Patents

Literature

44 results about "Femtosecond laser micromachining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

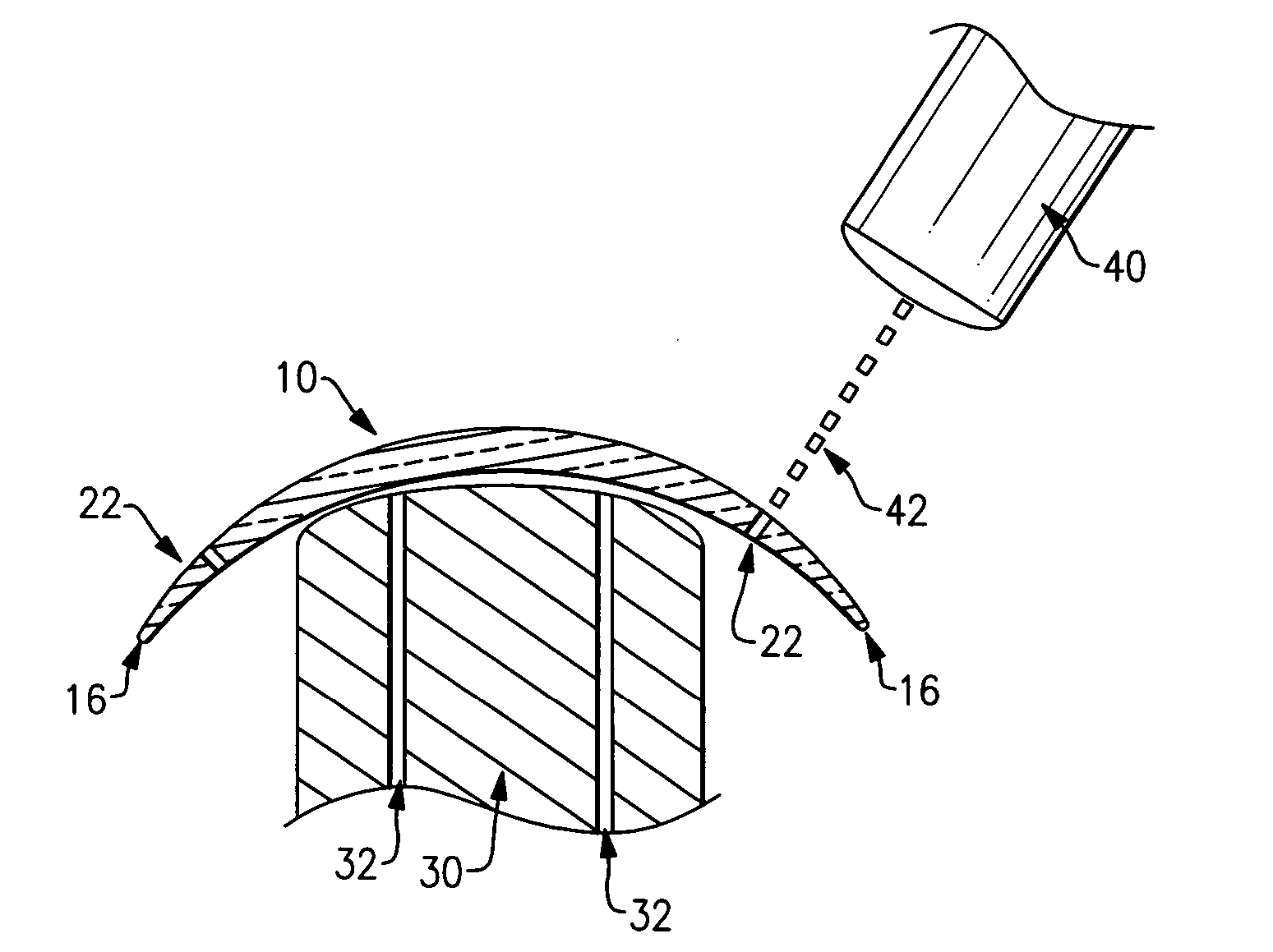

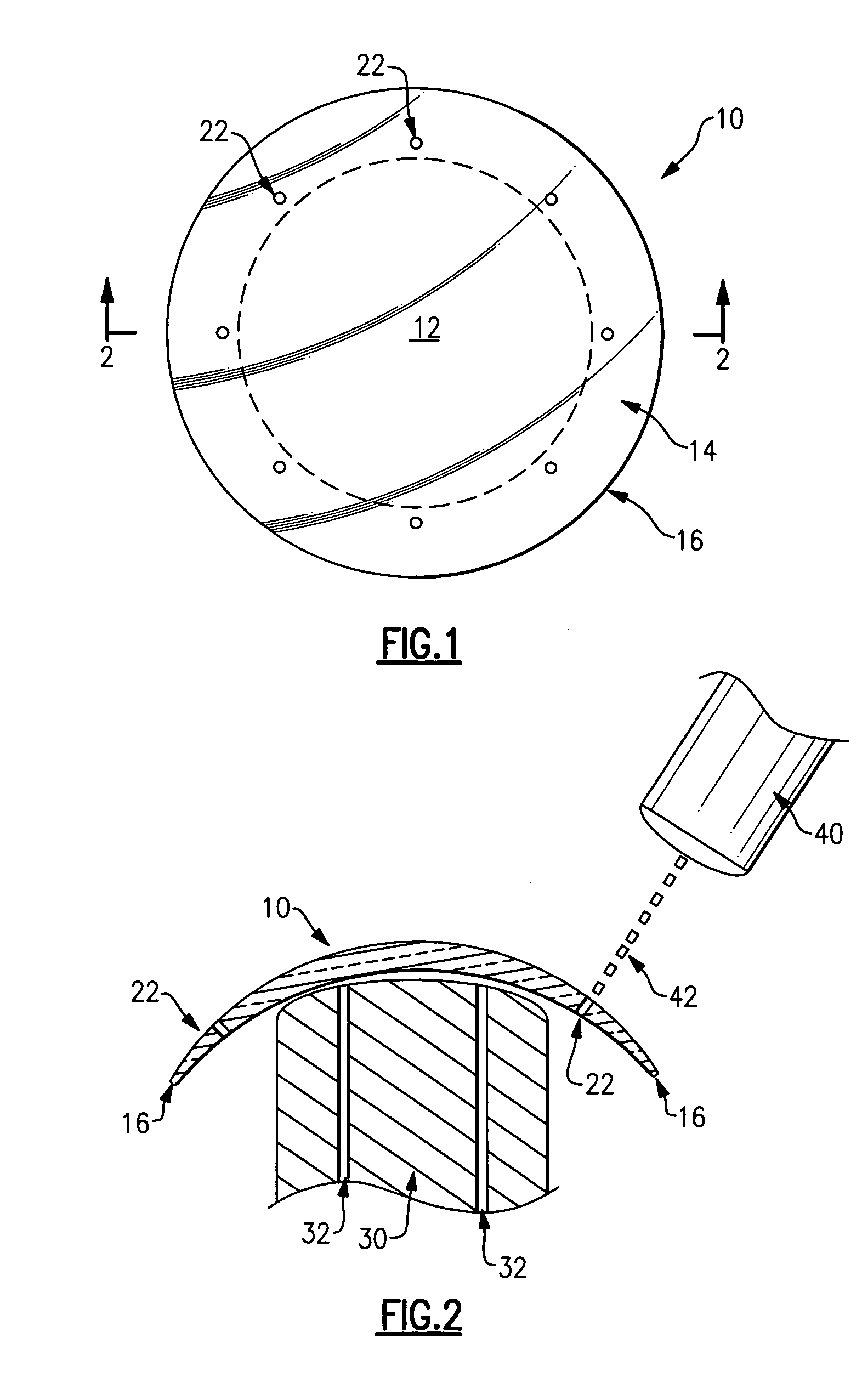

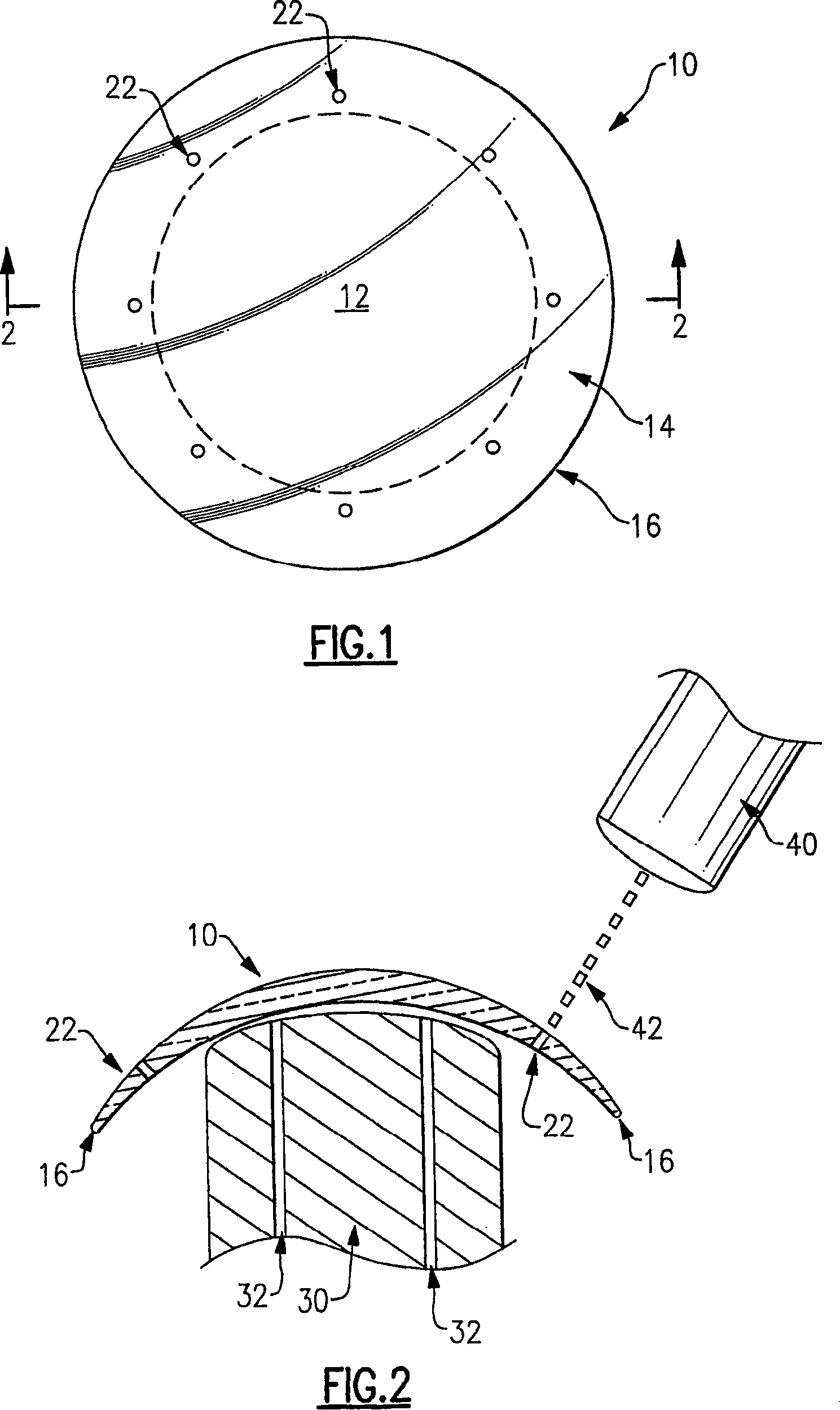

Femtosecond laser micromachining of a contact lens and a contact lens manufactured thereby

InactiveUS20060285071A1Minimal heat related damageEye diagnosticsLaser beam welding apparatusFemto second laserLight beam

A method of providing a feature on a contact lens including applying a femtosecond laser beam to ablate at least a portion of the contact lens to provide the feature on the contact lens. In one embodiment, the femtosecond laser beam has a pulse width between 10×10−15 seconds and 200×10−15 seconds, and has a wavelength between 100 nm and 1500 nm. A contact lens is also provided including at least one fenestration fluidically connecting the anterior surface and the posterior surface, the fenestration being formed using a femtosecond laser in a manner that areas surrounding the fenestration are substantially free of heat damage.

