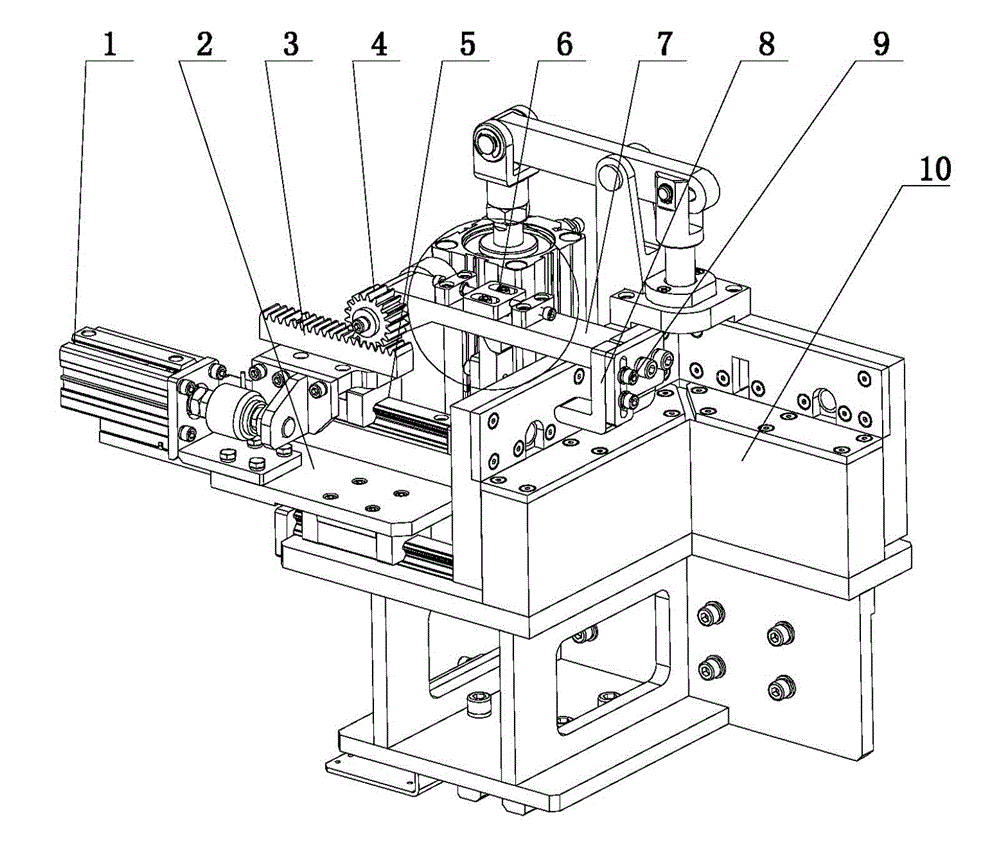

Photovoltaic module section bar straightening and backboard flattening mechanism

A technology for photovoltaic modules and profiles, applied in electrical components, semiconductor devices, sustainable manufacturing/processing, etc., can solve the problems of uneven glue overflow, shutdown and frame, in place, etc., to ensure product consistency and even glue overflow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

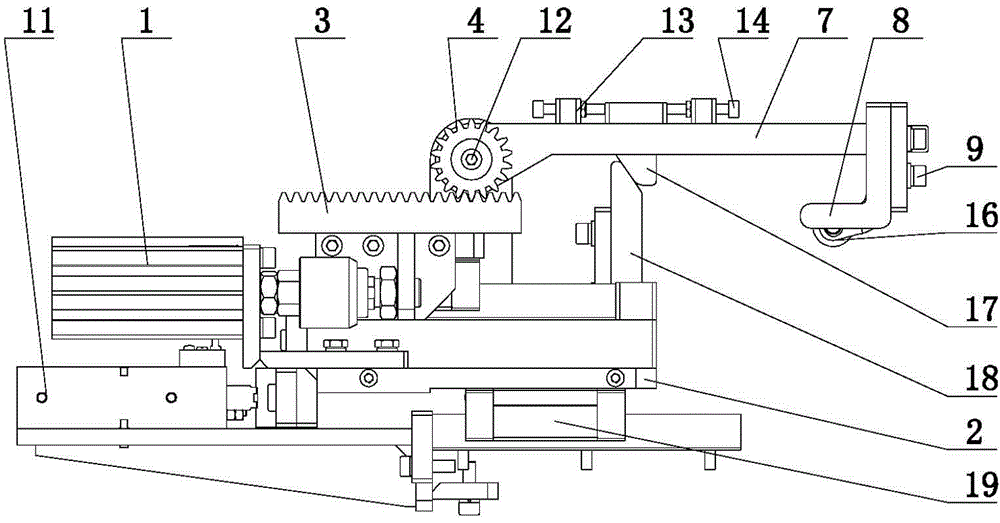

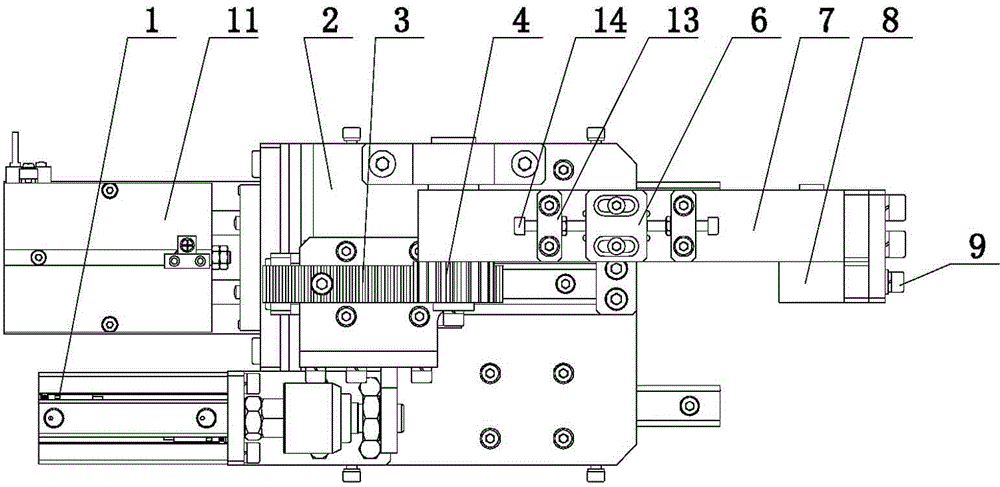

[0019] The present invention includes a telescopic cylinder 11, which is characterized in that: the telescopic cylinder 11 is connected with the mobile frame 2, the mobile frame 2 is provided with an overturning cylinder 1, the overturning cylinder 1 is connected with the rack 3 on the mobile frame 2, and the mobile frame 2 is turned over The shaft 12 is provided with a turning arm 7, and the end of the turning arm 7 is provided with a hook 8; the turning shaft 12 of the turning arm 7 is provided with a gear 4 meshing with the rack 3; the lower surface of the turning hook 8 is arranged There are pressure rollers 16 .

[0020] As a preferred solution of the present invention, a limit seat 17 is provided in the middle of the turning arm 7, and a stop seat 18 is provided on the moving frame 2, and the upper end of the stop seat 18 and the lower end of the stop seat 17 are connected to each other. Fitted slopes.

[0021] The limiting seat 17 is arranged in the middle of the turni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com