Grinding device for chemical powdery raw materials

A powder raw material and grinding device technology, applied in the chemical industry, can solve the problems of reducing the grinding quality of chemical raw materials, insufficient grinding of chemical raw materials, and low grinding efficiency, and achieves the effects of novel design, high reliability and increased grinding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

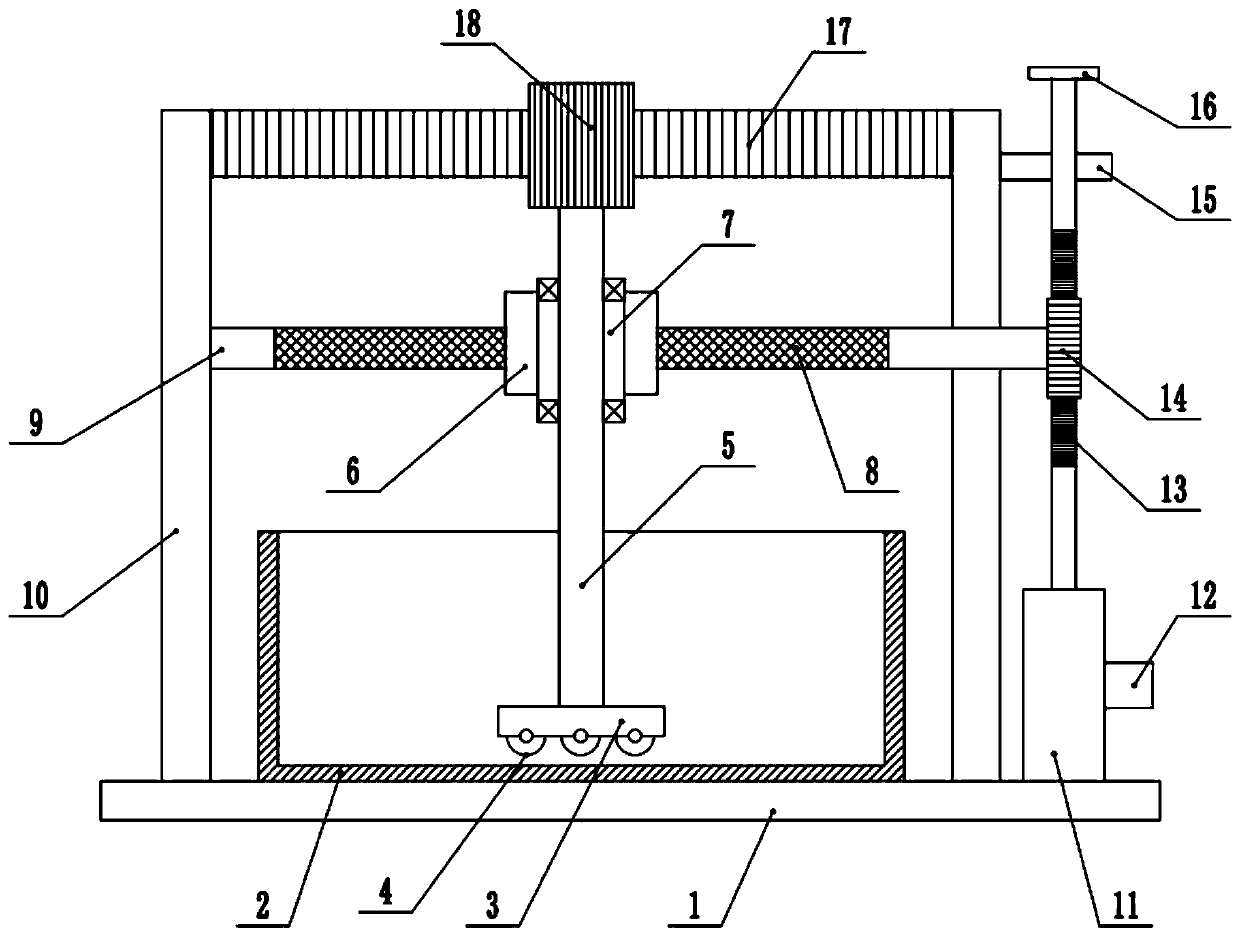

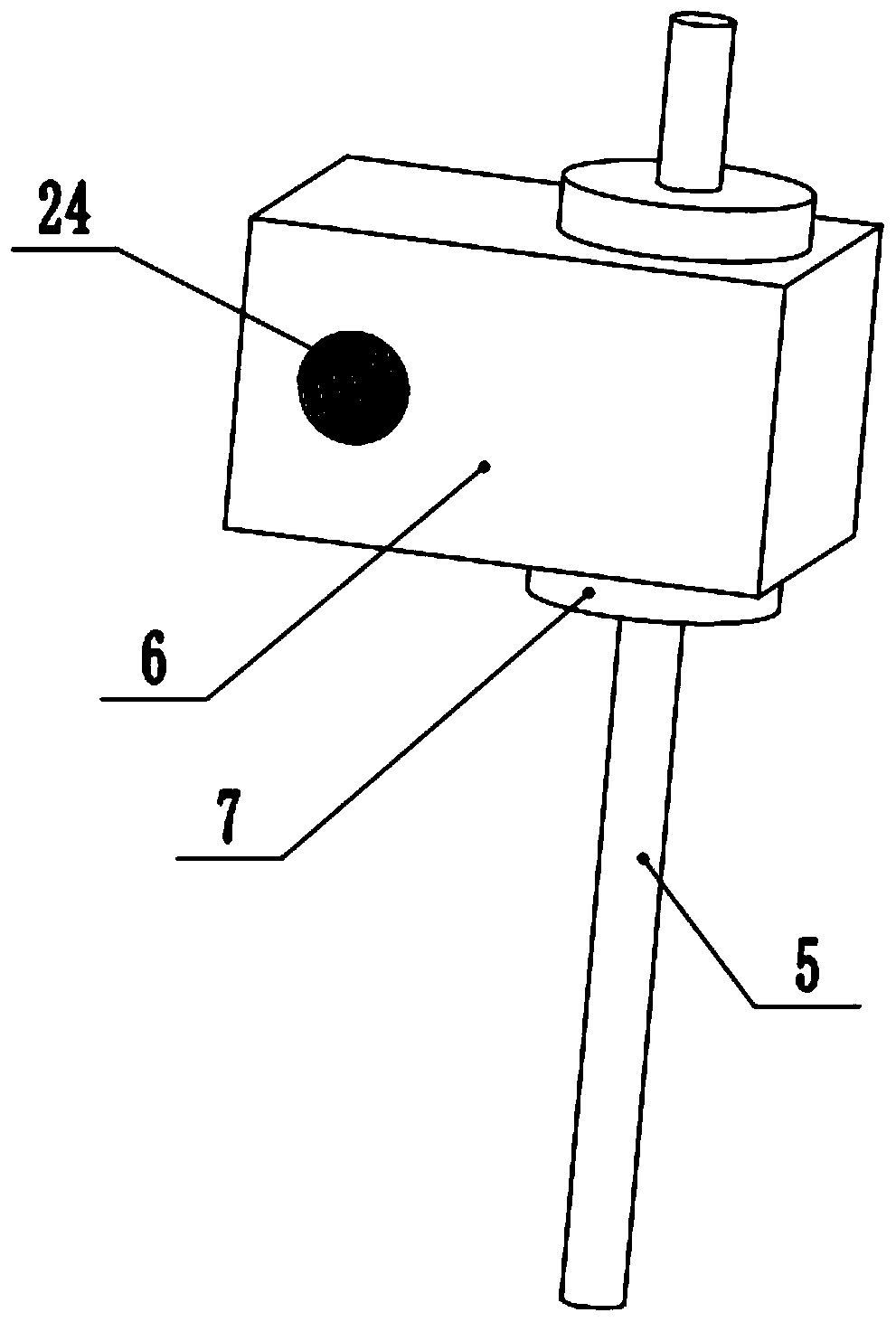

[0028] see Figure 1~3 , In the embodiment of the present invention, a chemical powder raw material grinding device includes a fixed bottom plate 1, a grinding frame 2 is installed in the middle of the upper end of the fixed bottom plate 1 for placing the chemical raw materials to be ground, and support frames are installed on both sides of the upper end of the fixed bottom plate 1 10. The support frame 10 is used to install and fix the fixed rack 17, and at the same time ensure the reliability of the entire grinding system. The right top of the support frame 10 on the right side is installed with a limit frame 15, which is used for the lifting gear. The upper and lower positions of the rack 13 are moved to limit the support to ensure that the lifting rack 13 will not shake in a large range during the remaining movement process. The middle of the limit frame 15 moves up and down, and a fixed rack 17 is installed between the top ends of the support frame 10. The front end of th...

