Capsule production line system

A production line and capsule technology, which is applied in the field of capsule production line system, can solve the problems of complex structure, reduce the service life of equipment, increase the cost of capsule manufacturing, etc., and achieve the effect of simple structure and uniform oiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

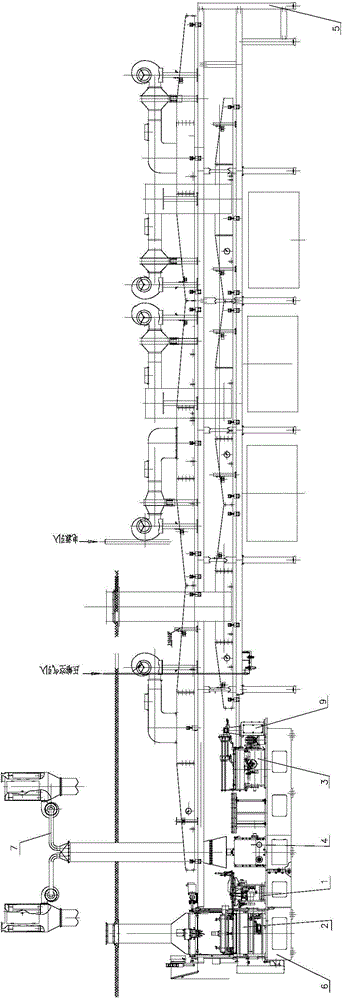

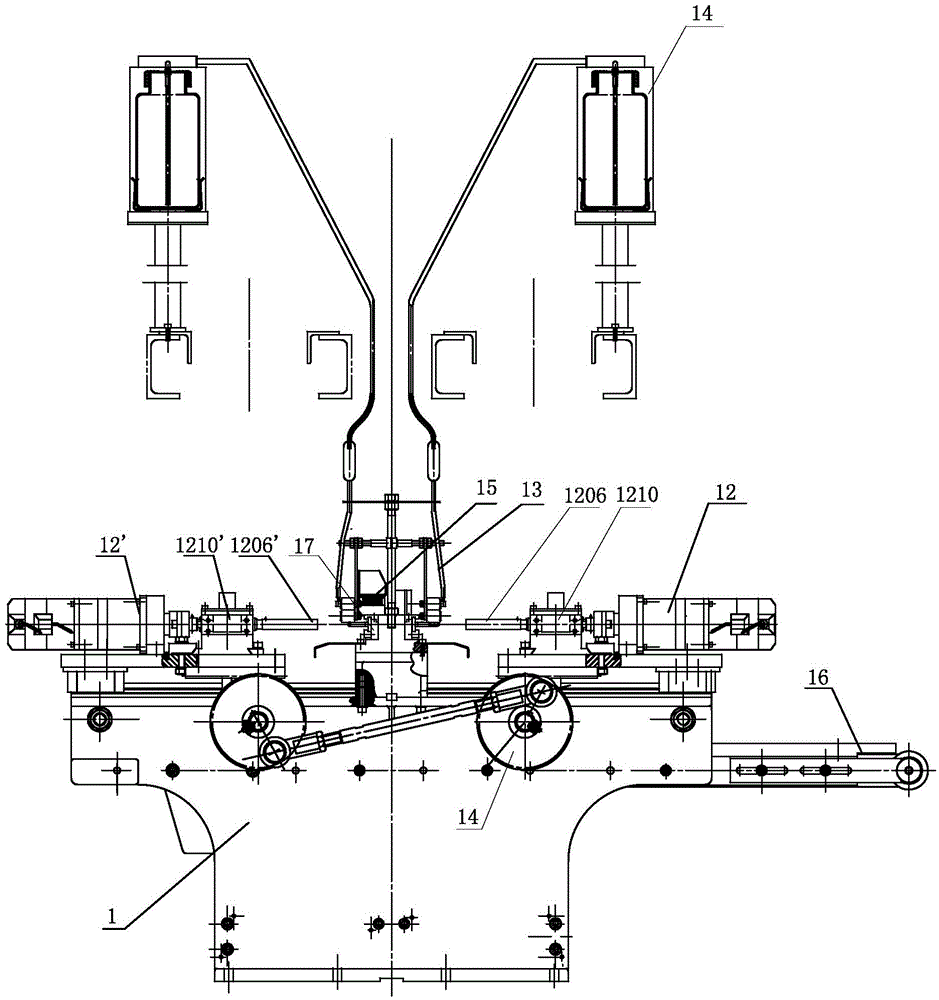

[0091] Example: such as figure 1 As shown, the present invention includes a main base 6, an oiling machine 1, a glue dipping machine 2, an automatic machine 4, a platform machine 3, a conveying drying device, a tail platform lifting mechanism 5 arranged at the end of the conveying drying device, The waste suction device 7 above the automatic machine 4, the large and small conveyor belt devices 16, 15, and the main motor transmission box 9 placed on the oil spreader 1;

[0092] The oiling machine 1, the glue dipping machine 2, the automatic machine 4 and the platform machine 3 are arranged in parallel on the main base 6, respectively connected to the servo motors, and driven by the servo motors;

