Continuous type material mixing device

A material mixing and pre-mixing technology, applied in clay preparation devices, clay mixing devices, chemical instruments and methods, etc., can solve the problems of low mixing efficiency and poor mixing effect, and achieve good mixing effect and high material mixing efficiency. , The effect of material mixing evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

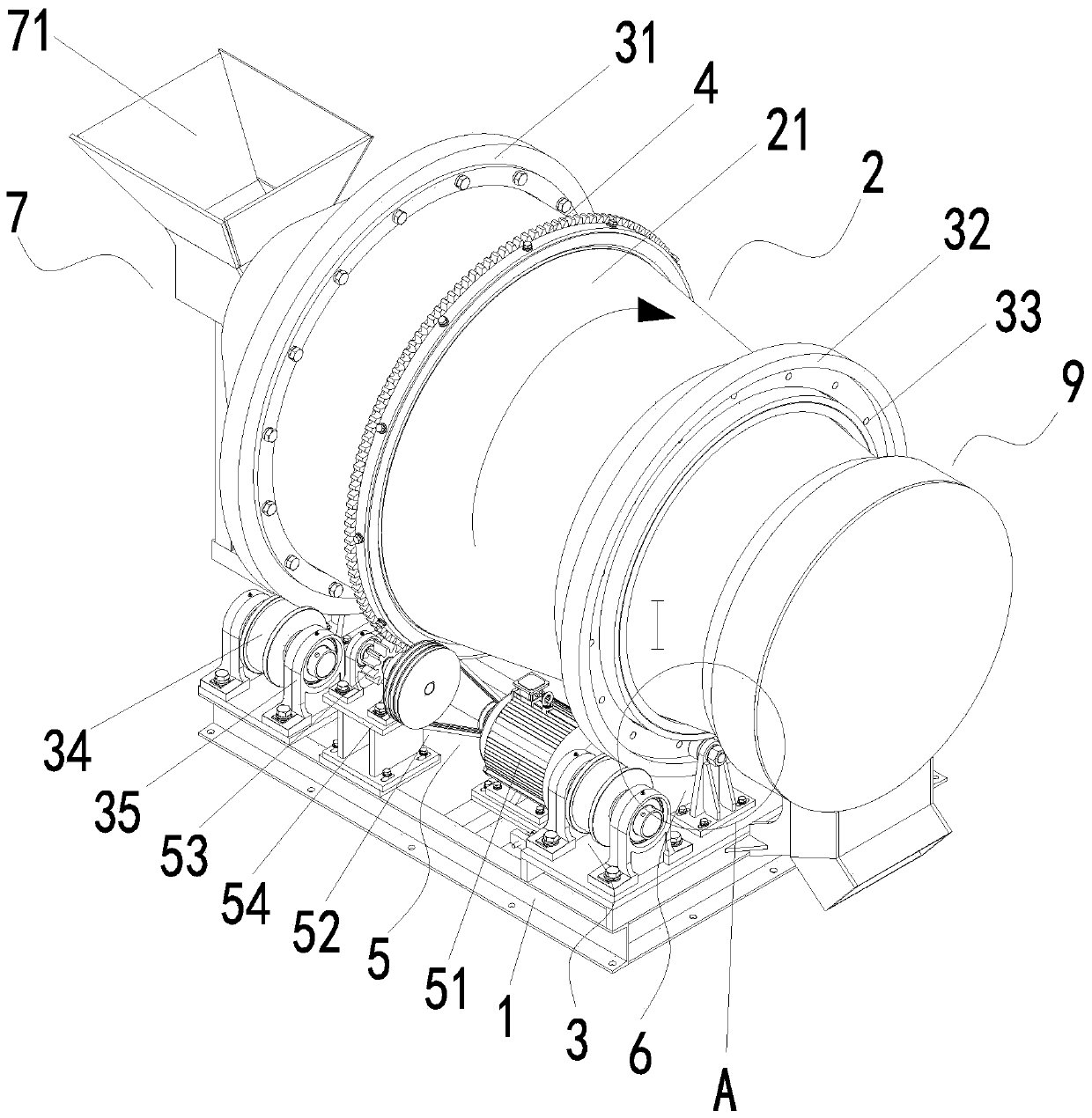

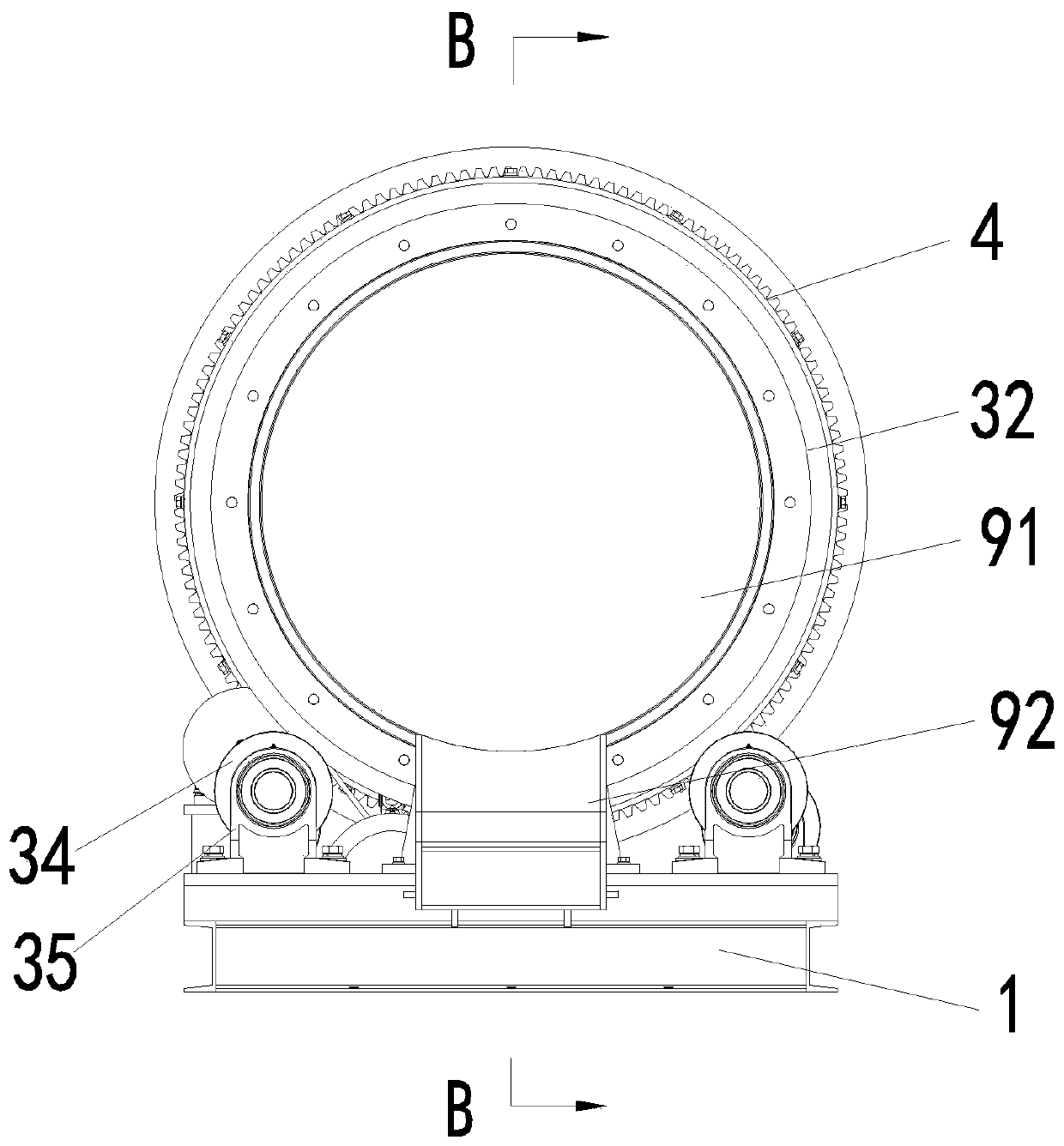

[0054] see figure 1 and Figure 4 , the present invention provides a continuous material mixing device. The pre-mixing device is preferably used for mixing materials before powder grinding, and of course it can also be used for mixing construction materials on construction sites. The mixed materials include dry materials and wet material. Specifically, the pre-mixing device includes a base 1, a mixing cylinder 2, a rolling support mechanism 3, a driving gear 4 and a driving mechanism 5;

