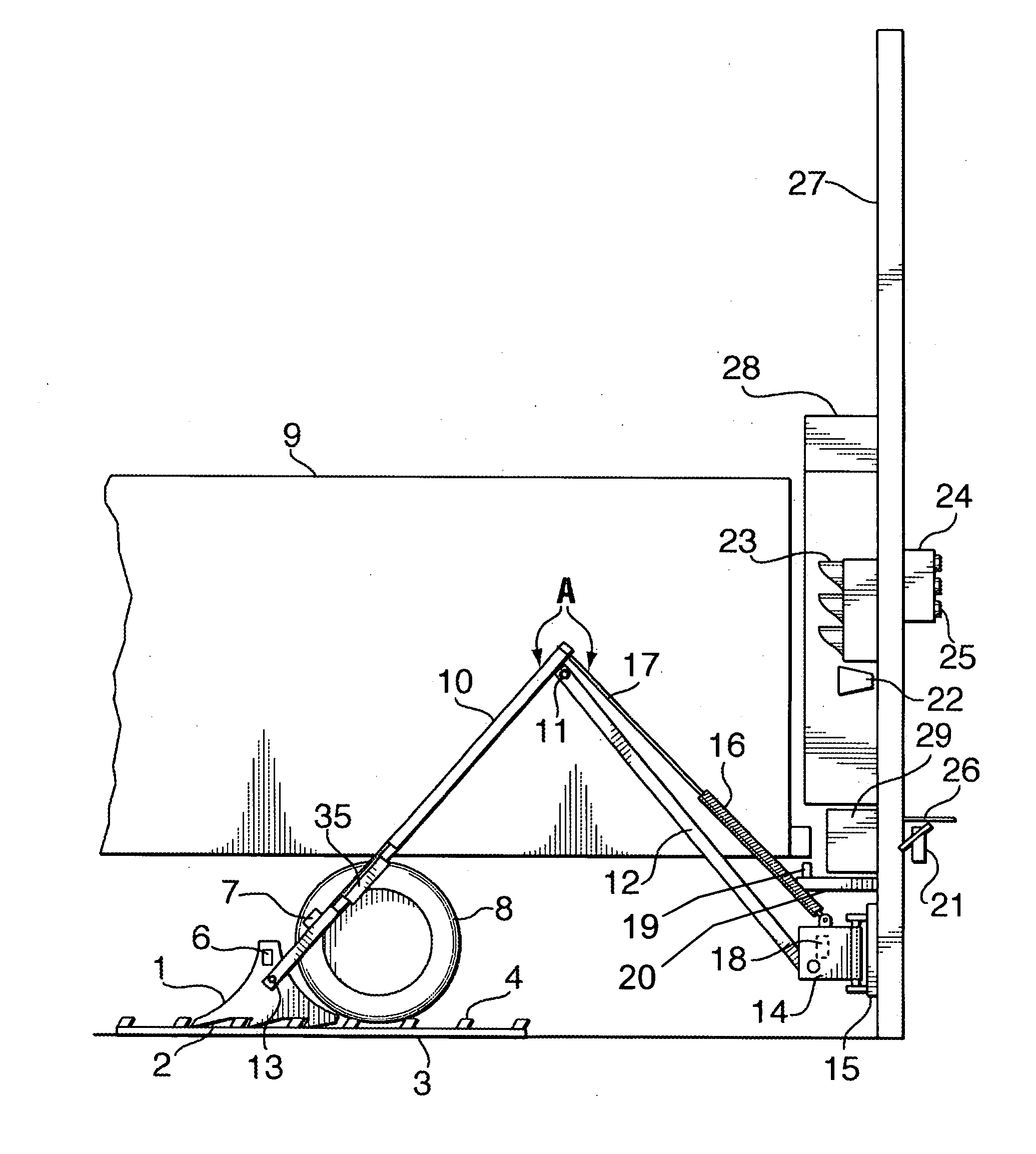

Wheel chock systems

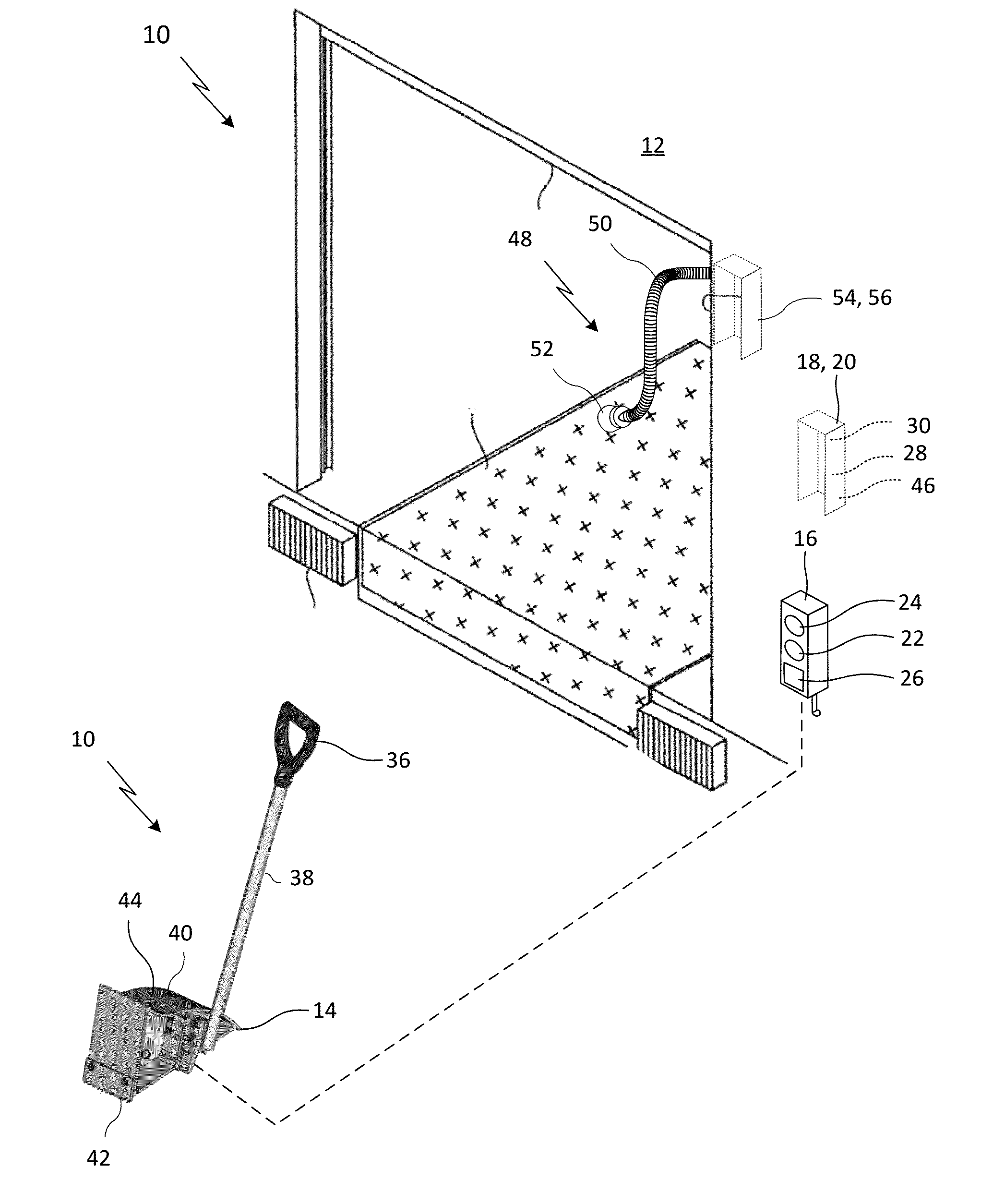

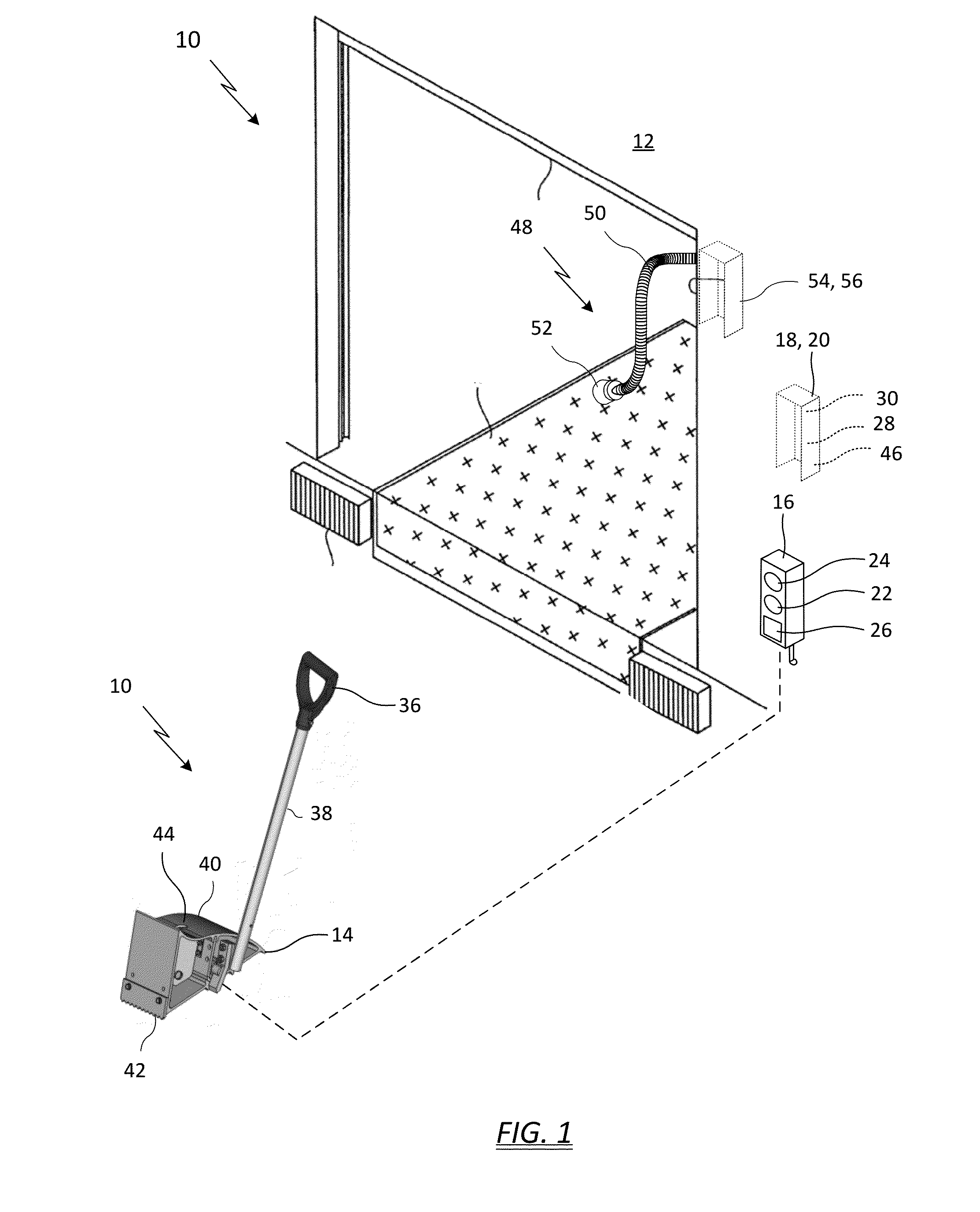

Wheel chock systems for use at loading docks and other locations are described herein. In some embodiments, the wheel chock systems can include a wheel chock assembly that is positionable in contact with a vehicle wheel to restrain the vehicle at a loading dock. The wheel chock assembly can include a sensor target, and a corresponding sensor can be mounted to, for example, an outer wall of the loading dock or a wheel chock storage cradle mounted to the outer wall. In operation, the sensor can emit a wireless signal (e.g., an electromagnetic signal) that is reflected off of the sensor target and received back by the sensor when the wheel chock has been positioned in a blocking relationship relative to the vehicle wheel to restrain the vehicle at the loading dock. The sensor can be operably connected to a loading dock signal system (e.g., a signal light system) that displays appropriate signals to loading dock personnel based on detection of proper wheel chock placement. In other embodiments, wheel chock systems can include other types of devices for wirelessly communicating wheel chock placement information to loading dock systems. Such device types can include, for example, Bluetooth, Wi-Fi, RFID, etc.

Owner:ASSA ABLOY ENTRANCE SYST

Hitch-mounted cargo lift for personal mobility device

InactiveUS7798760B2Easy to adaptLifting framesLoading/unloading vehicle arrangmentPower inverterPersonal mobility

