Chuck clamping type multi-specification rolling bearing fault simulation experiment platform mounted on basis of stepped shaft

A rolling bearing and fault simulation technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of high time and economic costs, and achieve the effects of high automation, high detection accuracy, complete data collection, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

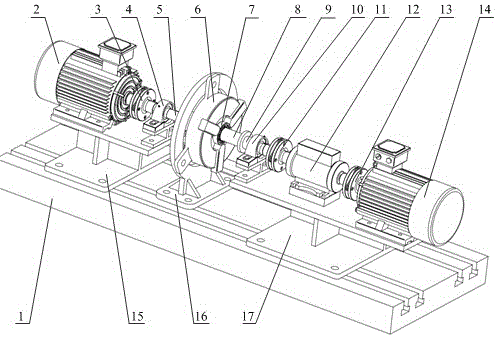

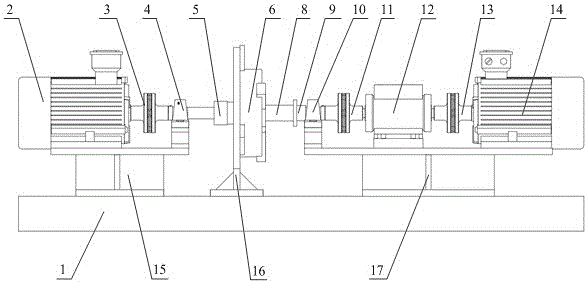

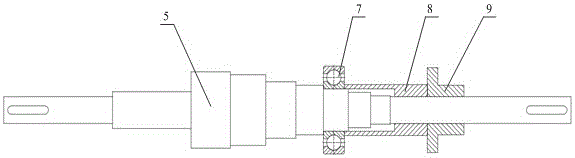

[0025] refer to Figure 1~Figure 5 , a chuck clamping multi-standard rolling bearing failure simulation test bench based on stepped shaft installation, characterized in that it includes a base platform 1, a drive motor 2, a multi-stage stepped shaft 5, an experimental rolling bearing 7, a straight sleeve 8, Band flange sleeve 9, three-jaw chuck 6, torque tachometer 12 and loading motor 14.

[0026] Steps with diameters of 20mm, 25mm, 30mm, 35mm, 40mm and 50mm are processed in the middle of the multi-step stepped shaft 5, and experiments can be carried out on rolling bearings with 6 inner diameter specifications. One end of the multi-stage stepped shaft 5 runs through the first bearing with seat 4, and is connected with the extension shaft of the drive motor 2 through the first elastic coupling 3, and the other end of the multi-stage stepped shaft 5 runs through the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com