Fiber grating accelerometer in optical fiber

An accelerometer and fiber grating technology, which is applied in the direction of acceleration measurement using inertial force, and can solve problems such as low processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

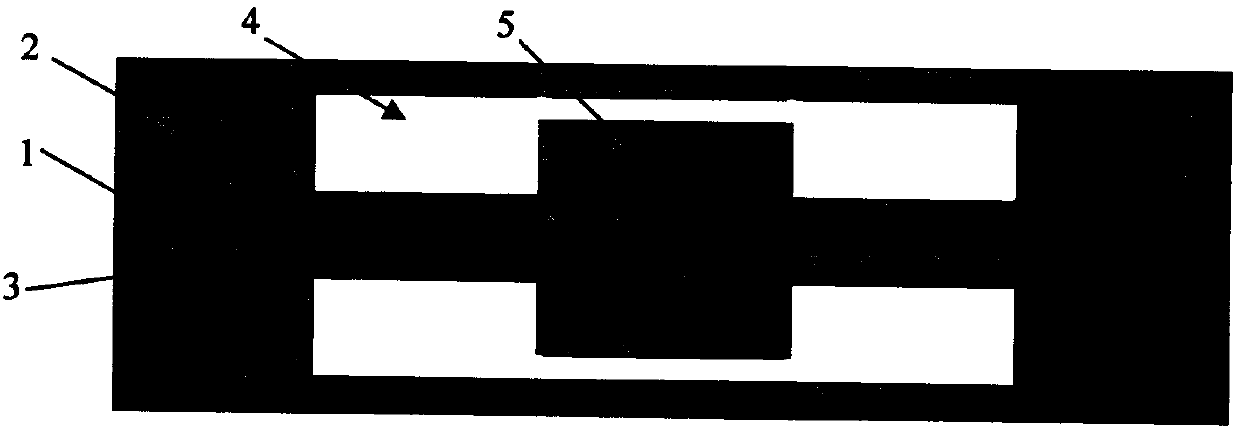

[0013] For example, as attached figure 1 As shown, for an ordinary optical fiber (core diameter is 9 microns, cladding outer diameter is 125 microns), a femtosecond laser point-by-point writing method can be used to write a 50 micron long grating (G.D.Marshall, et al., "Point- by-pointwritten fiber-Bragg gratings and their application in complex grating designs, "Optics Express, vol. 18, pp. 19844-19859, 2010). Then use femtosecond laser etching method and oil immersion method to write 3D pattern on this optical fiber. The grating can be machined down to 11 microns in diameter. The diameter of the retained fiber cladding can be positioned 100 microns; a 5 micron wide ring can be cut around it. On the other side of the retained fiber cladding, it can be cut into the same size structure as the grating side. When the retained fiber cladding is accelerated, the grating will measure this acceleration as a change in its resonant wavelength. In order to better protect its structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com