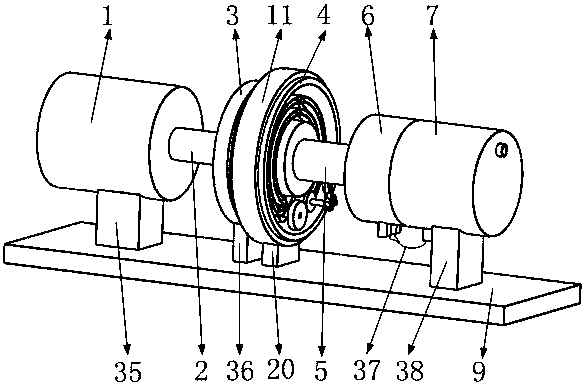

Swing type air compressor

An air compressor and swing type technology, which is applied in the field of air compressors, can solve the problems of complex reciprocating motion structure of the plunger, reduced practical use effect, and increased equipment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

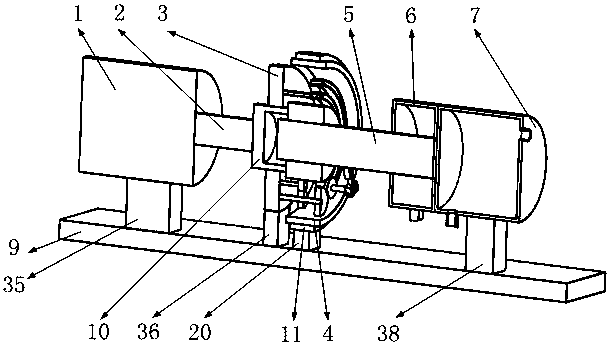

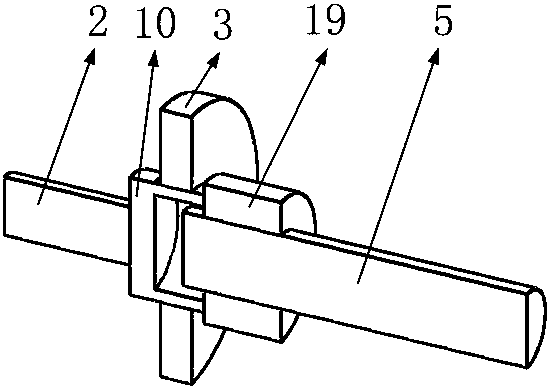

[0034] Specific embodiments: in the present invention, the drive shaft 2 is driven by the motor 1, and the rotational kinetic energy on the drive shaft 2 drives the sun gear 19 connected to the transmission shaft 5 through the sun gear drive structure 10 to rotate around the axis of the transmission shaft 5; the sun gear 19 Part of the rotational kinetic energy drives the planetary gear 18 to rotate around the axis of the planetary gear shaft 21, and the other part of the rotational kinetic energy drives the conversion gear 32 to rotate around the axis of the conversion gear shaft 34; the rotational kinetic energy of the planetary gear 18 drives the ring gear 4 to revolve around the transmission shaft 5 axis rotation; the rotational kinetic energy of the conversion gear 32 drives the auxiliary pinion gear 31 to rotate around the auxiliary gear shaft 33 axis, and the rotational kinetic energy of the auxiliary gear shaft 33 drives the auxiliary large gear 30 to rotate around the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com