Wisdom school solid waste recycling treatment device

A solid waste and treatment device technology, which is applied in the field of solid waste recycling treatment devices in smart schools, can solve the problems of uneven stirring of solid waste, lower work efficiency, and affect the speed of fermentation, etc., and achieve novel design and reasonable structure , high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

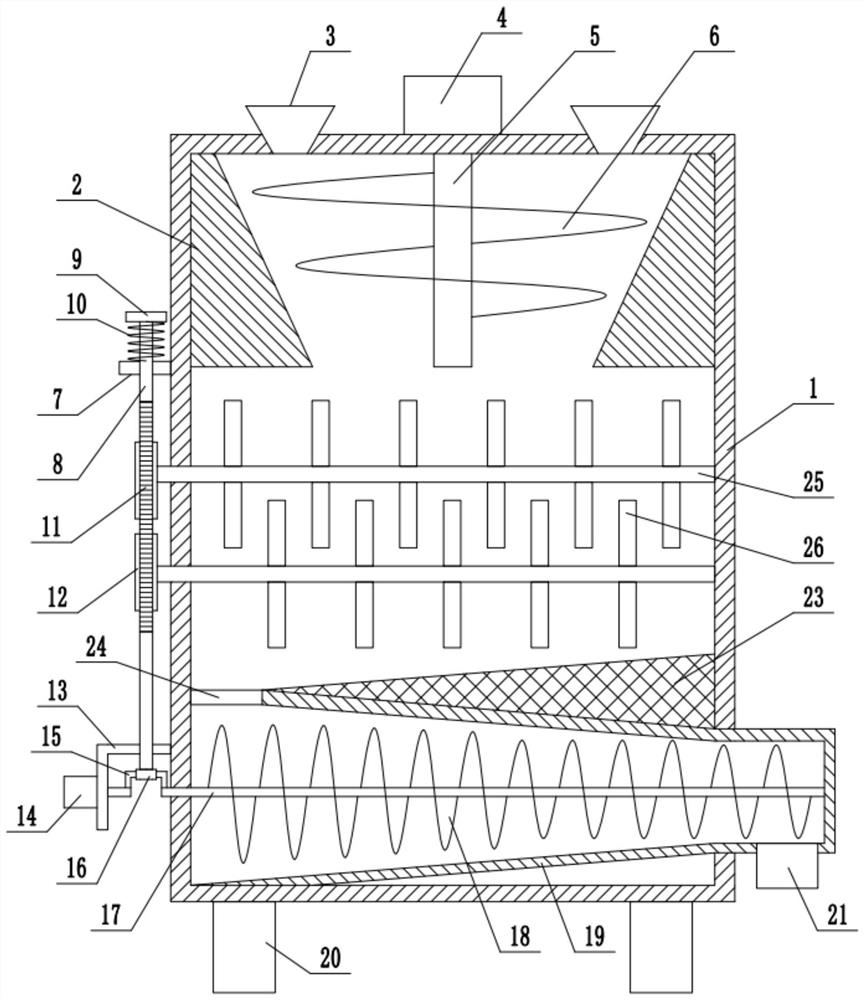

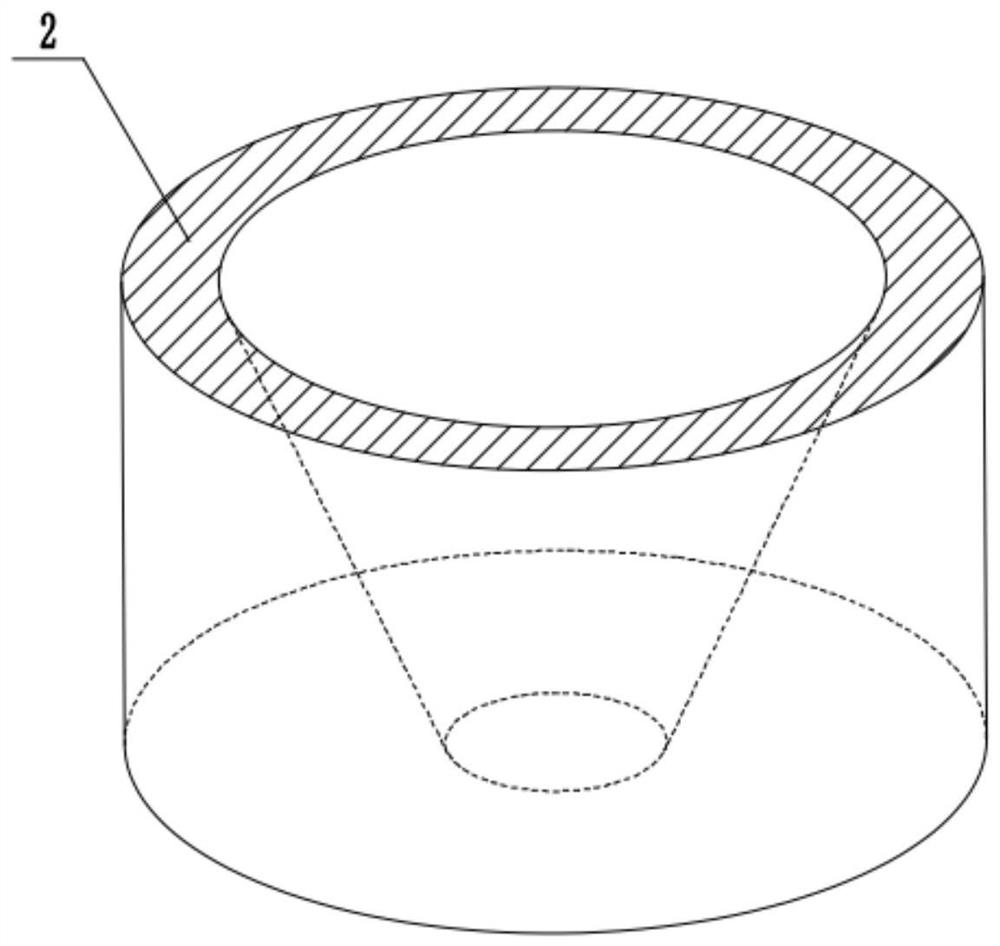

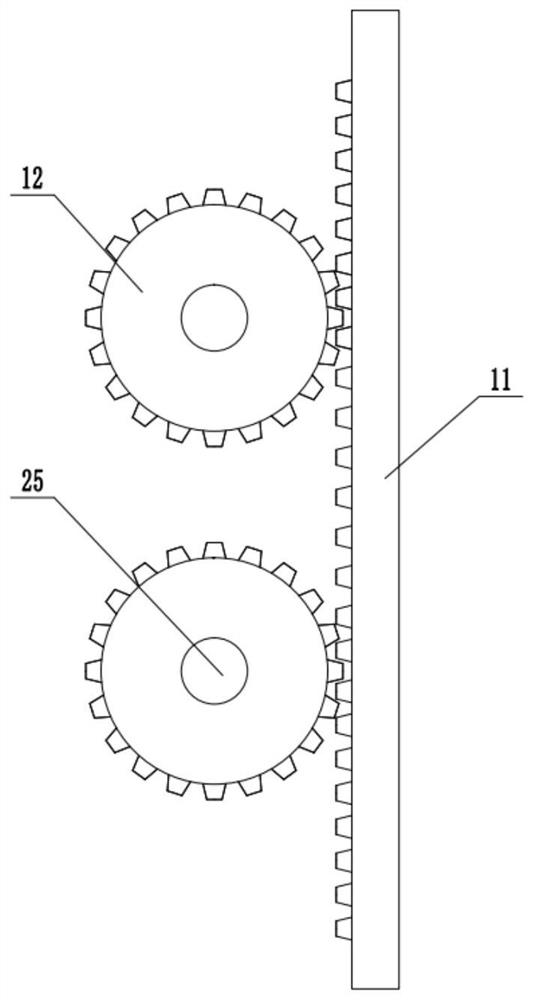

[0028] See Figure 1~3 In an embodiment of the present invention, a smart school solid waste recycling treatment device includes a treatment box 1. Support legs 20 are installed on both sides of the lower end of the treatment box 1 for supporting and fixing the entire device. A hopper 3 is installed on both sides of the upper end of the processing box 1 to introduce solid waste into the processing box 1, and a hopper cover is installed on the upper end of the hopper 3 to realize the installation and fixation of the hopper 3. The processing box 1 A crushing shaft 25 is installed inside. The right end of the crushing shaft 25 is fixed to the inner wall of the processing box 1 through a bearing, so that the crushing shaft 25 can rotate along the processing box 1. A number of staggered crushing leaves 26 are provided on the outside of the crushing shaft 25. In order to crush garbage more efficiently, the left side of the crushing shaft 25 passes through the treatment box 1 and is c...

Embodiment 2

[0030] In another embodiment of the present invention, a smart school solid waste recycling treatment device includes a treatment box 1, with supporting legs 20 installed on both sides of the lower end of the treatment box 1, and installed on both sides of the upper end of the treatment box 1 The upper end of the feeding hopper 3 is equipped with a hopper cover. The processing box 1 is equipped with a crushing shaft 25. The right end of the crushing shaft 25 is fixed to the inner wall of the processing box 1 through a bearing. For the crushing blade 26, the crushing shaft 25 passes through the processing box 1 on the left side and is connected with a gear 12, the inner bottom of the processing box 1 is equipped with a crushing drum 19, and the bottom left of the crushing drum 19 is installed with a discharge hopper 21 and a crushing drum 19 A rotating shaft 17 is installed inside. The lower end of the rotating shaft 17 is installed with an L-shaped bracket 13 in the middle. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com