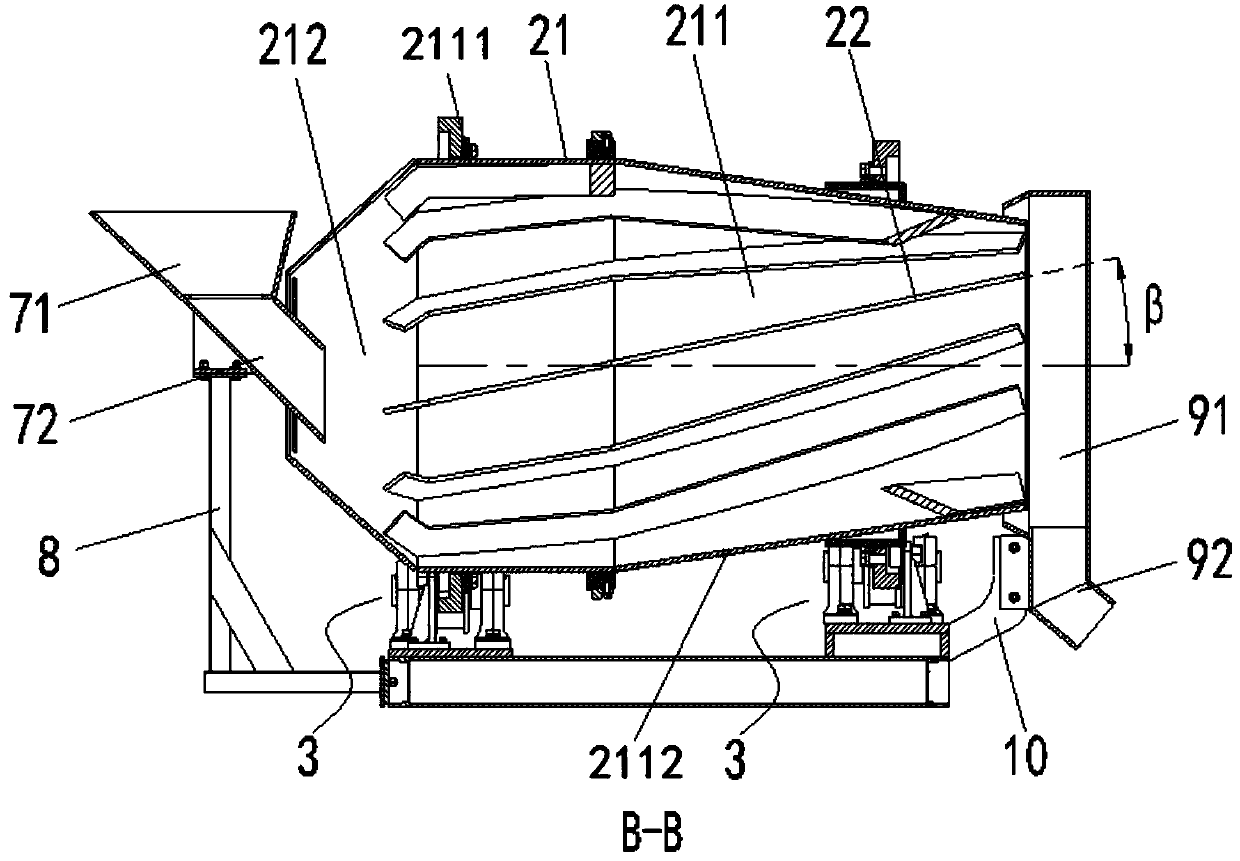

[0055] Such as image 3As shown, the mixing barrel 2 is used as a material storage and mixing mechanism. Specifically, the mixing cylinder includes a cylinder body 21 and a stirring blade 22. The cylinder body 21 has a mixing chamber 211 inside, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com