Femtosecond laser micromachining of a contact lens and a contact lens manufactured thereby

A femtosecond laser and contact lens technology, used in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of inappropriate setting of window holes, affecting the performance of contact lenses, and discomfort to contact lens wearers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

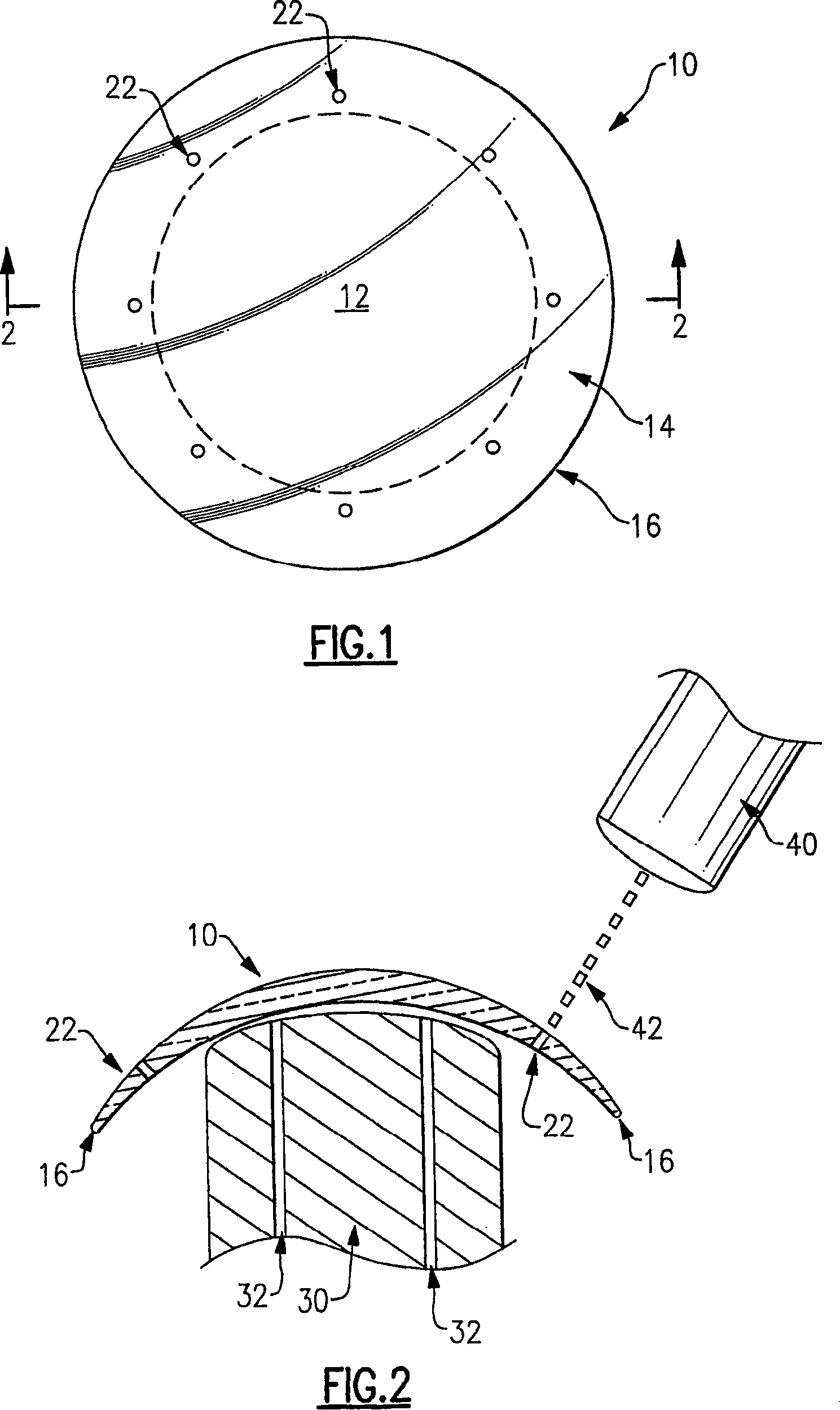

[0018] Figure 1 shows a front view of a contact lens 10 suitable for manufacture using the method of the present invention. FIG. 2 is an enlarged cross-sectional view of the contact lens 10 shown in FIG. 1, taken along line 2-2, made by the method of the present invention. As described below, it is an advantage of the present invention to provide a method for laser micromachining a contact lens 10 to provide various structural features thereon. In this regard, the present invention allows for structural features, such as apertures, grooves, and / or horns, to be provided on the contact lens 10 without substantially subjecting the surrounding area to heat-related damage. Of course, the method of the present invention can be used to provide different structural features on the contact lens, for example, machining the peripheral edge of the contact lens.

[0019] As shown in FIGS. 1 and 2 , the contact lens 10 of the illustrated example includes a central portion 12 schematically ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com