Owner:BAUSCH & LOMB INC

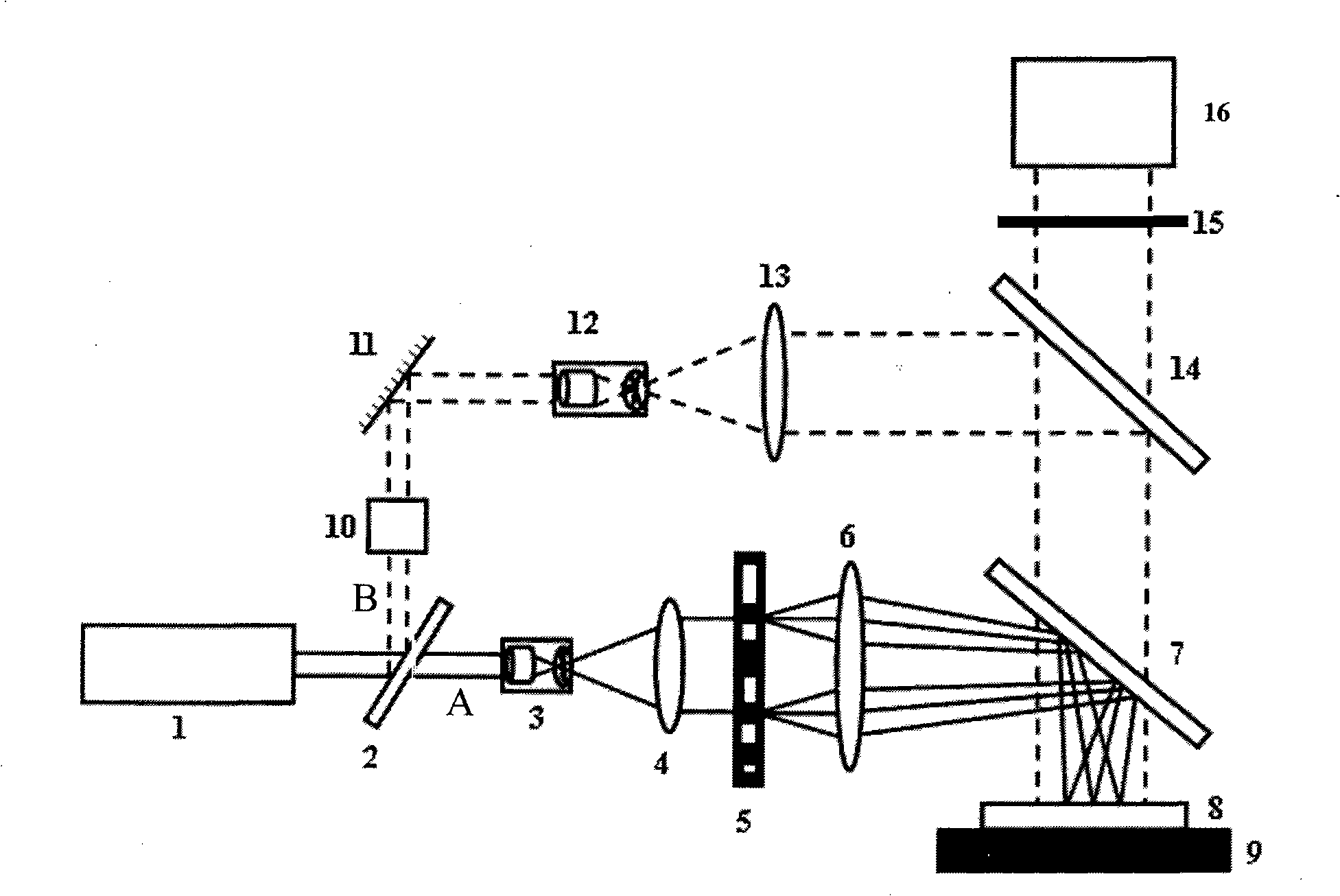

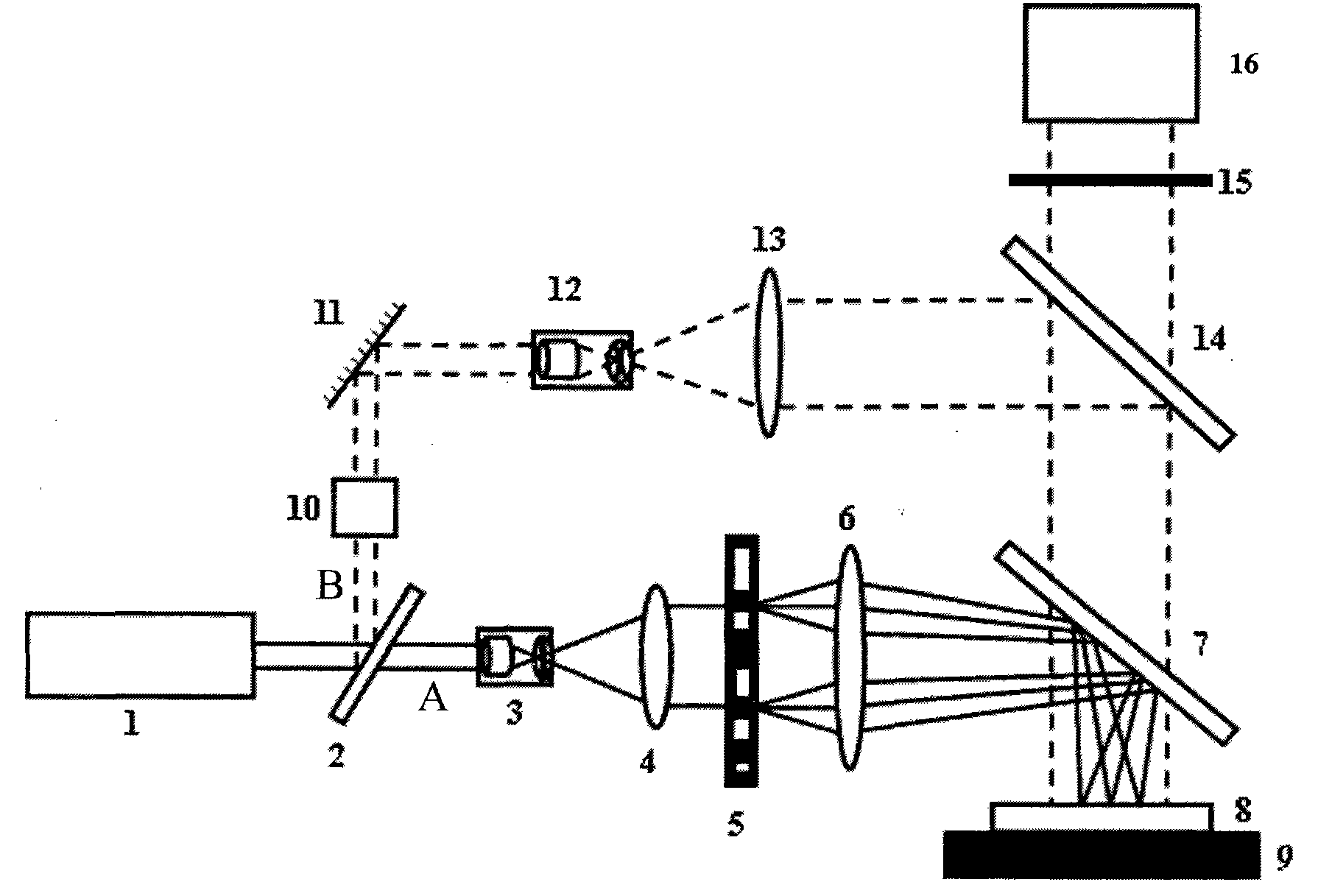

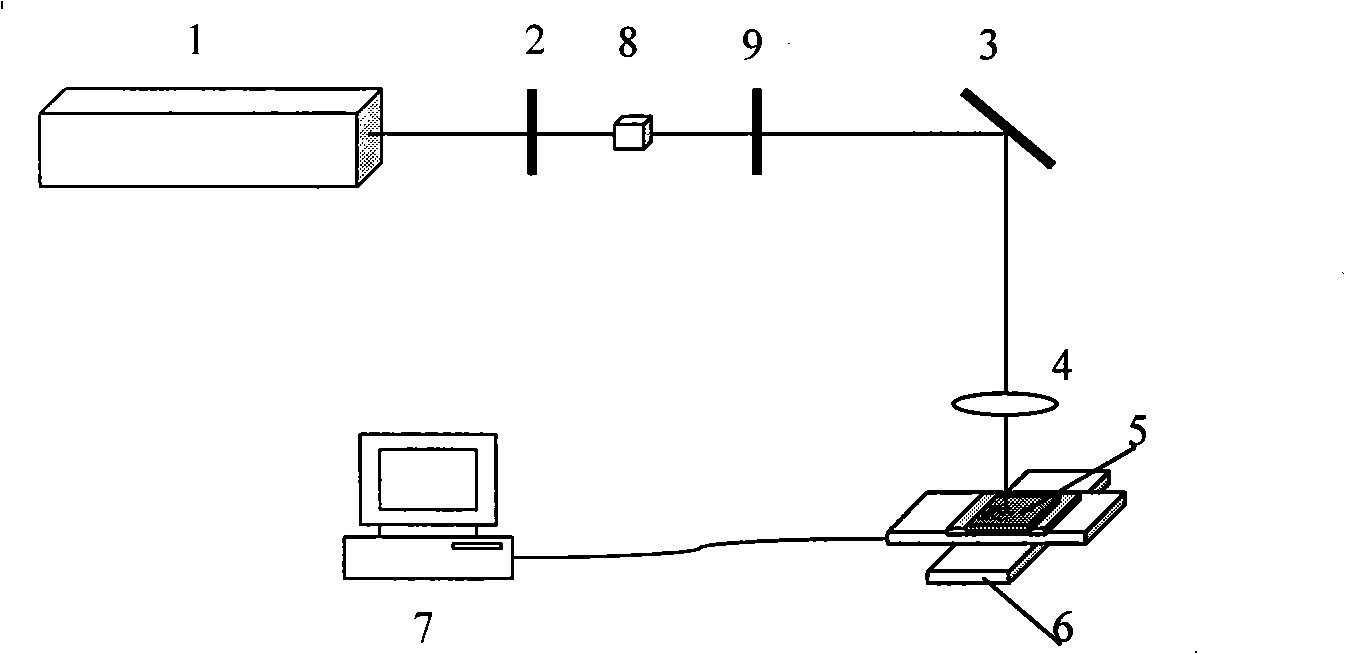

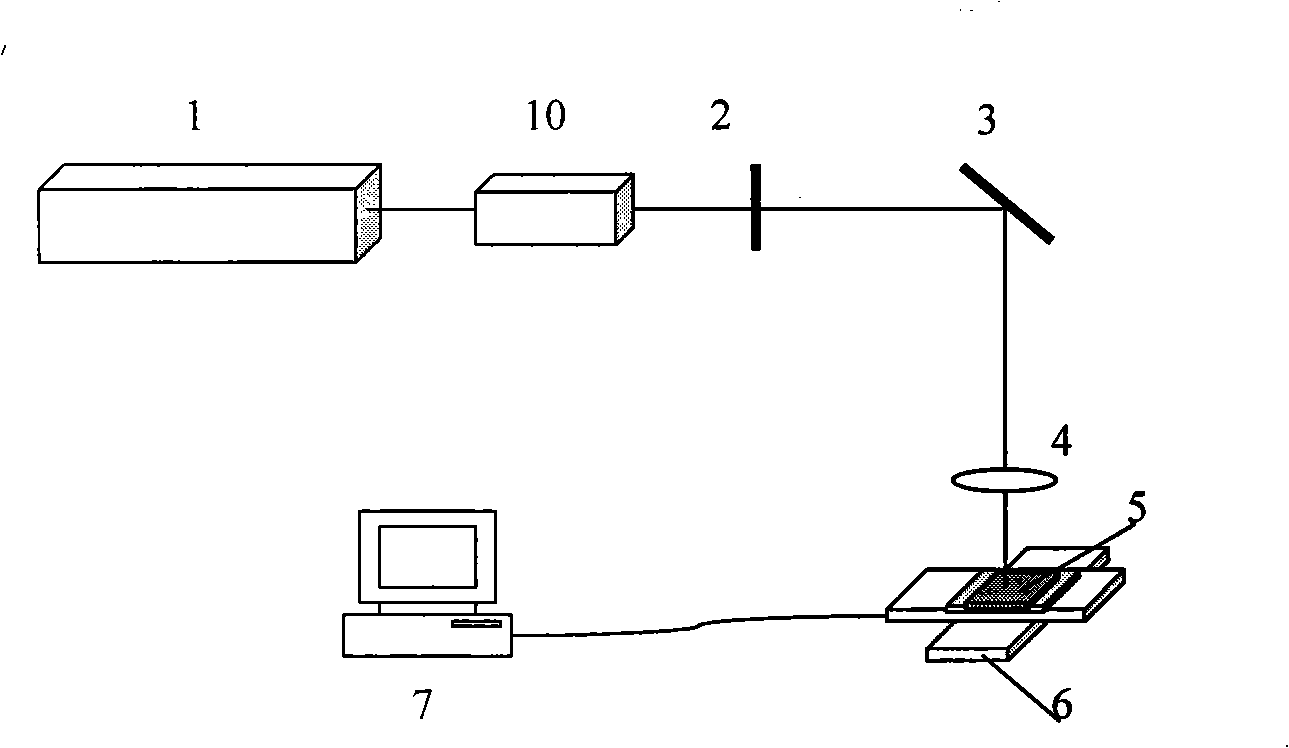

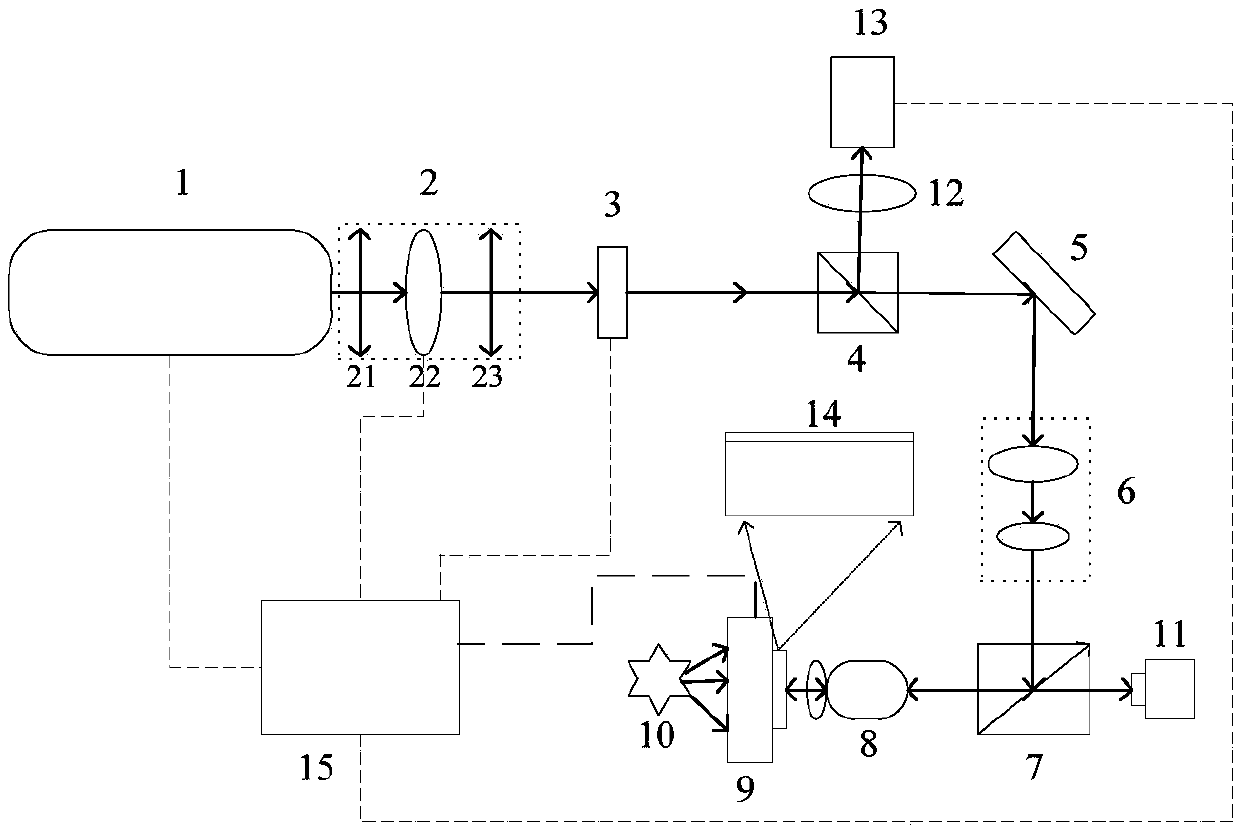

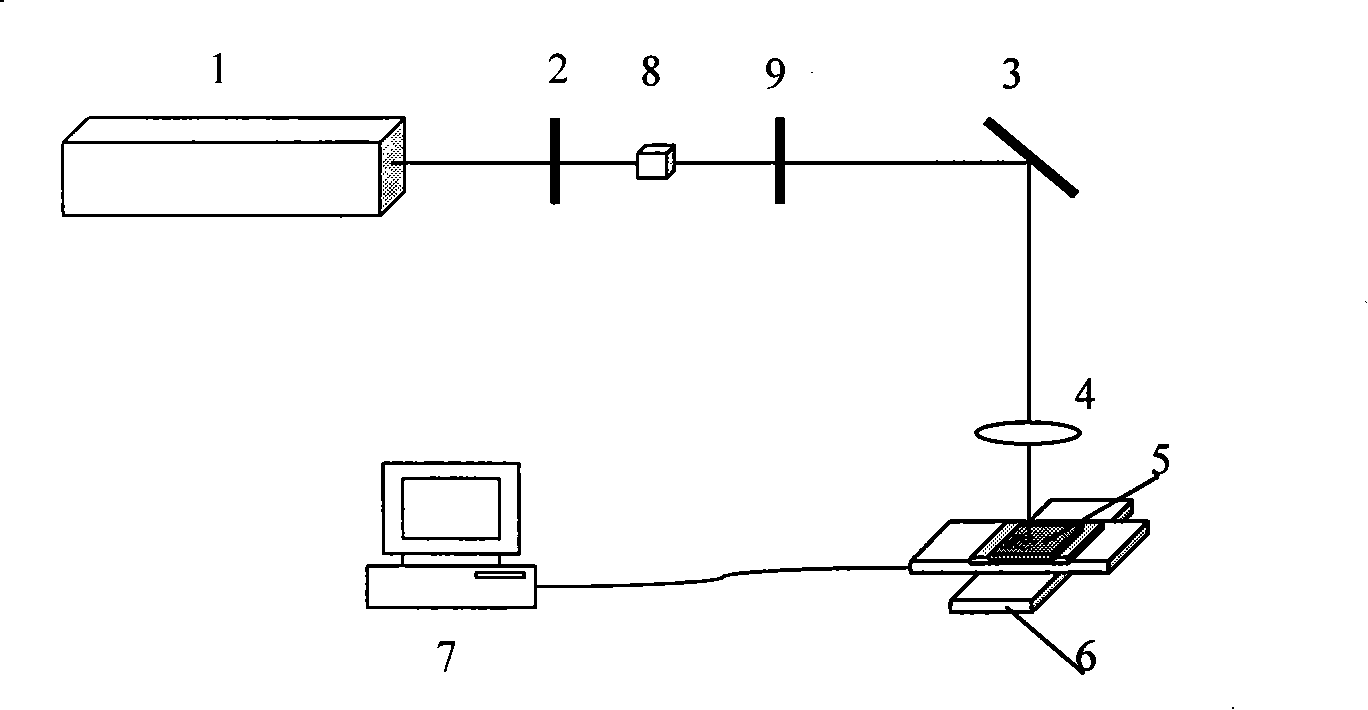

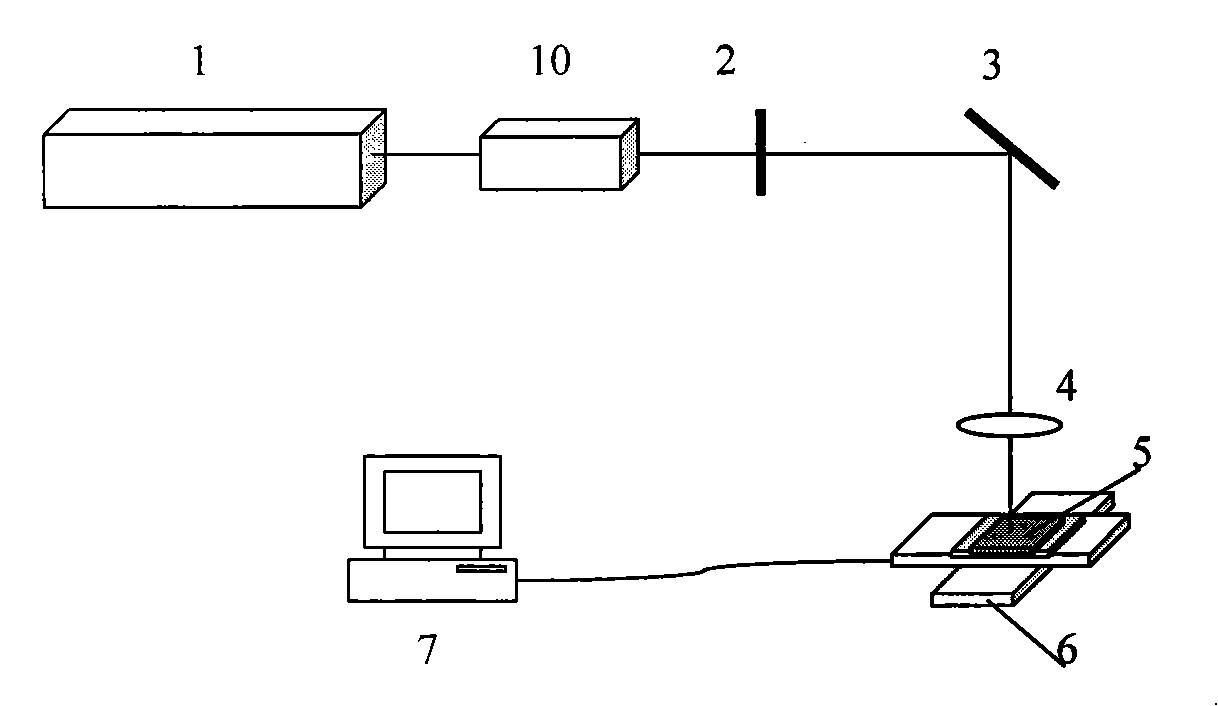

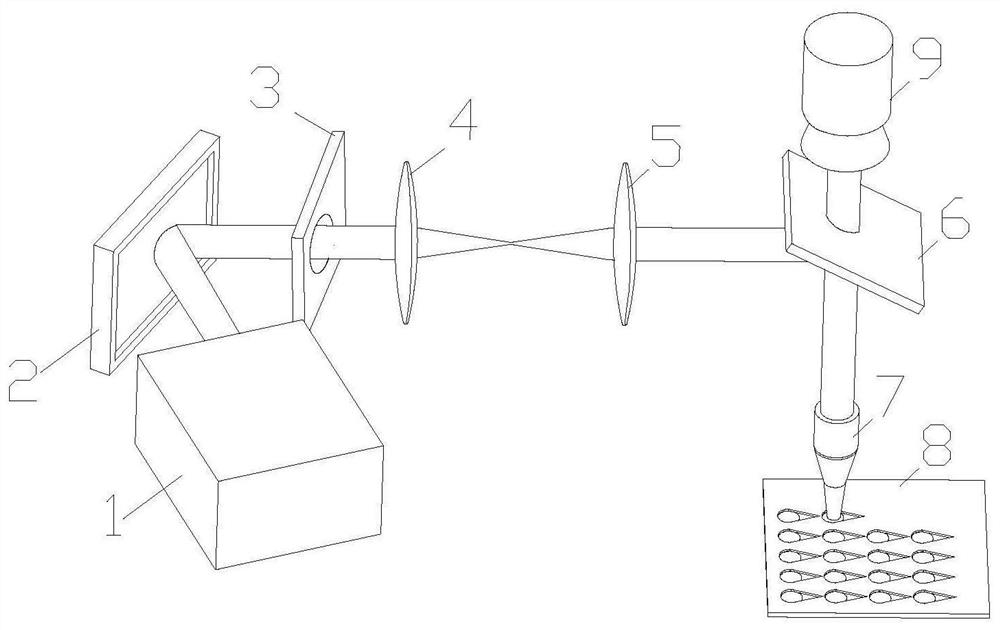

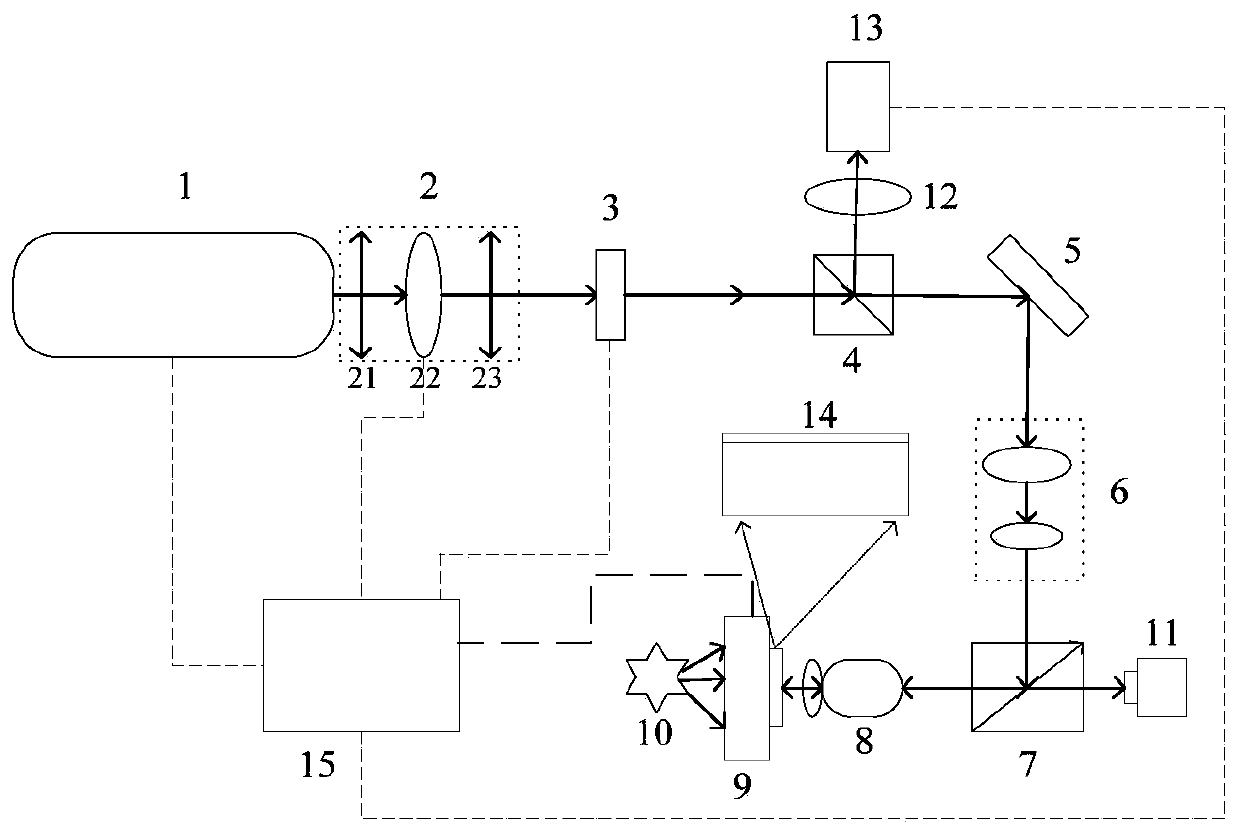

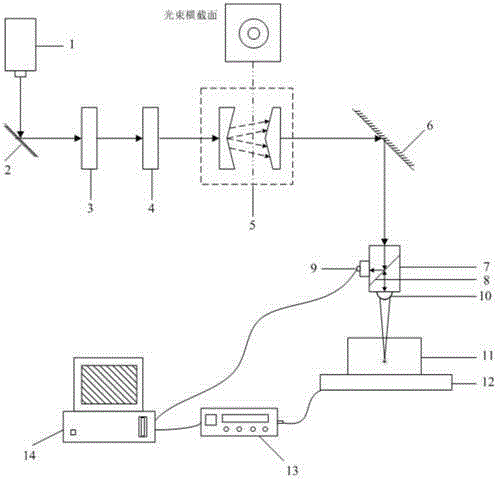

Dammann grating-based femtosecond laser parallel micromachining device with real-time monitoring function

InactiveCN101890575AEasy spacing adjustmentLow costLaser beam welding apparatusGratingBeam splitting

The invention relates to a dammann grating-based femtosecond laser parallel micromachining device with a real-time monitoring function. The device is characterized in that femtosecond laser parallel micromachining is performed on the basis of the beam splitting characteristic of the dammann grating, thus greatly increasing the efficiency of femtosecond laser machining; and a CCD detector is utilized to observe and monitor the machining process in real time. The invention has good application prospect in the aspect of femtosecond laser parallel micromachining.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI +1

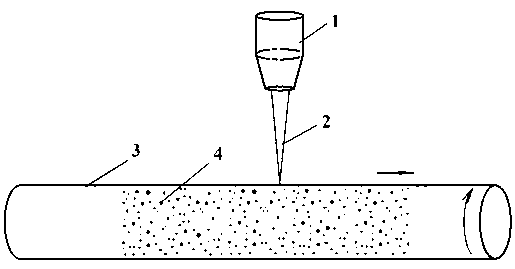

Fiber bragg grating hydrogen sensor based on femtosecond laser micromachining and preparation method for fiber bragg grating hydrogen sensor

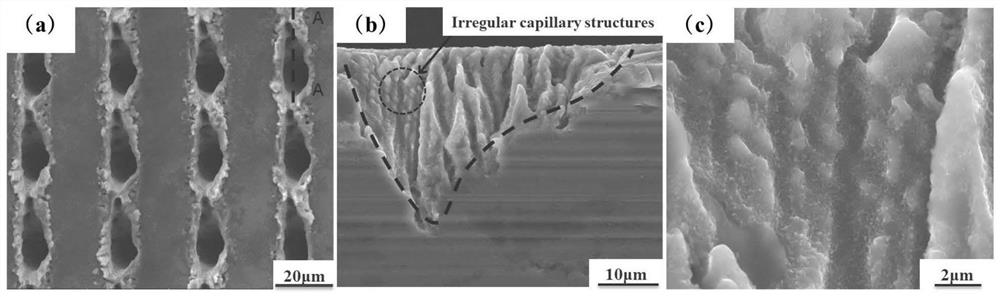

InactiveCN103175784AImprove the pulling effectImprove bindingCladded optical fibreMaterial analysis by optical meansMicro structureFiber

The invention discloses a fiber bragg grating hydrogen sensor based on femtosecond laser micromachining and a preparation method for the fiber bragg grating hydrogen sensor. The method comprises the following steps of: preparing a straight slot array or an intersected helical slot three-dimensional micro structure on a fiber bragg grating wrapping layer through femtosecond laser, and plating a palladium alloy film, wherein the sensitivity of the sensor is greatly improved, and the service life of a thin film is prolonged. The fiber bragg grating hydrogen sensor is characterized in that a femtosecond laser micromachining technology is introduced; by a clamp, irregular micro pits are obtained by quickly scanning the wrapping layer; and the three-dimensional micro structure is prepared inside the grating wrapping layer. After the fiber bragg grating with the micro structure is plated with the film, a hydrogen absorption surface area is enlarged, and the axial direction of an optical fiber is softened; the grating wavelength drift is greatly improved by hydrogen absorption expanding strain; and therefore, the measuring precision is improved, and the measuring range is expanded. By the grating wrapping layer plated film with the surface micro pits and the bent three-dimensional micro structure, the adhesive force of the thin film can be greatly improved, and the service life of the thin film is prolonged. The sensor has the advantages of high sensitivity, wide measuring range, long service life and the like, and is suitable for remote monitoring.

