Seat electric rotation mechanism

A technology of electric rotation and seats, which is applied in the direction of movable seats, vehicle seats, special positions of vehicles, etc., can solve the problems of heavy weight, large space occupation, complex structure, etc., and achieves few parts, small space occupation, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

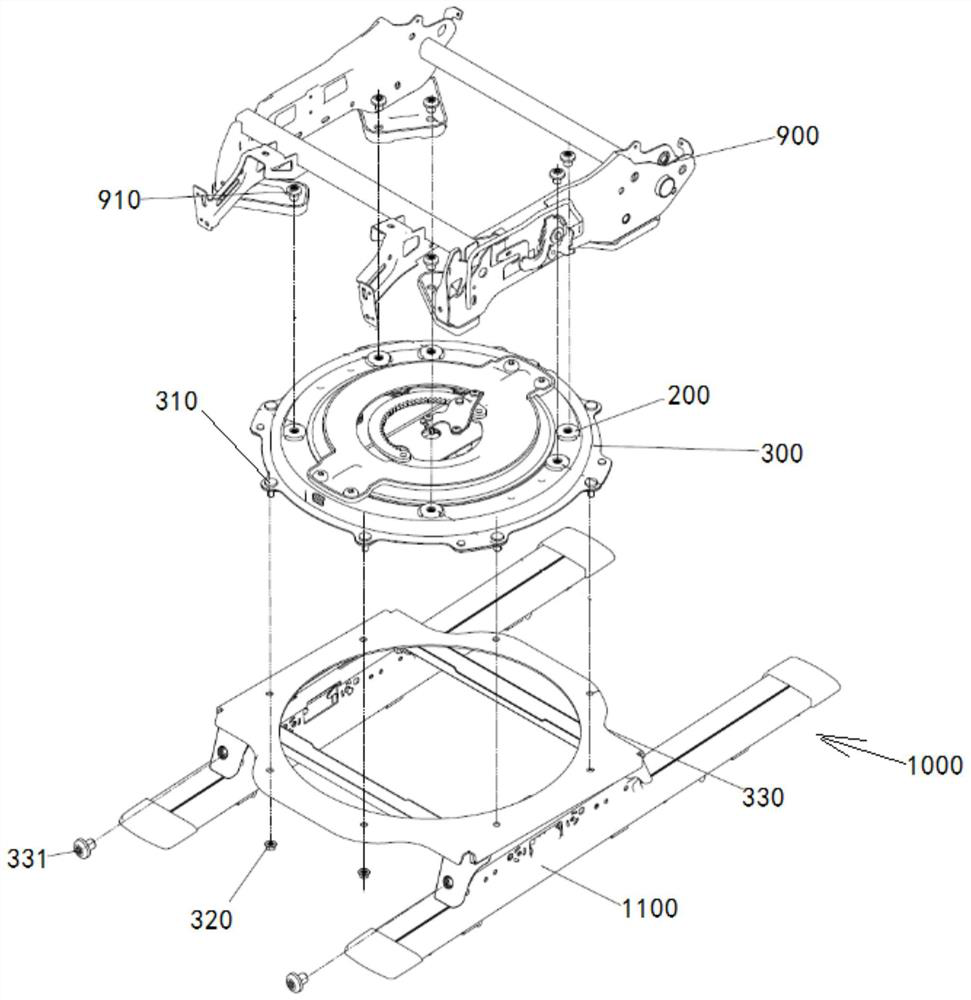

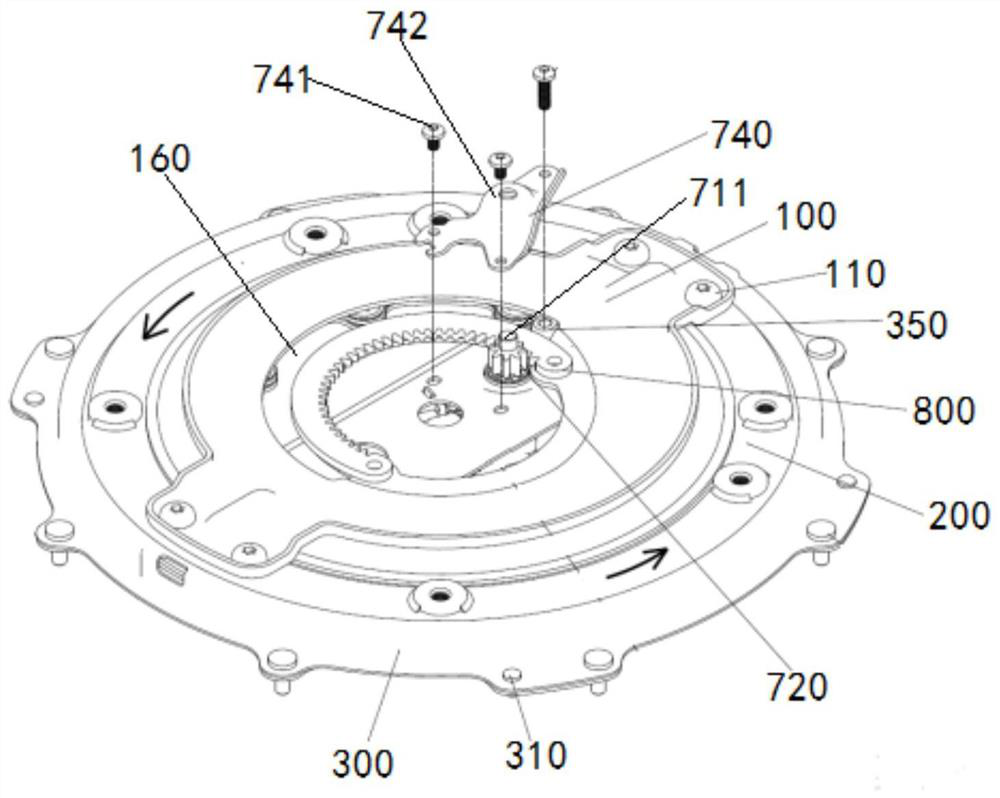

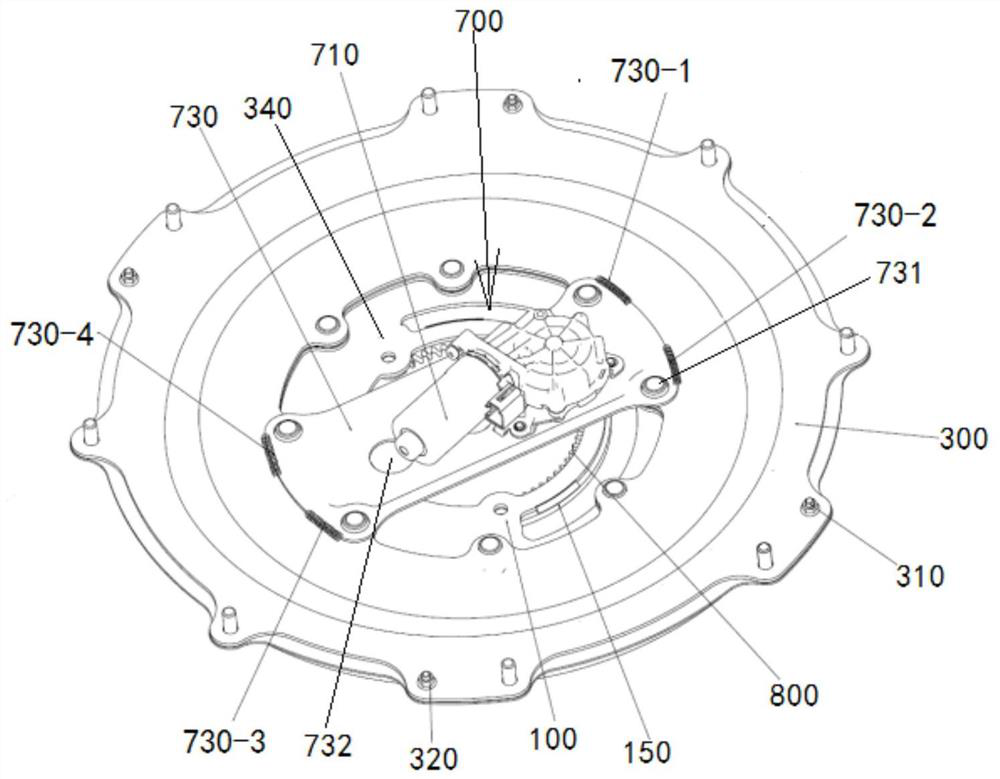

[0050] see Figure 4 and Figure 5, the seat electric rotating mechanism shown in the figure includes a rotating bracket 100, a rotating disk 200, a fixed disk 300, a pressure plate 400, an upper ball assembly 500, a lower ball assembly 600, a drive motor assembly 700 and a semicircular rack 800 . The above-mentioned rotating bracket 100, rotating disc 200, fixed disc 300, pressure plate 400, semicircular rack 800, upper ball cage 520 in the upper ball assembly 500, and lower ball cage 620 in the lower ball assembly 600 are all stamped. It has the advantages of high strength and light weight.

[0051] see in conjunction figure 1 , there are 6 M10 nuts 200-1, 200-2, 200-3, 200-4, 200-5, 200-6 spot welded on the rotating disk 200, and the seat cushion frame 900 in the seat is screwed in by 6 Bolts 910 of six M10 nuts 200-1, 200-2, 200-3, 200-4, 200-5, 200-6 are fixedly connected with the rotating disk 200 .

[0052] Eight M8 bolts 310 are spot-welded on the fixed plate 300,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com