A kind of dissolving agent for removing cured silicone rubber and preparation method thereof

A technology of curing silicone rubber and dissolving agent, which is applied in the field of silicone rubber dissolving agent and its preparation, which can solve the problems of device influence, soaking time should not be too long, etc., and achieve the effect of non-damage degumming and high degumming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

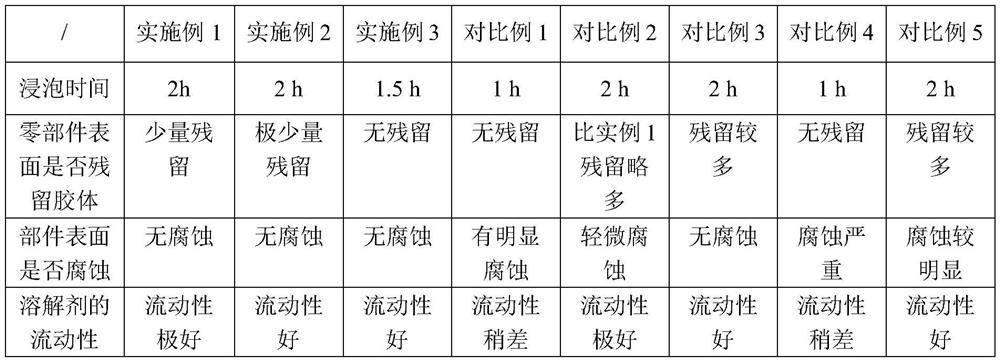

Examples

Embodiment 1

[0016] By weight percentage, 30% ethanol, 4% sodium hydroxide, and 2% dimethyl silicone oil with a viscosity of 300 mPa.s were stirred and heated at 50° C. for 1 h, and the obtained reaction product was mixed with 58.4% of 120# solvent oil, 0.6% benzotriazole and 5% liquid paraffin are mixed and stirred evenly to obtain a silicone rubber dissolving agent.

Embodiment 2

[0018] 30% isobutanol, 4% potassium hydroxide, 2% dimethicone oil with a viscosity of 500mPa.s were stirred and heated at 50°C for 1.5h, and the obtained reaction product was mixed with 55% 200# solvent oil, 4% The benzotriazole and 5% liquid paraffin are mixed and stirred evenly to obtain the silicone rubber dissolving agent.

Embodiment 3

[0020] 60% isobutanol, 6% potassium hydroxide, 8% dimethicone oil with a viscosity of 800mPa.s were stirred and heated at 60°C for 1.5h, and the obtained reaction product was mixed with 21.5% 120# solvent oil, 4% The benzotriazole and 0.5% liquid paraffin are mixed and stirred evenly to obtain the silicone rubber dissolving agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com