Owner:WUHAN UNIV OF TECH

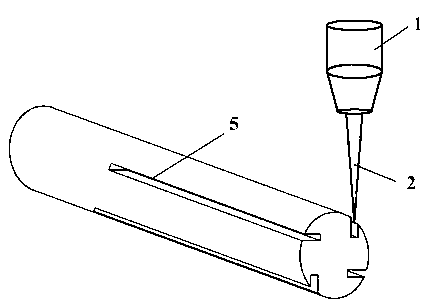

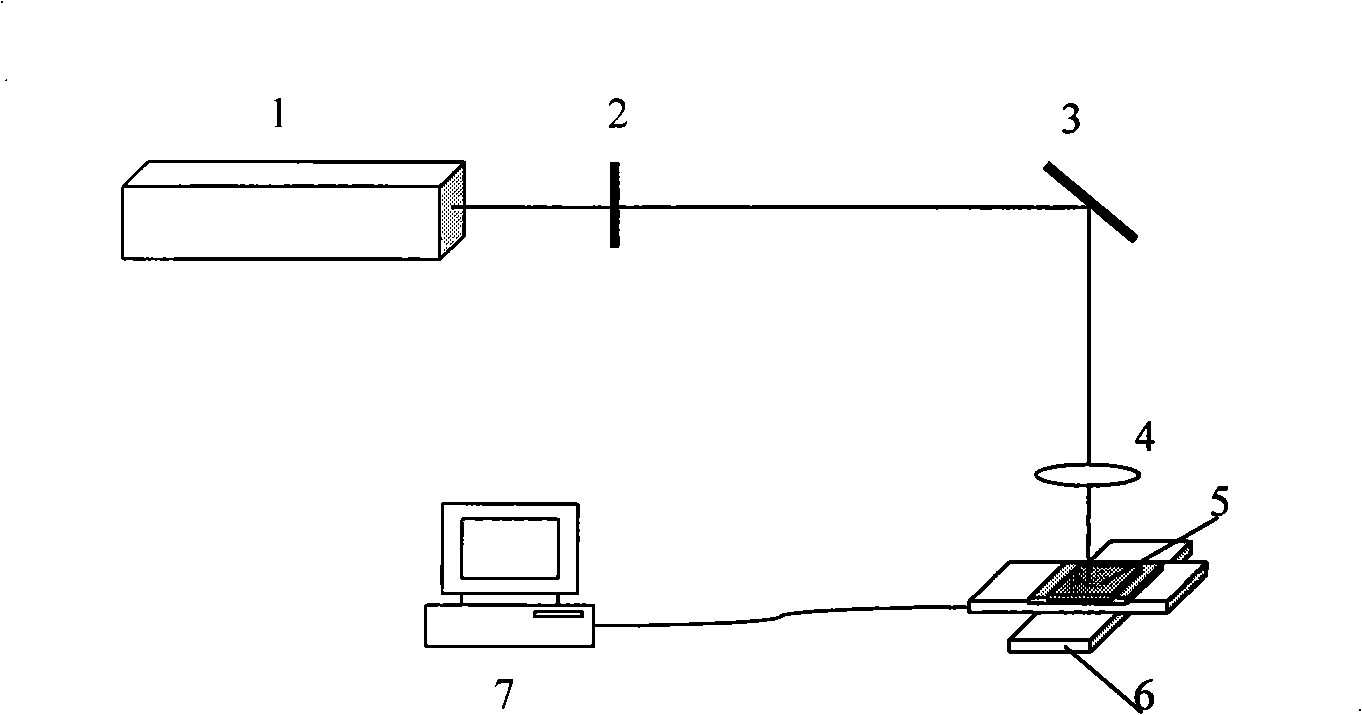

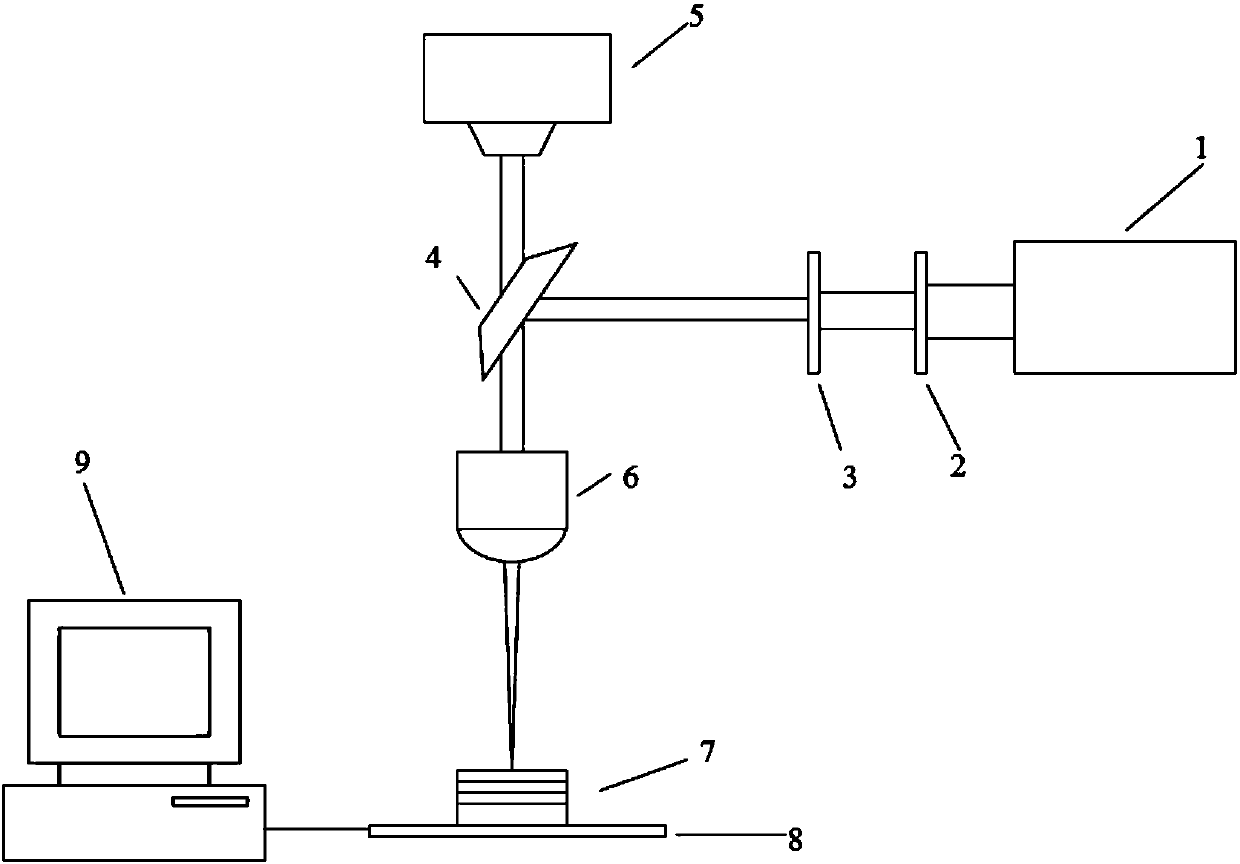

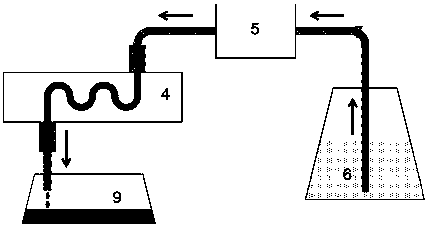

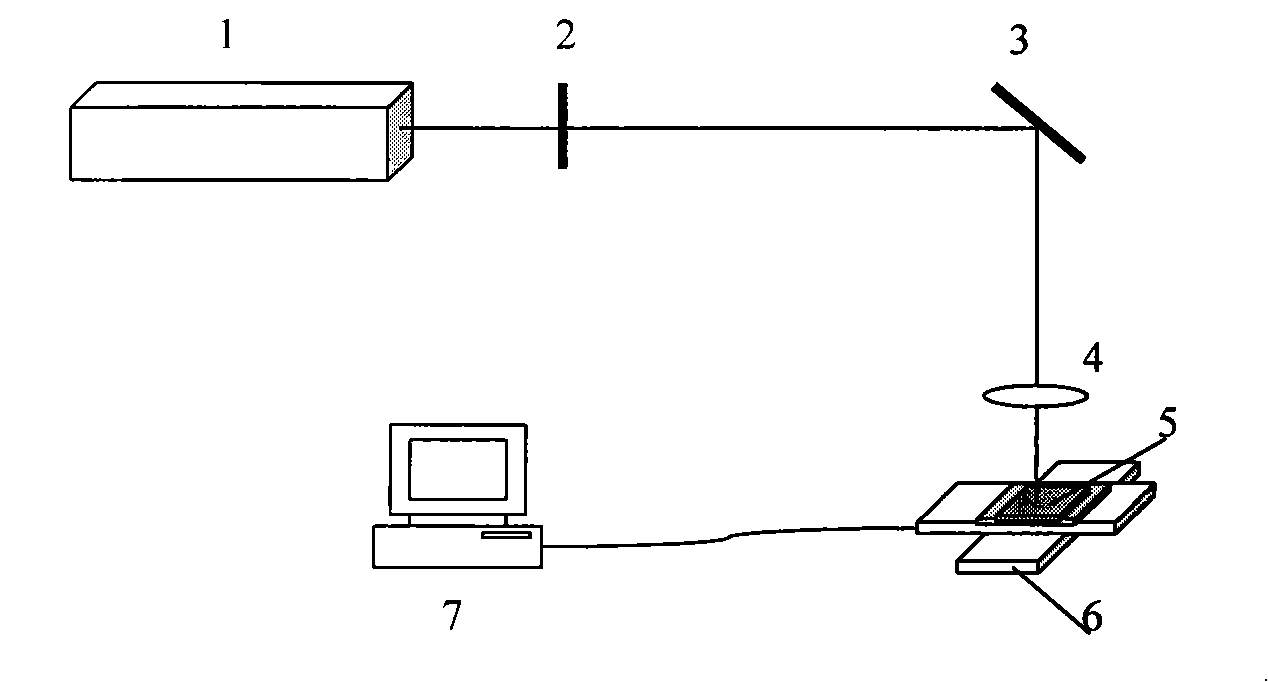

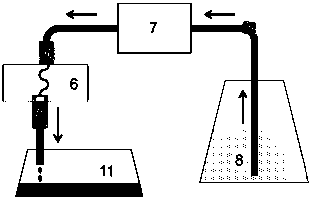

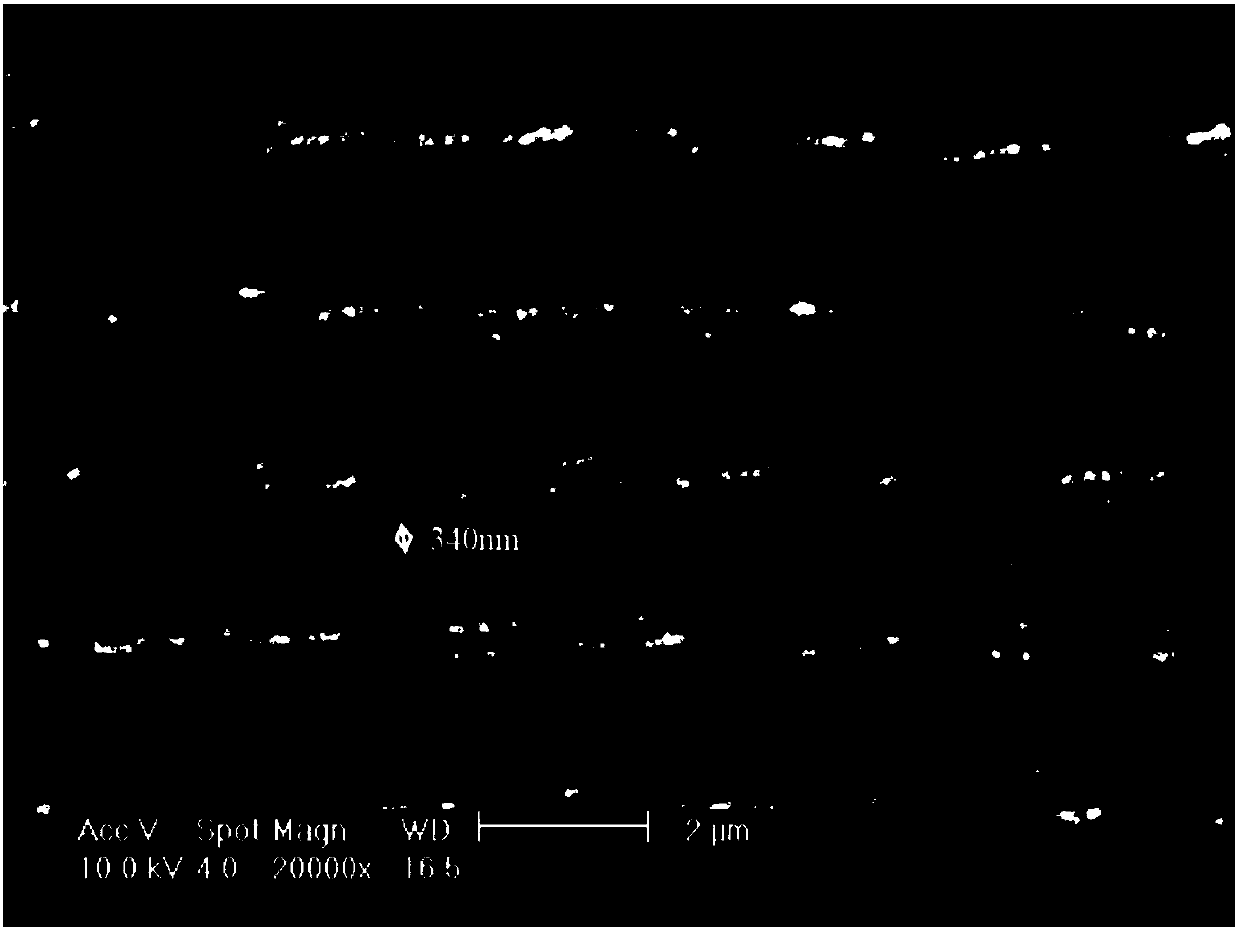

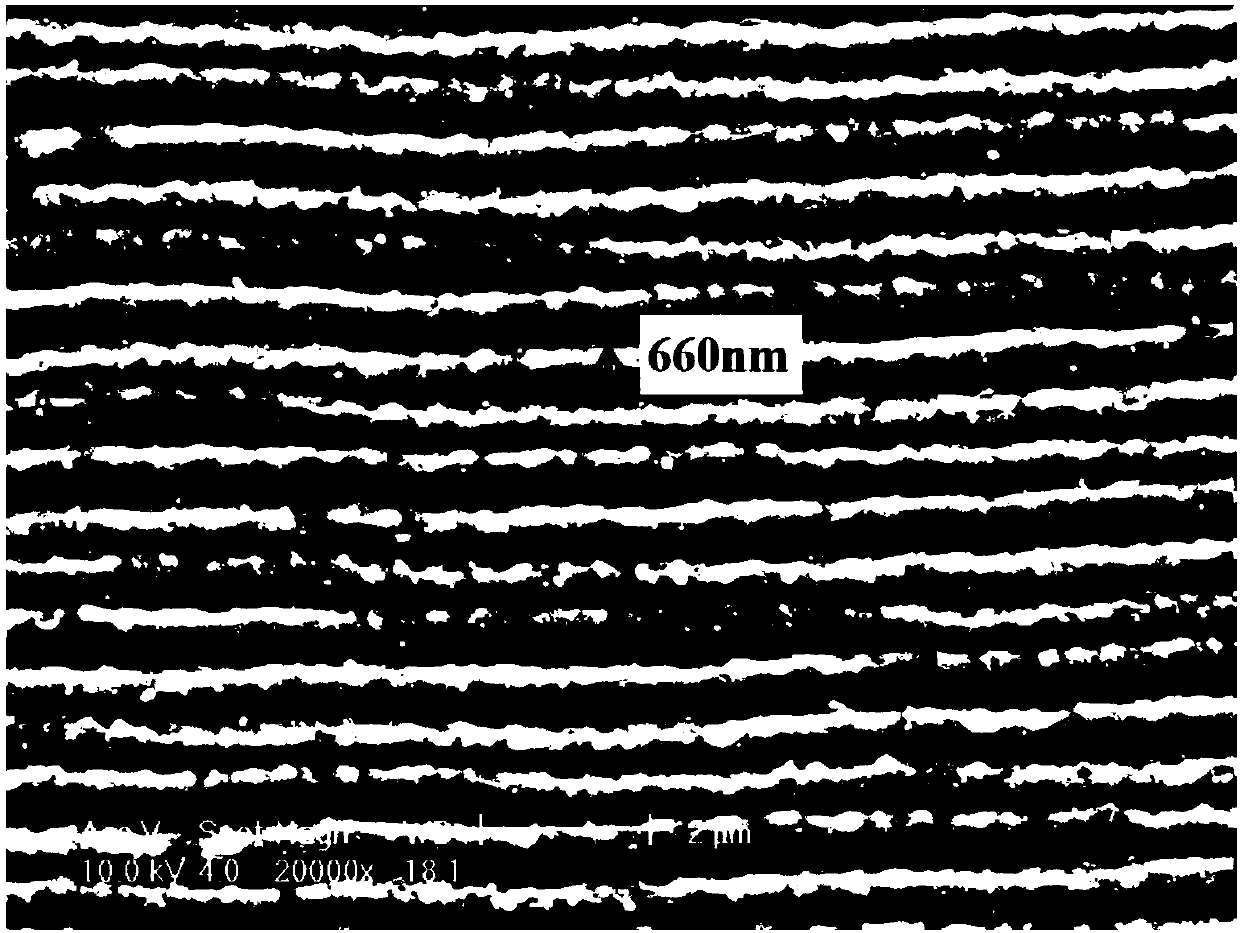

Process for preparing zinc oxide nanometer wire array by femtosecond laser and device thereof

InactiveCN101311358AImprove uniformityReduce consumptionPolycrystalline material growthSingle crystal growth detailsMaterials preparationOptoelectronics

The invention discloses a method for preparing a zinc oxide nanowires array by femtosecond laser and a device thereof, which belongs to technical fields of micro nanophase material preparation and femtosecond laser micro processing, relates to a periodical nanometer microstructure of zinc oxide material, and particularly provides a method for preparing a periodical nanowires array on the target of the zinc oxide by means of a femtosecond laser radiation field. When the zinc oxide nanowires array is prepared, zinc oxide target material is first fixed on a two-dimensional accurate displacement station, and then a bunch of light femtosecond laser is focalized by a lens to act on the zinc oxide target material; by a coordinated scan of femtosecond induction and the two-dimensional accurate displacement station, the zinc oxide periodical nanowires array is generated. The method for preparing the zinc oxide nanowires array by the femtosecond laser and the device thereof have the advantages that the preparation efficiency is high; the application scope is wide; the zinc oxide nanowires array processed and obtained is neatly and evenly arrayed.

Owner:XI AN JIAOTONG UNIV

Femtosecond laser micromachining of a contact lens and a contact lens manufactured thereby

A method of providing a feature on a contact lens including applying a femtosecond laser beam to ablate at least a portion of the contact lens to provide the feature on the contact lens. In one embodiment, the femtosecond laser beam has a pulse width between 10x10<-15> seconds and 200x10<-15> seconds, and has a wavelength between 100 nm and 1500 nm. A contact lens is also provided including at least one fenestration fluidically connecting the anterior surface and the posterior surface, the fenestration being formed using a femtosecond laser in a manner that areas surrounding the fenestration are substantially free of heat damage.

Owner:BAUSCH & LOMB INC

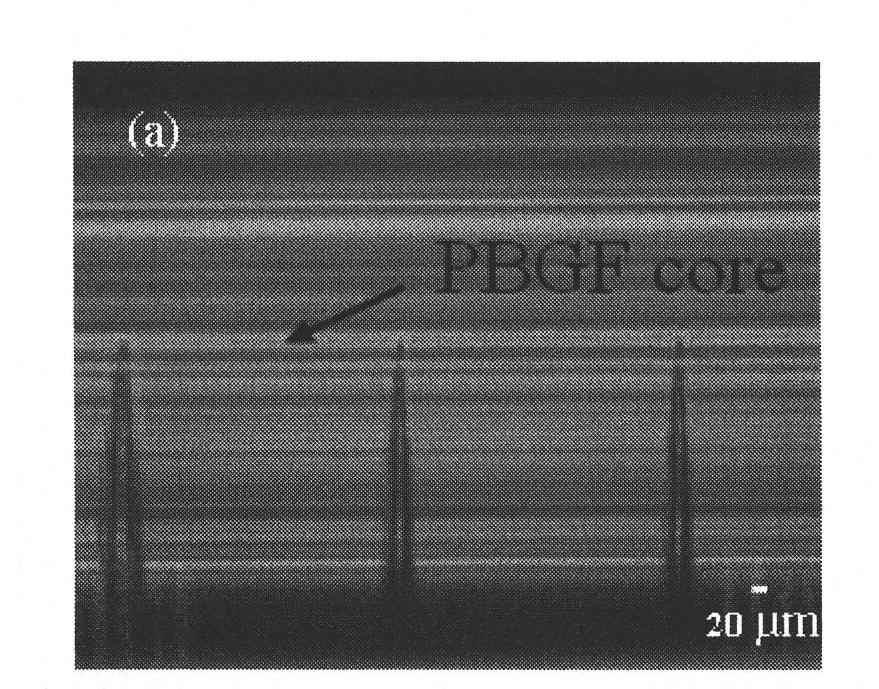

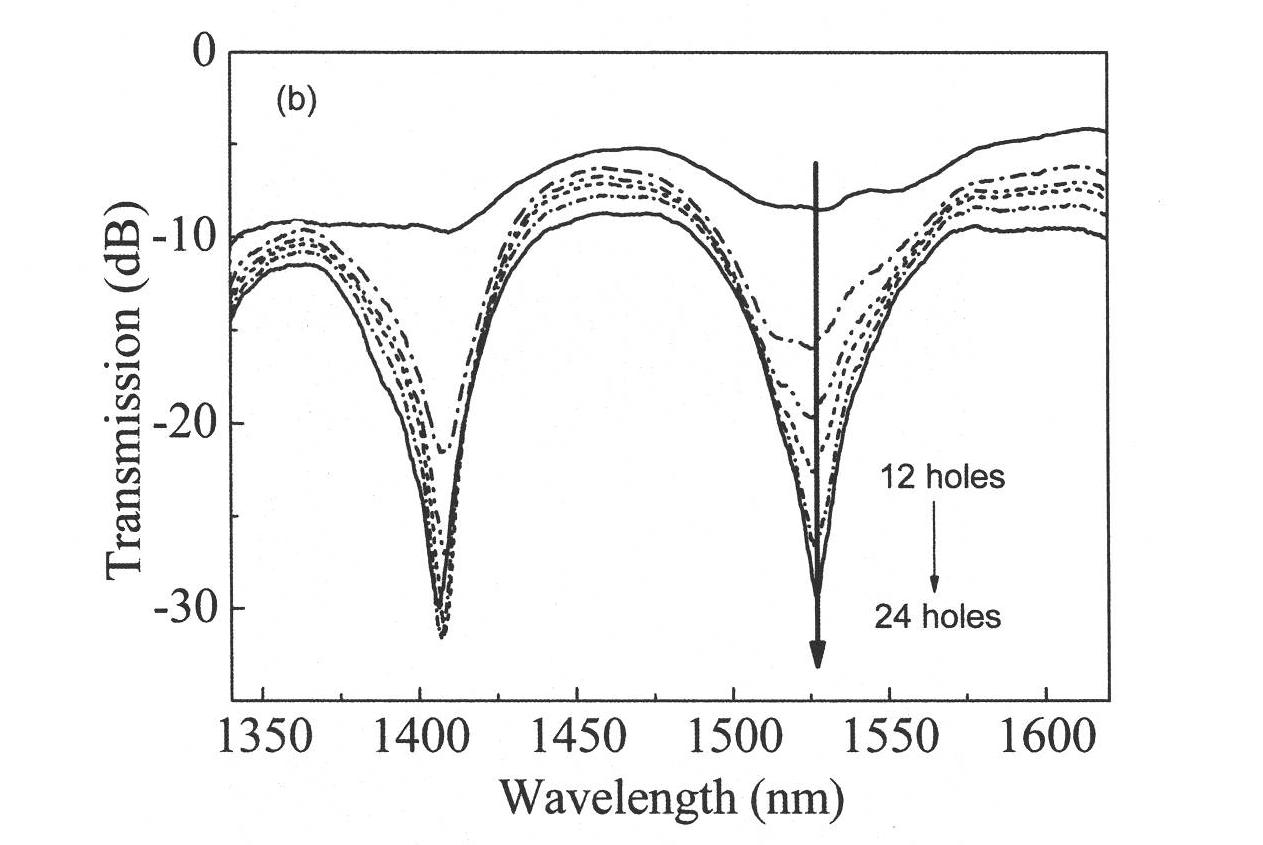

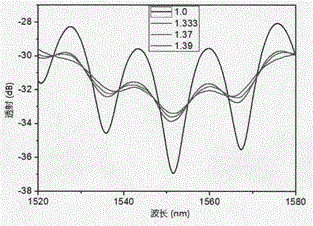

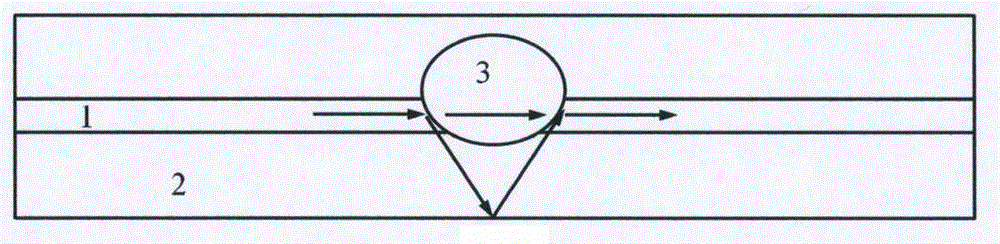

M-Z type hydrogen sensing head based on femto-second laser micro-machined hollow PBGF with written-in LPGs

InactiveCN102608071ASimple structurePrecise structurePhase-affecting property measurementsHydrogen concentrationFiber

Owner:CHINA JILIANG UNIV

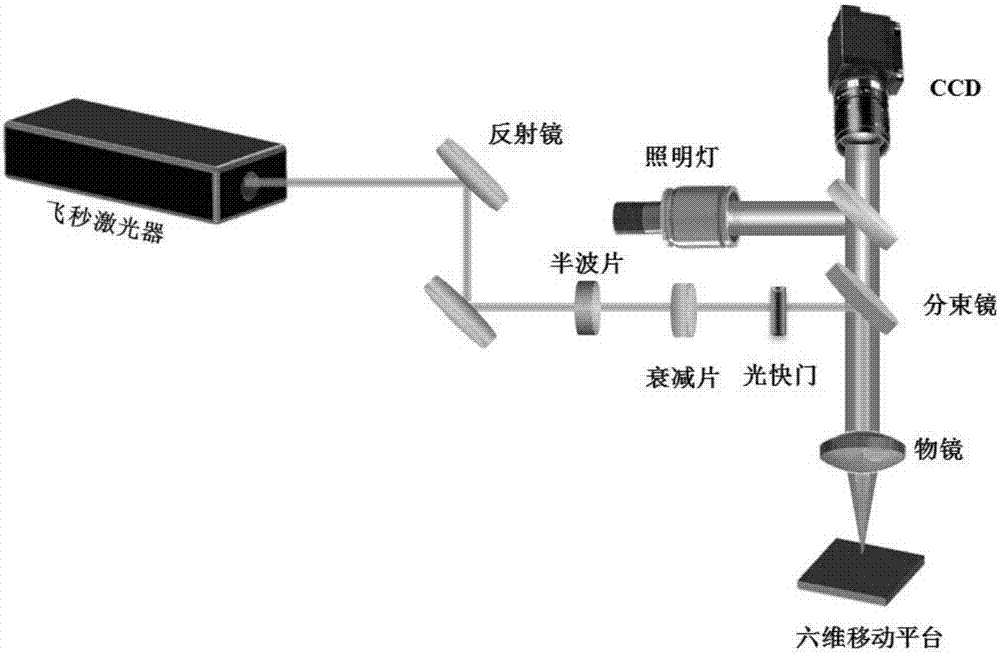

Femtosecond laser micromachining-based optical fiber Mach-Zehnder's sensor and manufacturing method thereof

ActiveCN106153578AProcessing safetyQuick and easy processingPhase-affecting property measurementsHydrofluoric acidUltrasound attenuation

The invention discloses a manufacturing method of a femtosecond laser micromachining-based optical fiber Mach-Zehnder's sensor. The manufacturing method comprises 1, taking a monomode optical fiber, stripping an optical fiber coating through a fiber stripper and cutting the optical fiber through a cutter to obtain a neat optical fiber end surface, 2, carrying out femtosecond laser micromachining, wherein in laser micromachining, laser has wavelength of 800nm, a repetition rate of 1KHz, pulse width of 120fs and the highest output power of 100mW, has the power of about 1mW after passing through a shutter and an attenuation slice and is focused on the optical fiber end surface through a 20-fold objective lens and the optical fiber is fixed to a 3D translation table with a precision of 0.1 microns, 3, carrying out ablation on the optical fiber end surface to obtain a rectangle with width of 28 microns, length of 32 microns and depth of 40-50 microns, wherein a distance between the center of the rectangle and an optical fiber central axis is 18 microns, and 4, cleaning the ablated optical fiber end surface through alcohol for 1min, and welding the cleaned optical fiber end surface to the other untreated optical fiber end surface so that air bubbles are formed in the welded optical fiber and the optical fiber Mach-Zehnder's sensor is obtained. The manufacturing method is free of hydrofluoric acid corrosion and tapering, carries out micromachining on the optical fiber end surface and has the advantages of micromachining safety, fastness, east control, small size and good fastness.

