Method for preparing micro optical element on quartz glass substrate by applying femto-second laser

A technology of quartz glass and femtosecond laser, which is used in cleaning methods using liquids, optical components, chemical instruments and methods, etc., can solve the problems of large difference in photothermal characteristics, expensive and difficult to obtain photosensitive glass, etc. Excellent optical and electrical properties, fast polishing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

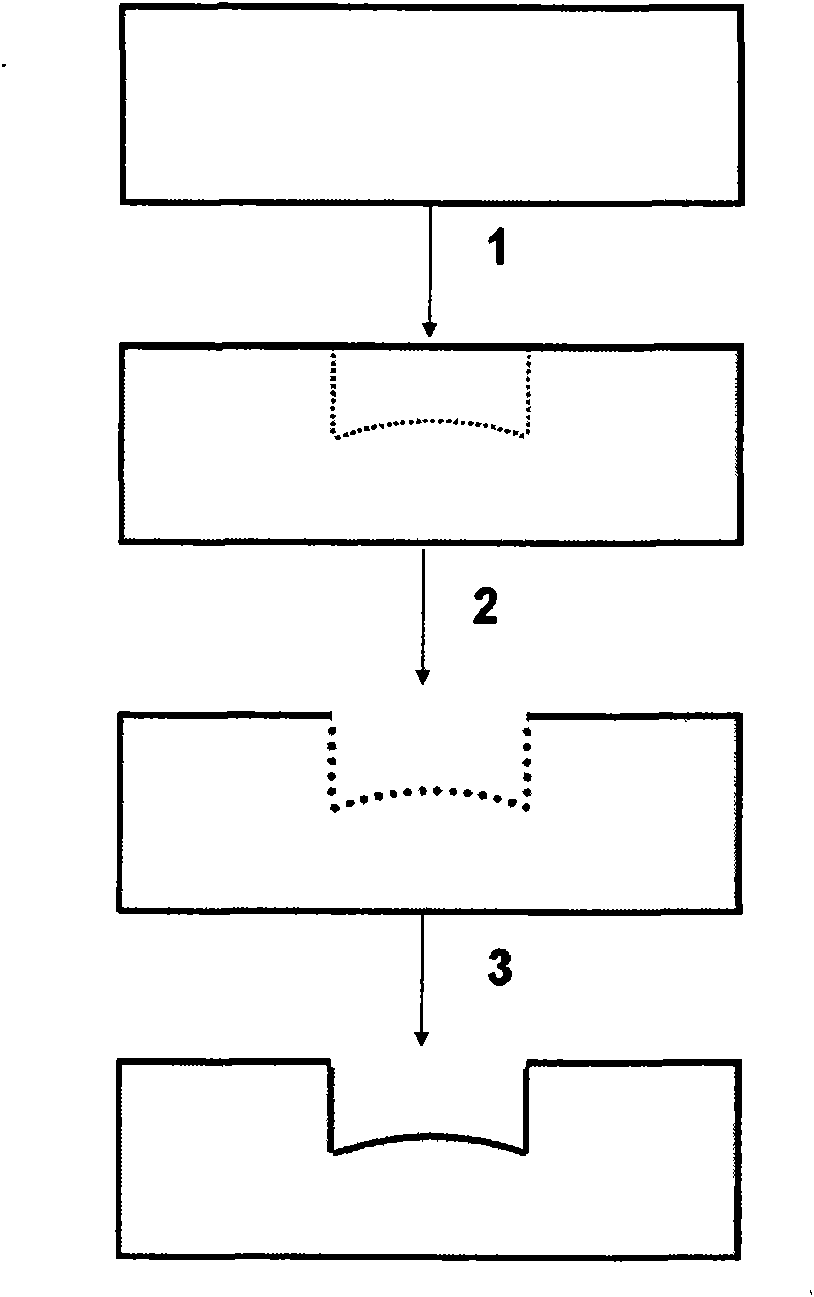

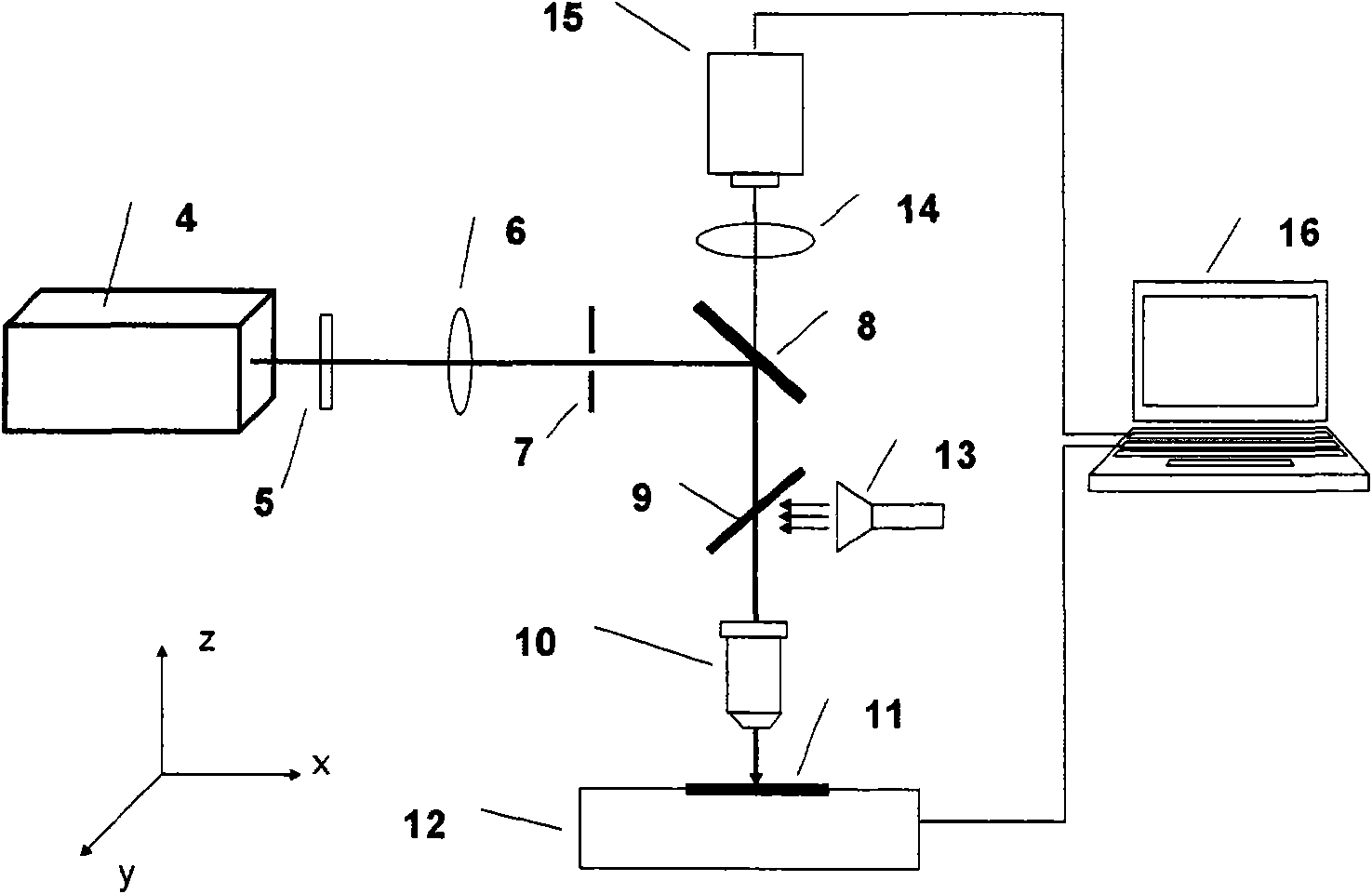

[0037] Embodiment 1: Micromirror preparation

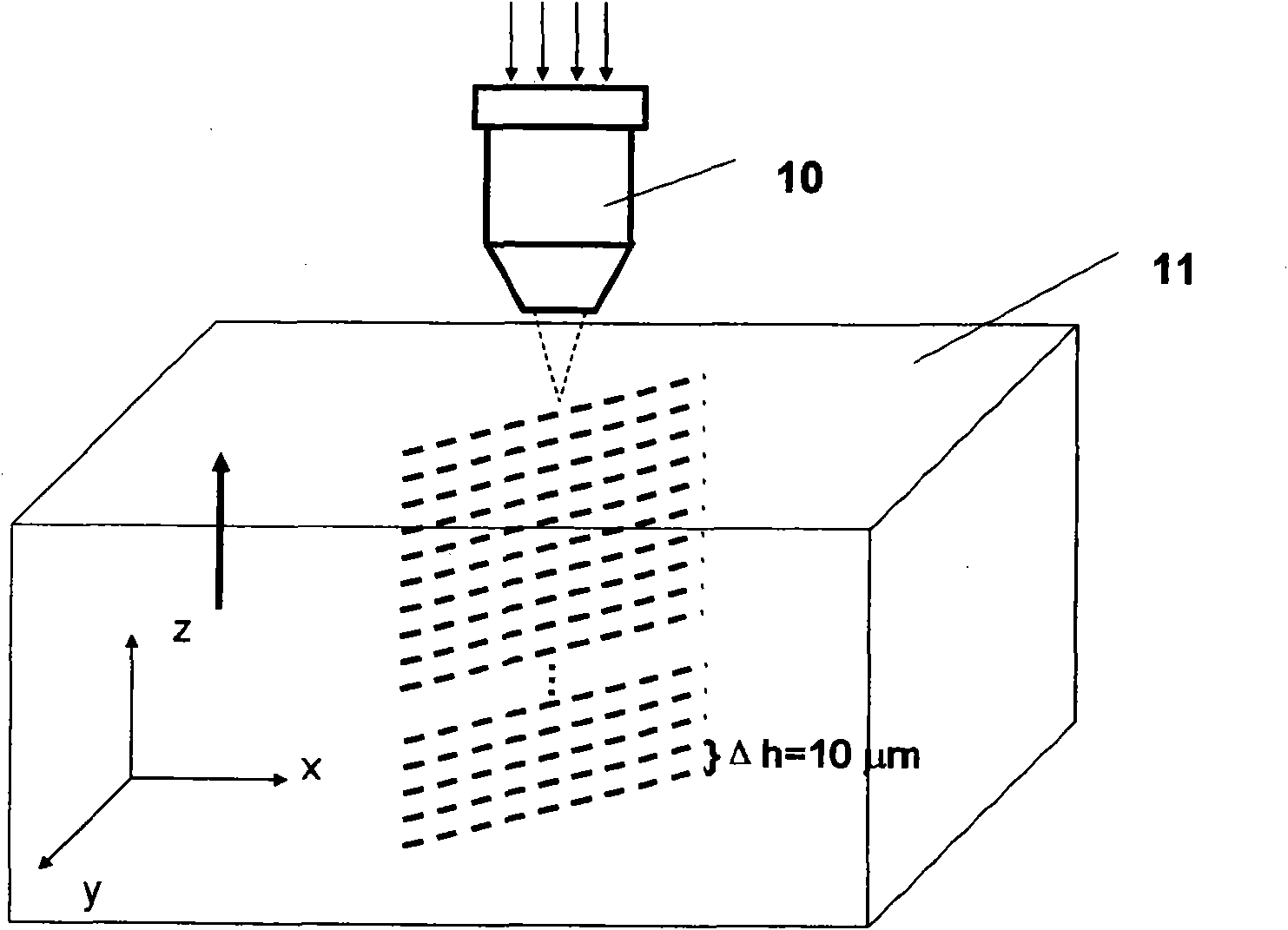

[0038]When scanning the profile of the micromirror, parallel lines need to be layered and scanned from the lower surface of the quartz glass substrate from the bottom to the upper surface. The distance between