Mold bar push-out mechanism in capsule production system

A technology of capsule production system and ejection mechanism, which is applied to electromechanical devices, mechanical equipment, and mechanical energy control, etc., can solve the problems of high noise, easy wear and tear, and inconvenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

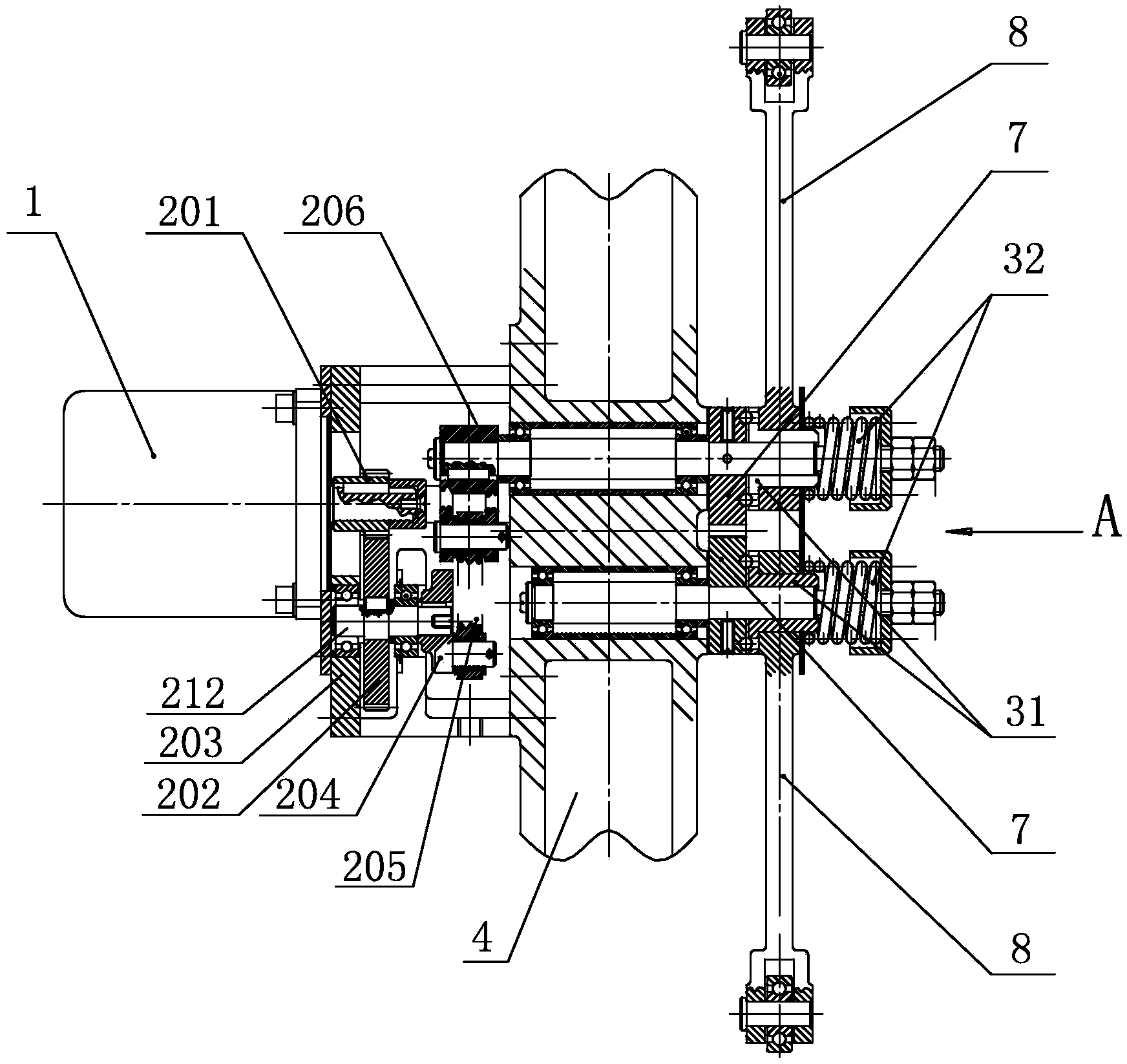

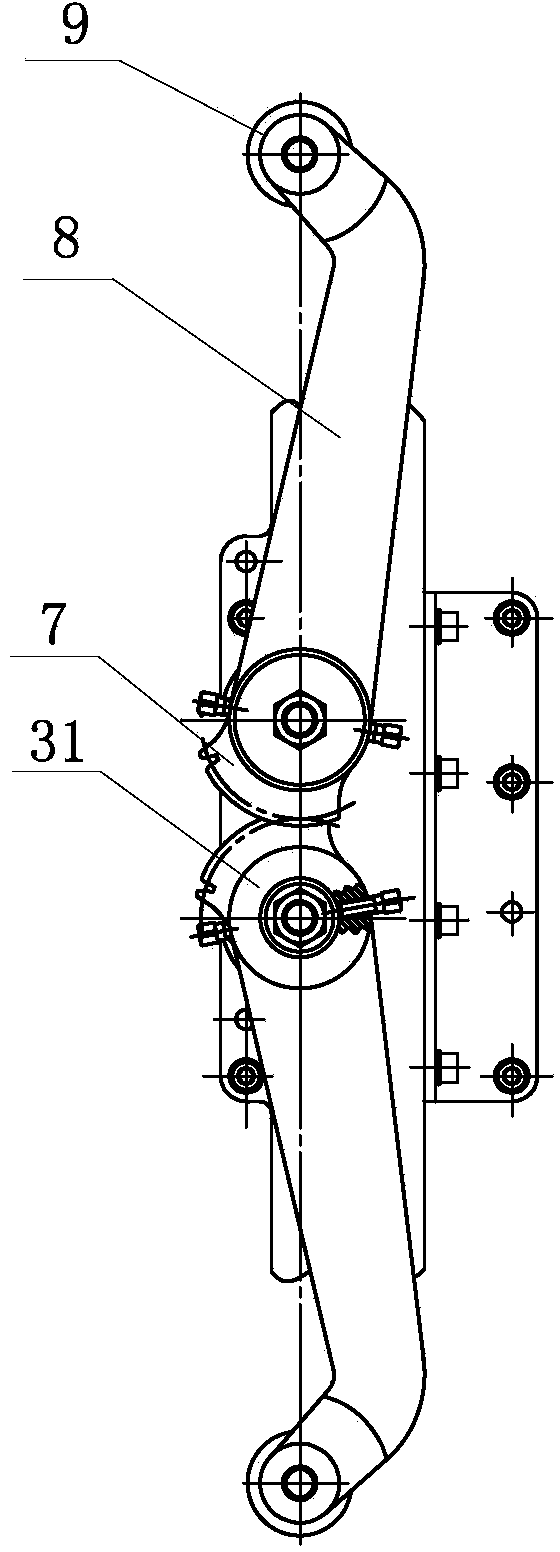

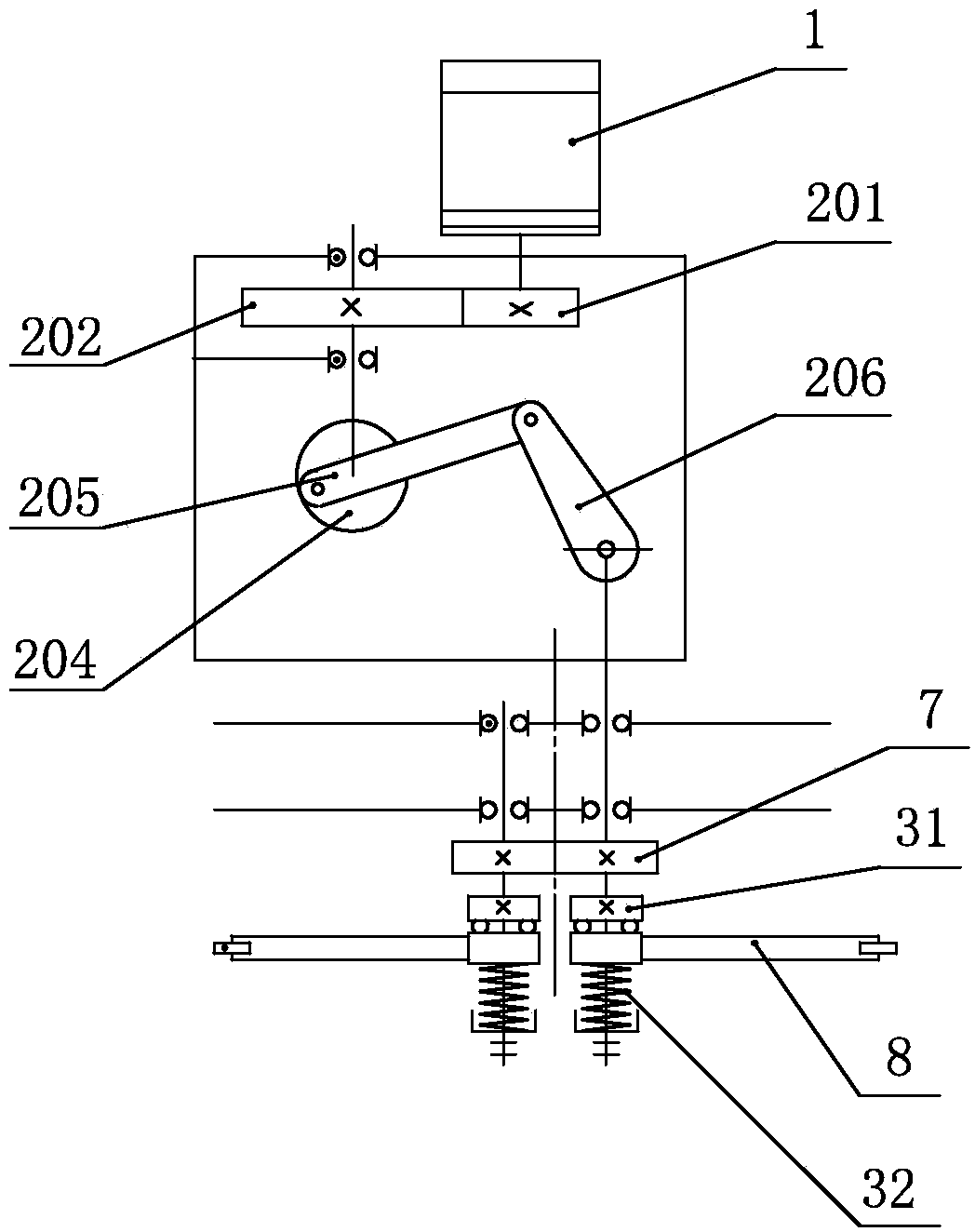

[0026] Example: such as figure 1 , figure 2 As shown, the present invention is installed on the push-out crossbeam 4 of the dipping machine, including a push-out motor 1, a transmission device 2, an active push-out shaft 5, a driven push-out shaft 6, two push-out arms 8 and an overload protection device 3 thereof. The push-out shaft 5 and the driven