Owner:CHINA JILIANG UNIV

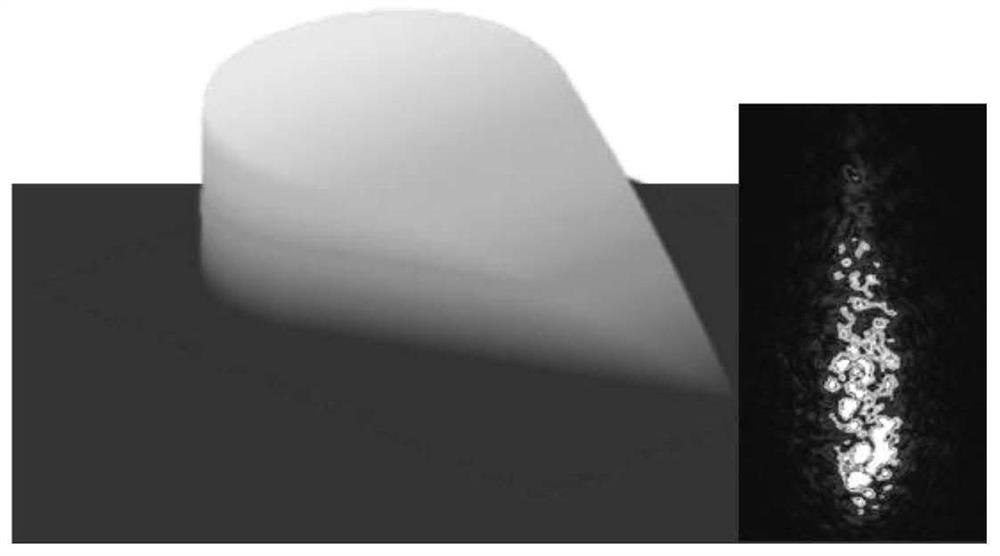

Micro nano fiber vibration sensor based on femtosecond laser micromachining

ActiveCN106124028AReduce volumeGood quality interference signalSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansMicro nanoFemto second laser

The invention relates to a micro nano fiber vibration sensor based on femtosecond laser micromachining and belongs to the field of fiber sensing. A single-mode fiber, a hollow fiber and a solid core fiber are welded in sequence. A fiber end face is burned using a femto second laser to form a mass block and a cantilever beam. The mass block is a circular column, and the diameter of the circular column is smaller than the internal diameter of the hollow fiber. The hollow fiber and the solid core fiber are fixedly connected through the cantilever beam. The invention solves the problem that a reflective surface formed when processing the fiber with the femto second laser has a low reflectivity or does not have a reflectivity; a detected vibration direction is parallel to an axial direction of the fiber; the sensor installation is easy; and the vibration sensor is featured by small size, high resonance frequency, high temperature resistance, electromagnetic interference resistance and the like, and can be used for vibration measurement in high temperature environments.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

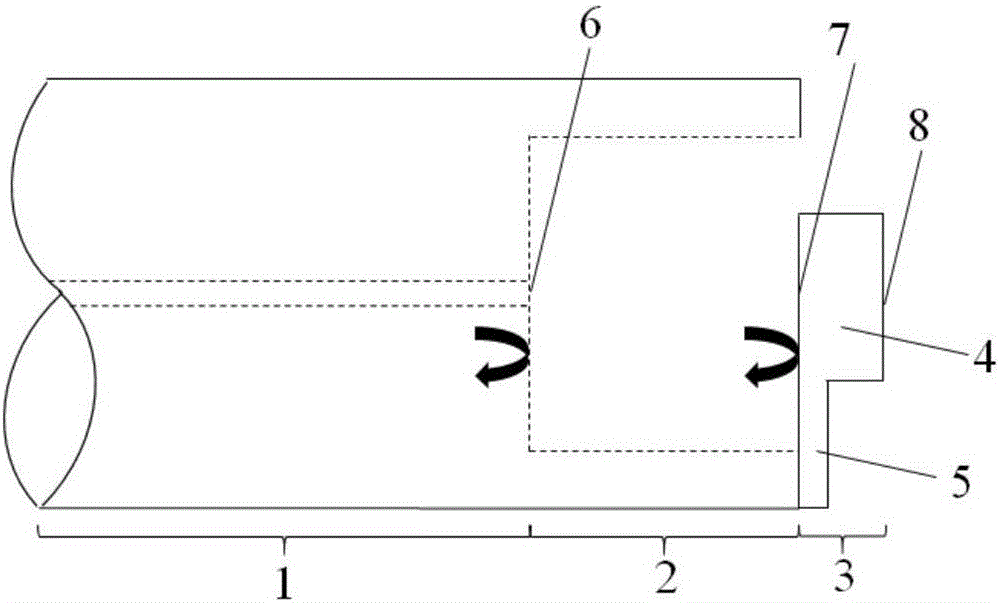

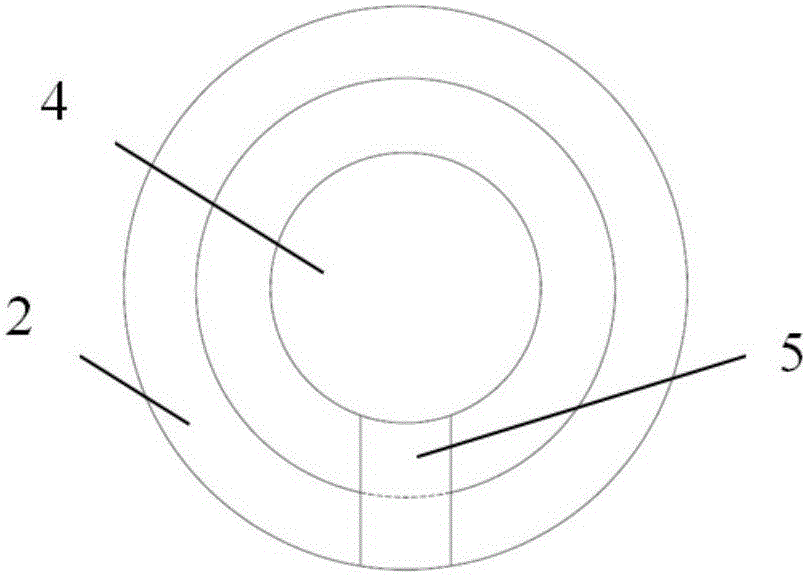

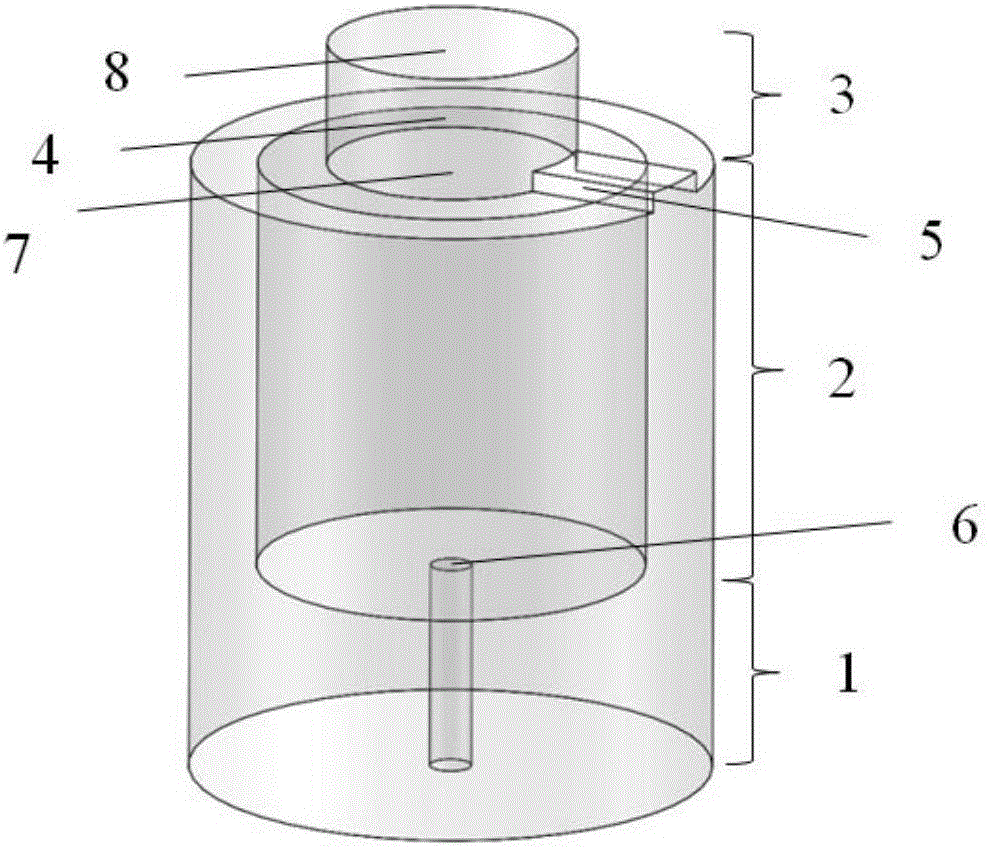

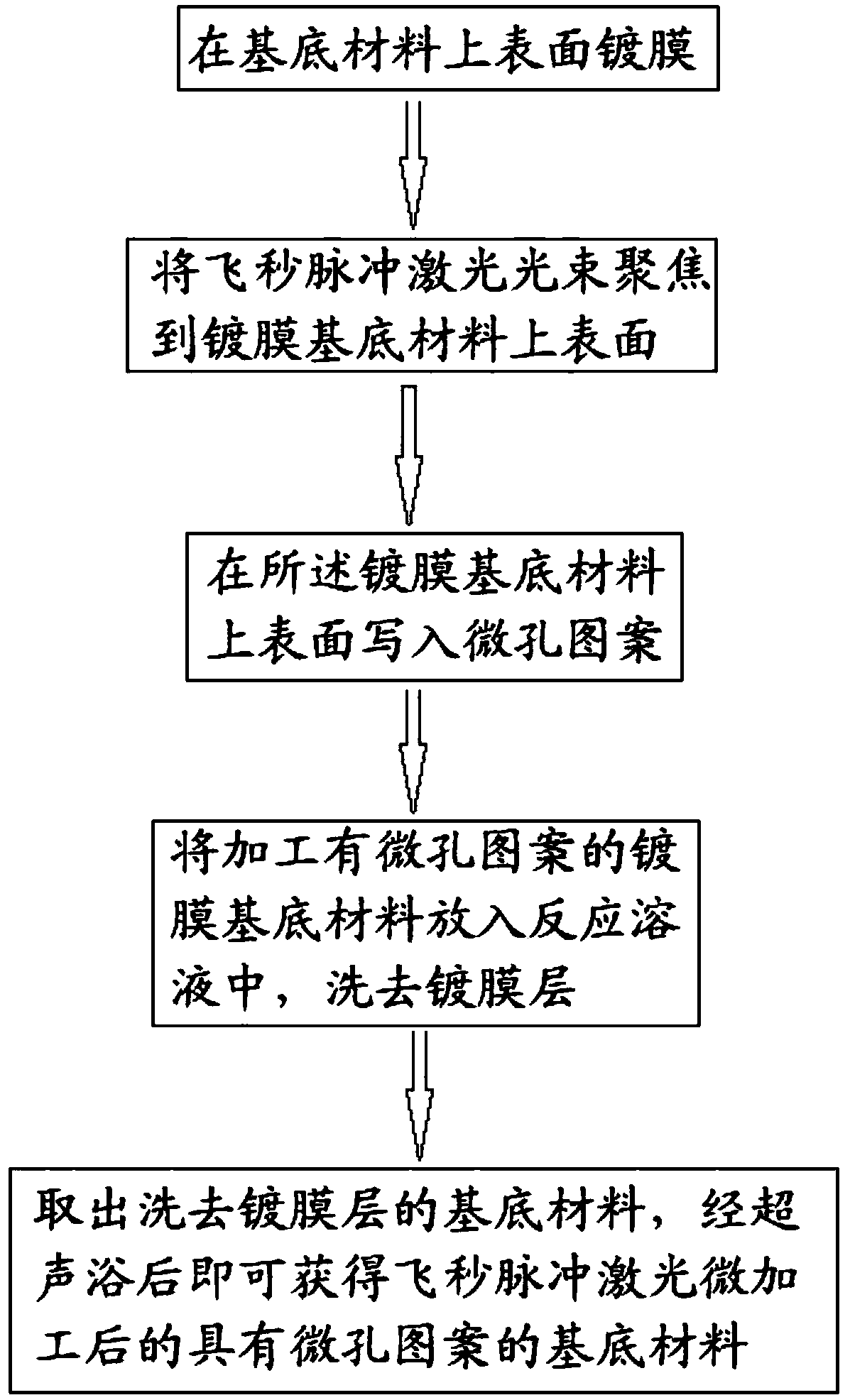

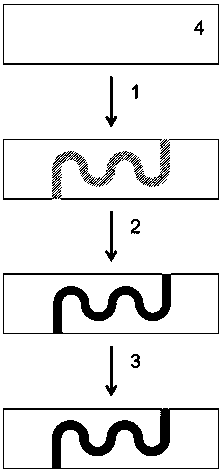

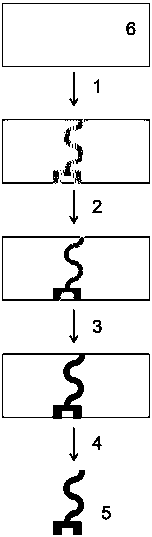

Femtosecond laser micromachining method and device

ActiveCN107717216APrevent thermal deformationAvoid crackingLaser beam welding apparatusHeat-affected zoneFemtosecond pulsed laser

The invention discloses a femtosecond laser micromachining method and device. The method comprises the steps that coatings are formed on the upper surface of substrate materials; femtosecond pulse laser beam focuses on the upper surface of the coated substrate materials; microporous patterns are formed in the upper surface of the coated substrate materials; the coated substrate materials with themicroporous patterns formed are placed into a reaction solution, and the coatings are removed by washing; and the substrate materials with the coatings removed are taken out, and the substrate materials with the microporous patterns through femtosecond pulse laser micromachining are obtained after ultrasonic bath. With the above method, the technical problem that the machining quality and machining precision are affected by heat-affected areas, recast layers, thermal deformation, cracks and so forth existing in machining areas in the femtosecond laser micromachining process in the prior art are solved, and the technical effects that the heat-affected areas, recast layers, thermal deformation, cracks and so forth are avoided and the machining quality and machining precision are improved areachieved.

Owner:武汉光谷航天三江激光产业技术研究院有限公司

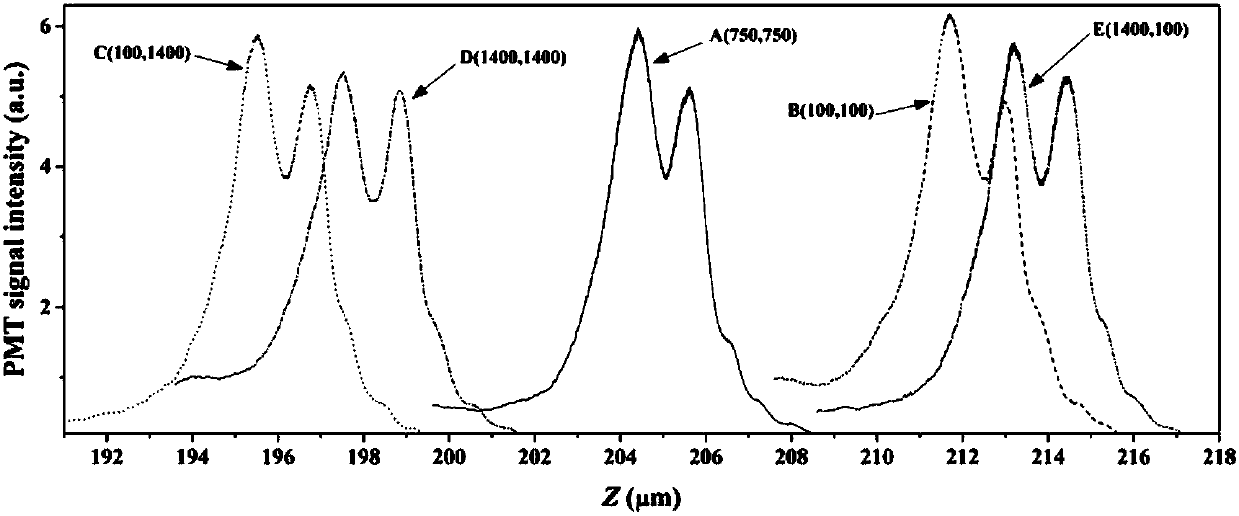

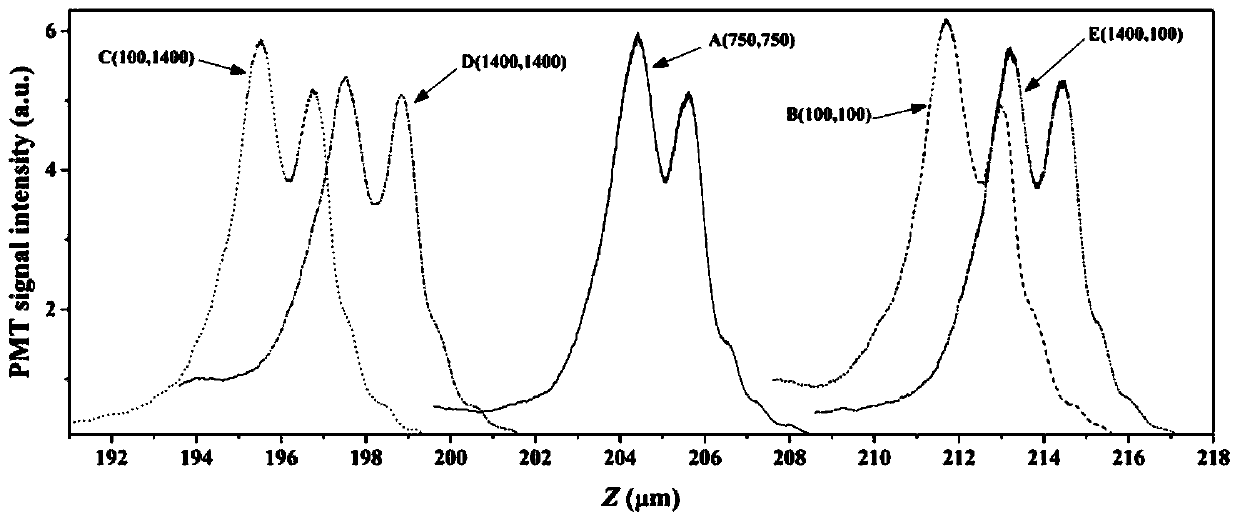

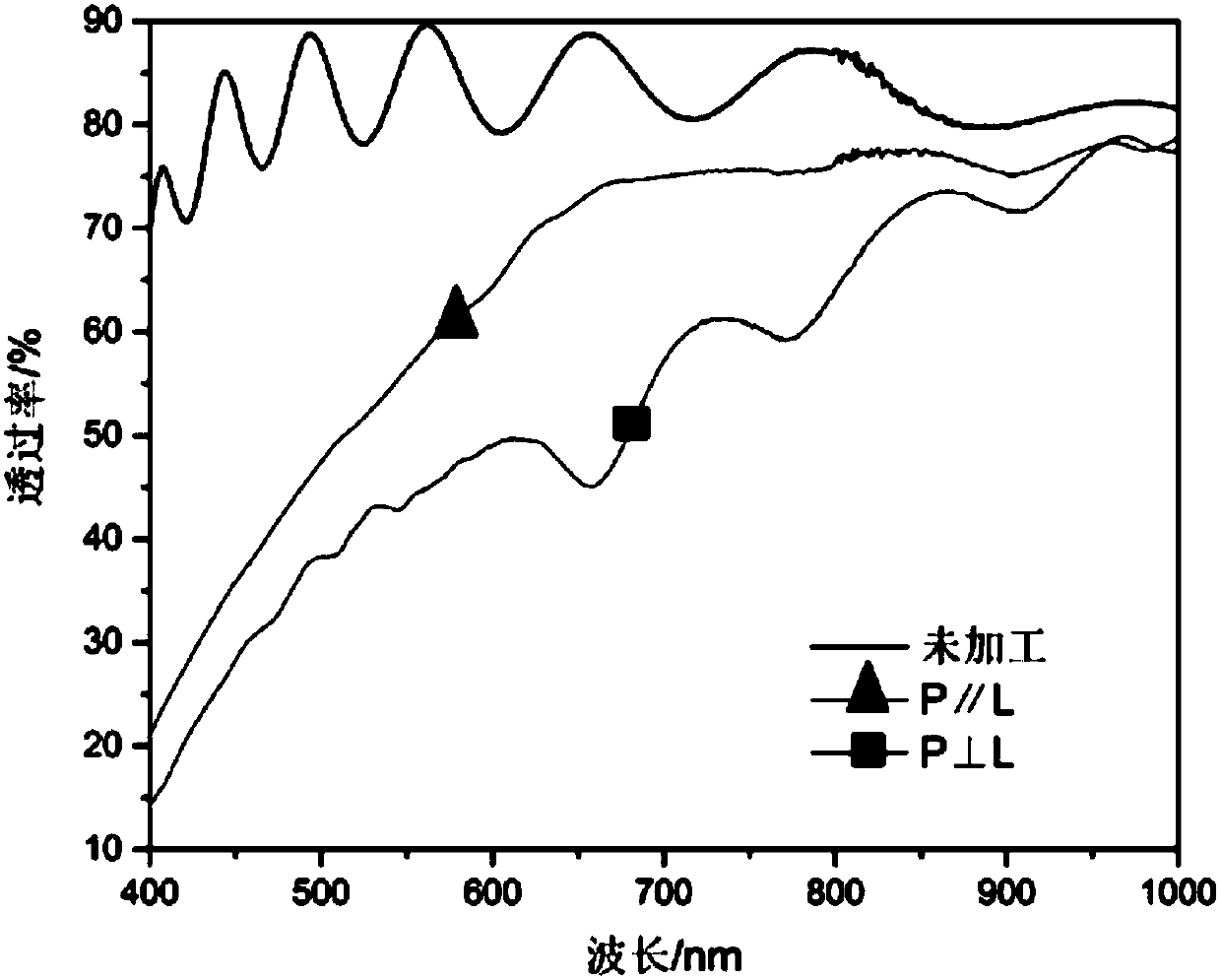

Method for acquiring refractive index variation of transparent film in femtosecond laser micromachining

ActiveCN107064064AUniform change in refractive indexPhase-affecting property measurementsLaser processingRefractive index

The invention discloses a method for acquiring the refractive index variation of a transparent film in femtosecond laser micromachining. According to the method, 64 areas which are related to laser power and platform scanning speed and have a size of 80 mu m*80 mu m and variation of the refractive index can be obtained by utilizing a laser plane processing device and adopting a method for scanning line by line at an interval of 300nm, the transmission spectrum of the 64 areas can be detected by a Fourier infrared spectrometer with a microscopic system and a three-dimensional mobile platform, and the refractive index of the film can be calculated from the transmission spectrum by adopting an improved Swanepoel method, so that the refractive index variation of a film in the laser processing area can be obtained.

