Fabrication method for electro-optical tuning whispering gallery mode microcavity of integrated electrode

A technology of a whispering gallery mode and an integrated electrode is applied in the field of femtosecond laser micromachining technology to prepare an integrated electrode electro-optically tuned whispering gallery mode optical microcavity, which can solve the problems of low refractive index, low quality factor, complicated preparation process, etc. Refractive index ratio, high Q value, the effect of broadening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below through the examples and accompanying drawings, but the protection scope of the present invention should not be limited by this.

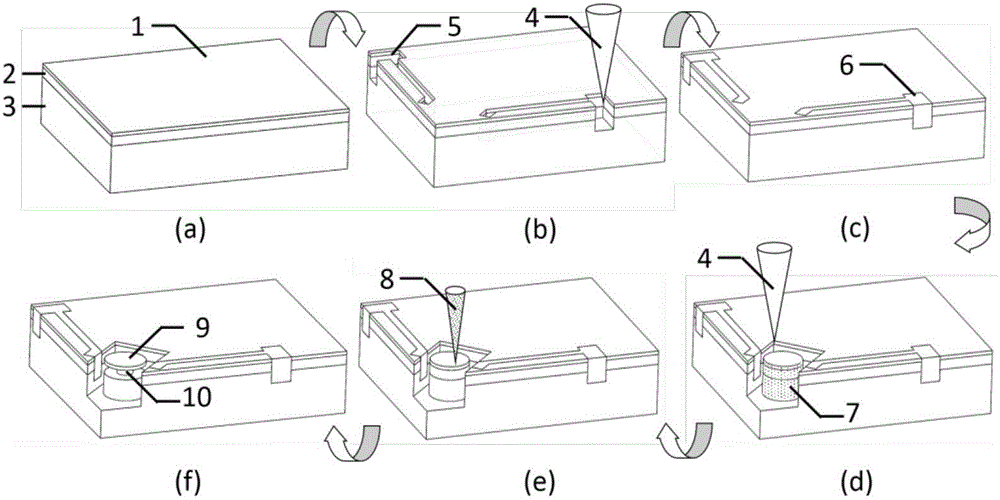

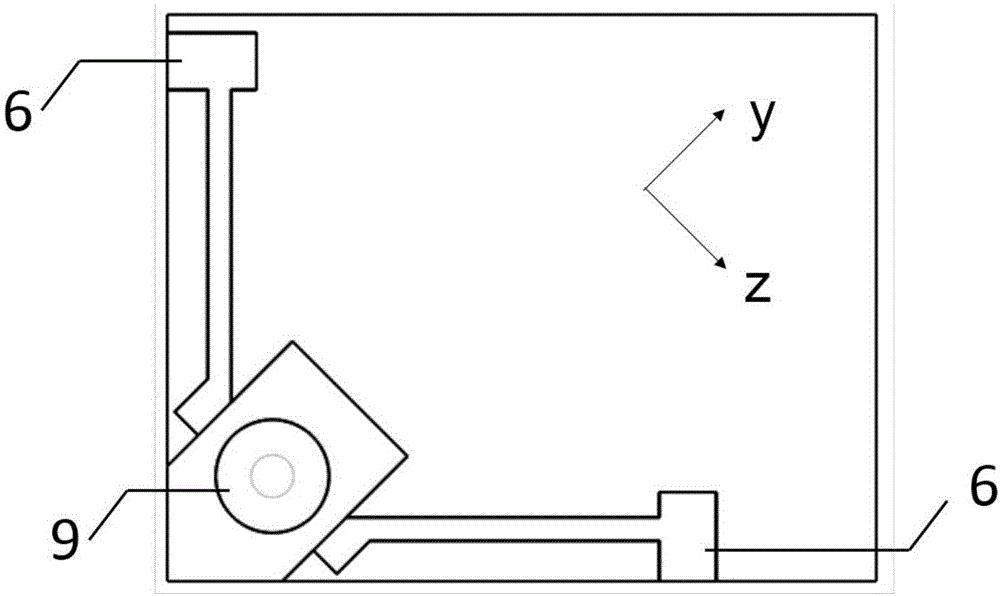

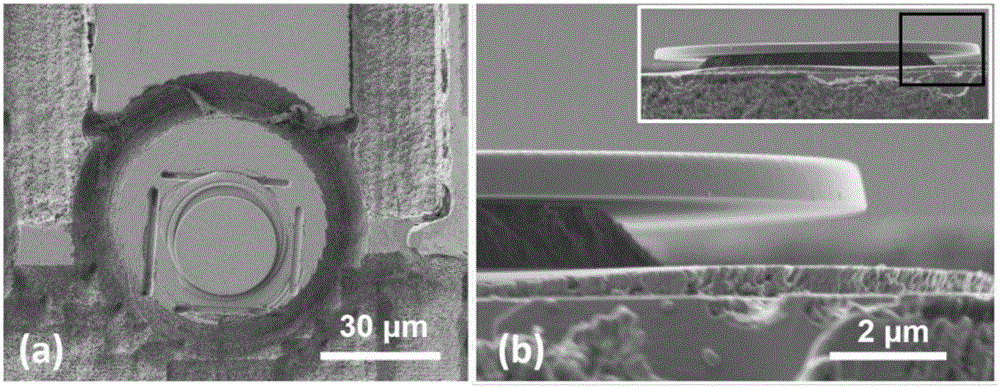

[0035] see first figure 1 , figure 1 It is a schematic flow chart of the method for preparing an integrated electrode electro-optic tunable whispering gallery mode microcavity by femtosecond laser in the present invention. Now, the commercialized lithium niobate thin film product is taken as an example to illustrate the method of the present invention, as figure 1 As shown in (a), the lithium niobate thin film product has a three-layer structure: the first layer is a 700nm thick x-cut lithium niobate single crystal thin film layer 1, and the specific orientation of its crystal axis is as follows figure 2 As shown in the middle coordinates; the second layer is a silicon dioxide sacrificial layer 2 with a thickness of 2 μm; the third layer is a lithium niobate base layer 3 with a thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com