Owner:STRASSMAN DAVID R +1

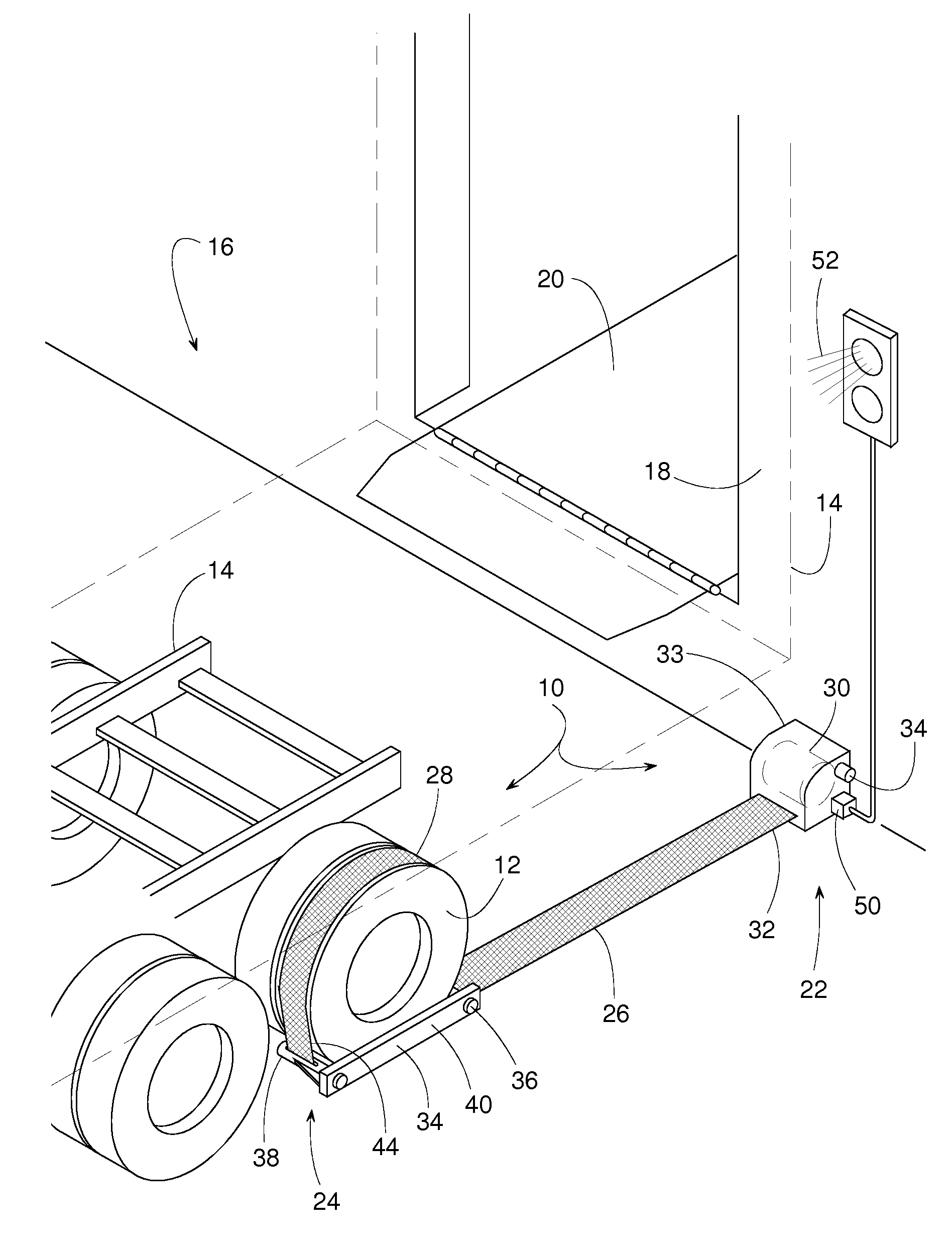

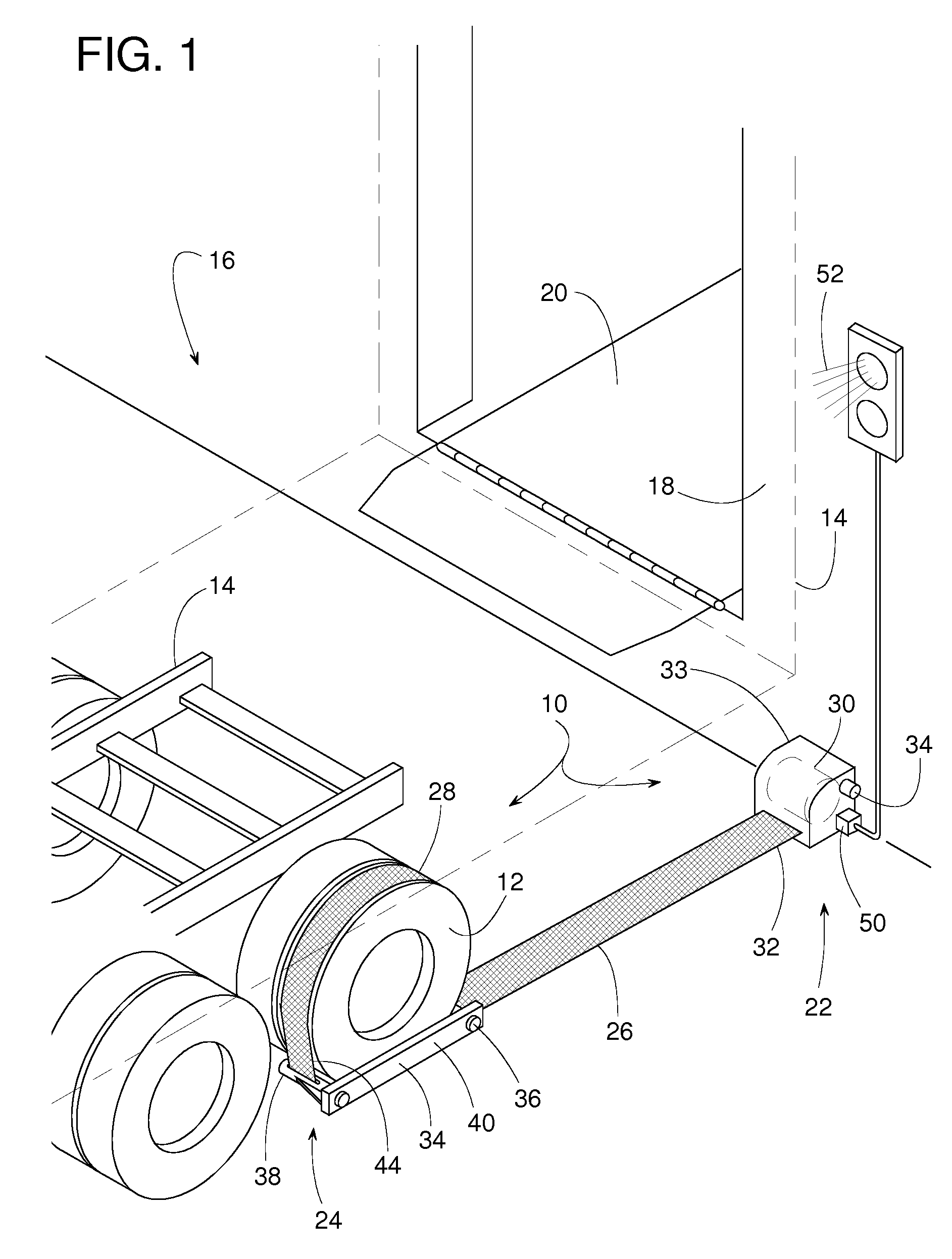

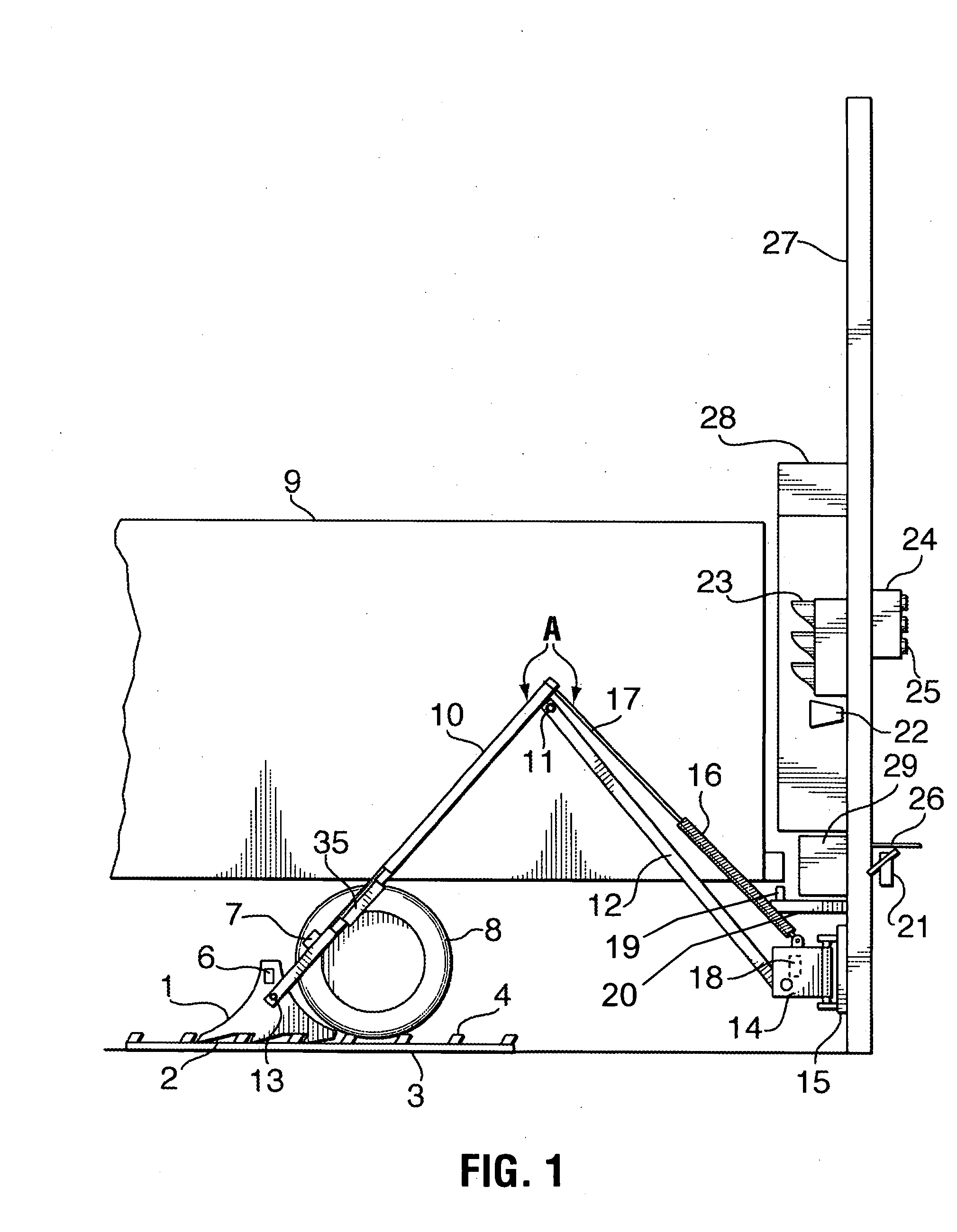

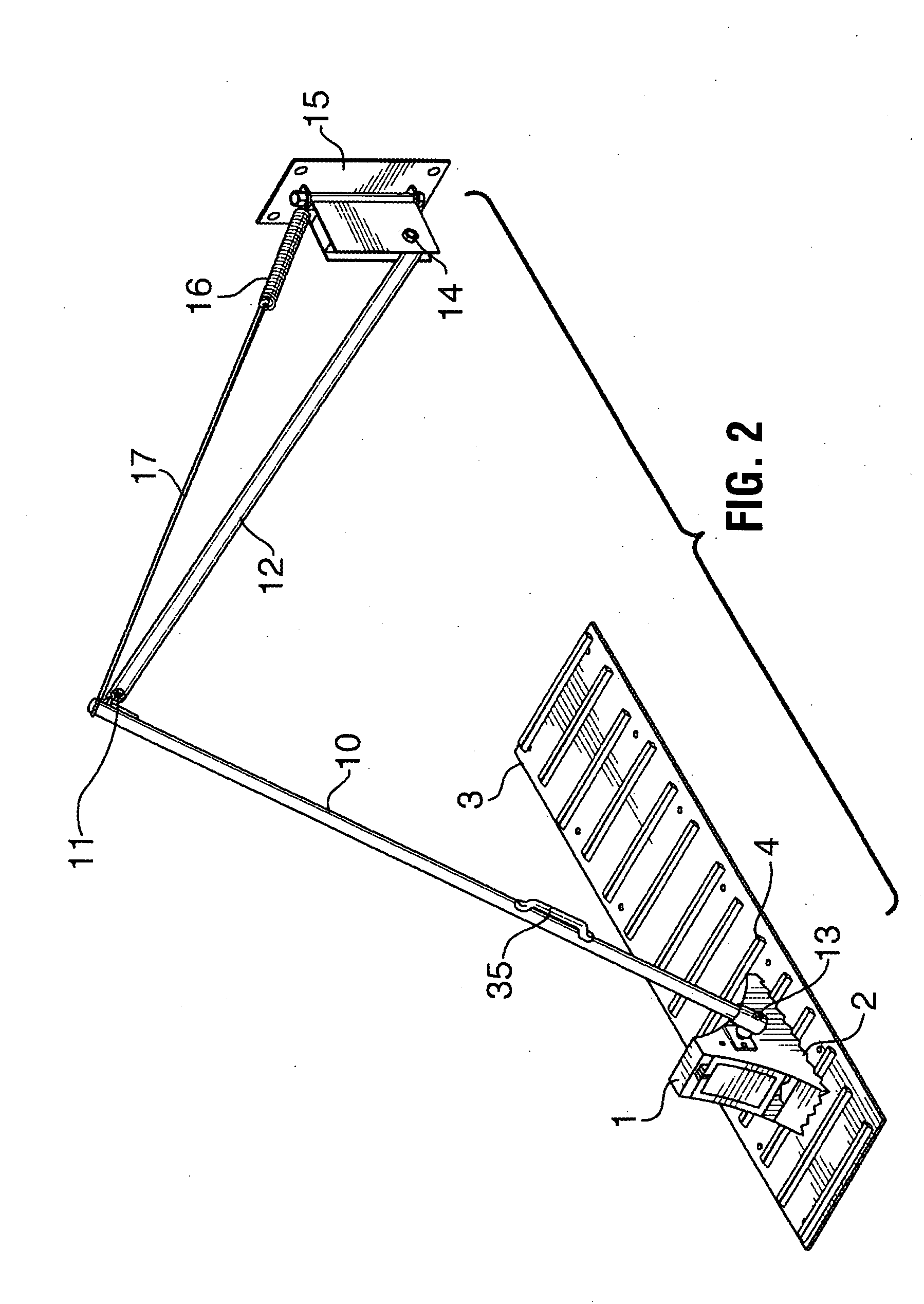

Loading dock wheel restraint comprising a flexible elongate member

ActiveUS8006811B2Avoid interferencePortable braking systemRail brake actuationEngineeringMechanical engineering

A wheel restraint for restraining a vehicle at a loading dock includes a flexible elongate member with one end that can be manually wrapped at least partially around at least one of the vehicle's wheels. The other end of the elongate member is connected to an anchor that is generally fixed relative to the dock. The anchor preferably