Four-axis femtosecond laser micromachining system for medical stent

A femtosecond laser and micromachining technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of limited processing medical equipment, limited application fields, and high single-machine price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

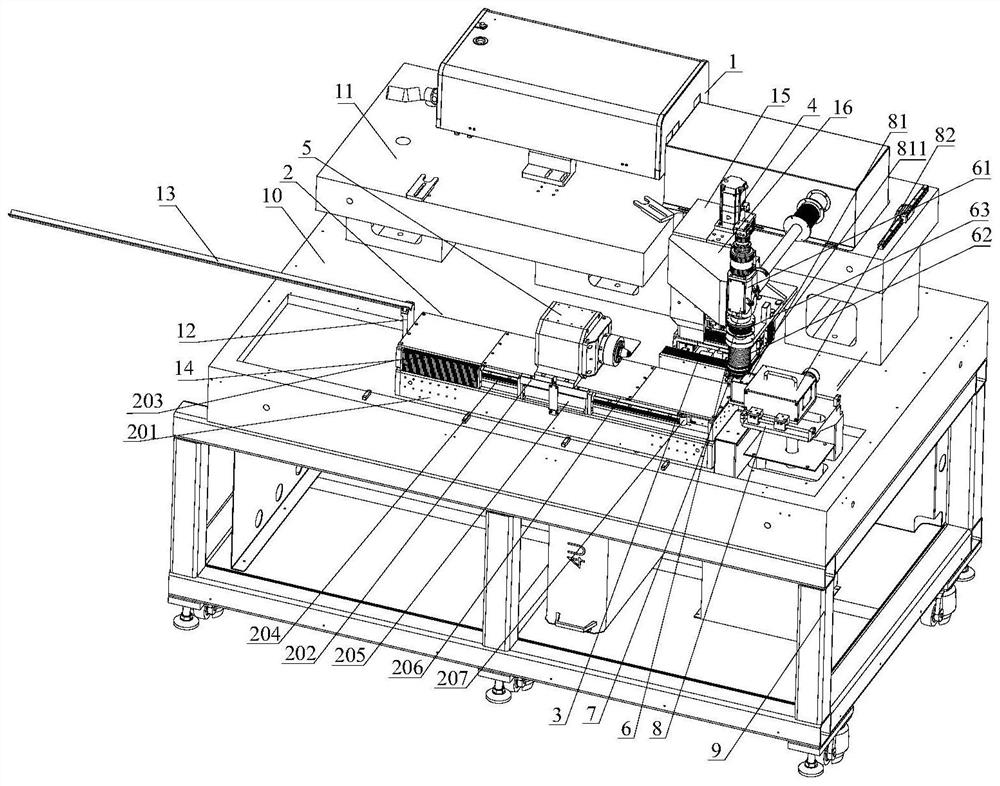

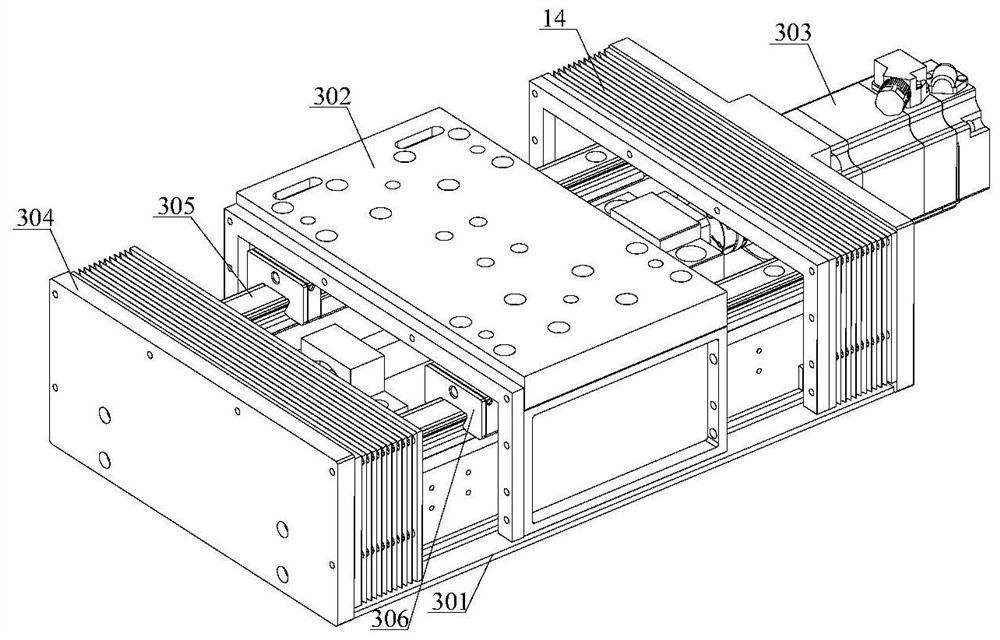

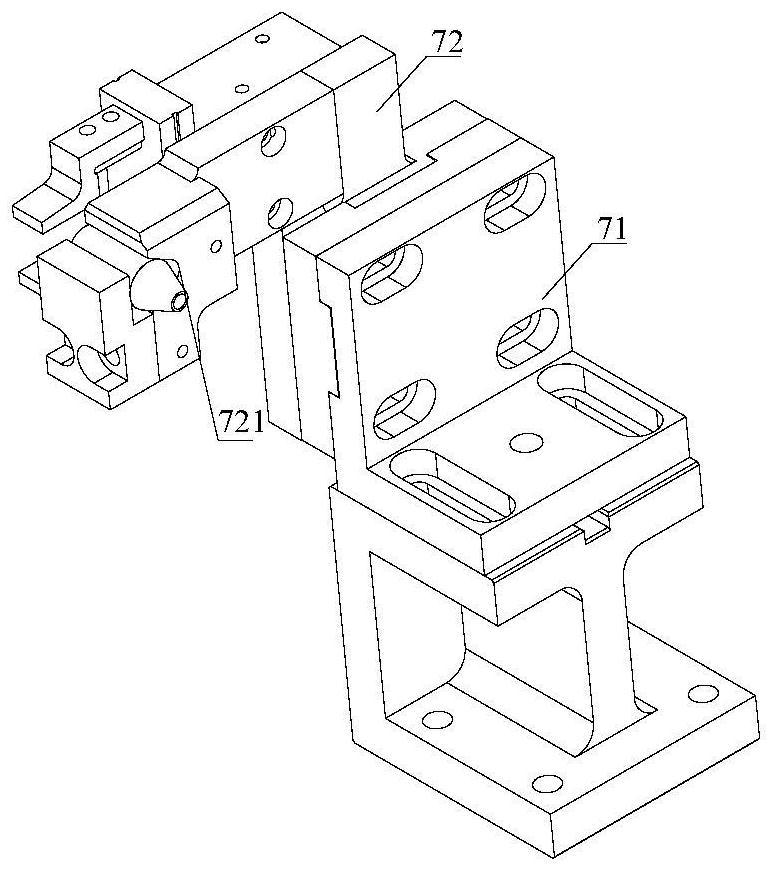

[0022] like Figure 1-4 As shown, a four-axis femtosecond laser micromachining system for medical stents includes a system base 9, a working platform 10, a femtosecond laser optical path system 1, a fine laser cutting head 6, a motion control system, a linear axis X2, a linear axis Y3, Linear axis Z4, precision rotation axis 5, microtube follow-up clamping system 7 and sealed material receiving system 8, the working platform 10 is placed on the upper end surface of the system base 9, femtosecond laser optical path system 1, linear axis X2 , the linear axis Y3, the linear axis Z4, the micro tube follow-up clamping system 7 and the sealed material receiving system 8 are placed on the working platform, and a drainage groove is embedded in the working platform 10, and the fine polishing cutting head 6 is located at On the front side of one end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com