Sintering kiln and process of preparing regeneration bricks through sintering kiln

A sintering kiln and kiln chamber technology, applied in the field of sintering kilns, can solve the problems of insufficient sintering degree of the inner brick body and uneven heating of the brick body, and achieve the effects of simple and convenient production process, uniform heating, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings.

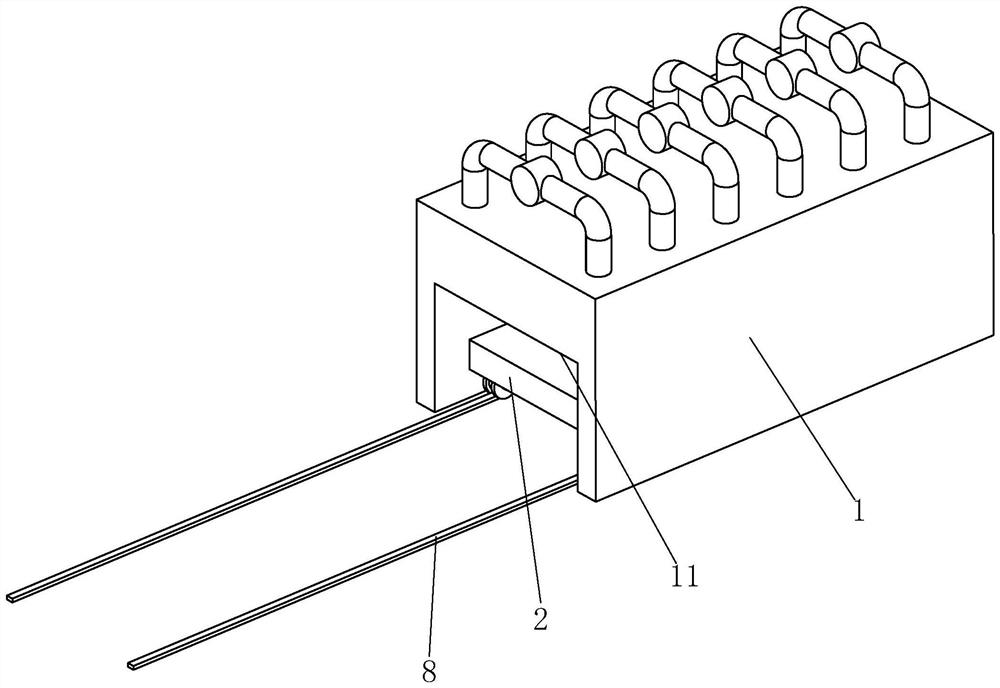

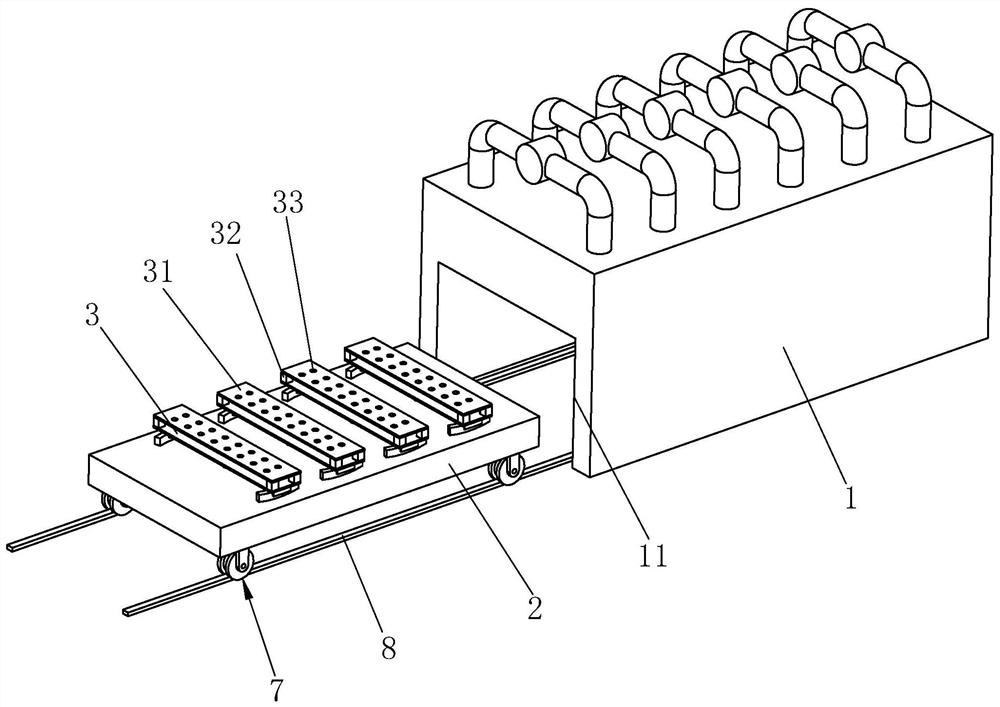

[0050] refer to figure 1 , is a sintering kiln disclosed by the present invention, comprising a kiln chamber 1 and a kiln car arranged in the kiln chamber 1, one side of the kiln chamber 1 is provided with a kiln mouth 11 