push-out shaft 6 are all installed on the push-out crossbeam 4, and one end of the active push-out shaft 5 and the driven push-out shaft 6 stretches out the push-out crossbeam 4, and the half teeth 7 which mesh with each other are respectively installed on it, and the two push-out arms 8 respectively Installed on the active push-out shaft 5 and the driven push-out shaft 6, the overload protection device 3 is installed at the ends of the active push-out shaft 5 and the driven push-out shaft 6 where the push-out arm 8 is installed, and the other end of the active push-out shaft 5 protrudes out of the push-out beam 4. Connect the ej...

Embodiment 2

[0034] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the transmission device 2 includes a box body 203 and intermeshed third and fourth gears 208 and 209 placed in the box body 203, an in-situ trigger ring 210 and The trigger ring 211 is in place, the third gear 208 is installed on the ejection motor shaft, the fourth gear 209 is installed on the active ejection shaft 5 extending into the transmission box 203, the fourth gear 209 has a sleeve structure, The active release shaft 5 end at the fourth gear 209 end is equipped with an in-situ trigger ring 210, and the sleeve outer sleeve of the fourth gear 209 is equipped with a trigger ring 211 in place; the active release shaft 5 rotates to the trigger position of the trigger ring in place, and the motor 1 is released. Reverse and return, the active push-out shaft 5 rotates to the trigger position of the original trigger ring 210, and the push-out motor 1 rotates forward.

[0035]When the mold bar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com