Bearing assembly method

A bearing assembly and bearing technology, which is applied in the field of bearings with angular limit requirements, can solve the problems of marking error assembly knocking, position deviation, and repeated times in the assembly process, so as to avoid knocking on the bearing, stabilize assembly, and improve The effect of efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

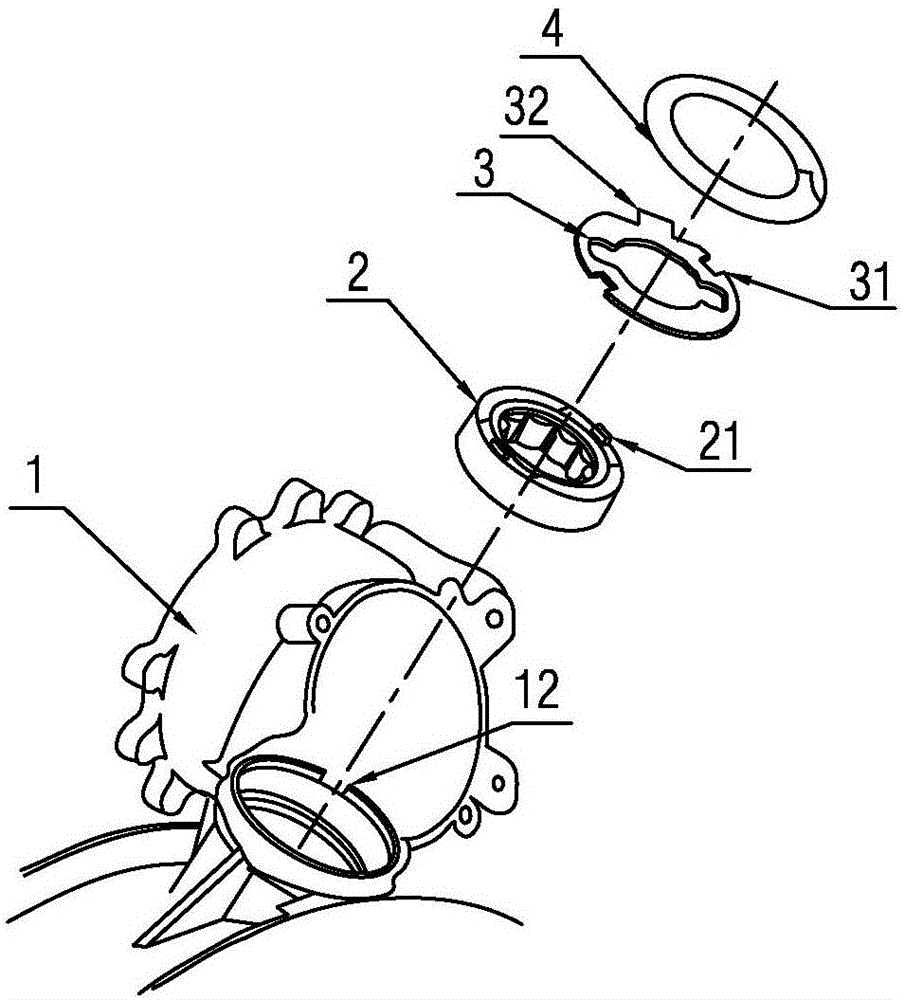

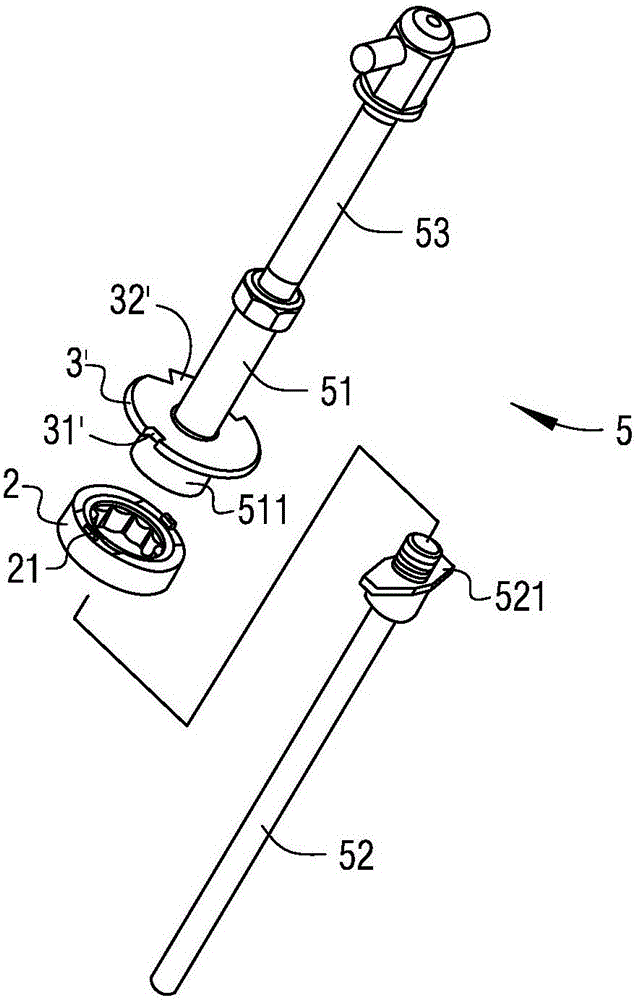

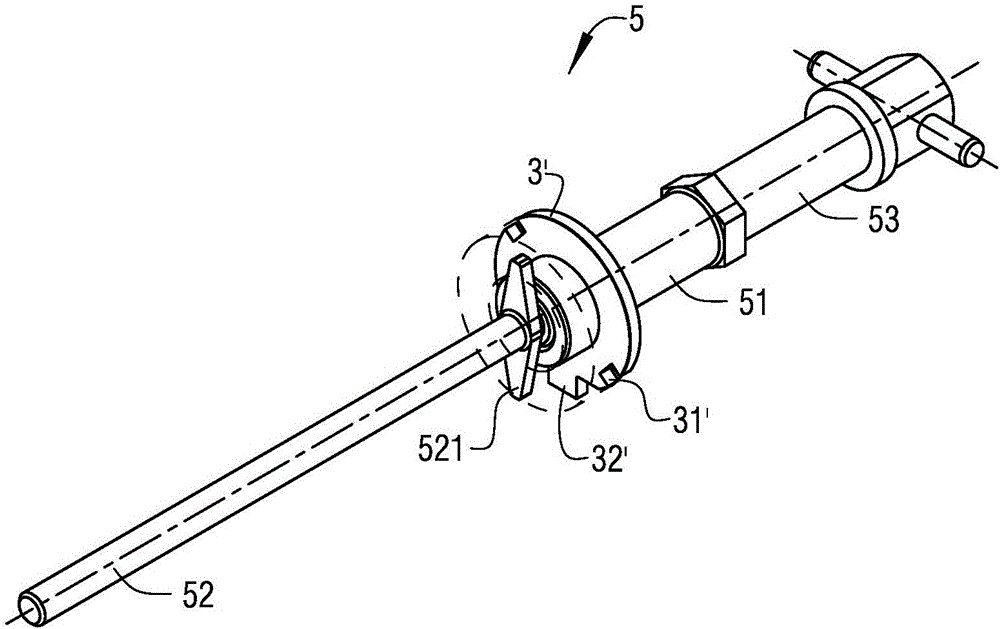

[0020] figure 1 Shown is a schematic diagram of an assembly relationship decomposition structure of a bearing used in an aero-engine; figure 2 A schematic diagram showing a three-dimensional exploded structure of an assembly tool according to a specific embodiment of the present invention; image 3 Shown is figure 2 Schematic diagram of the combined state structure of the assembly tool; see Figure 1-3 As shown, the present invention provides a bearing assembly method, which is used to assemble a bearing 2 without an inner ring on the intermediate case 1 of the aero-engine, the bearing 2 is interference fit with the case hole, and the collar is 3 is fixed with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com