includes a reel for taking up slack in the elongate member. When the restraint is not in use, the reel can take up and store the elongate member. The restraint preferably provides a signal that indicates whether the wheel is actually restrained. The restraint might also include a wheel chock coupled to the elongate member. A floor-mounted guide can help prevent interference between the elongate member and certain parts of the vehicle.

Owner:RITE HITE HLDG CORP

Wheel chock restraint system

InactiveUS20060144649A1Easy to operatePrevent movementBraking element arrangementsPortable braking systemEngineeringMechanical engineering

Wheel chock restraint system comprising a wheel chock, a supporting element mounted on the ground in vicinity of a loading dock and a wheel chock support assembly connected by one end to the wheel chock and by another end in vicinity of the loading dock. A base portion of the chock is provided with first engagement elements and the supporting elements are provide with corresponding second engagement elements. The first engagement elements are adapted to cooperate with the second engagement elements, thus creating a retention force directed away from the loading dock and preventing the chock from sliding away from the wheel of a vehicle making an attempt to depart prematurely from the loading dock. Wheel chock support assembly is adapted to ensure a secure positioning of the chock under the wheel of the vehicle during loading and unloading operation by creating an engagement force directed towards the loading dock and pressing the chock against the wheel. The first engagement elements comprise a plurality of teeth extending downwardly from the base portion of the chock under a predetermined angle and the second engagement elements are a plurality of stoppers extending upwardly from the supporting element. This system also comprises an anti-theft locking means, wherein these locking means together with the first and second engagement means are adapted to securely lock the chock on the wheel of the vehicle and to prevent any unauthorized removal of the chock and theft of the vehicle.

