Method for processing micro array on glass surface via femtosecond laser pulse sequence

A pulse sequence, femtosecond laser technology, applied in the field of femtosecond laser applications, can solve problems such as low etching efficiency, achieve the effect of improving etching efficiency and promoting material modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

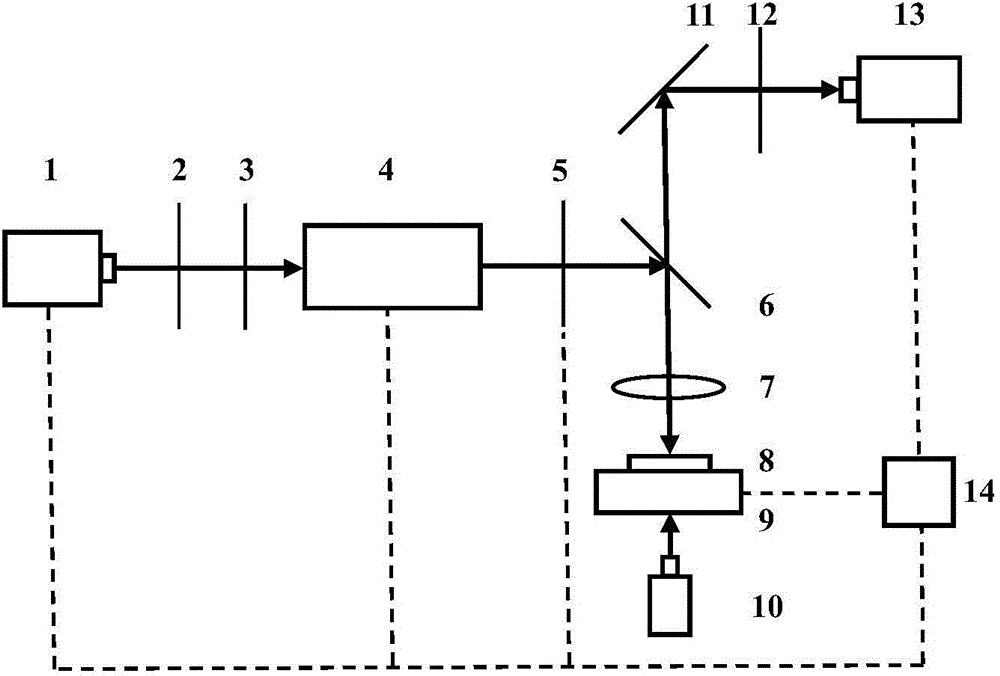

Image

Examples

Embodiment 1

[0022] A method for processing a microarray on the glass surface with a femtosecond laser pulse sequence, the specific steps are as follows:

[0023] Step 1: Through the basic method of pulse shaping, the traditional femtosecond laser is modulated in the time domain into a femtosecond laser pulse sequence containing two sub-pulses; and the time interval between the two sub-pulses is 150 fs, the energy of the two sub-pulses The ratio is 5:1.

[0024] Step 2: Focus the femtosecond laser pulse sequence obtained in Step 1 on the surface of the fused silica glass, and scan a dot-shaped microarray with a dot pitch of 30 μm on the glass surface through the relative movement of the glass material and the laser focus.

[0025] Step 3: Immerse the fused silica glass with scanning microarray pattern obtained in Step 2 into a hydrofluoric acid solution with a concentration of 8%, and the scanned microarray pattern area reacts with the hydrofluoric acid solution to form a recessed microarray stru...

Embodiment 2

[0036] A method for processing a microarray on the glass surface with a femtosecond laser pulse sequence, the specific steps are as follows:

[0037] Step 1. Through the basic method of pulse shaping, the traditional femtosecond laser is modulated in the time domain into a femtosecond laser pulse sequence containing two sub-pulses; and the time interval between the two sub-pulses is 350 fs, the energy of the two sub-pulses The ratio is 1:1.

[0038] Step 2: Focus the femtosecond laser pulse sequence obtained in Step 1 on the surface of the fused silica glass, and scan a dot-shaped microarray with a dot pitch of 30 μm on the glass surface through the relative movement of the glass material and the laser focus.

[0039] Step 3: Immerse the fused silica glass with scanning microarray pattern obtained in Step 2 into a hydrofluoric acid solution with a concentration of 8%, and the scanned microarray pattern area reacts with the hydrofluoric acid solution to form a recessed microarray stru...

Embodiment 3

[0049] A method for processing a microarray on the glass surface with a femtosecond laser pulse sequence, the specific steps are as follows:

[0050] Step 1. Through the basic method of pulse shaping, the traditional femtosecond laser is modulated in the time domain into a femtosecond laser pulse sequence containing two sub-pulses; and the time interval between the two sub-pulses is 1 ps, the energy of the two sub-pulses The ratio is 1:5.

[0051] Step 2: Focus the femtosecond laser pulse sequence obtained in Step 1 on the surface of the fused silica glass, and scan a dot-shaped microarray with a dot pitch of 30 μm on the glass surface through the relative movement of the glass material and the laser focus.

[0052] Step 3: Immerse the fused silica glass with scanning microarray pattern obtained in Step 2 into a hydrofluoric acid solution with a concentration of 8%, and the scanned microarray pattern area reacts with the hydrofluoric acid solution to form a recessed microarray struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com