them is Δh=10μm, such as image 3 As shown, the three-dimensional precision platform is moved along the -z direction by 10 μm and then scanned and irradiated in a straight line. After femtosecond laser irradiation, the quartz glass sample was placed in 10% hydrofluoric acid aqueous solution and assisted by ultrasonic cleaning for about 3 hours, until the femtosecond laser irradiation area was selectively etched away. Take out the glass sample, clean it ultrasonically with alcohol, dry it, place it on the high-temperature refractory brick, and use a hydrogen-oxygen torch to polish the microlens area for about 5 minutes. The flame temperature should be close to but not exceeding the softening temperature of quartz glass at 17...

Embodiment 2

[0039] Embodiment 2: microlens preparation

[0040] When scanning the profile of the microlens, it is necessary to decompose the profile of the microlens into a cylindrical surface and a microsphere, and scan them sequentially with a femtosecond laser. When scanning the cylindrical surface, according to the condition of layered scanning of the three-dimensional pattern in the present invention, the distance between two adjacent layers of parallel circular surfaces is selected as Δh=10 μm, such as Figure 4 As shown, the three-dimensional precision platform is moved 10 μm along the z direction to perform circular scanning irradiation; when scanning the spherical surface of the microlens, since the radius of each layer of the ring is not the same, in order to enable the laser to irradiate uniformly, the scanning microlens In the process of lensing, it is necessary to keep the arc length between two adjacent scanning layers as Δs=2μm ( Figure 5 ) remains unchanged, if the radiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com