Owner:9172 9863 QUEBEC

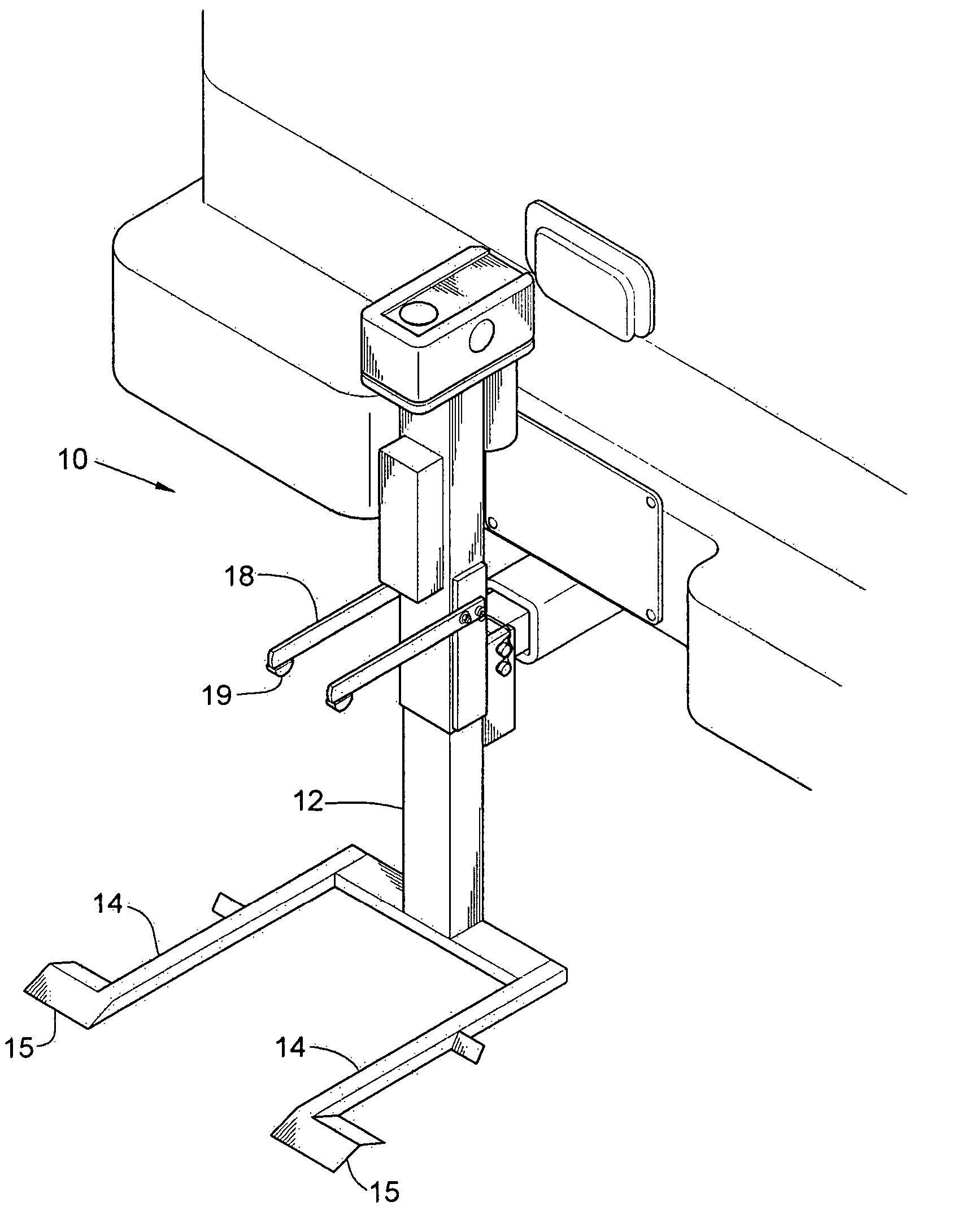

System For Improving Performance Of Wheel Chock Safety Procedures

A wheel chock system includes a chock, a sensor disposed within the chock to sense the proximity to the tire, an outside light box, and an inside control panel. Lamps on the outside light box provide a visual indication as to when the chock is in close proximity to the wheel. Lights on the inside control panel provide a visual indication of the loading dock safety status. The wheel chock system further includes a controller coupled to the inside control panel, programmed to change visual indications of both the outside light signal box and the inside control panel, based at least on the sensor and a loading dock door sensor. The wheel chock system further includes a camera positioned to view the tire and the chock and convey an image of the tire and the chock to a display on or near the inside control panel.

Owner:DLMFG

Chock system

ActiveUS20110226565A1Strong securityPrevent movementBraking element arrangementsPortable braking systemEngineeringMechanical engineering

A wheel chock restraint system which comprises a wheel chock having a base, a plurality of teeth extending outwardly from the base, the teeth extending in a first direction, and a locking member mounted within the chock, the locking member having a plurality of locking member teeth extending from a bottom thereof, the locking member teeth extending in a second direction generally opposed to the first direction, and an arrangement for moving the locking member in a generally vertical direction.

Owner:9172 9863 QUEBEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com