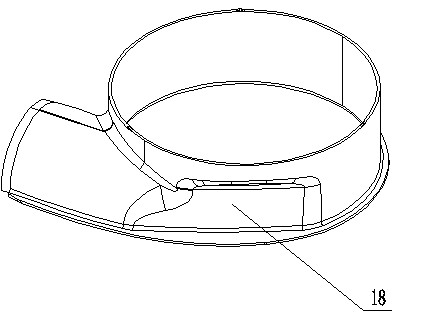

Leveling die of automobile exhaust gas recycling cooling system diffuser

A technology of exhaust gas recirculation and cooling system, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as inability to level and process, and achieve the effect of avoiding interference between the top and the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

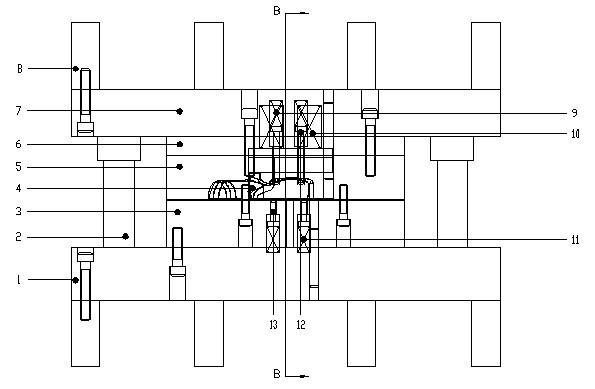

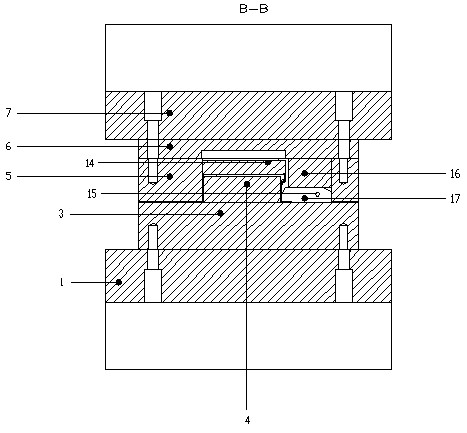

[0011] See figure 2 , image 3 and Figure 4 , the present invention comprises an upper mold structure and a lower mold structure, the upper mold structure includes an upper mold 7 and a leveling upper mold 5, the leveling upper mold 5 is fixed on the lower part of the upper mold 7 by an upper backing plate 6, and the surface of the leveling upper mold 5 There is a cavity enveloping the largest outer peripheral surface of the workpiece to be processed. The lower mold structure includes a lower template 1, a leveling lower mold 3 is installed on the lower template 1, and a workpiece positioning block 4 is arranged on the surface of the leveling lower mold 3. The workpiece positioning block 4. The outer surface is matched with the inner peripheral surface of the workpiece to be processed; it also includes a leveling movable block 17, which is embedded in the bottom of the upper mold insert 16, and the rear end of the leveling movable block 17 is passed through the pin 15 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com