for the kiln car to enter and exit the interior, that is, the kiln car can Slip out of the kiln chamber 1 from the kiln mouth 11. The kiln car is used to hold the bricks that have been formed and to be sintered. When the bricks are sintered, multiple bricks are stacked on the kiln car, and then the stacked bricks are sent into the kiln chamber 1 through the kiln car. Carry out sintering work.

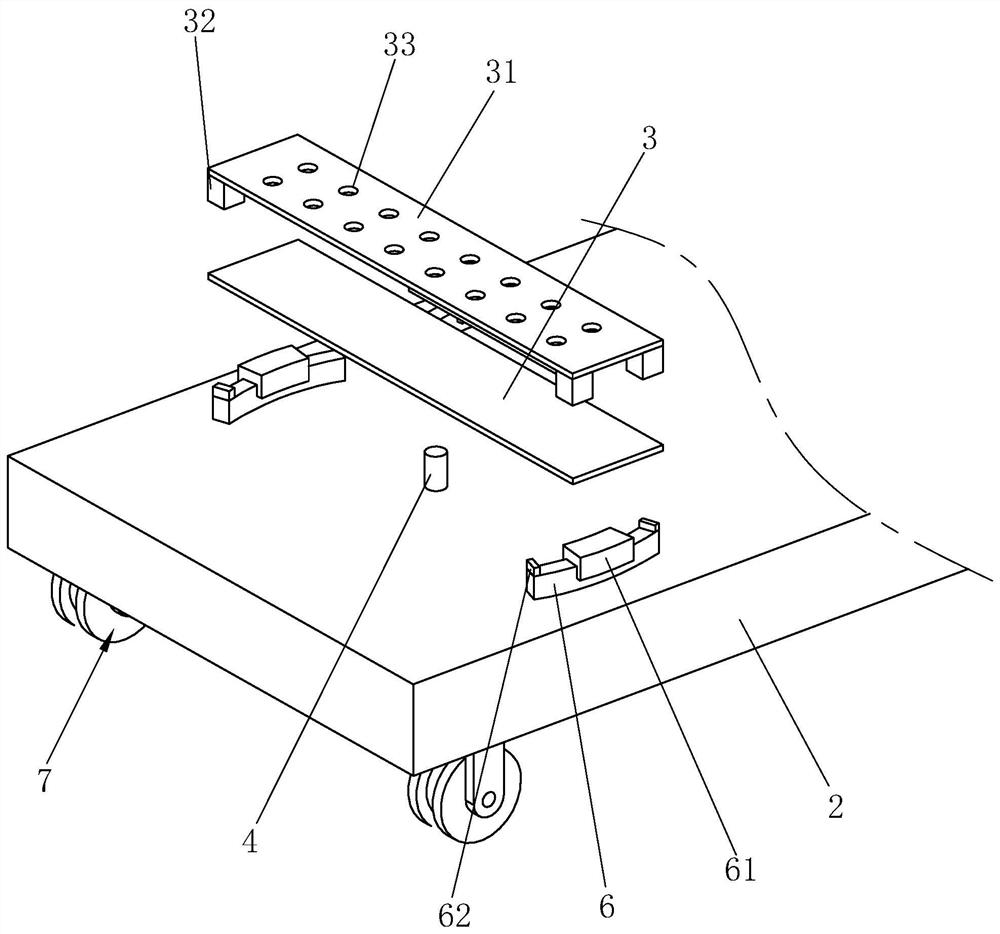

[0051] Among them, refer to figure 2 and image 3 , The kiln car includes a base 2, the base 2 is arranged as a hollow rectangular shell, a plurality of bearing platforms 3 are arranged above the base 2, the bearing platforms 3 are arranged along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com