Owner:NINGBO UNIV

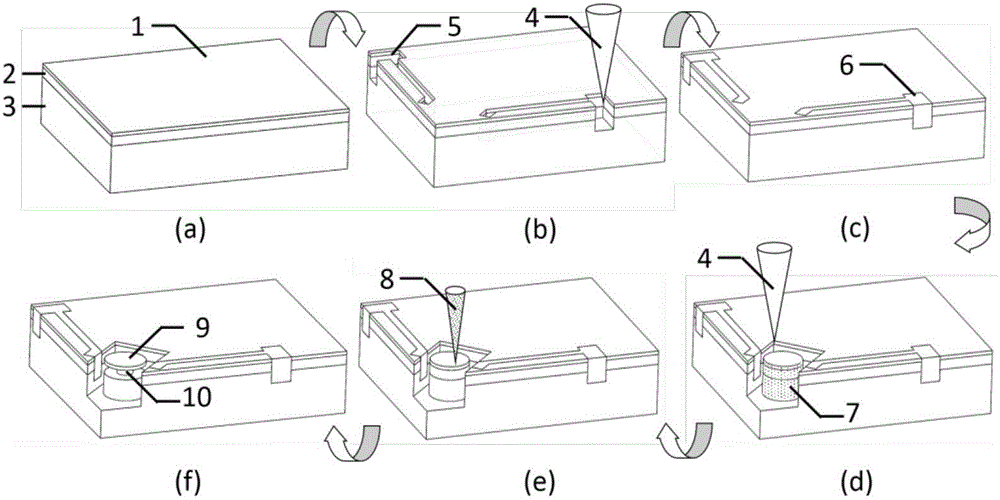

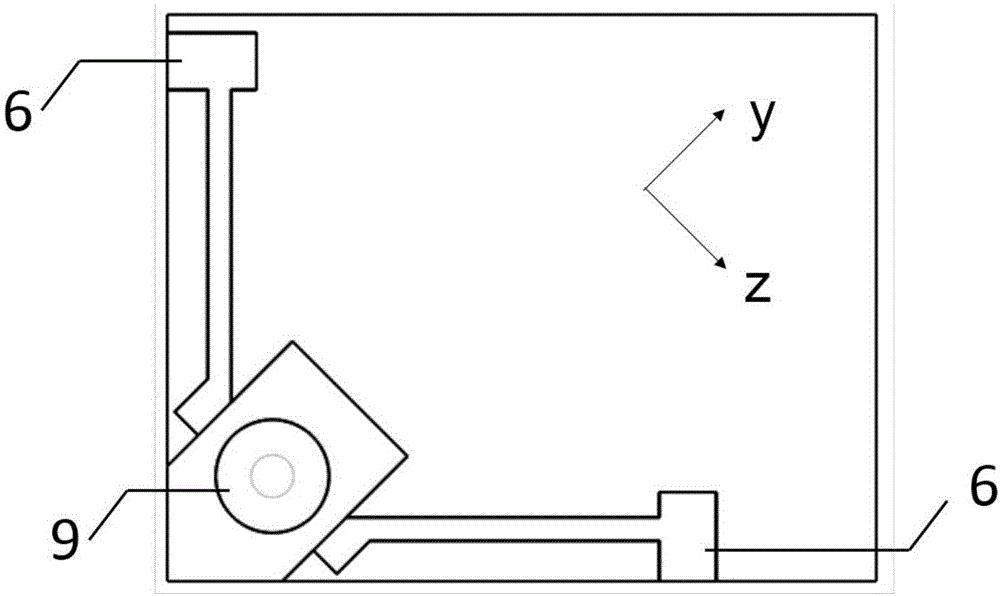

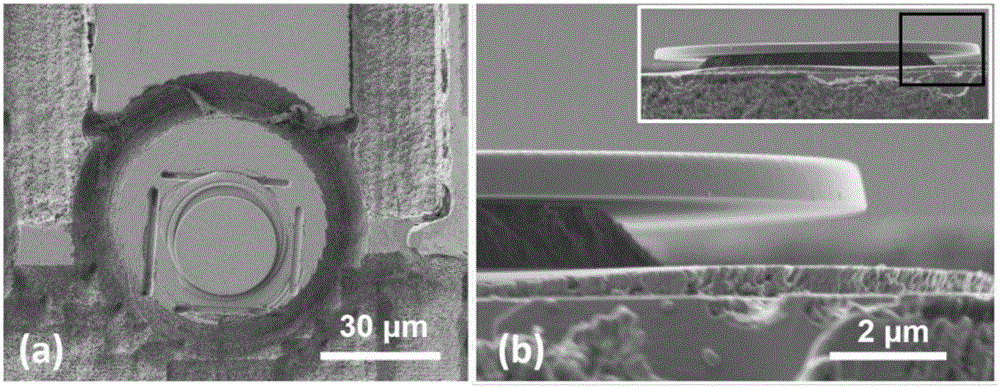

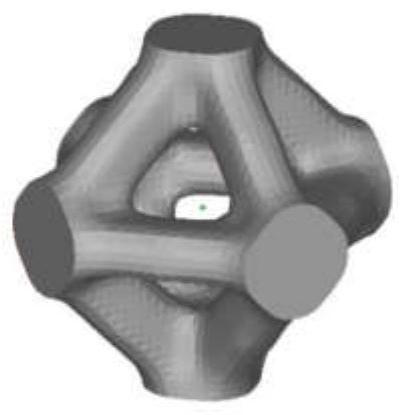

Fabrication method for electro-optical tuning whispering gallery mode microcavity of integrated electrode

InactiveCN106374335AHigh Q valueIncrease the refractive index ratioLaser optical resonator constructionChemical platingWhispering gallery

A method for fabricating an electro-optical tuning whispering gallery mode microcavity of an integrated electrode by a femtosecond laser microprocessing technology comprises the steps of helping to induce electrode chemical plating by a femtosecond laser, etching a microcavity structure by the femtosecond laser, grinding focused ion beam and performing chemical corrosion. In the three-dimensional whispering gallery mode optical microcavity fabricated according to the method, continuous total internal reflection of light is achieved by the ratio between refractive indexes of a cavity and an external environment, the three-dimensional whispering gallery mode optical microcavity has extremely high surface smoothness, and a small mode size and a high quality factor (larger than 10<5>) are supported; and meanwhile, accurate control on an electric field around the microcavity can be achieved by a transversely-integrated electrode, continuous adjustment of the refractive indexes is achieved by an electro-optical effect of a cavity material, and the purpose of mode cavity tuning in a whispering gallery mode is further achieved. The method is applicable to various dielectric thin film materials with electro-optical effects.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

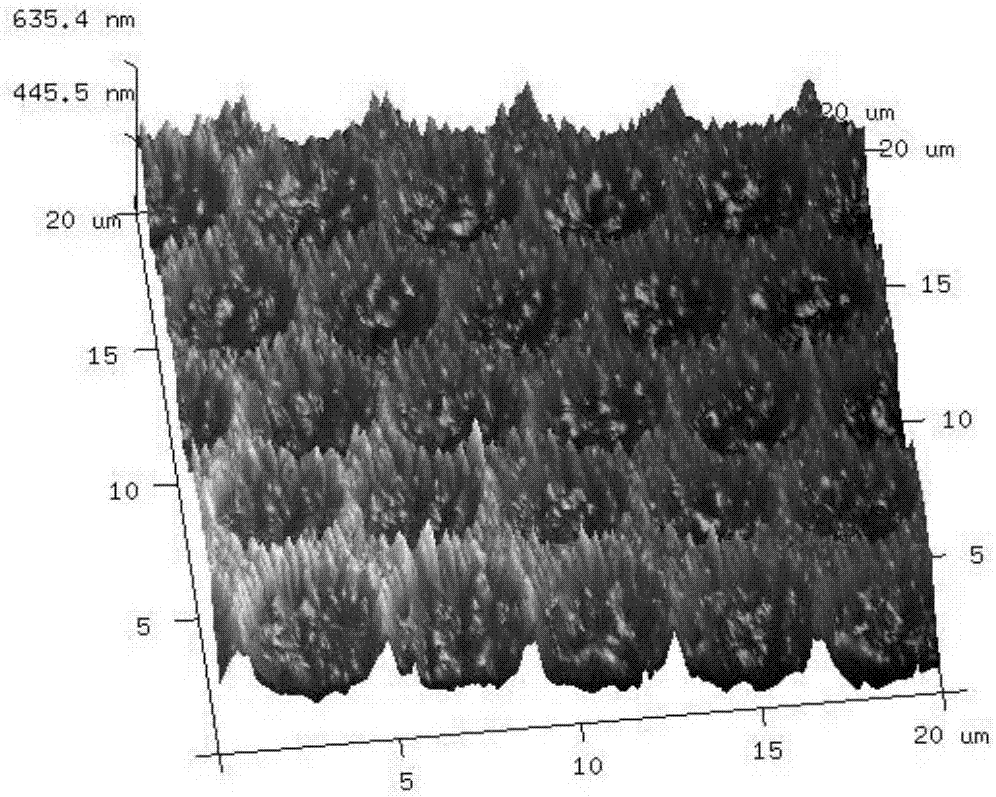

Method for improving photoelectric properties of aluminum-doped zinc oxide film through femtosecond lasers

InactiveCN107262918ALower resistanceRepairing Al-doped Zinc Oxide Surface DefectsFinal product manufacturePhotovoltaic energy generationMicro fabricationAluminum doped zinc oxide

The invention provides a method for improving photoelectric properties of an aluminum-doped zinc oxide (AZO) film through femtosecond lasers based on electronic dynamic control and belongs to the technical field of functional materials. The method for improving the photoelectric properties of the AZO film through the femtosecond lasers is based on a femtosecond laser micro-nanometer fabrication system and comprises the following steps that after being cleaned, an AZO deposition substrate sample is placed in a femtosecond laser micro fabrication laser path, femtosecond lasers generated by a femtosecond laser device are concentrated by an objective lens to an aluminum oxide material, and through adjustment of the energy and the repetition frequency of the femtosecond lasers, the displacement speed of the substrate sample and other parameters, the processed morphology on the surface of the sample is controlled. Compared with the prior art, the method for improving the photoelectric properties of the AZO film through the femtosecond lasers can repair surface defects of AZO, reduce the sheet resistance of the material and improve the conductivity of the material; and meanwhile, the processed morphology generated on the surface of the sample can lower the reflectivity of the surface, light absorption is enhanced when the AZO is applied to solar cells, and the photoelectric efficiency is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

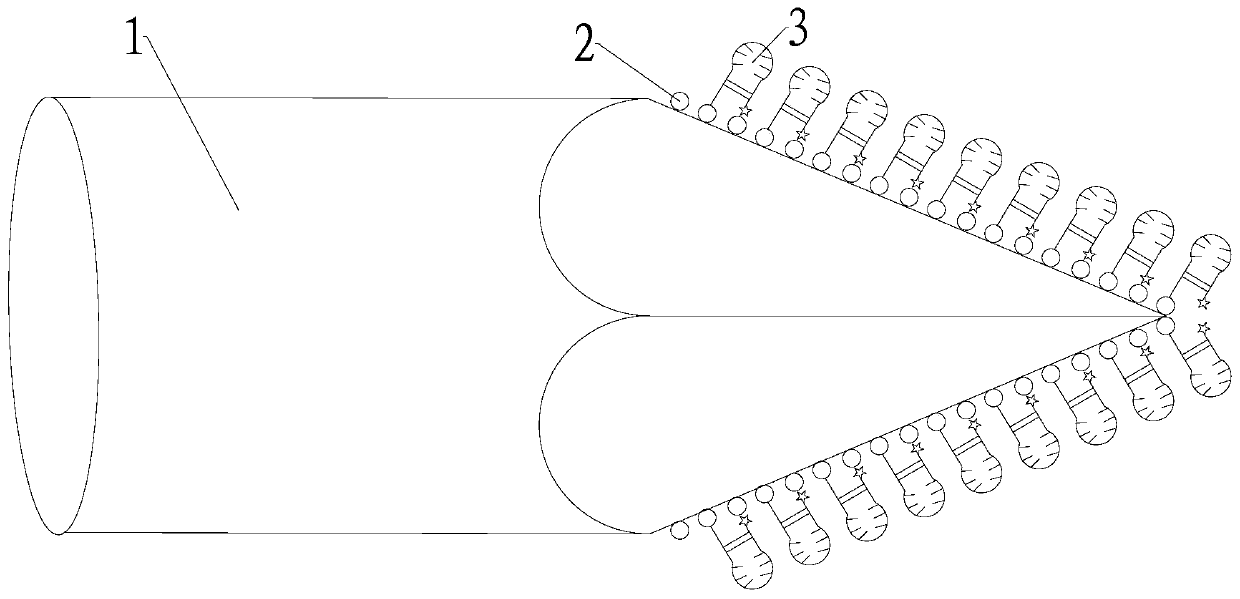

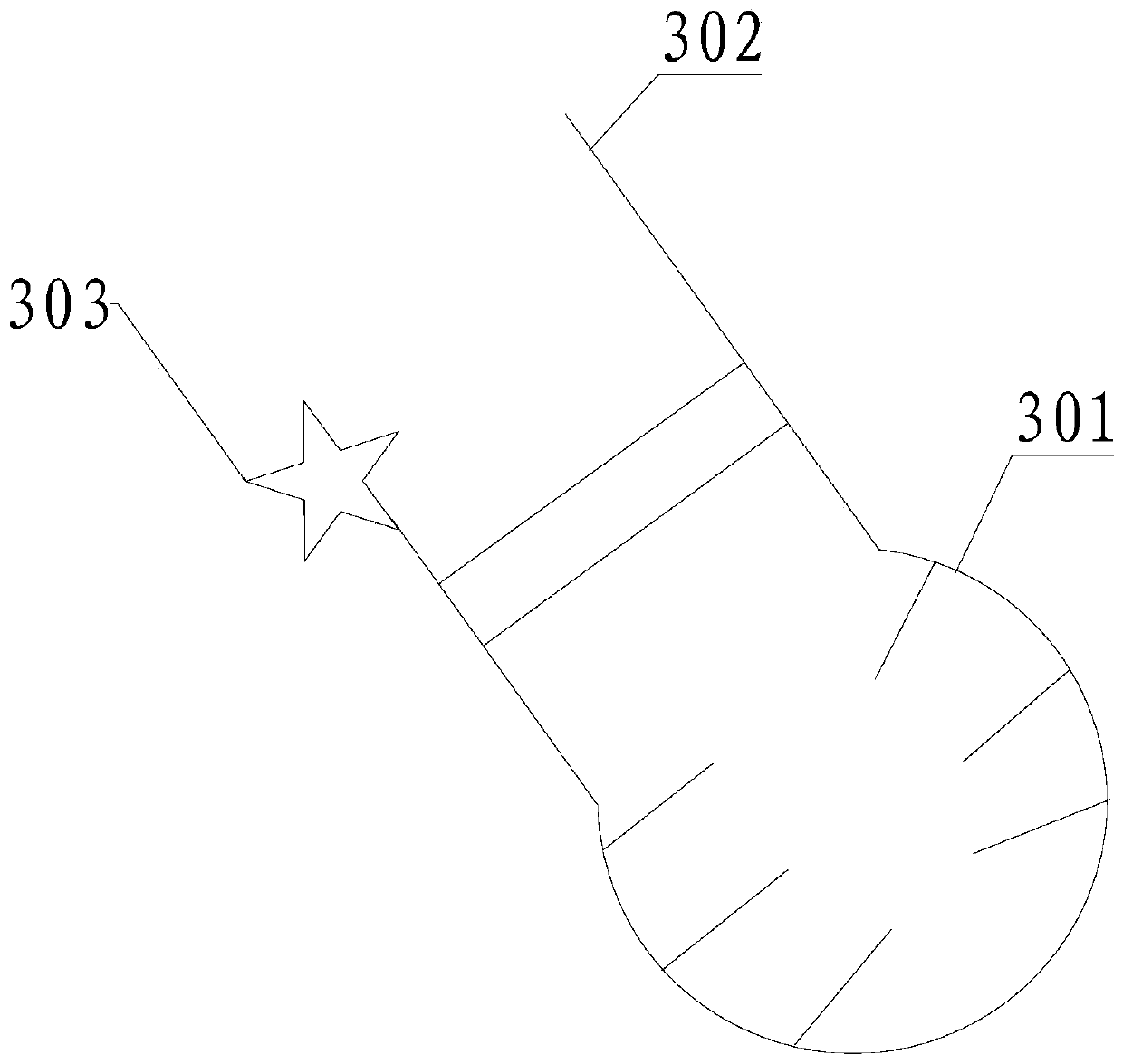

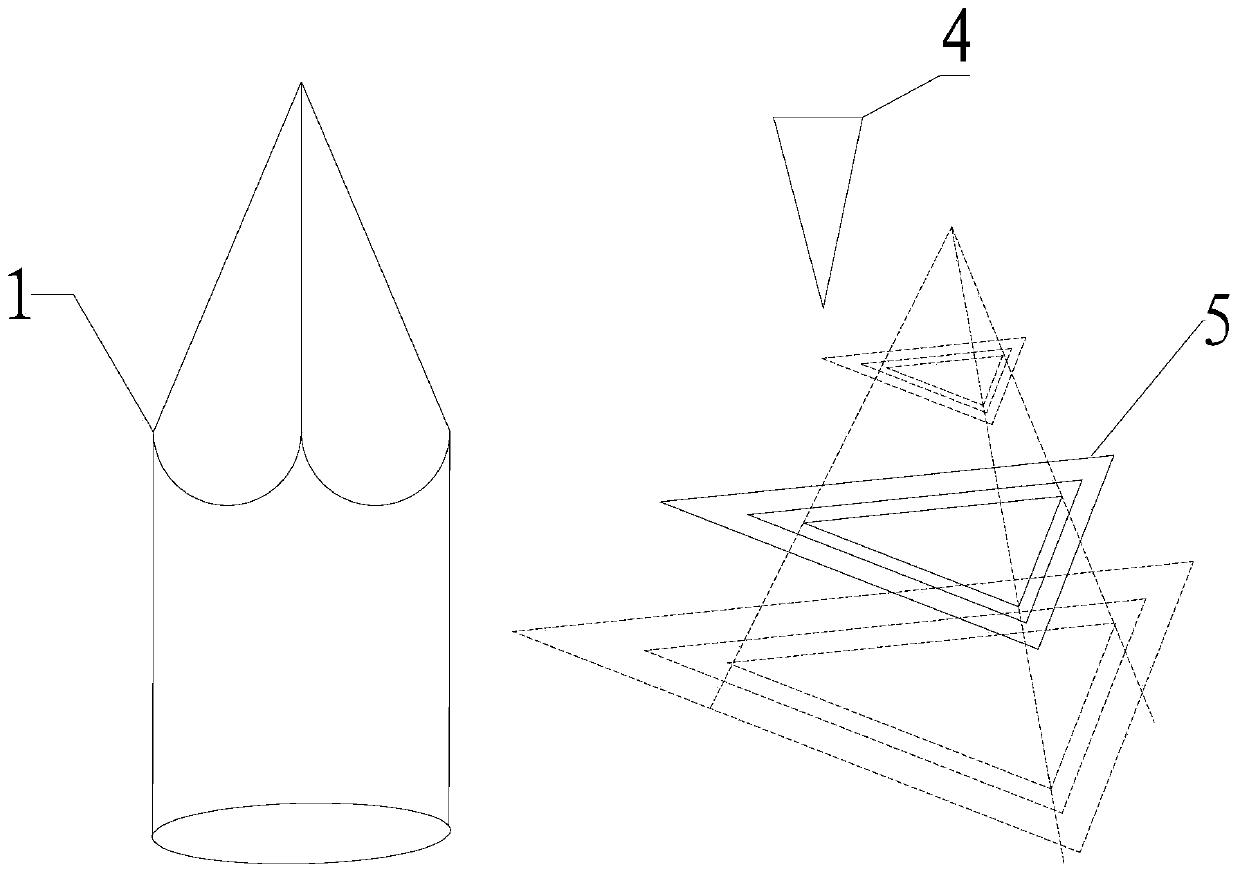

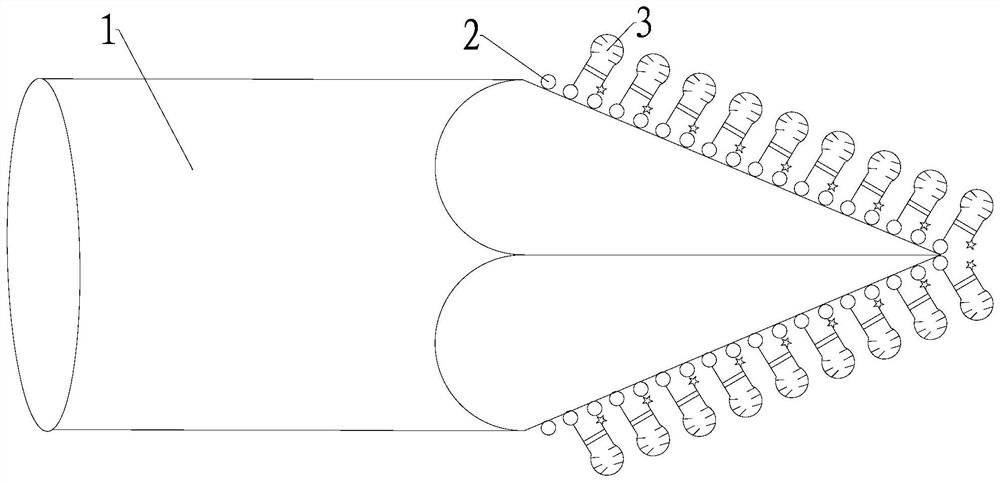

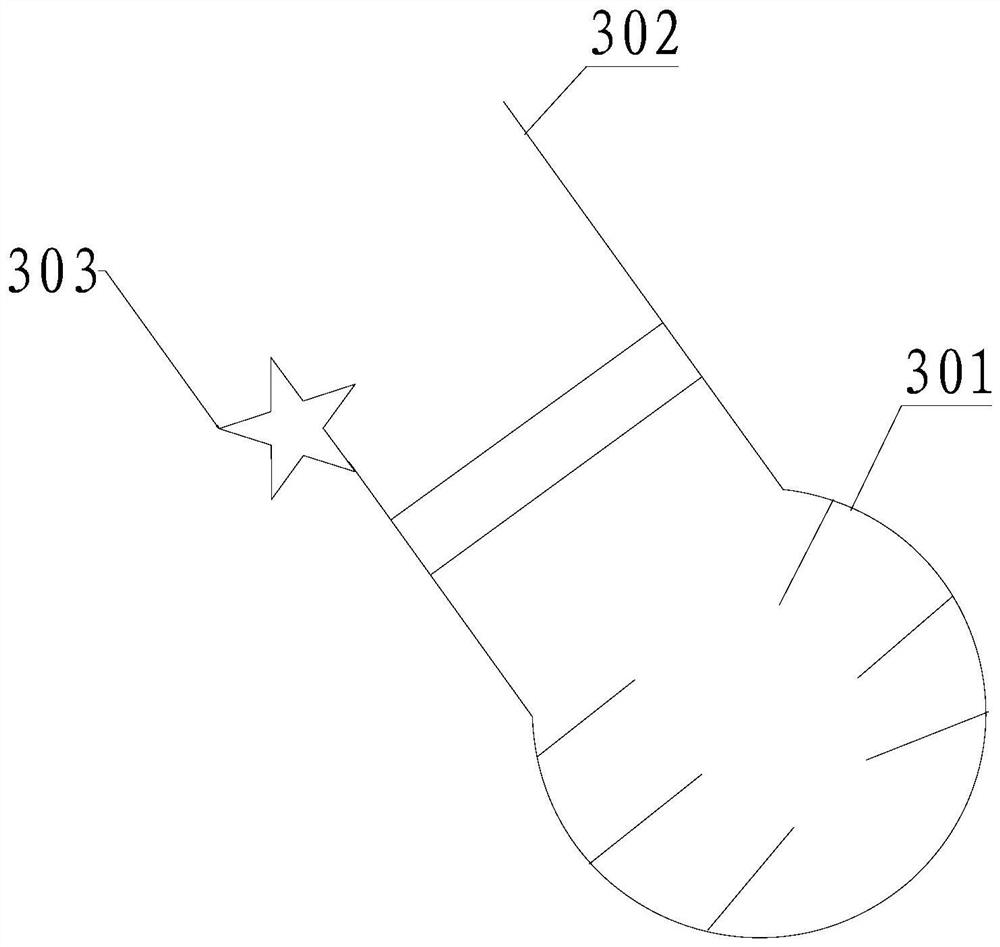

DNA probe structure and manufacturing method thereof

ActiveCN110455754AGood effectEasy to makeRaman scatteringFluorescence/phosphorescenceFiberSpecific detection

The invention, which is suitable for the field of optical fiber sensing, provides a tapered optical fiber Raman DNA probe structure and a manufacturing method thereof. The probe structure comprises apyramidal optical fiber substrate 1 with a roughened surface, a metal nanoparticle reinforced substrate 2 and a DNA probe sensitive layer 3 with a hairpin structure. In addition, the invention also provides a manufacturing method of the tapered optical fiber Raman DNA probe structure. The method includes: making a pyramidal fiber 1 with a roughened surface by using a femtosecond laser micromachining technology; on the basis of an electrostatic adsorption or light-induced growth method, modifying the surface of the tapered fiber with metal nanoparticles 2 and growing the metal nanoparticles 2 on the surface of the tapered fiber; and then assembling a DNA probe sensitive layer 3 with a hairpin structure to realize a highly sensitive optical fiber DNA probe. According to the invention, the tapered optical fiber Raman DNA probe structure has advantages of simple structure and high sensitivity; and high-sensitivity specific detection of DNA target fragments is realized.

