Die elevating device applied to tube bending machine

The technology of a lifting device and a pipe bender is applied in the field of mold lifting devices, which can solve the problems of easy damage of the lead screw, inability to run, insufficient power and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

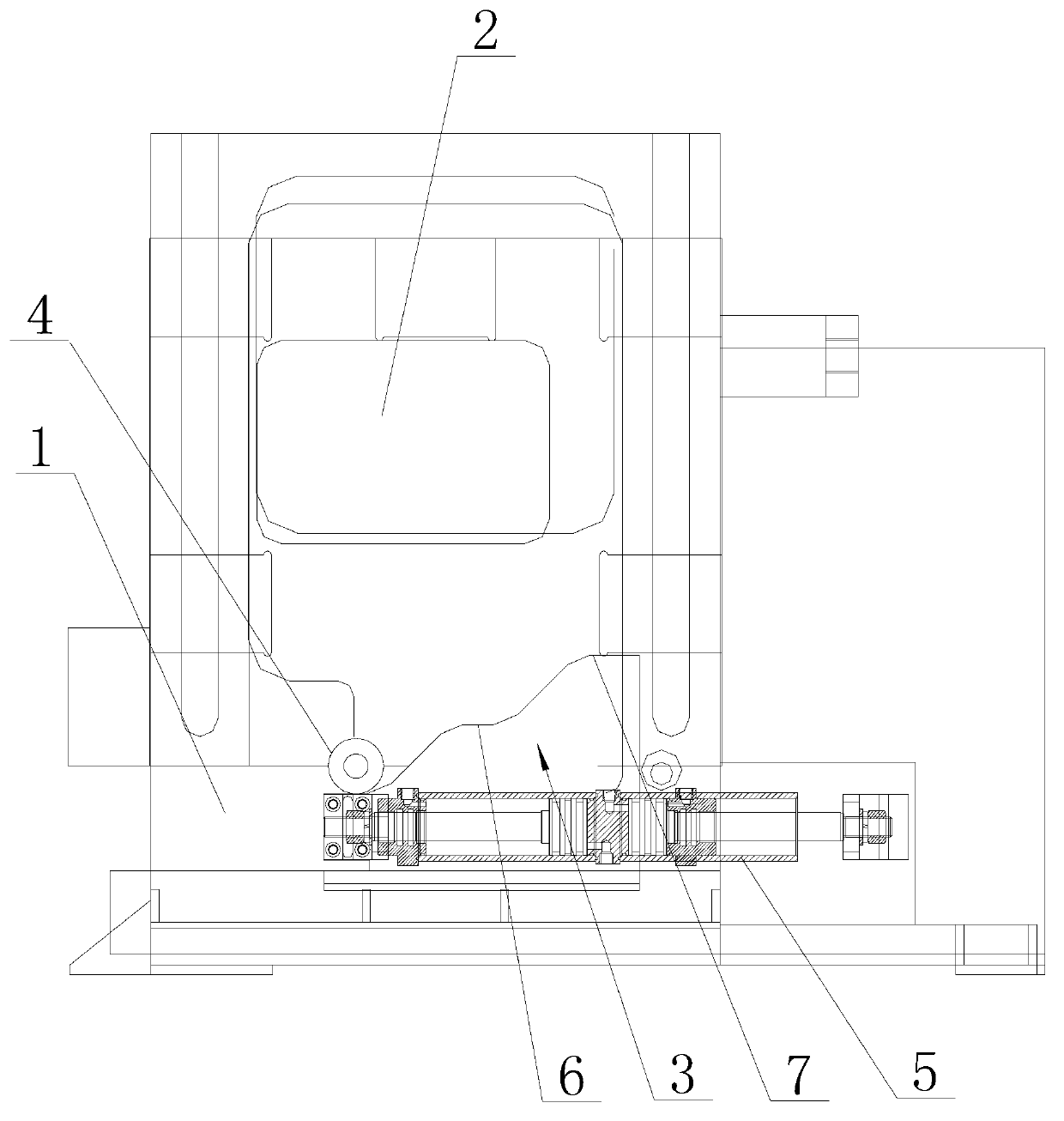

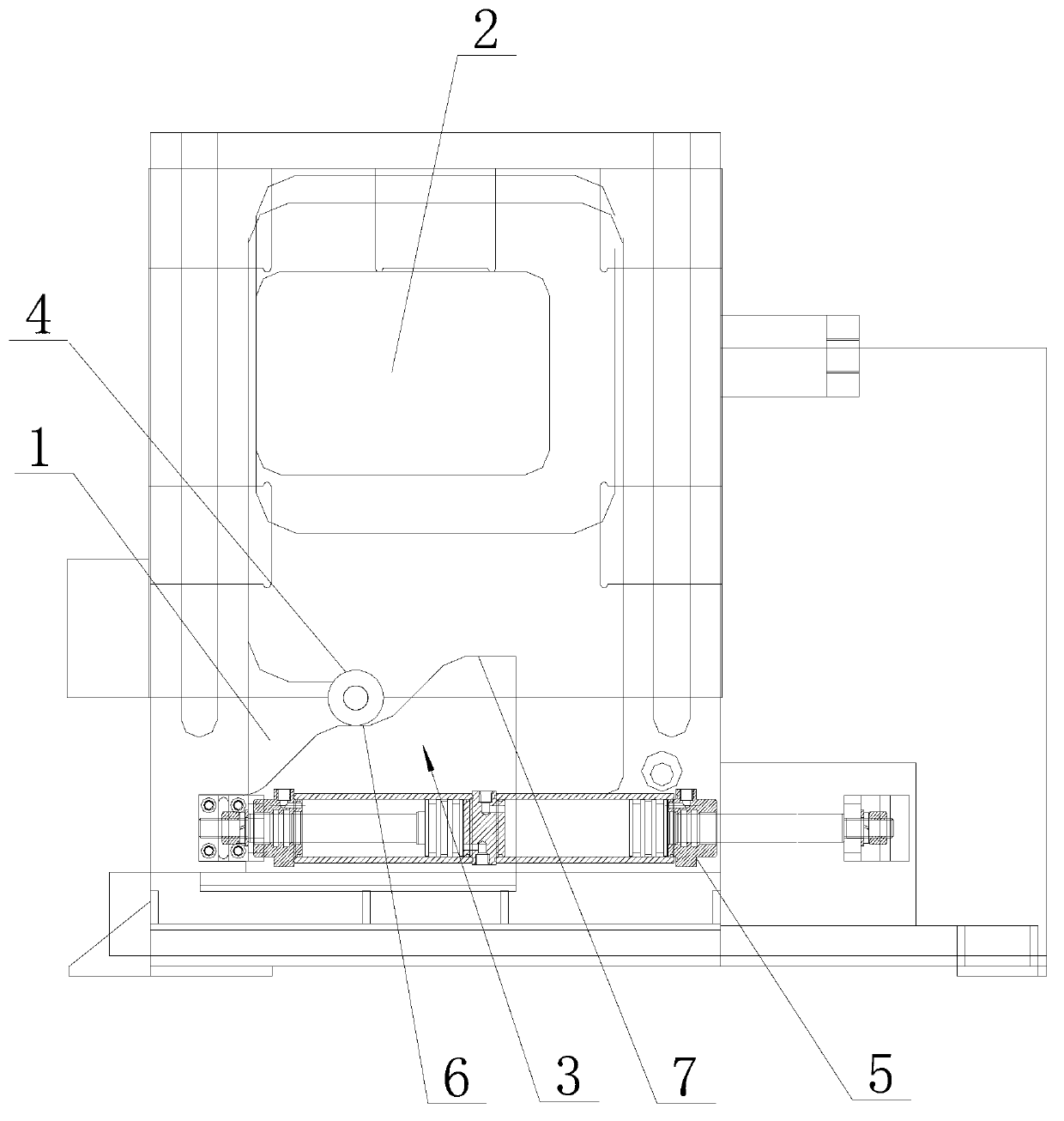

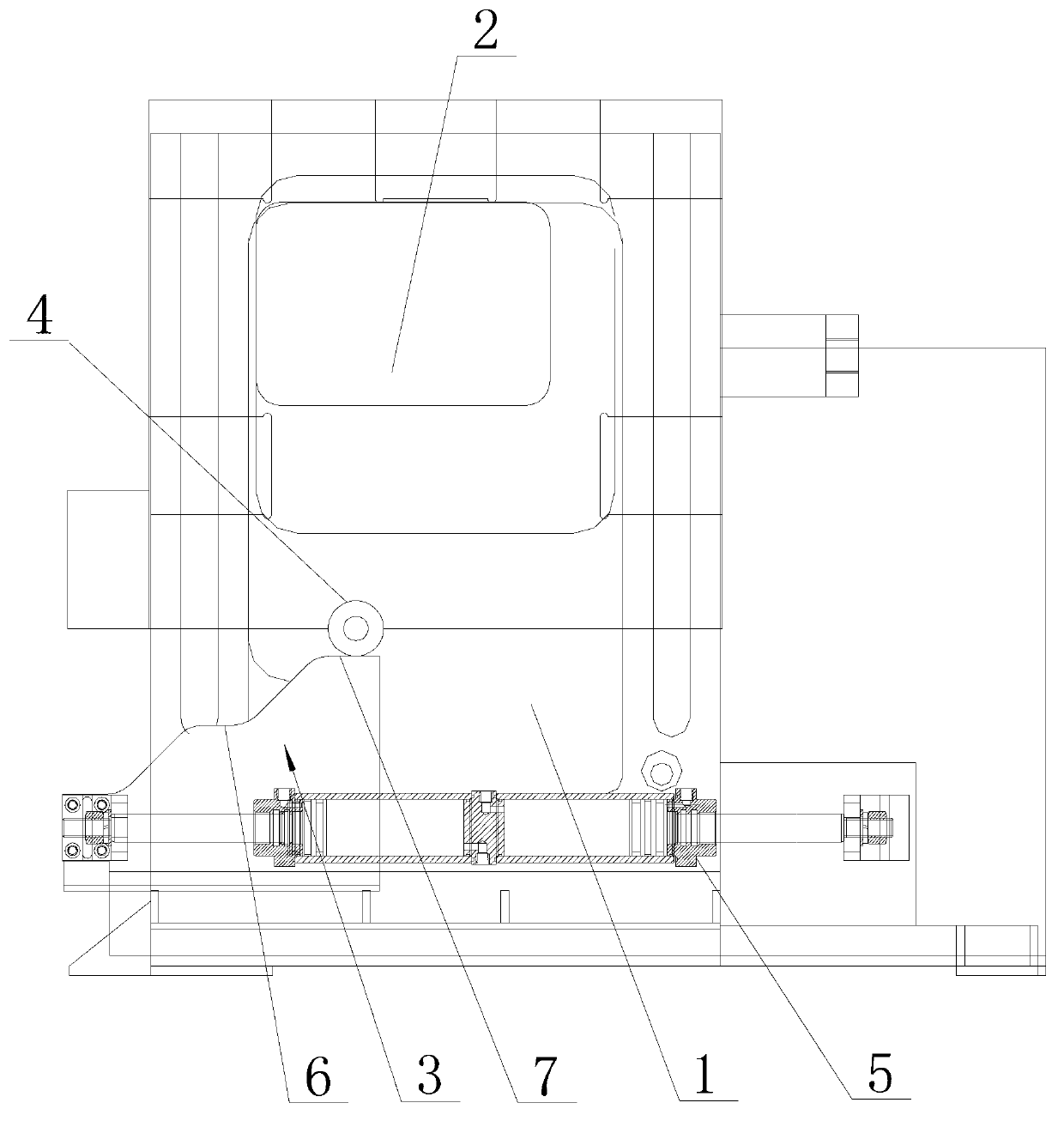

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] Such as figure 1 figure 2 image 3 As shown, a mold lifting device for a pipe bending machine includes a body 1, a mold seat 2 that can slide up and down is installed on the body 1, and a wedge 3 that can slide horizontally is installed on the bottom of the body 1. The upper surface of the wedge 3 is provided with at least one layer of steps with a slope on one side. The specific number of steps depends on actual needs. In this embodiment, two steps are used, that is, the wedge 3 has 3 layers for the roller 3 to roll. platform. The lower end of the mold base 2 is provided with a roller 4, which is in contact with the upper surface of the wedge 3 and can roll from the upper surface of the wedge 3 to the step. The mold base 2 is installed on the fuselage 1 through slide rails on both sides. In order to minimize the resistance of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com