Embodiment 2

[0030] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that a discharge hopper is installed in the middle of the rear end of the grinding frame 2, and the setting of the discharge hopper ensures that the material of the grinding frame 2 can be fully ground after grinding. of discharge.

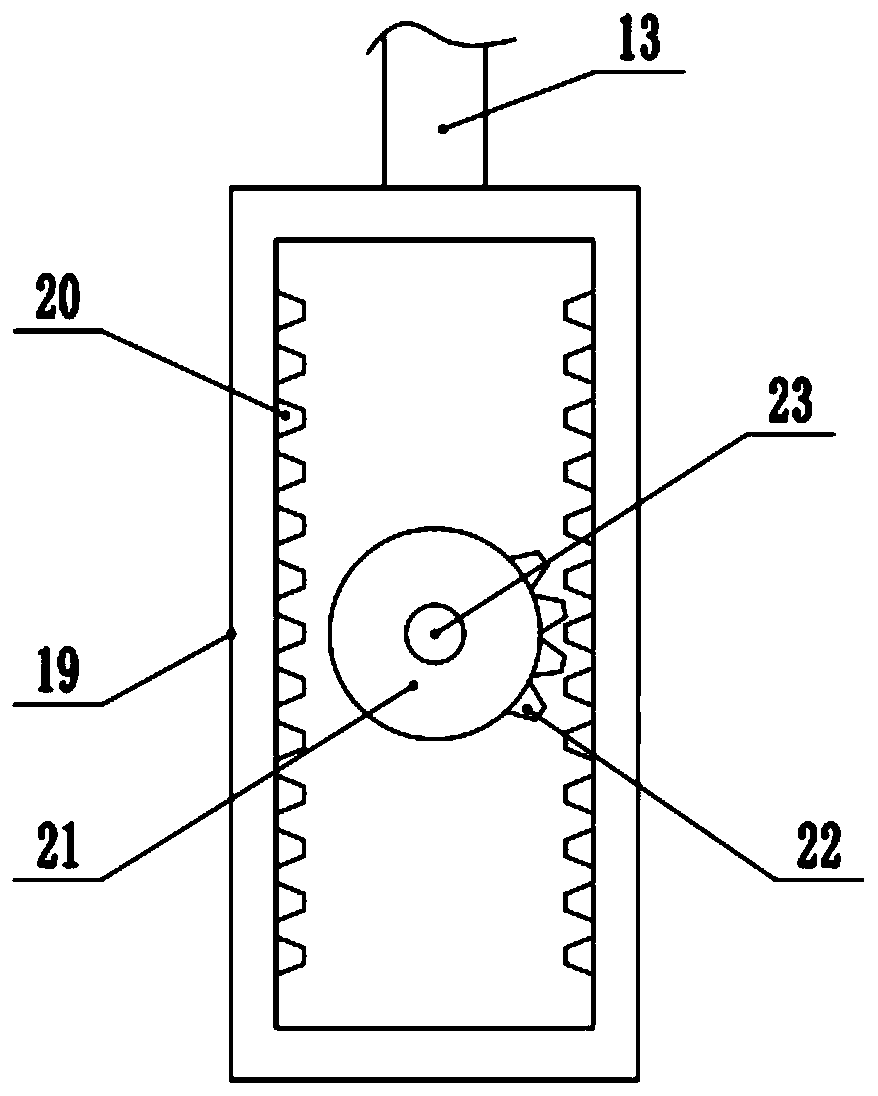

[0031]In the present invention, when in use, the chemical powder to be ground is placed inside the grinding frame 2, then the rotating motor 12 is started, and the rotating motor 12 drives the rotating wheel 21 to rotate, and then cooperates with the rack frame 19, so that the entire reciprocating mechanism 11 goes up and down Reciprocating movement, and then through the up and down movement of the elevating rack 13, the driving gear 14 can rotate alternately clockwise and counterclockwise, so that the driving shaft 9 also has the same movement, and then the threaded portion 8 in the middle of the driving shaft 9 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com