Owner:SHENZHEN UNIV

Method for integrating three-dimensional conductive metal micro-nano structure inside transparent material

InactiveCN108394856AEnables continuous depositionImprove conductivityDecorative surface effectsChemical vapor deposition coatingPeristaltic pumpOptoelectronics

The invention discloses a method for integrating a three-dimensional conductive metal micro-nano structure inside a transparent material. The method comprises the following steps: firstly, preparing athree-dimensional micro-channel inside the transparent material by using the femtosecond laser micro-machining technology; and then continuously transmitting electroless plating solution through a peristaltic pump, carrying out surface modification and metal deposition inside the channel through the micro-channel, so that the three-dimensional conductive metal micro-nano structure is integrated inside the transparent material. According to the integrated three-dimensional conductive metal micro-nano structure manufactured by the invention, the space shape can be randomly designed, the size isadjustable, the electrical conductivity is high, and the melting point is high; and the integrated three-dimensional conductive metal micro-nano structure has great application prospect in the technical fields of microelectronic devices, optoelectronic devices, micro-nano motor systems and the like.

Owner:EAST CHINA NORMAL UNIVERSITY

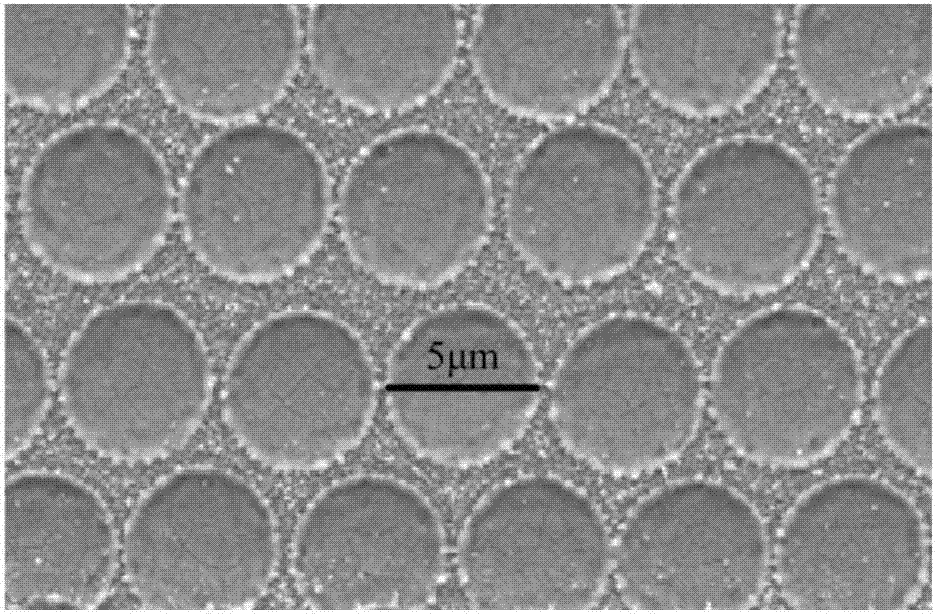

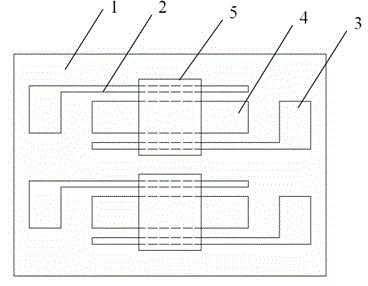

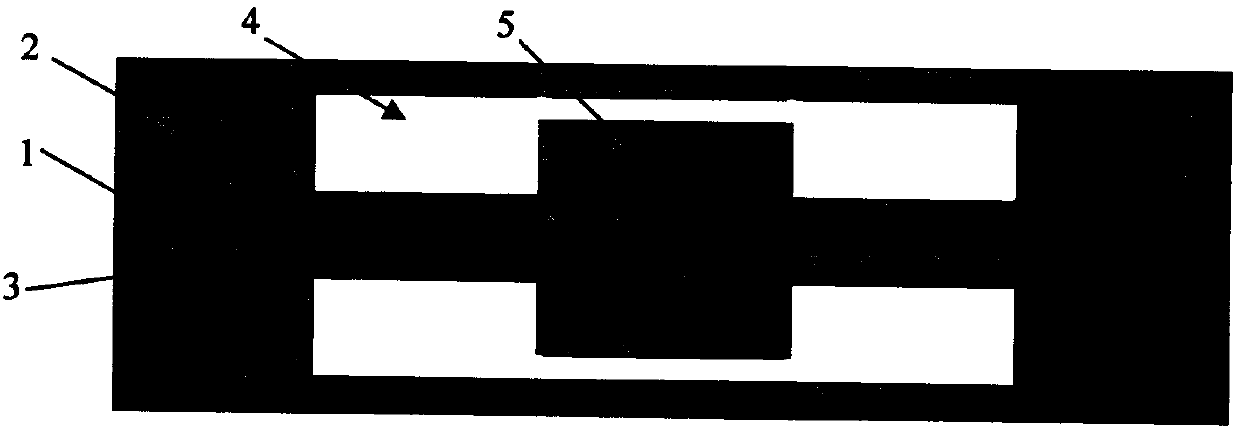

Preparation method of large-scale array graphene nanoelectronic resonator based on femtosecond laser

ActiveCN104310305AReduce secondary pollutionRaise the resonant frequencyDecorative surface effectsChemical vapor deposition coatingAlloyFemtosecond laser micromachining

The invention discloses a preparation method of a large-scale array graphene nanoelectronic resonator based on femtosecond laser. The preparation method comprises the following steps: sputtering a TiW alloy and Au on the surface of a SiO2 / Si substrate; preparing a single-layered graphene thin film by a chemical vapor deposition method; transferring the single-layered graphene thin film onto TiW / Au connection wires; and scanning and cutting the two adjacent TiW / Au connection wires and a single-layered graphene thin film region between two adjacent Au electrode sheets by adopting the femtosecond laser to form the array graphene nanoelectronic resonator, wherein the energy density of the femtosecond laser is more than 0.16J / cm<2>-0.21J / cm<2>. According to the preparation method of the large-scale array graphene nanoelectronic resonator based on the femtosecond laser, a traditional CMOS process is combined with a preparation process of a femtosecond laser micro-machining technology and a preparation technology from bottom to top is completely adopted; photoresist does not need to be spun and plasma etching is avoided; the secondary pollution to graphene is reduced and the resonant frequency and the quality factor of the nanoelectronic resonator are greatly improved; and meanwhile, the manufacturing cost is extremely reduced.

Owner:JIANGSU UNIV

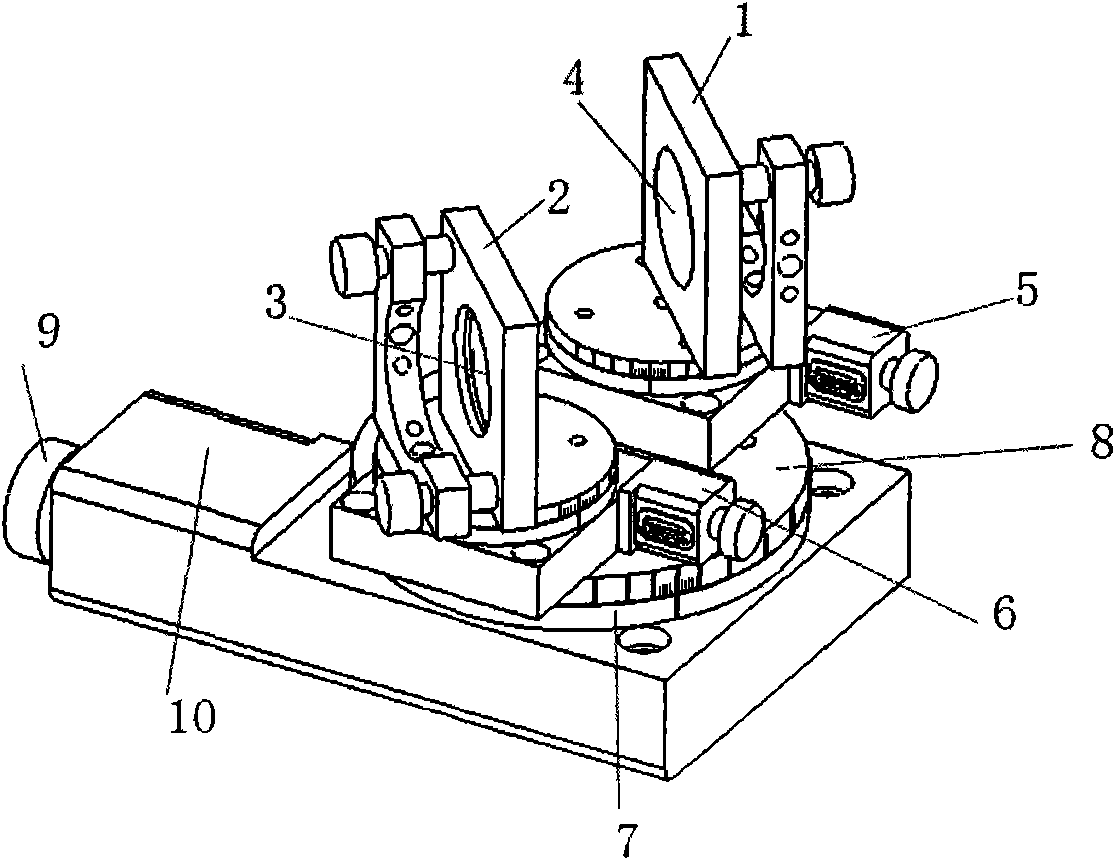

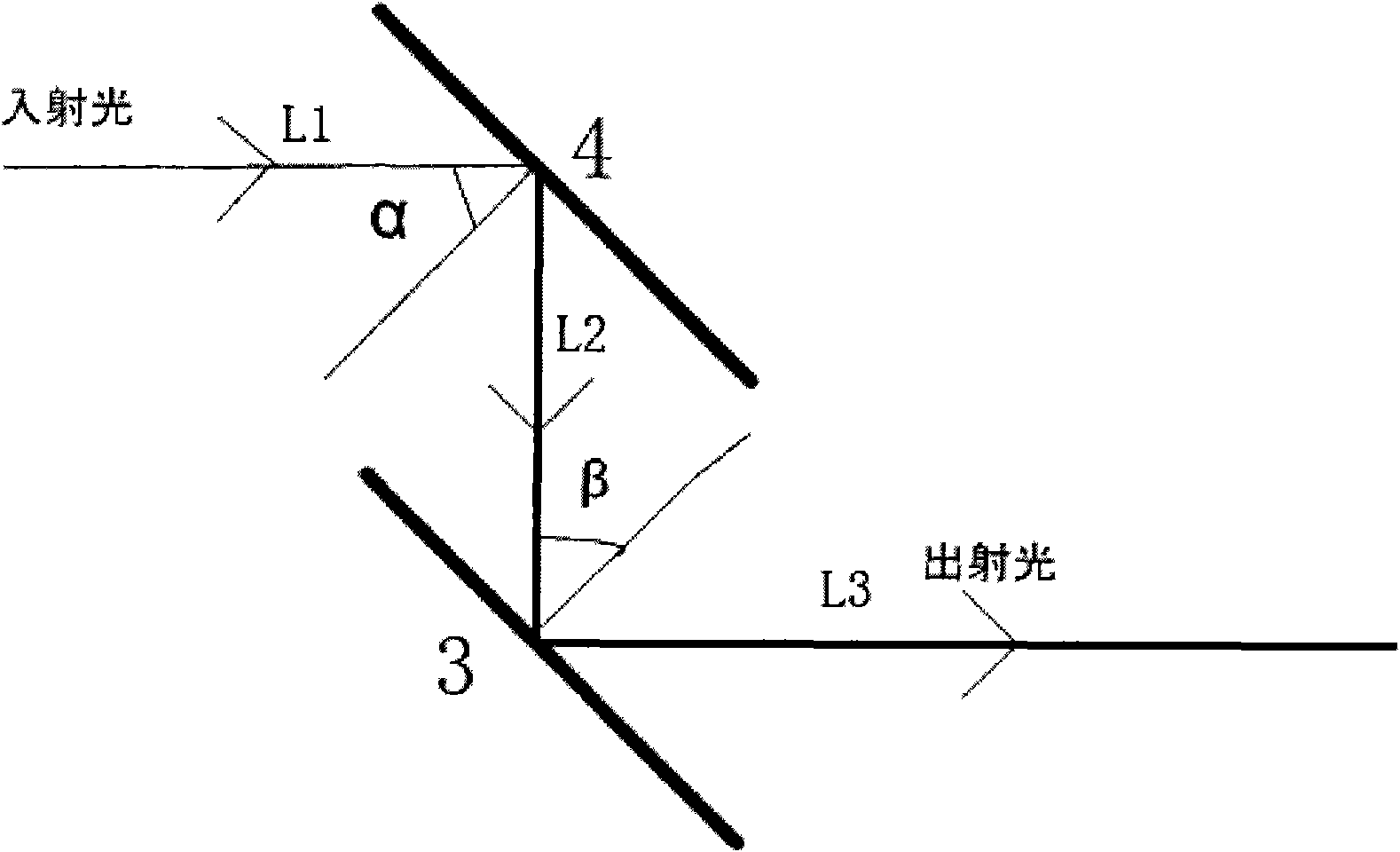

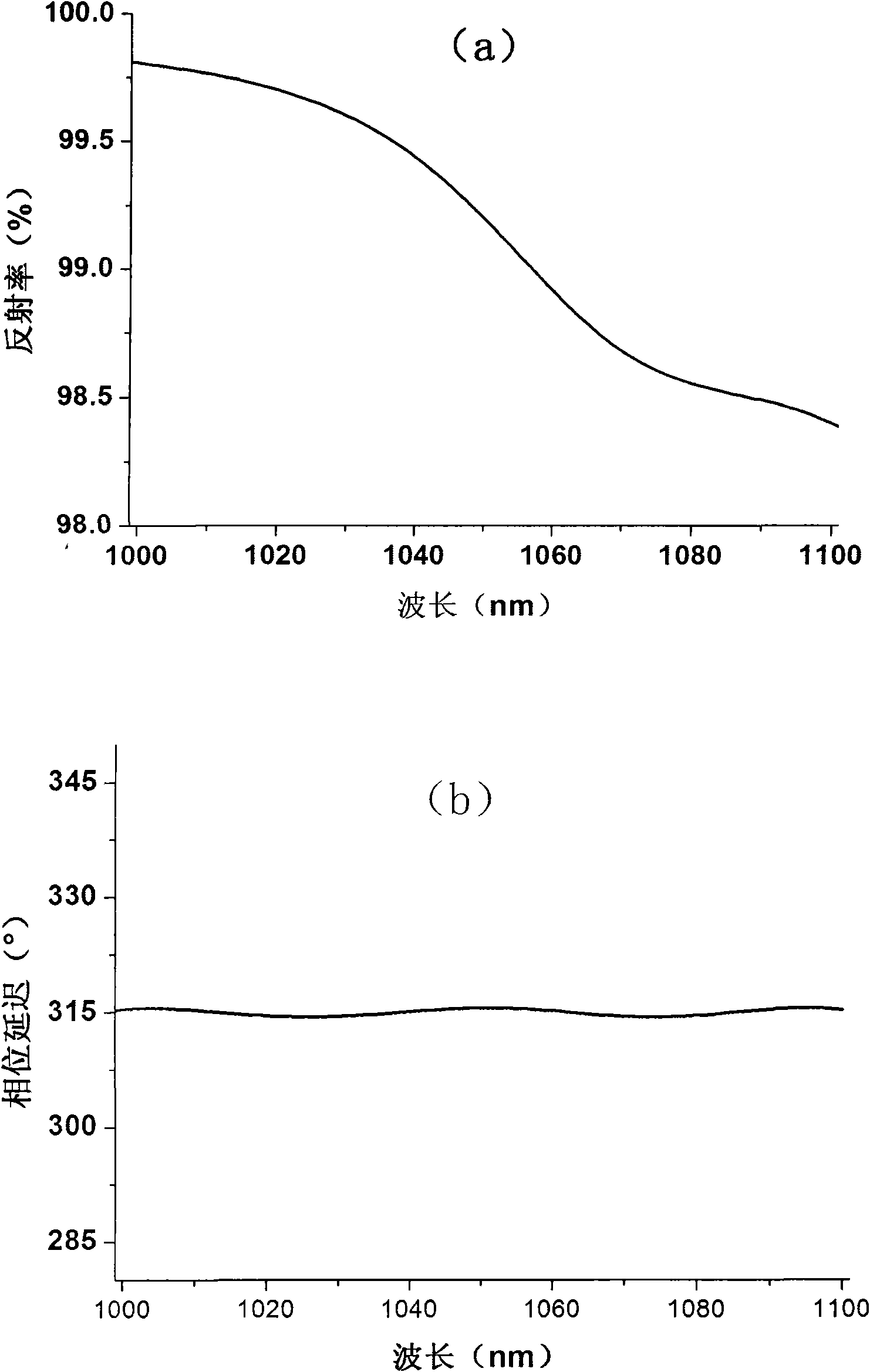

Tunable wideband phase self-compensation retarder

InactiveCN102156349AImprove reflectivityAchieving wideband phase delayPolarising elementsPhase retardationSelf compensation

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

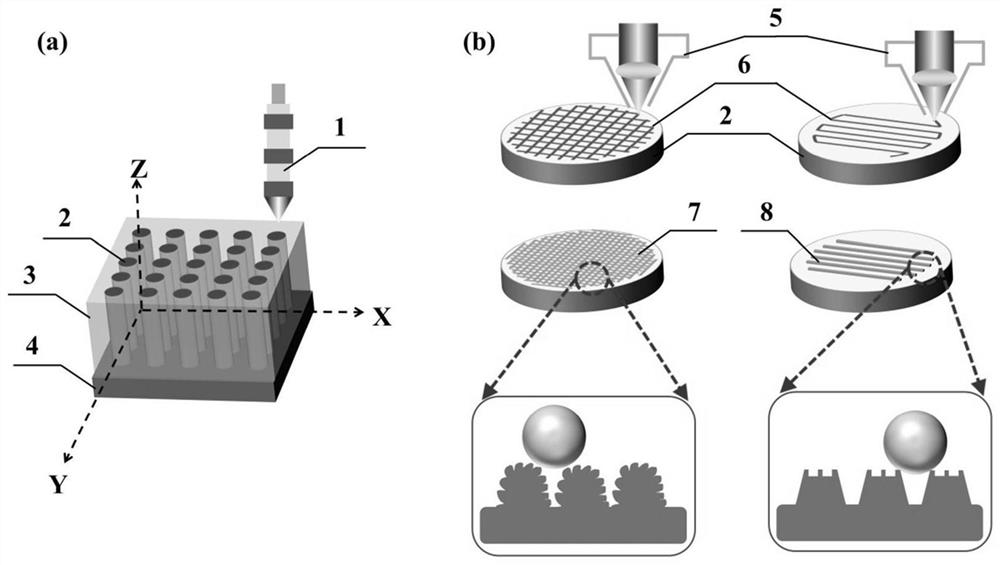

Method for manufacturing high-performance medical metal by mixing selective laser melting and laser surface texture

ActiveCN113732307ARealize personalized designAchieve preparationAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingOsseointegration

The invention discloses a method for manufacturing high-performance medical metal by mixing selective laser melting and laser surface texture. The method comprises the following steps of layering and slicing a CAD model of a medical metal part to generate a series of two-dimensional scanning tracks; according to the scanning track, medical metal powder is stacked point by point, line by line and layer by layer through a selective laser melting method to form a three-dimensional porous structure, and the hole pattern is designed in a topological optimization mode; performing femtosecond laser micromachining on the surface of the porous structure to generate a hydrophilic structure; and enabling the medical metal powder to be composed of pure copper powder and 316L stainless steel powder or titanium alloy powder. The medical metal prepared through the method has a fine microstructure, the corrosion resistance, biocompatibility and antibacterial performance of the medical metal can be improved, the osseointegration performance of the medical metal is greatly improved, as a bone implant, the medical metal greatly improves the stress shielding effect caused by mismatching with the elastic modulus of bones, easily infects in the operation and overcomes the contradiction between the antibacterial property and the osseointegration property.

