Fiber micro-nano Fabry-Perot interference type pressure sensor and manufacturing method thereof

A pressure sensor, micro-nano Farper technology, applied in the direction of measuring the change force of the optical properties of the material when it is stressed, can solve the problems of easy stress, easy damage, large size of the sensor head, etc., to achieve high Reliability, reduction of cross-effects, and effects of avoiding structural failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

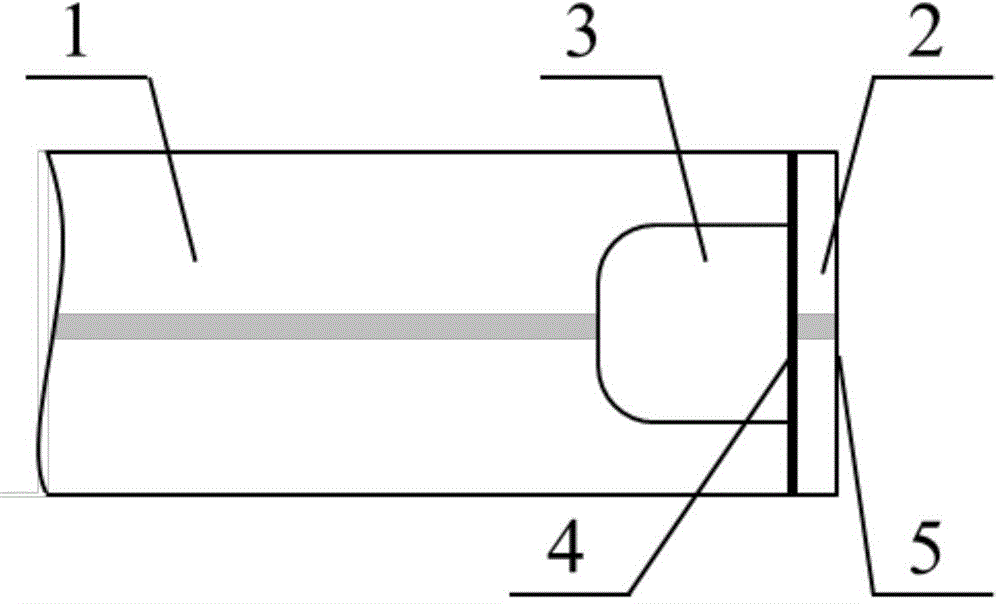

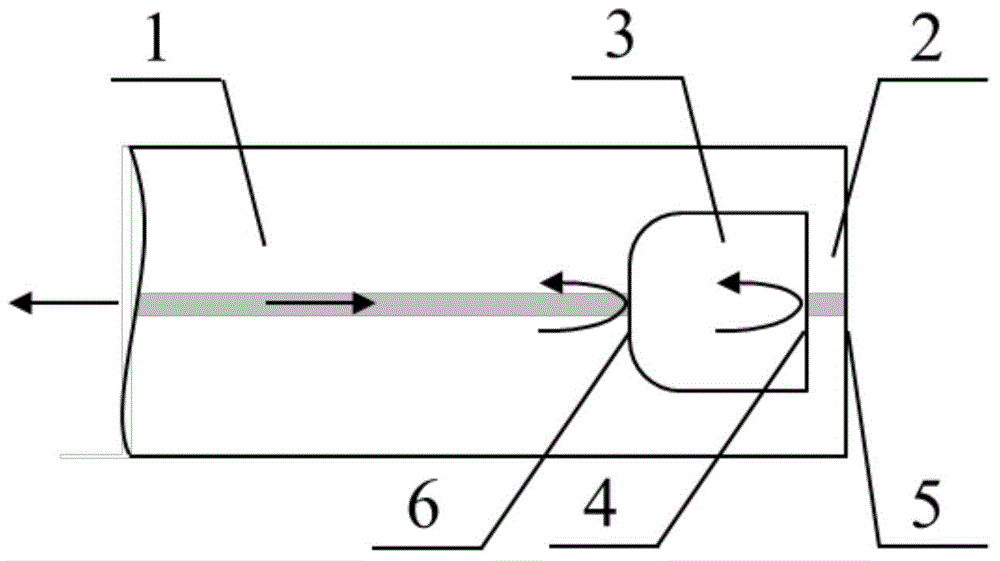

[0016] An optical fiber micro-nano Fa-Per interference pressure sensor, the structure of which is as follows figure 1 As shown, it includes an optical fiber 1 with a microporous structure processed on its end face and a piece of optical fiber membrane 2 with a complete end face, which are fused to form a Fabry-Perot microcavity embedded in the optical fiber.

[0017] Further, the material of the optical fiber 1 and the diaphragm 2 can be selected as ordinary single-mode optical fiber, or the material of the optical fiber 1 can be selected from a pure silica photonic crystal fiber, and the diaphragm 2 can be selected from a pure silica photonic crystal fiber or a pure silica coreless optical fiber. Since the pure silica photonic crystal fiber can still maintain good light transmission performance in the environment up to 1200 °C, the pure silica coreless fiber is not only resistant to high temperature, but also has no wave-guiding structure, so it is not worried that high temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com