Method and system for removing colloids

A colloid and viscose technology, applied in metal processing and other directions, can solve the problems of component damage, immature and effective, easy to damage components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

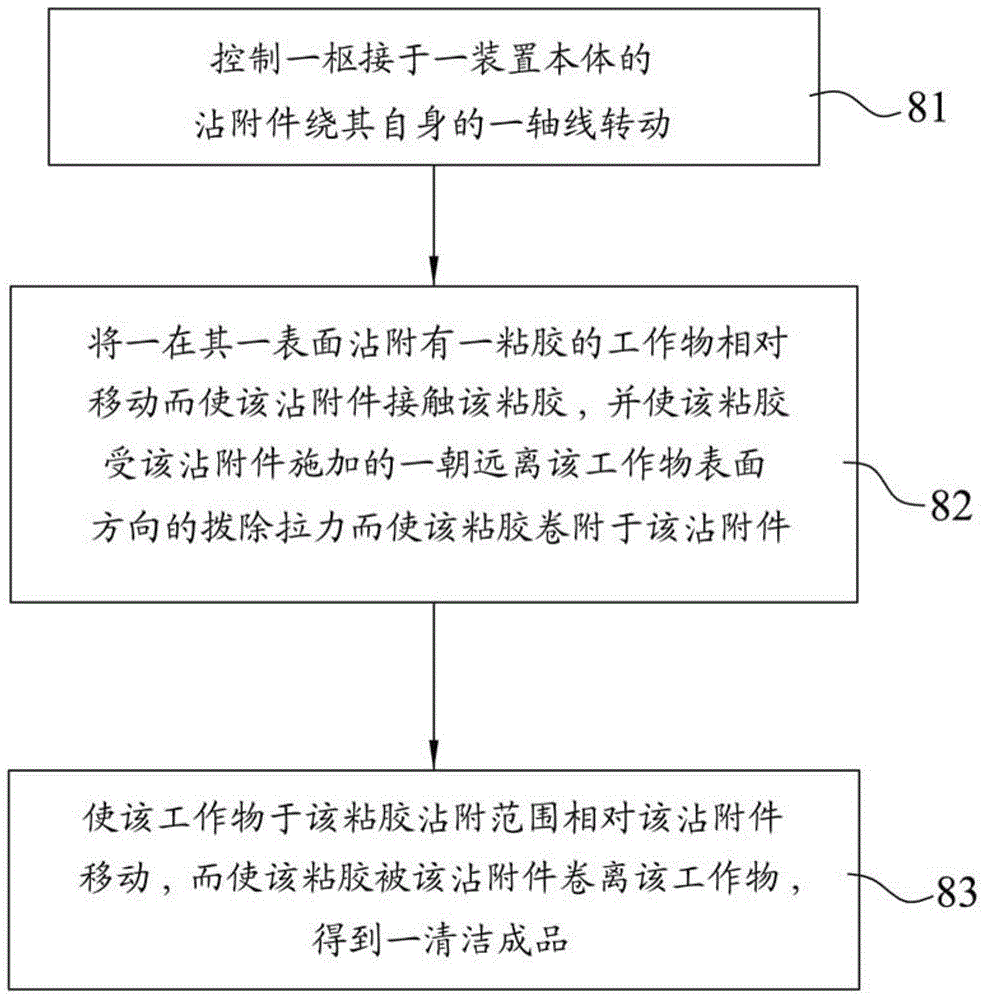

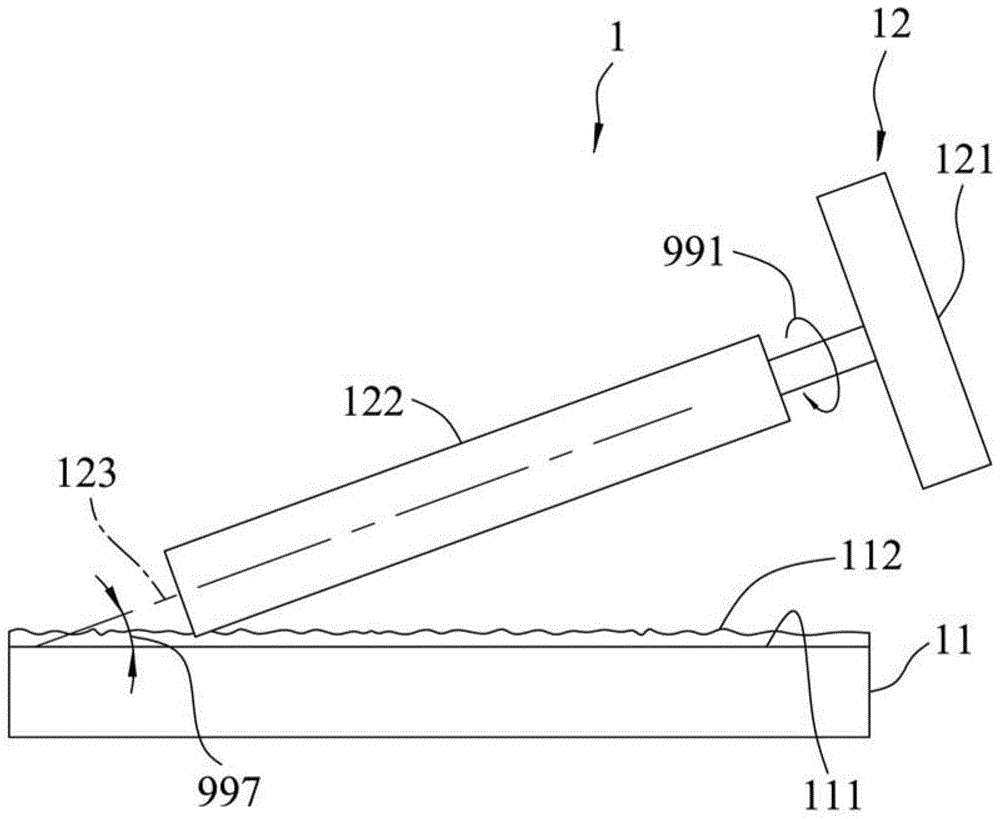

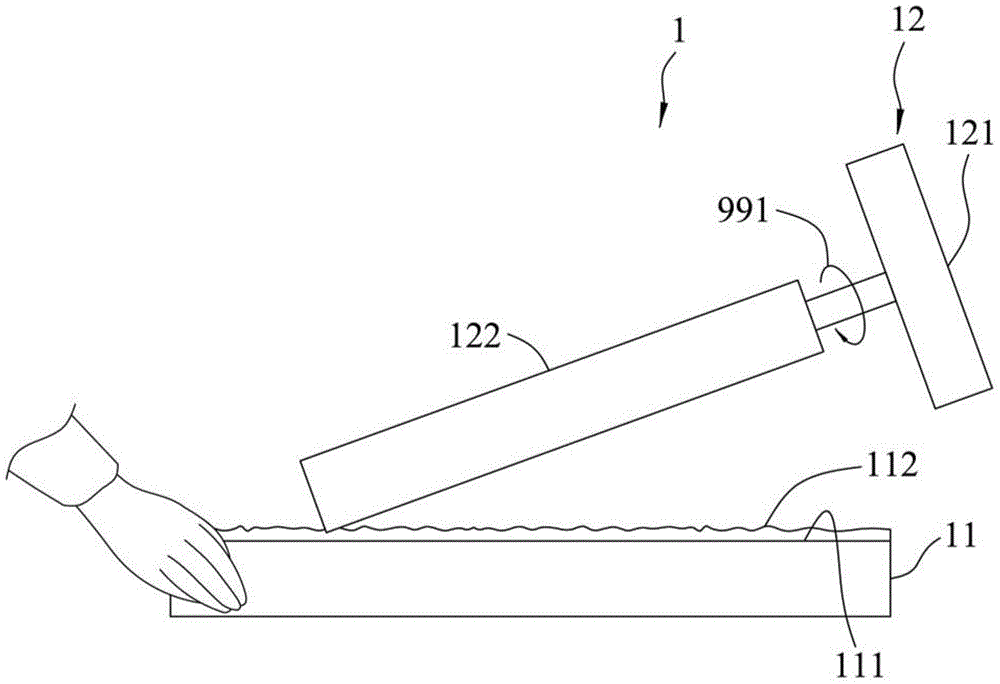

[0037] refer to figure 1 , figure 2 , a preferred embodiment of the method for removing colloids of the present invention is as figure 2 The degumming system 1 shown is performed.

[0038] The glue removing system 1 includes a work piece 11, a glue removing device 12, and a control interface (not shown). The work object 11 includes a surface 111, and an adhesive 112 attached to the surface 111 of the work object 11. In the adhesive removal system 1 implemented in this preferred embodiment, the work object 11 is, for example, a capacitor in a touch device. Touch panels, resistive touch panels, optical touch panels and other components, or components such as liquid crystal display panels, light-emitting diode display panels, plasma display panels, and electronic paper in display devices.

[0039] The adhesive removing device 12 includes a device body 121 , and a sticking member 122 pivotally connected to the device body 121 and capable of being controlled to rotate around a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com