Owner:JINAN UNIVERSITY

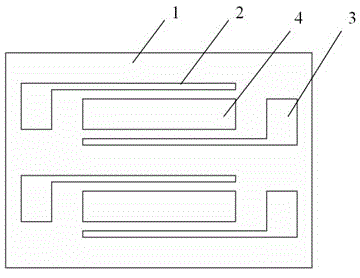

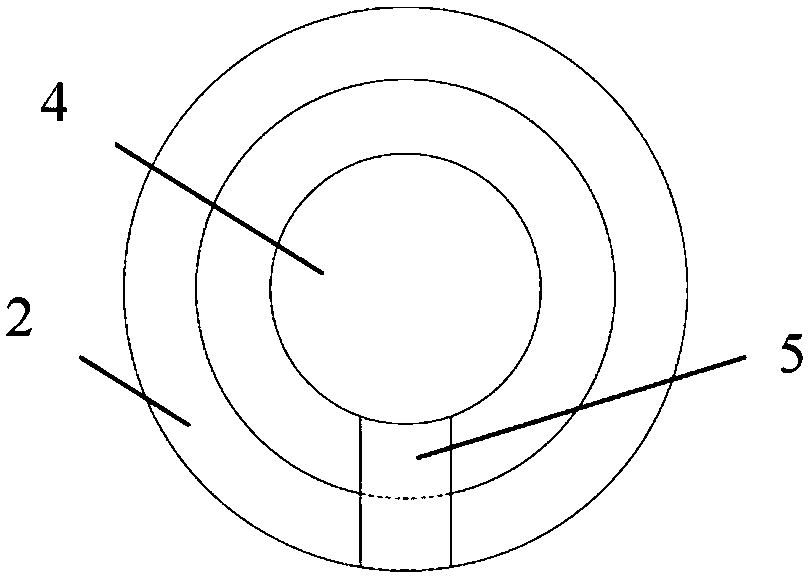

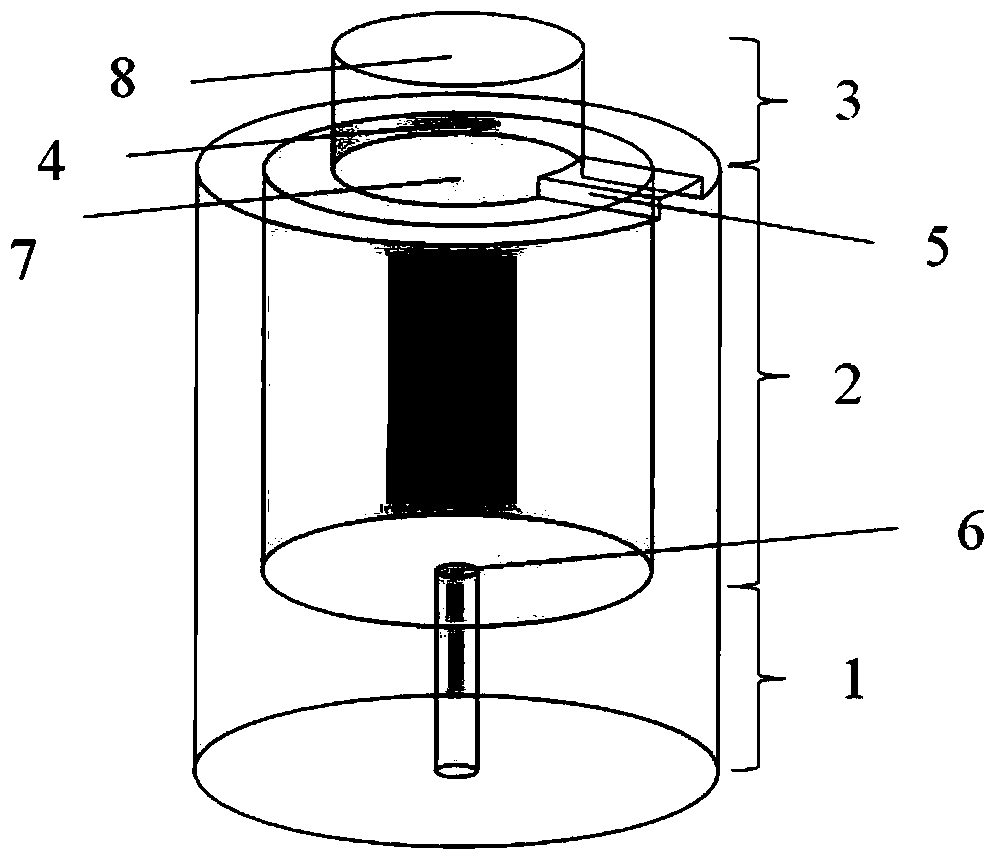

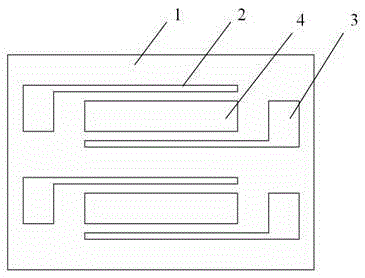

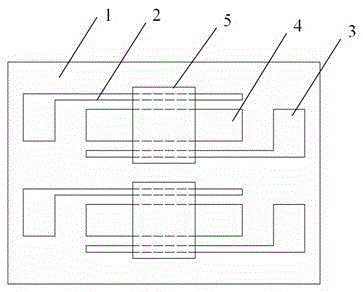

Fiber grating accelerometer in optical fiber

The invention relates to a fiber grating accelerometer in an optical fiber. According to the principle of an accelerometer, the only method to simultaneously increase the sensitivity and eigenfrequency of the accelerometer is to reduce the length of the vibrating arms of the accelerometer. According to the fiber grating accelerometer in the optical fiber, a femtosecond laser micro-machining technology is adopted to cut the cladding of the optical fiber, so that the diameter of the optical fiber at the vibration portion of the accelerometer can be decreased, and therefore, vibration arms can beformed at a fiber grating, and an inertial component can be formed in the optical fiber. As shown in the drawings described in the descriptions of the invention, most of the cladding of the grating is removed, so that the cladding can form the vibrating arms. Although the mass of the inertial component (fiber cladding block) between the two vibrating arms which are formed by means of laser cutting is small, the diameter of the vibrating arms is smaller, and as a result, stress generated by vibration is still concentrated on the vibrating arms, and therefore, the length of the fiber grating and the return wavelengths of the fiber grating can be changed, and vibration information can be obtained. The diameter ratio of the inertial component and the vibrating arms can be changed, so that thesensitivity and eigenfrequency of the fiber grating accelerometer can be changed.

Owner:BENGBU COLLEGE

Process for preparing zinc oxide nanometer wire array by femtosecond laser and device thereof

InactiveCN101311358BImprove uniformityReduce consumptionPolycrystalline material growthSingle crystal growth detailsMaterials preparationOptoelectronics

The invention discloses a method for preparing a zinc oxide nanowires array by femtosecond laser and a device thereof, which belongs to technical fields of micro nanophase material preparation and femtosecond laser micro processing, relates to a periodical nanometer microstructure of zinc oxide material, and particularly provides a method for preparing a periodical nanowires array on the target of the zinc oxide by means of a femtosecond laser radiation field. When the zinc oxide nanowires array is prepared, zinc oxide target material is first fixed on a two-dimensional accurate displacement station, and then a bunch of light femtosecond laser is focalized by a lens to act on the zinc oxide target material; by a coordinated scan of femtosecond induction and the two-dimensional accurate displacement station, the zinc oxide periodical nanowires array is generated. The method for preparing the zinc oxide nanowires array by the femtosecond laser and the device thereof have the advantages that the preparation efficiency is high; the application scope is wide; the zinc oxide nanowires array processed and obtained is neatly and evenly arrayed.

Owner:XI AN JIAOTONG UNIV

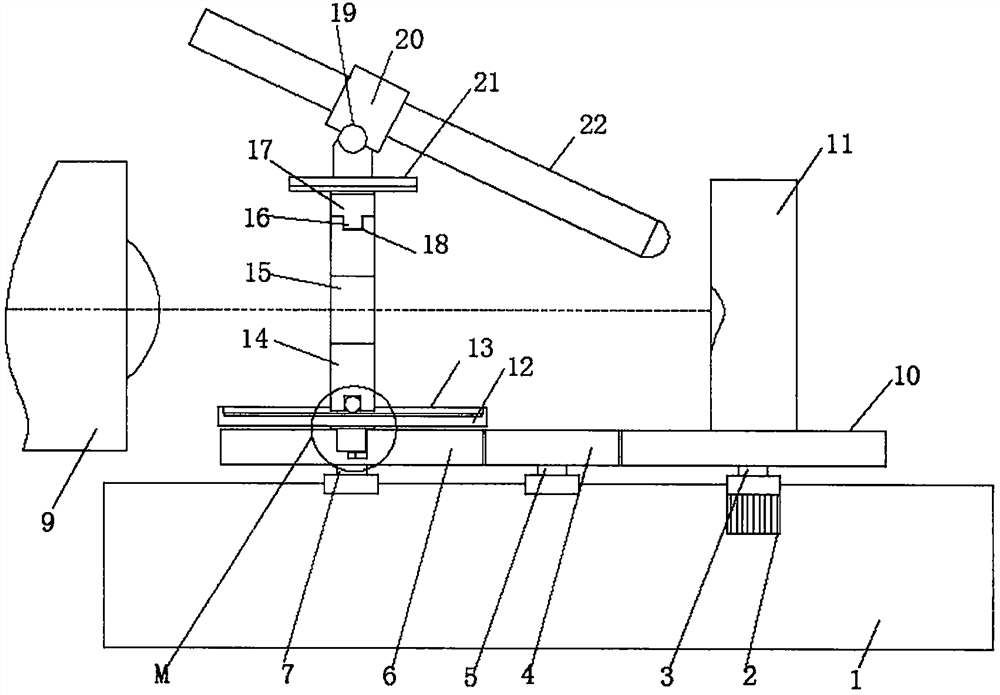

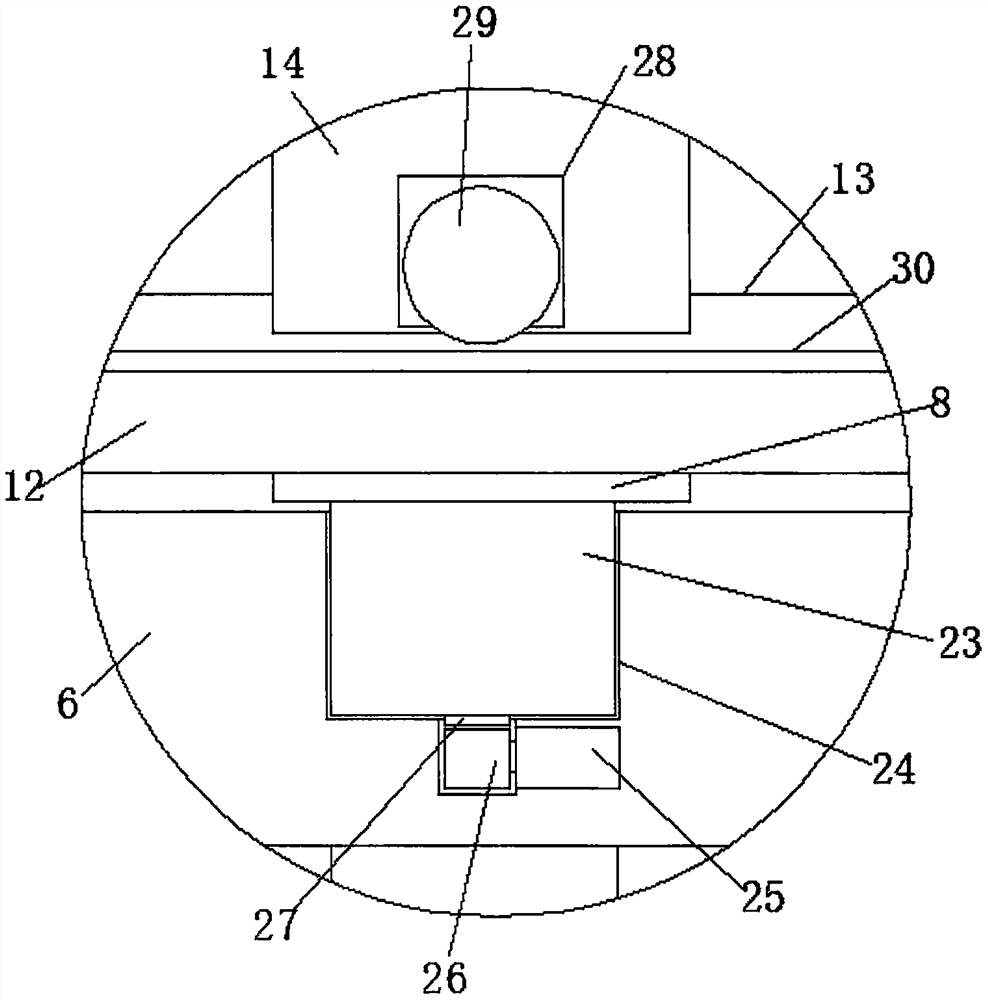

Synchronous monitoring device for femtosecond laser micromachining

The invention discloses a synchronous monitoring device for femtosecond laser micromachining, and belongs to the field of monitoring of femtosecond laser micromachining. The synchronous monitoring device for femtosecond laser micromachining comprises an adjusting base, and a machined part is arranged on the adjusting base. The adjusting base is located on one side of a femtosecond laser. A first driving motor is fixedly connected to the adjusting base, a first driving shaft is fixedly connected to the driving end of the first driving motor, a first gear disc is fixedly connected to the first driving shaft, the machined part is located at the center of the first gear disc, and a transmission gear is rotatably connected to the adjusting base through a rotating shaft. According to the synchronous monitoring device, a CCD for monitoring is always vertical to the machined part; and meanwhile, in order to ensure that the CCD for monitoring is accurately aligned to the machining position of the machined part, the monitoring effect during oblique incidence machining and the monitoring effect during vertical incidence machining are kept the same, automatic adjustment is completed at a time,automatic and accurate adjustment is conducted, and the monitoring effect is ensured.

Owner:JINAN G WEIKE SCI & TECH

Fabrication method of arbitrary-configuration three-dimensional conductive metal micro-nano structure

PendingCN108411286AEnables continuous depositionImprove fidelityLiquid/solution decomposition chemical coatingPeristaltic pumpMicro nano

Owner:EAST CHINA NORMAL UNIV

A kind of dna probe and making method

ActiveCN110455754BGood effectEasy to makeRaman scatteringFluorescence/phosphorescenceFiberSpecific detection

Owner:SHENZHEN UNIV

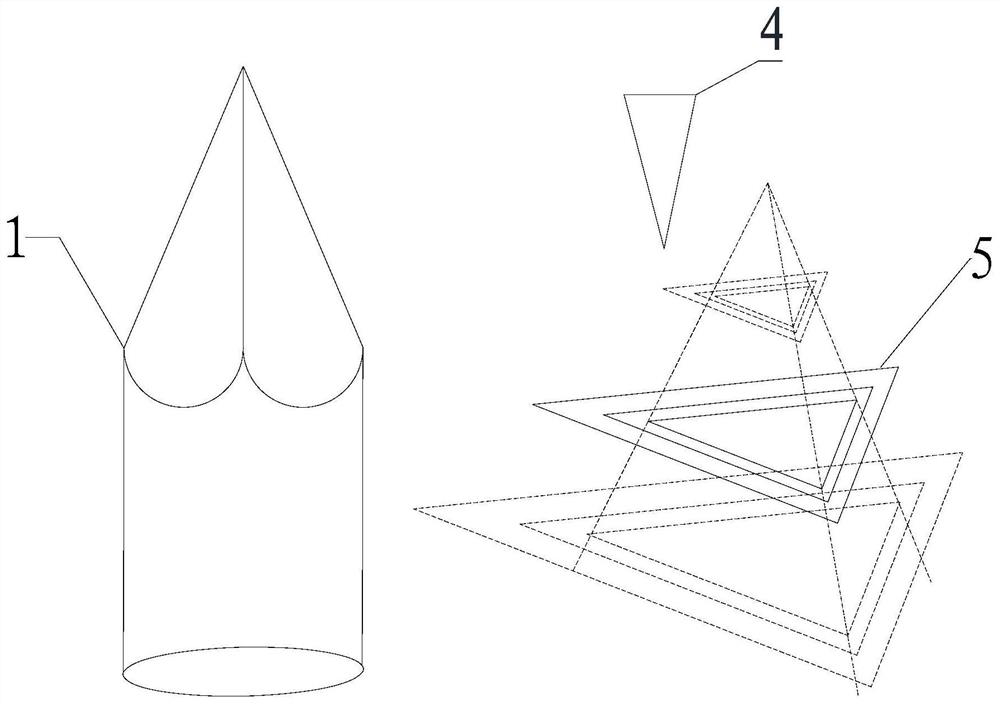

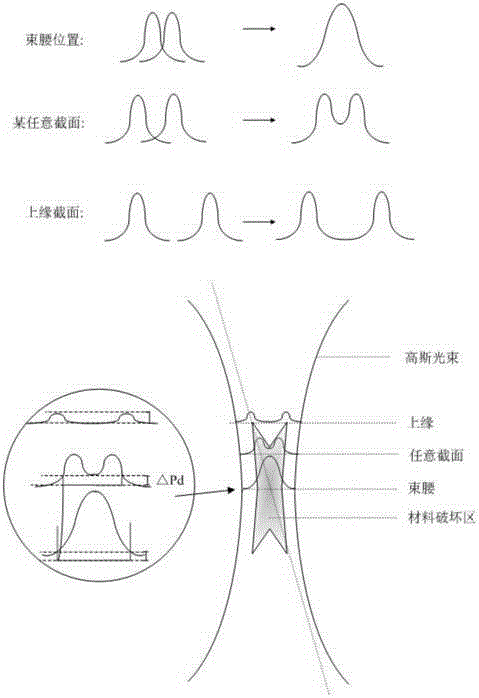

A method for one-way flow surface shaping based on electronic dynamic control space shaping

ActiveCN113118632BPromote absorptionSpeed up the flowLaser beam welding apparatusChemical reactionFemto second laser

The invention relates to a method based on electronic dynamic regulation and control of space shaping and processing of one-way flow surface, using a space light shaper to change the Gaussian light field into a light field with different shapes and energy distribution, and processing to obtain a bionic that can make the liquid flow in one direction A functional surface belongs to the technical field of femtosecond laser application. The femtosecond laser light field is transformed from a Gaussian distribution to a three-dimensional bionic light field distribution, so that bionic anisotropic structure processing can be realized on a variety of solid materials. The anisotropic bionic structure can control the direction of liquid flow and utilize spatial light The modulator (SLM) performs phase transformation on the Gaussian beam, which can control the three-dimensional distribution of the output energy of the femtosecond laser, and obtain different anisotropic bionic spatial light fields. The anisotropic biomimetic structure includes sharp triangular edges of a single structure, height gradient changes, and a continuous and consistent functional surface. The research results can further expand the application of femtosecond laser micromachining in fields such as fog collection and chemical reaction control.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A Method for Obtaining Changes in Refractive Index of Transparent Films in Femtosecond Laser Processing

ActiveCN107064064BUniform change in refractive indexPhase-affecting property measurementsLaser processingRefractive index

The invention discloses a method for acquiring the refractive index variation of a transparent film in femtosecond laser micromachining. According to the method, 64 areas which are related to laser power and platform scanning speed and have a size of 80 mu m*80 mu m and variation of the refractive index can be obtained by utilizing a laser plane processing device and adopting a method for scanning line by line at an interval of 300nm, the transmission spectrum of the 64 areas can be detected by a Fourier infrared spectrometer with a microscopic system and a three-dimensional mobile platform, and the refractive index of the film can be calculated from the transmission spectrum by adopting an improved Swanepoel method, so that the refractive index variation of a film in the laser processing area can be obtained.

Owner:NINGBO UNIV

A micro-nano optical fiber vibration sensor based on femtosecond laser micromachining

ActiveCN106124028BReduce volumeGood quality interference signalSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansMicro nanoFemto second laser

The invention relates to a micro nano fiber vibration sensor based on femtosecond laser micromachining and belongs to the field of fiber sensing. A single-mode fiber, a hollow fiber and a solid core fiber are welded in sequence. A fiber end face is burned using a femto second laser to form a mass block and a cantilever beam. The mass block is a circular column, and the diameter of the circular column is smaller than the internal diameter of the hollow fiber. The hollow fiber and the solid core fiber are fixedly connected through the cantilever beam. The invention solves the problem that a reflective surface formed when processing the fiber with the femto second laser has a low reflectivity or does not have a reflectivity; a detected vibration direction is parallel to an axial direction of the fiber; the sensor installation is easy; and the vibration sensor is featured by small size, high resonance frequency, high temperature resistance, electromagnetic interference resistance and the like, and can be used for vibration measurement in high temperature environments.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

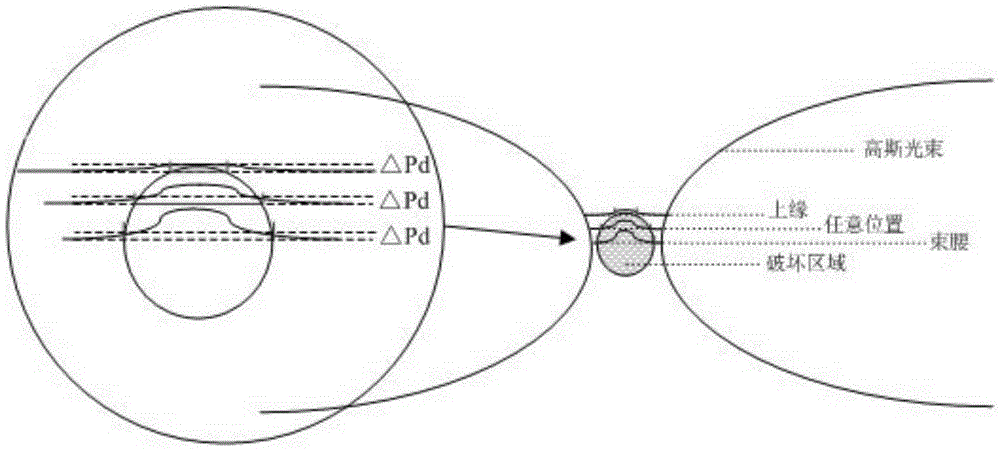

Tight focus spot energy optimization method and device for femtosecond laser three-dimensional micromachining

InactiveCN103862168BThe principle is simpleEasy to set upLaser beam welding apparatusUltrasound attenuationBeam energy

Owner:BEIJING UNIV OF TECH

Preparation method of large-scale array graphene nanoelectromechanical resonator based on femtosecond laser

ActiveCN104310305BReduce secondary pollutionRaise the resonant frequencyDecorative surface effectsChemical vapor deposition coatingLaser arrayAlloy

The invention discloses a preparation method of a large-scale array graphene nanoelectronic resonator based on femtosecond laser. The preparation method comprises the following steps: sputtering a TiW alloy and Au on the surface of a SiO2 / Si substrate; preparing a single-layered graphene thin film by a chemical vapor deposition method; transferring the single-layered graphene thin film onto TiW / Au connection wires; and scanning and cutting the two adjacent TiW / Au connection wires and a single-layered graphene thin film region between two adjacent Au electrode sheets by adopting the femtosecond laser to form the array graphene nanoelectronic resonator, wherein the energy density of the femtosecond laser is more than 0.16J / cm<2>-0.21J / cm<2>. According to the preparation method of the large-scale array graphene nanoelectronic resonator based on the femtosecond laser, a traditional CMOS process is combined with a preparation process of a femtosecond laser micro-machining technology and a preparation technology from bottom to top is completely adopted; photoresist does not need to be spun and plasma etching is avoided; the secondary pollution to graphene is reduced and the resonant frequency and the quality factor of the nanoelectronic resonator are greatly improved; and meanwhile, the manufacturing cost is extremely reduced.

Owner:JIANGSU UNIV

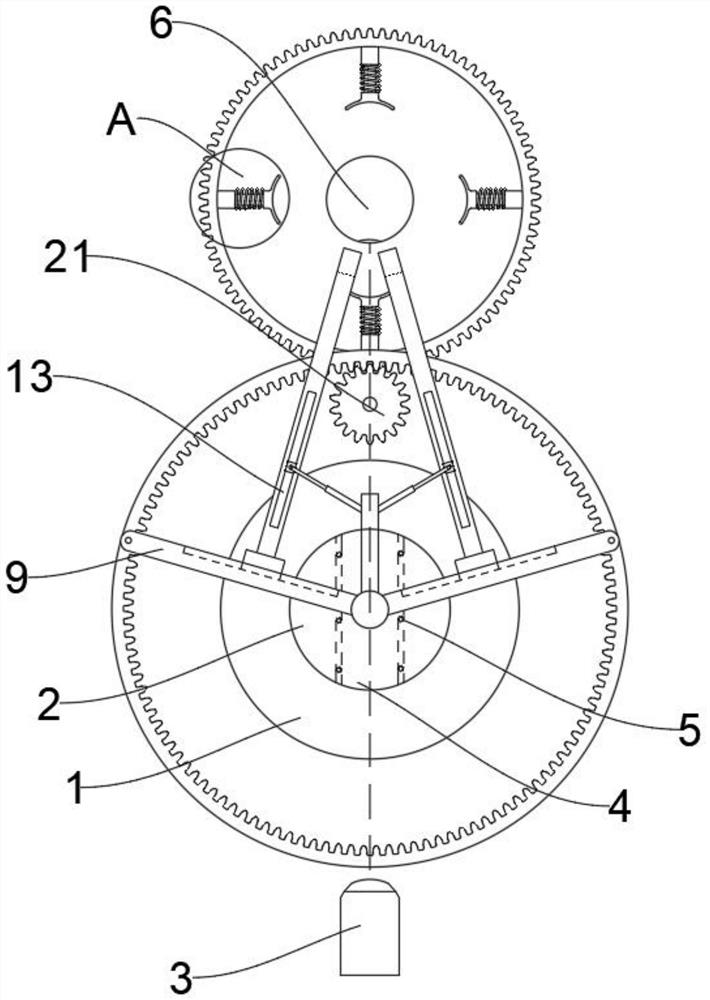

Synchronous monitoring device for femtosecond laser micromachining

PendingCN114178680AReal-time monitoring of processingLaser beam welding apparatusGear driveFemto second laser

The invention is applicable to the technical field of femtosecond laser micromachining, and provides a femtosecond laser micromachining synchronous monitoring device which comprises a base plate, a top plate, a femtosecond laser, an adjusting assembly, a stretching assembly and a gear transmission assembly, the top plate and the base plate are arranged in parallel, and the top plate is connected with the base plate through a supporting piece; the adjusting assembly is hinged to the gear transmission assembly, a monitoring head is installed at the tail end of the adjusting assembly, and the swing angle of the monitoring head is adjusted under driving of the gear transmission assembly. The stretching assembly is arranged at the tail end of the adjusting assembly; the gear transmission assembly is installed at one end of the adjusting assembly, and a clamping assembly is arranged on the gear transmission assembly and used for adjusting the workpiece to be machined and controlling the working process of the adjusting assembly at the same time. In the using process of the monitoring device, the machining process of a workpiece to be machined can be monitored in real time through laser emitted by the femtosecond laser device, the gear transmission assembly is arranged to drive the adjusting assembly to work, the position of the monitoring head is controlled, and the machining position is monitored in real time in a multi-angle and all-dimensional mode.

