Giant tire activating mold

A tire flexible mould, giant technology, applied to tires, household appliances, and other household appliances, etc., can solve the problems of difficult movement, large operating force of opening and closing molds, and inability to use vulcanization tanks, etc., to achieve flexible and accurate movement and convenient tire removal Save labor and ensure quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

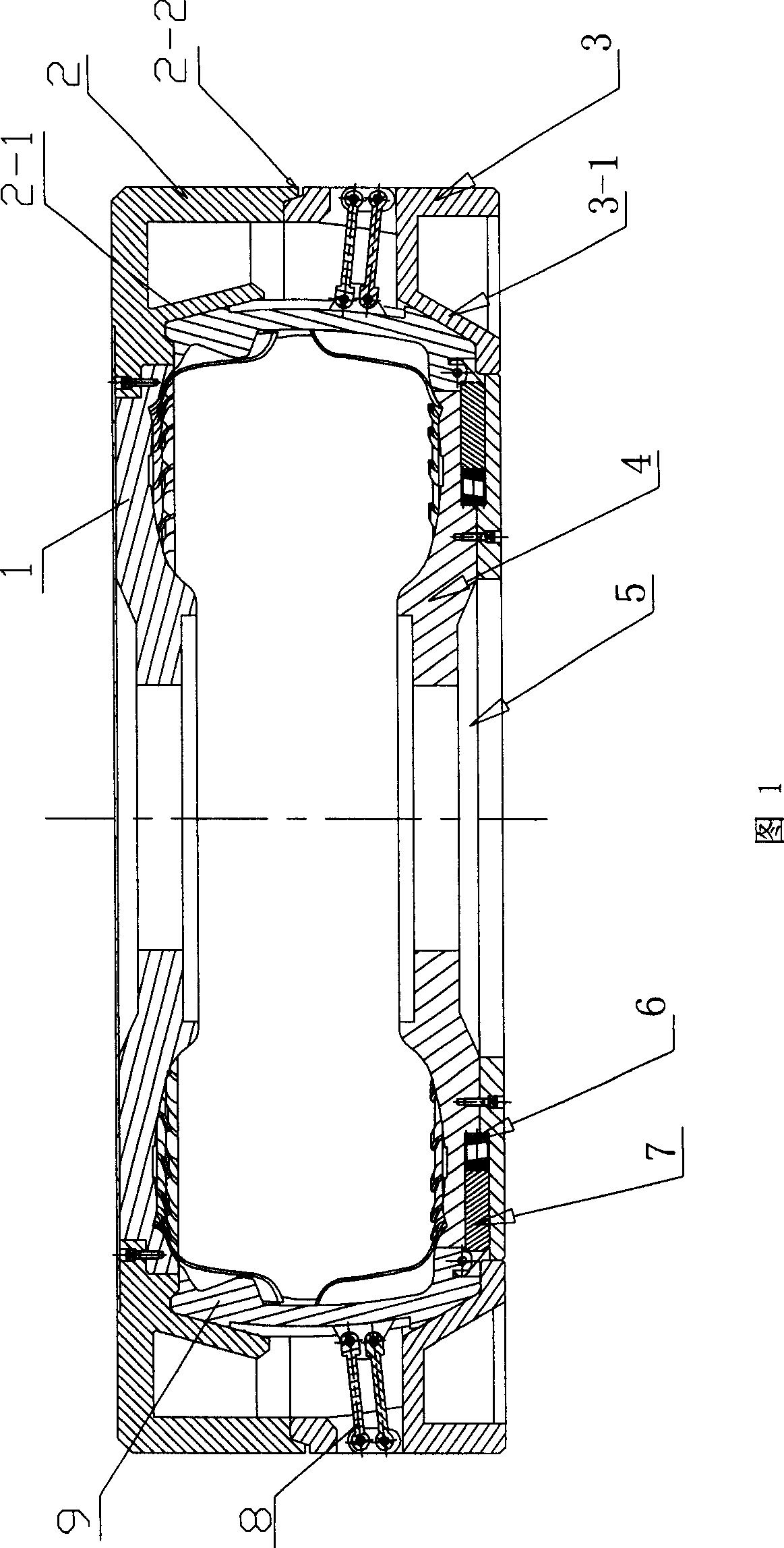

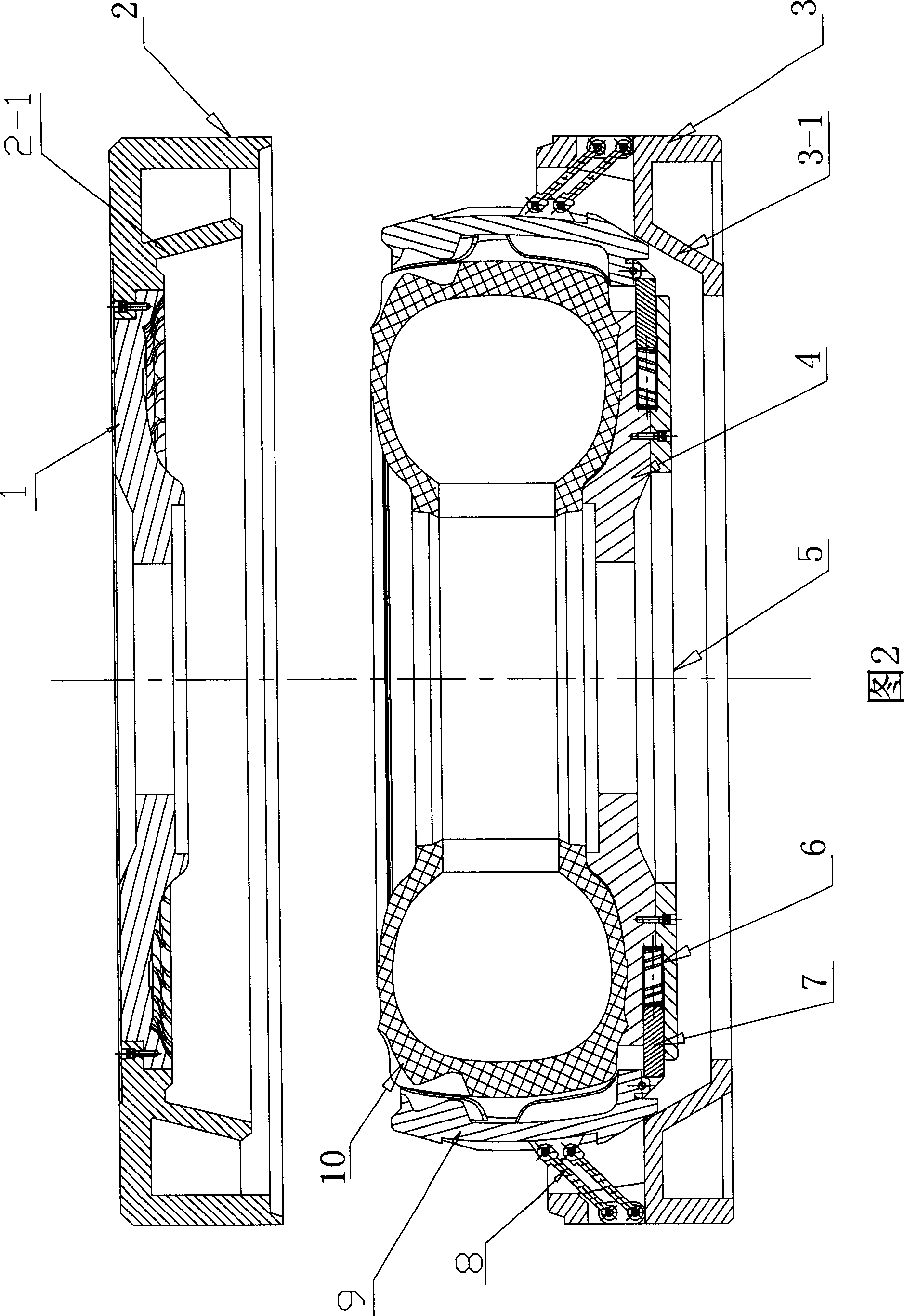