[0093] The platform machine 3 is installed between the carriage slide 515 and the automatic machine 4 under the conveying drying device, at the end of the main base 6, the main motor transmission box 9 is connected to the platform machine 3 to drive the operation of the platform machine 3;...

Embodiment 2

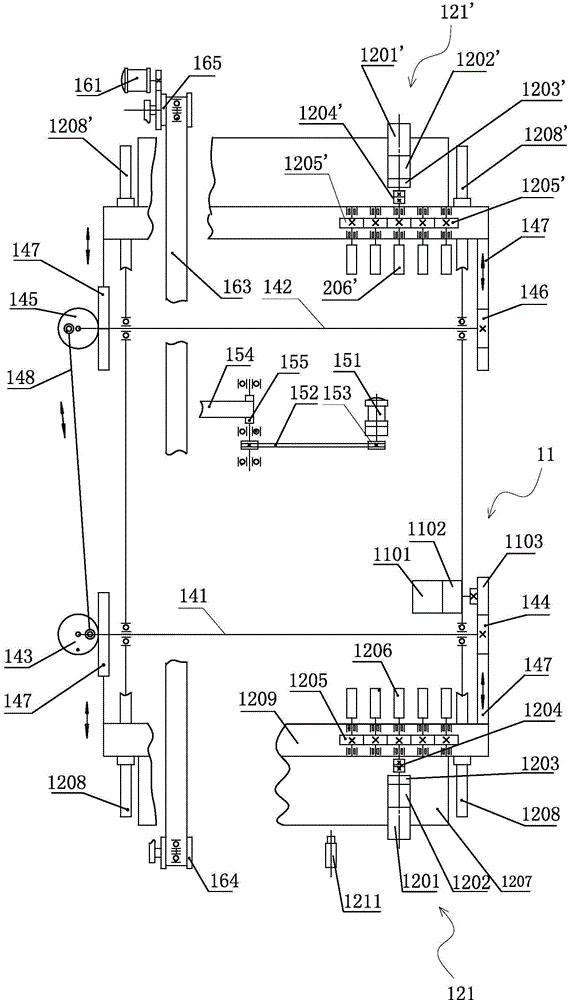

[0146] Embodiment 2: The difference between this embodiment and embodiment 1 is: Picture 11 , Picture 12 As shown, the transmission device 22 in the glue dipping machine 2 includes a box body 2203, third and fourth gears 2208, 2209, an in-situ trigger ring 2210, and an in-place trigger ring 2211 that are placed in the box 2203 and mesh with each other. The third gear 2208 is mounted on the push-out motor shaft, and the fourth gear 2209 is mounted on the active push-out shaft 5 that extends into the transmission box 2203. The fourth gear 2209 has a sleeve structure. An in-situ trigger ring 2210 is installed at the end of the active push-out shaft 25, and an in-place trigger ring 2211 is installed on the sleeve of the fourth gear 2209; the active push-out shaft 25 rotates to the trigger position of the in-place trigger ring, and the push-out motor 201 reverses and returns to the active position. The ejection shaft 25 rotates to the trigger position of the home position trigger r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com