Owner:XI'AN PETROLEUM UNIVERSITY

Femtosecond laser-based transparent conductive oxide polarizing and detecting realization method

InactiveCN107907931AStructural properties are stableSimple methodPolarising elementsDiffraction gratingsDevice PlateGrating

The invention provides a femtosecond laser-based transparent conductive oxide polarizing and detecting realization method, which belongs to the field of functional materials. The transparent conductive oxide is plated on the surface of an optical device in need of polarizing and detecting functions, the photoelectric device plated with the transparent conductive oxide is placed in a femtosecond laser microprocessing system, the energy and the scanning speed of specific femtosecond laser are adjusted, and a large-area and uniform transparent conductive oxide grating structure is prepared on thesurface of the photoelectric device. The prepared grating structure can block polarized light perpendicular to the structure direction, thereby reducing the transmissivity of the polarized light perpendicular to the processing direction. Compared with the prior art, the method provided in the invention is simple and easy to realize, the processed grating has stable structural properties, the manufactured product can turn circular polarized light to linear polarized light, and an important application value is realized in aspects of polarizing and detecting of the photoelectric device.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

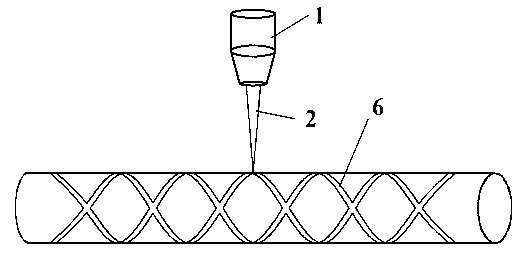

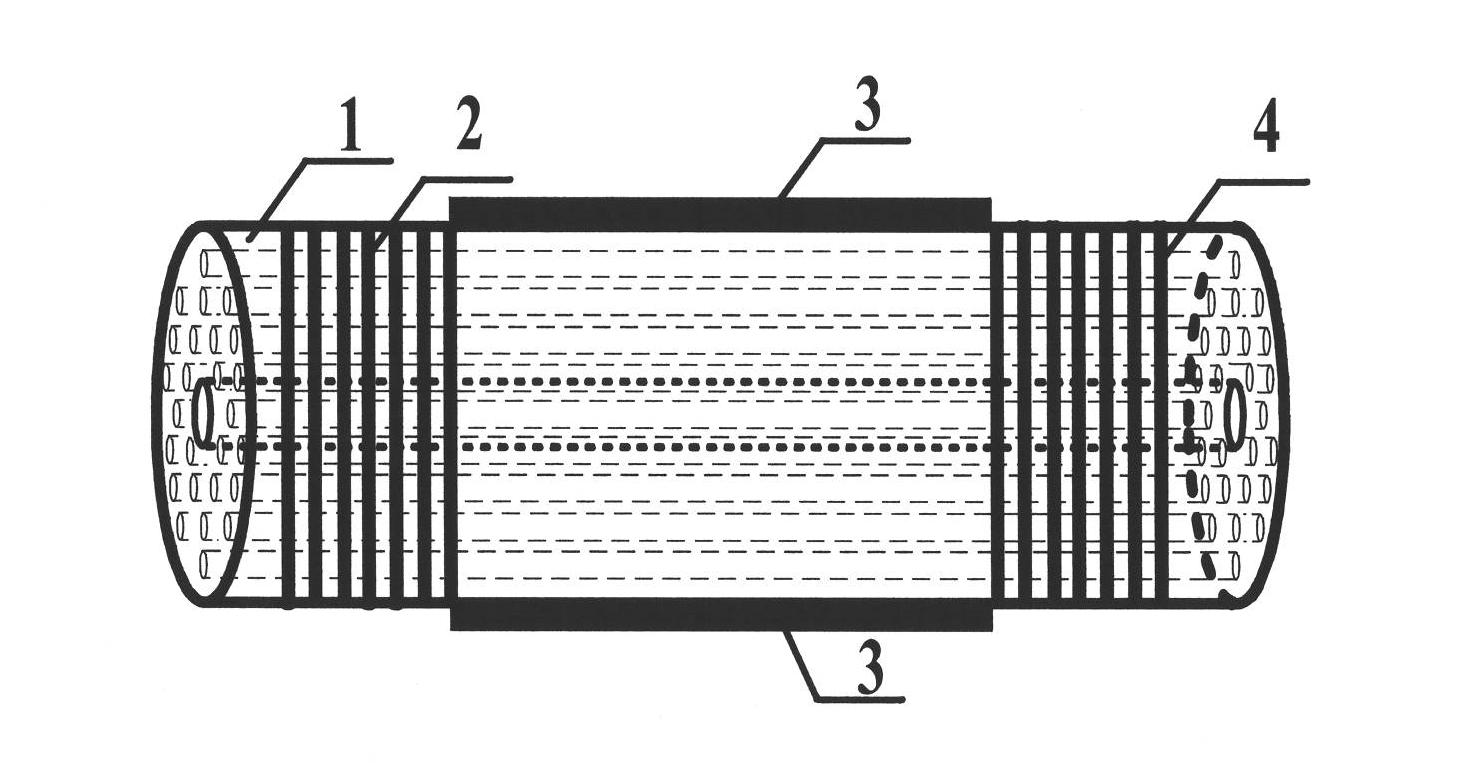

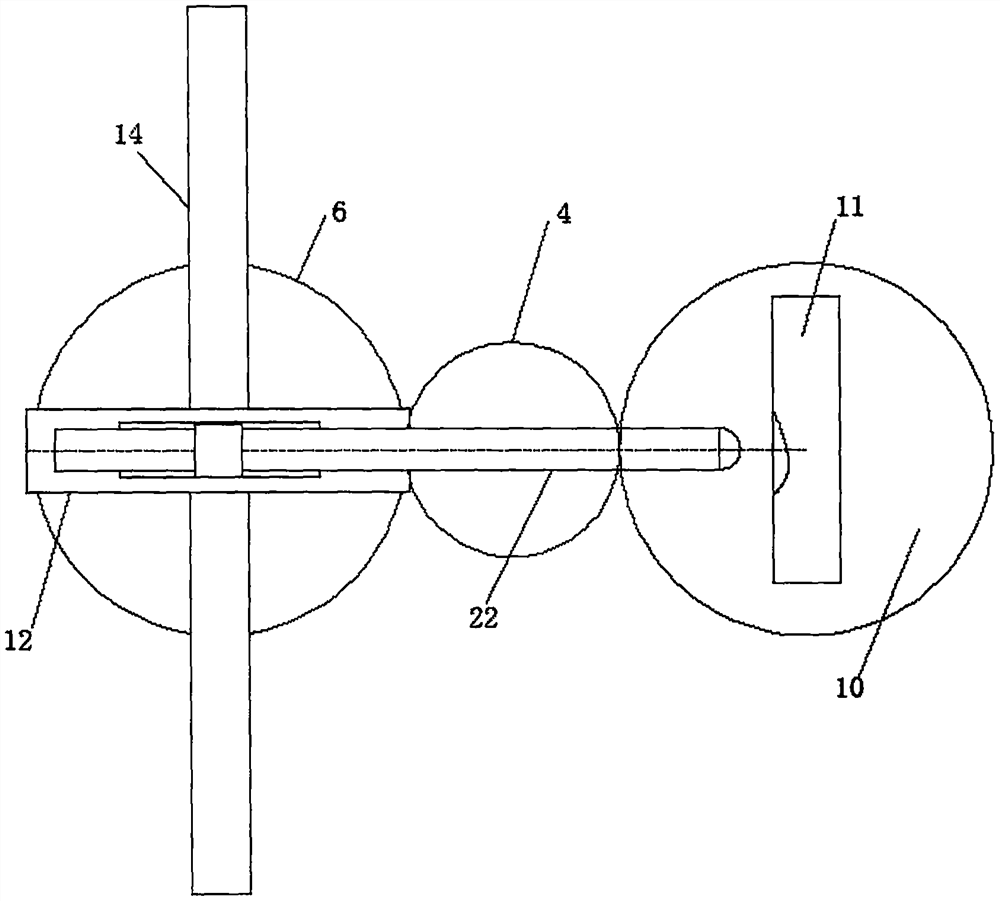

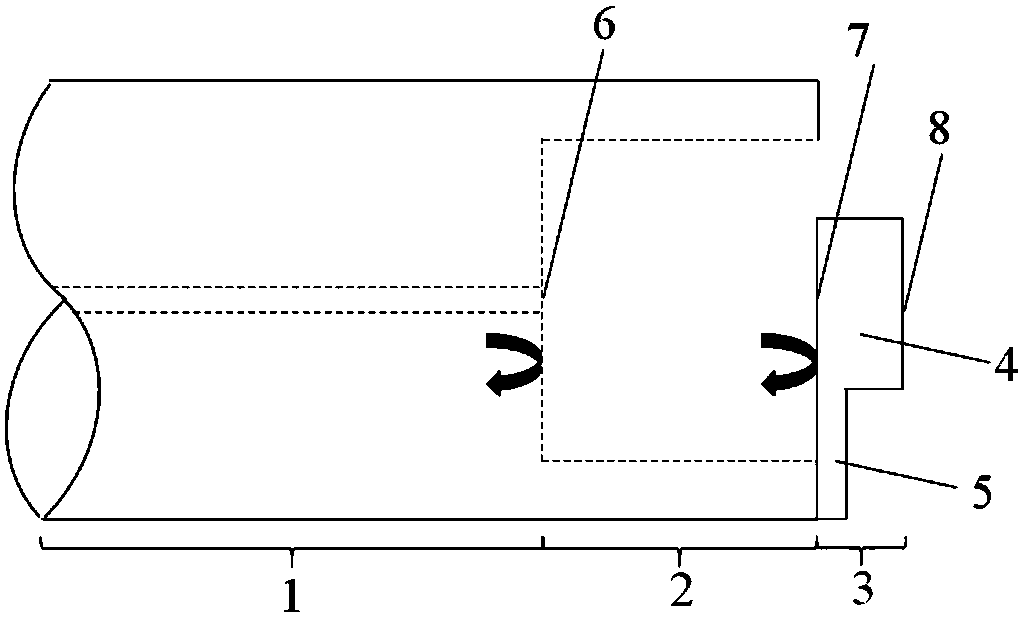

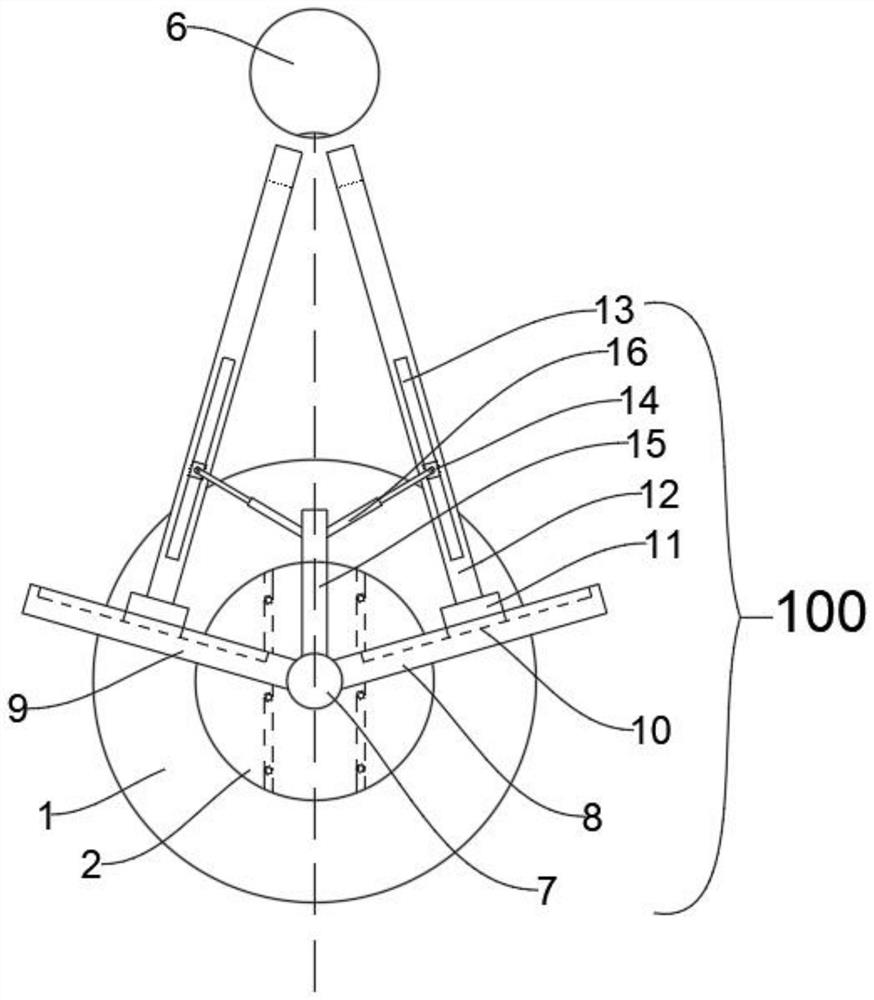

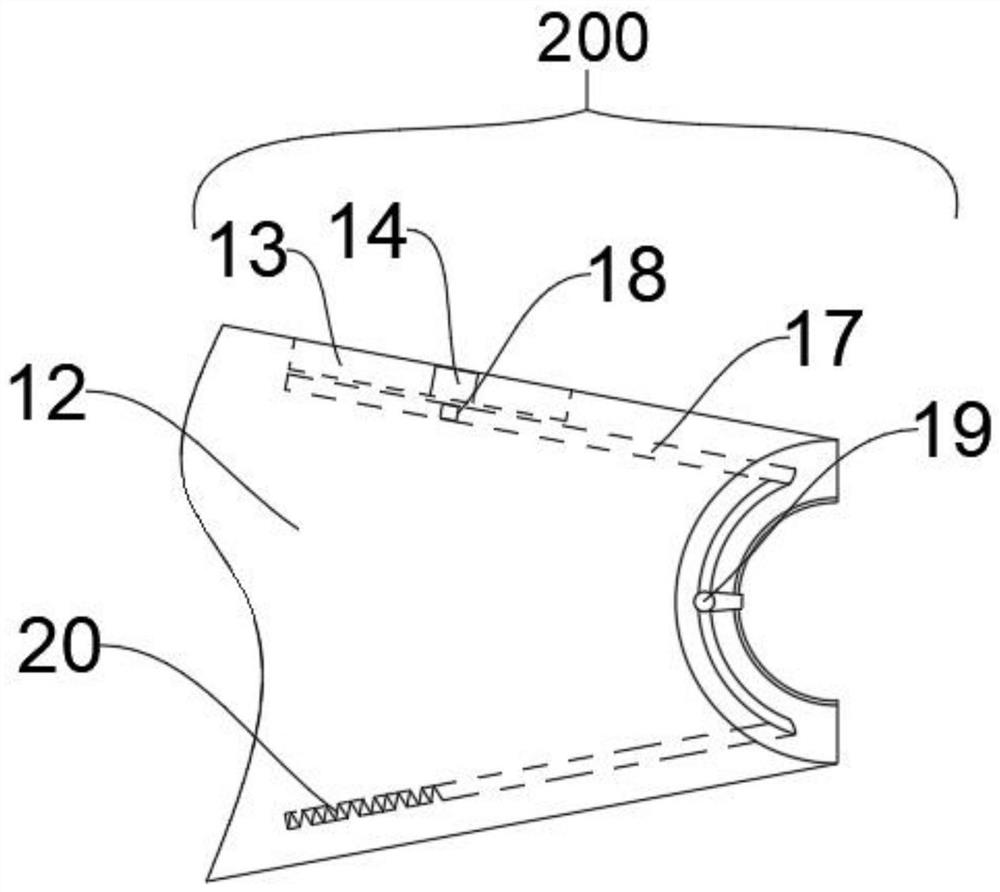

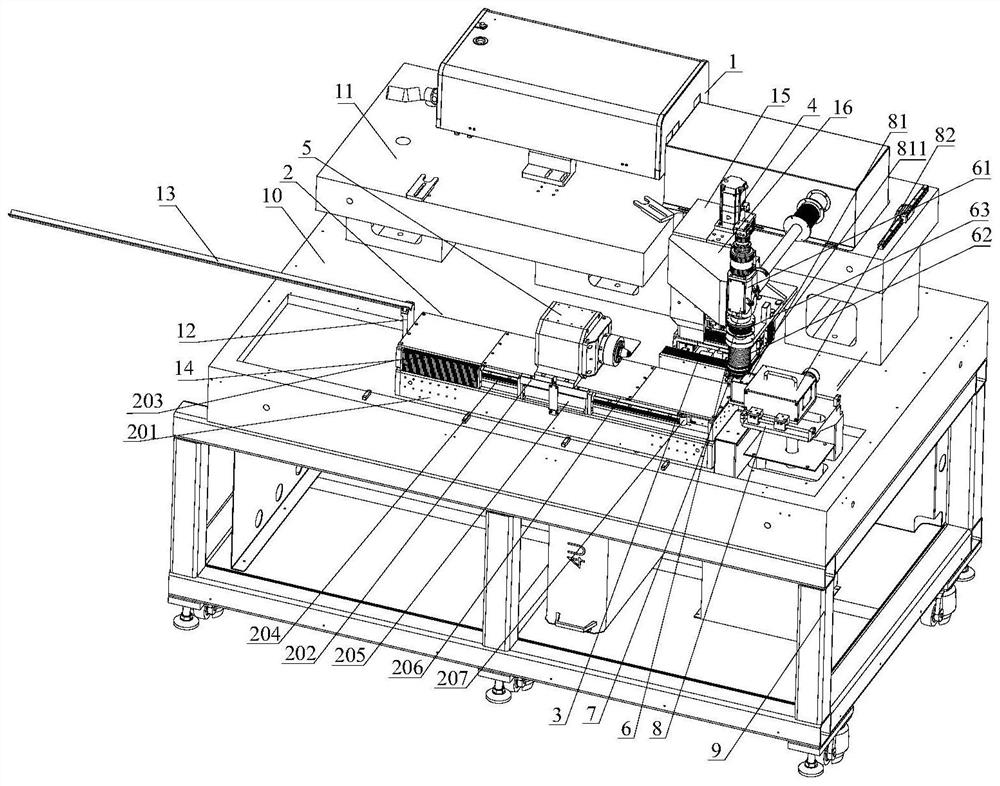

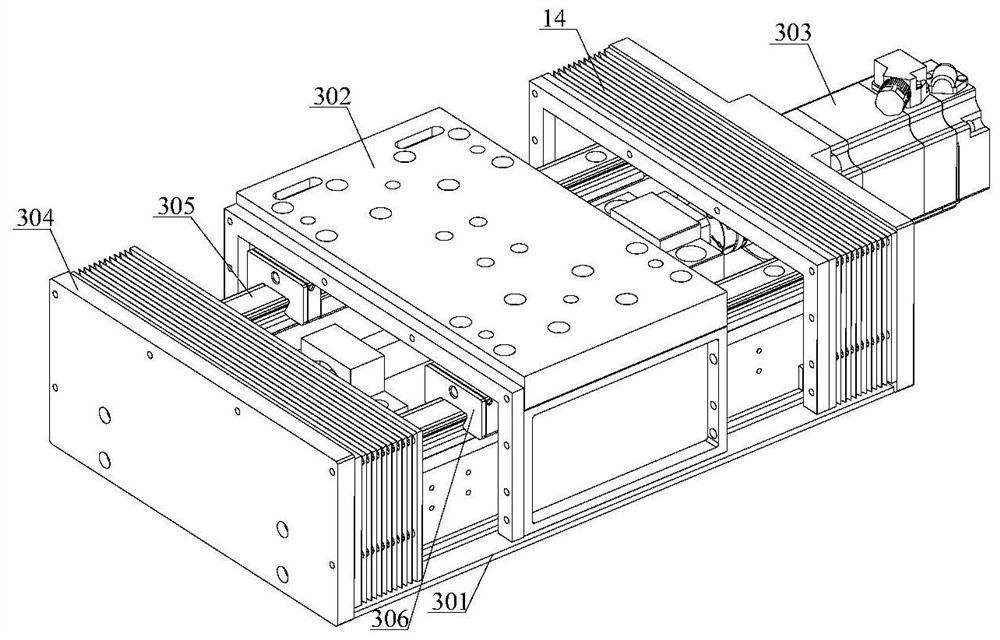

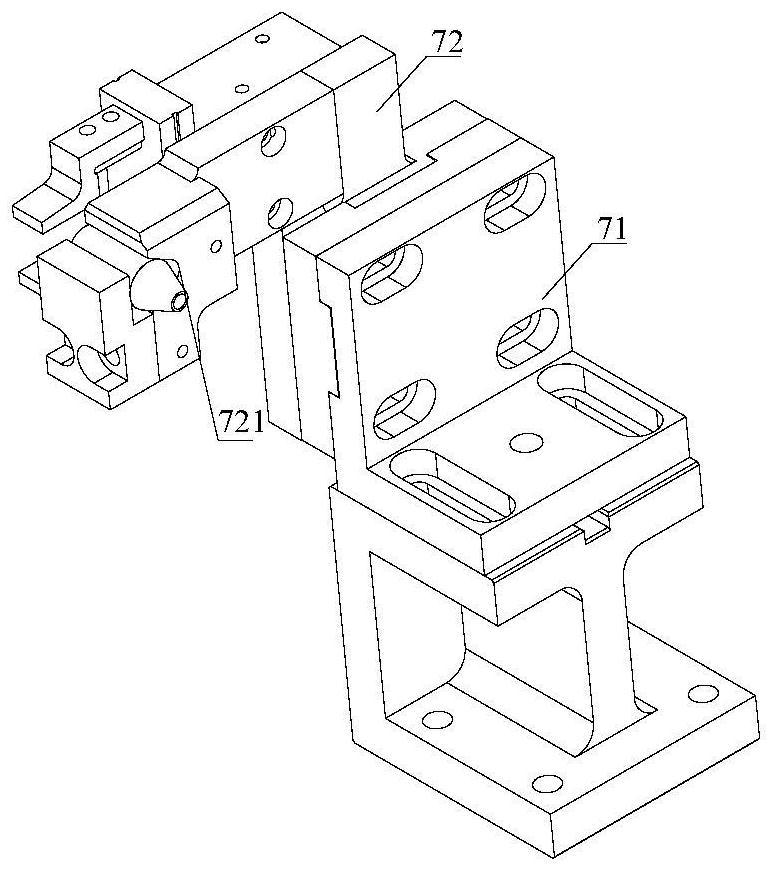

Four-axis femtosecond laser micromachining system for medical stent

The invention provides a medical stent four-axis femtosecond laser micromachining system which comprises a femtosecond laser light path system, a fine laser cutting head, a motion control system, a linear axis X, a linear axis Y, a linear axis Z and a precision rotating shaft. The motion control system is used for controlling the linear axis X, the linear axis Y, the linear axis Z and the rotating shaft to move; the linear shaft X is located on one side of the fine laser cutting head, the precision rotating shaft is fixed to a moving part of the linear shaft X, the linear shaft Y is arranged under the linear shaft Z, the lower end face of the linear shaft Z is connected with a moving part of the linear shaft Y, and the linear shaft Z is connected with the fine laser cutting head. According to the four-axis femtosecond laser micromachining system for the medical stent, precise control over the laser machining technology of the medical stent is achieved; and laser cutting, slotting and drilling machining of centripetal opening, vertical opening characteristics and composite opening characteristics of equal-diameter circular pipes, elliptical pipes and reducer pipes can be achieved.

Owner:KUNSHAN YUNCO PRECISION IND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com