Turnover trolley for loading and unloading of moulds

A mold and trolley technology, applied in the direction of lifting device, hoisting device, etc., can solve the problems of high labor intensity, failure to overcome, complicated process, etc., and achieve the effect of reducing labor intensity and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

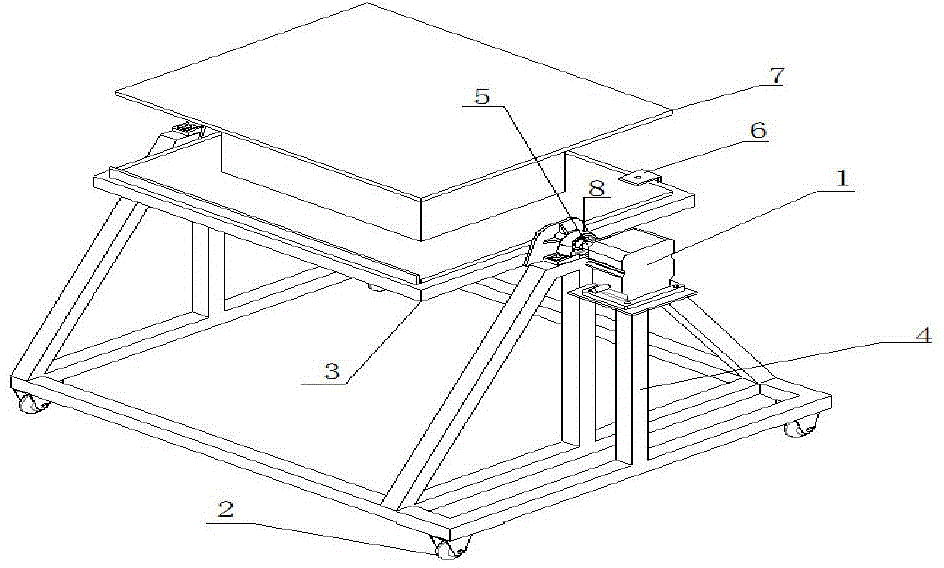

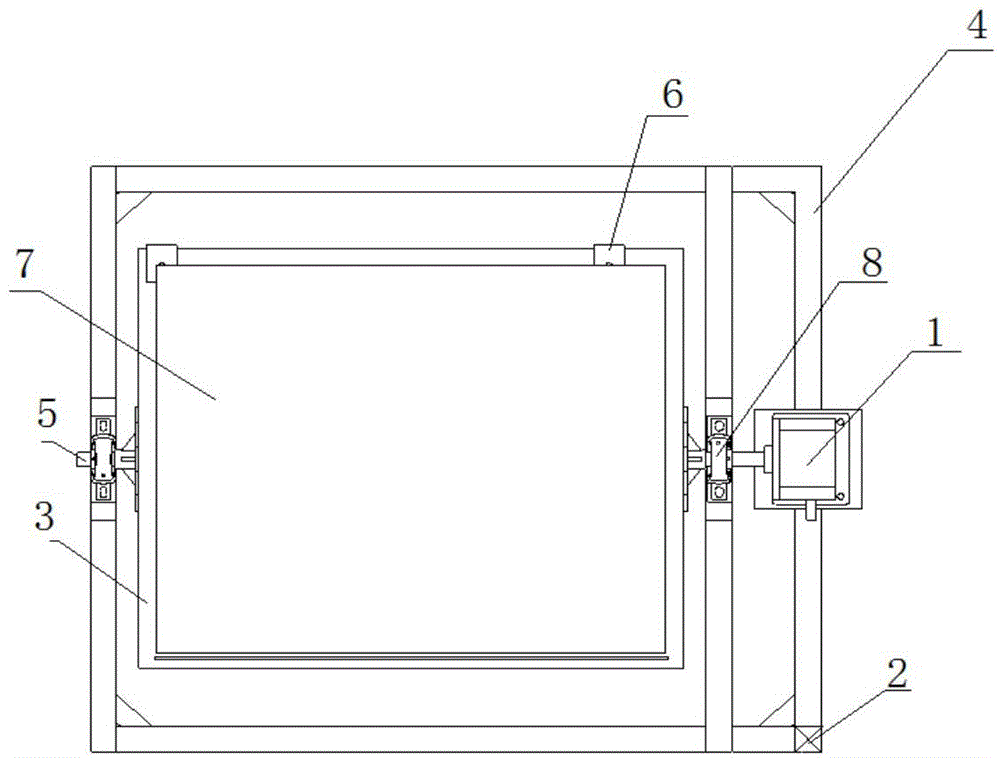

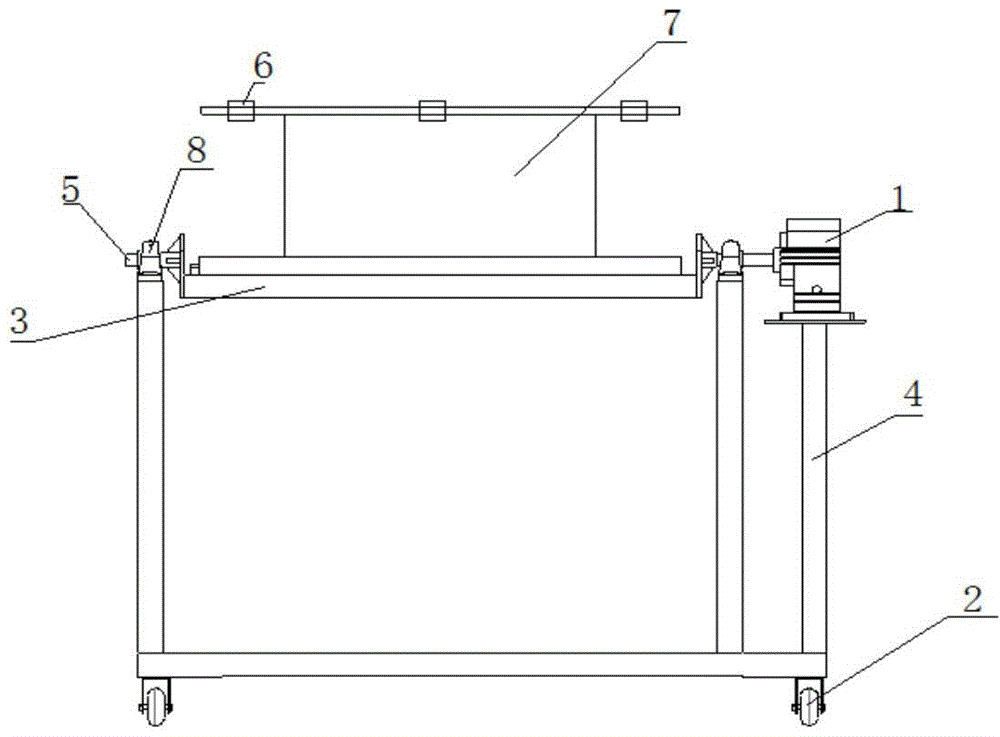

[0021] A turning trolley for loading and unloading moulds, such as figure 1 , 2 As shown in and 3: it includes a frame 4, a worm gear reducer 1 is fixed on the left side of the upper part of the frame 4, a pair of linkage shafts 5 are fixed on the left side of the reducer 1 and the right side of the frame 4, two linkage A mold fixing frame 3 is fixed between the shafts 5 through a clamp 6 , and a connecting block bearing 8 is fitted on the linkage shaft 5 close to the side of the reducer 1 .

[0022] Ten clamps 6 for fixing the mold are evenly distributed on the mold fixing frame 3, and there are three clamps 6 in the horizontal direction of the mold fixing frame 3, and two in the vertical direction.

[0023] The frame 4 is assembled from a horizontal support with a rectangular structure at the bottom and triangular supports at both sides.

[0024] Four wheels 2 with brake function are installed at the bottom of the frame 4 .

[0025] A platform is fixed by a square steel o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com