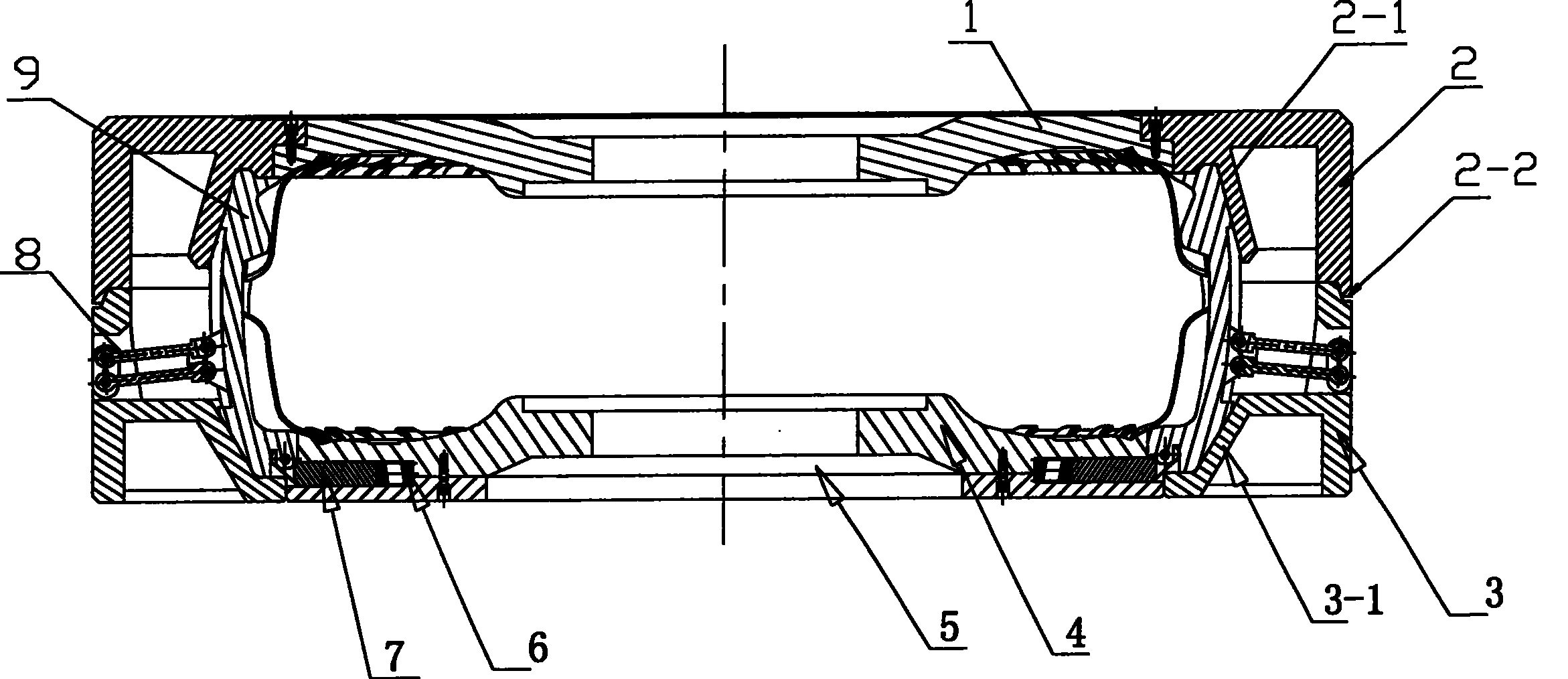

[0012] Embodiment of this giant tire flexible mold figure 1 with figure 2 As shown, it includes an upper mold case 2 and an upper template 1 installed on the upper mold case 2, a lower mold case 3 and a lower template 4 installed on the lower mold case 3, and 30 pattern modules 9 of the same size are installed around the lower template 4 Outer circumference, the bottom of the lower template 4 is fixedly connected with the push plate 5, and the bottom of each pattern module 9 is hinged with the outer end of a slider 7. The slider 7 is located between the lower template 4 and the push plate 5, and is embedded in the radial direction of the push plate 5. In the chute, two connecting rods 8 are hinged to connect the back of each pattern module 9 and the lower die sleeve 3 . The bottom of the back of each pattern module 9 is a downwardly inclined plane with the bottom end inwardly inclined, and the upper part of the back is an upwardly inclined plane with the upper end inclined i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com