Adsorption and decomposition integrated formaldehyde removal equipment

An all-in-one, formaldehyde-based technology, applied in gas treatment, separation methods, and dispersed particle separation, can solve the problems of unfavorable use, large volume, and high cost of use, and achieve the effects of accelerating absorption speed, increasing contact area, and ensuring dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

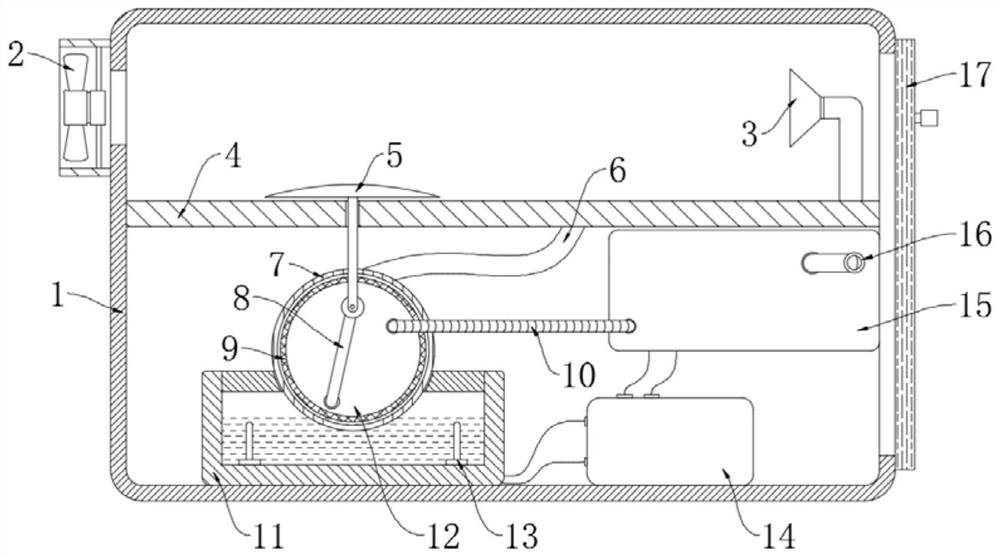

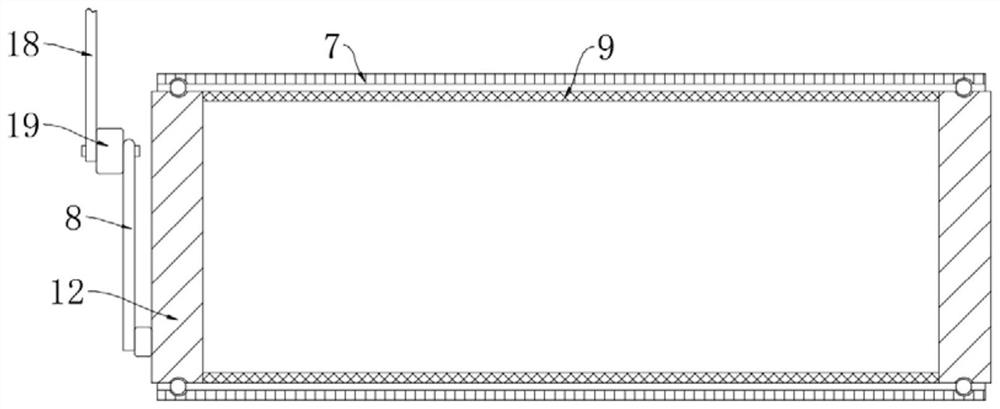

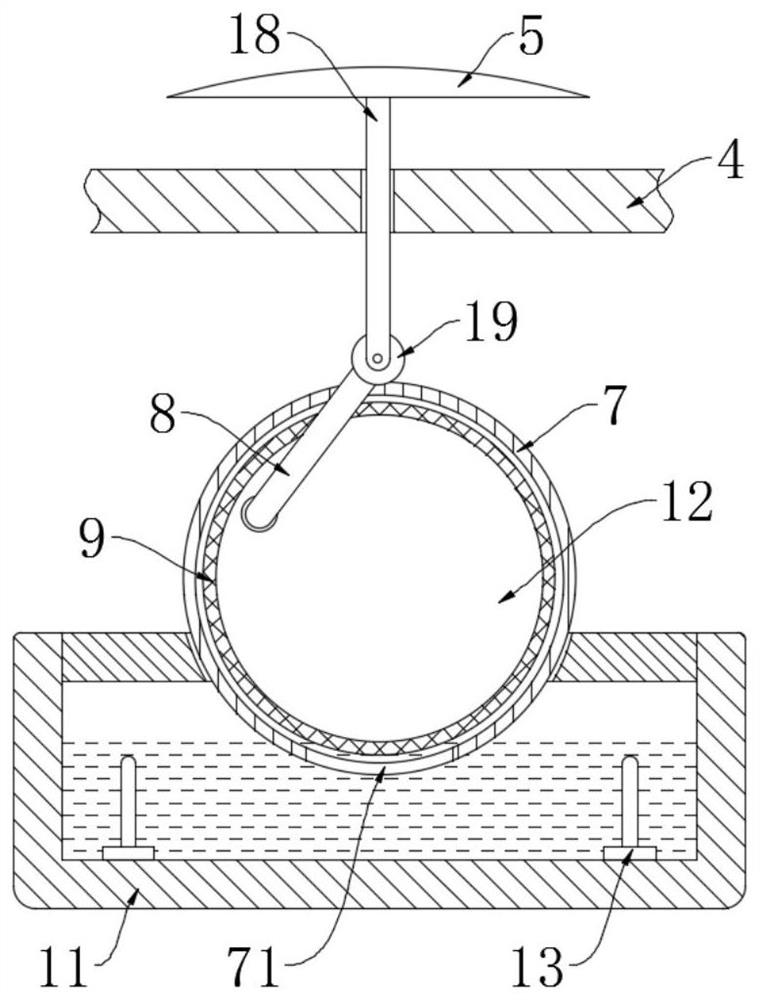

[0025] refer to Figure 1-3 , an adsorption and decomposition integrated formaldehyde removal equipment, including a casing 1, an axial flow fan 2 is installed on the outer wall of the casing 1, and an air inlet corresponding to the position of the axial flow fan 2 is opened on the side wall of the casing 1 The liquid storage box 11 and the control part 14 are fixedly placed on the inner bottom wall of the casing 1. The control part 14 includes structures such as circuit boards, lithium battery packs, and short circuit protection. The liquid storage box 11 contains electrolyte and control parts. 14 two electrodes 13 electrically connected, the electrolyte is sodium sulfate solution or a mixed solution containing sodium sulfite, ammonium sulfate, ammonium chloride and other substances, one of the two electrodes 13 is an inert electrode, such as a graphite rod, and the other electrode 13 is a catalytic electrode rod, such as a carbon fiber rod or a copper electrode rod loaded wi...

Embodiment 2

[0036] refer to Figure 4 , the present embodiment differs from Embodiment 1 in that: a liquid baffle 20 is sealed in the air induction area, and the liquid baffle 20 is located above the air inlet, and a plurality of capillary holes are evenly arranged on the liquid baffle 20, and the baffles A plurality of filter plates 21 are clamped between the liquid plate 20 and the sealing plate 4 .

[0037] When this embodiment is in use, a liquid replenishment port is also provided on the top wall of the casing 1, and water is added to the casing 1 through the liquid replenishment port, so that the upper part of the liquid separator 20 is filled with an aqueous solution. Active downward flow at the hole;

[0038] When the axial flow fan 2 guides the air into the air-inducing area, the high-speed airflow will cause the water to diffuse to the bottom of the liquid separator 20 through the capillary holes, and the water mist will be wrapped around the outside of the dust after mixing wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com