High-efficiency material screening and separation device with adaptive disturbance function

A technology of perturbation function and separation equipment, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of unsatisfactory screening effect and difficult to meet the needs of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

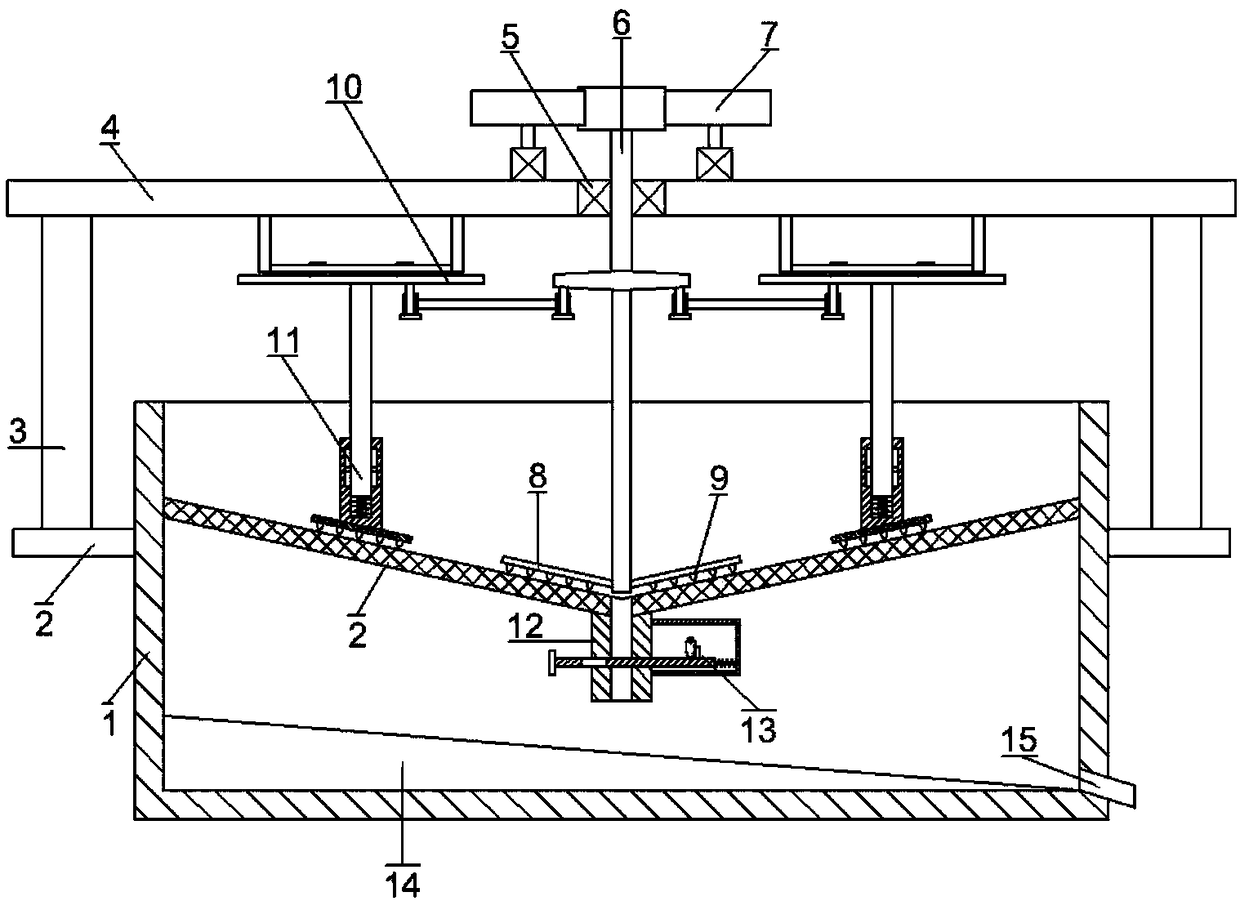

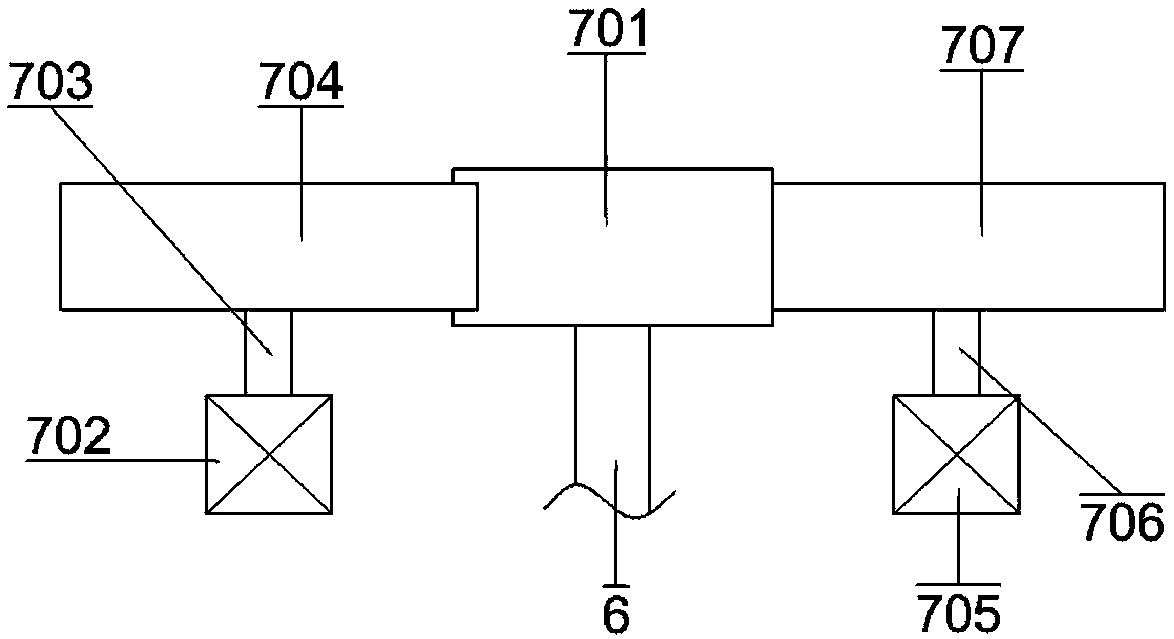

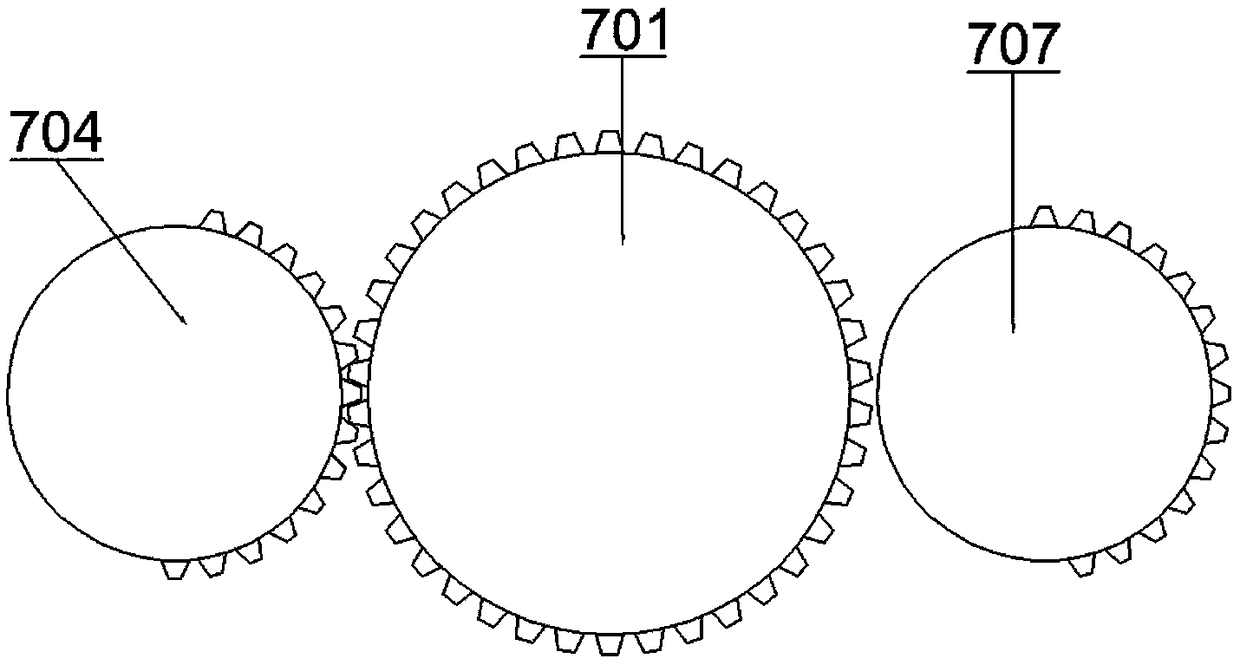

[0034] see figure 1 , figure 2 and image 3 , in this embodiment, a high-efficiency material screening and separation device with adaptive disturbance function includes a processing frame 1, the top of the processing frame 1 is open, and the inner wall of the processing frame 1 is fixedly connected with a screen The net 16 and the screen mesh 16 have a V-shaped section, and two horizontal seats 2 are symmetrically fixedly connected to the outer wall of the processing frame 1, and the upper side of the horizontal seat 2 is fixedly connected with a supporting column 3, and the tops of the two supporting columns 3 are connected to each other. A support plate 4 is fixedly connected, a bearing 5 is embedded in the middle of the support plate 4, a rotating ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com